Professional Documents

Culture Documents

F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More Information

F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More Information

Uploaded by

Tolga UZUNEROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More Information

F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More Information

Uploaded by

Tolga UZUNERCopyright:

Available Formats

.

~ _COVERED (STI_C K) ELECTRODES (SMAW)

1

r'' .LOW ALLOY ELECTRODES

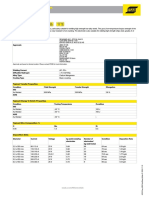

OK 76.35

IJ. PC

..- 2 0

OK 76.35 is an LMA electrode containing 5Cr0.5Mo for welding creep-resistant steels. It is especi . · (

. . . t f a 11 Y suit b

welding. The electrode runs with a quiet , stable arc and gives a minimum amoun _o spatter loss. A Pre a _le for .

Interpass temperature of 150-260°C is normally required . The mechanical properties stated here are atthea11ng a •

of heat treatment at 740°C . er 0 ne hot. 0

al

Classifications: SFNAWS A5.5:E8015-B6, EN ISO 3580-A:E CrMo5 4 2 H5 a

Approvals: Seproz UNA 272580, NAKS/HAKC 2.5-4.0 mm

Approvals are based on factory location. Please contact ESAB for more information.

Welding Current: DC+-

Diffusible Hydrogen: < 5.0 ml/1 OOg

Alloy Type: Creep resisting

Coating Type: Ume Basic

Typical Tensile Properties

Condition Yield Strength_ Tensile Strength Elongation

ISO

PWHT750°C 1h 500 MPa 620 MPa 22%

Typical Charpy V-Notch Properties

Condition / Testing Temperature :i".,pact Value

ISO

PWHT 750°C 1h

~ - - - - - - - - -- - L _20 I

__ _ _ _ _ _ _ _ ____ _ °c . 110 J

Typical Weld Metal Anal_ysis %

C Mn Si Ni Mo

Cr

0.05 0.7 0.4 0.03 0.55

5

Deposition Data

Diameter Current Voltage kg weld metal/ Number of Deposition

Fusion time

kg electrodes electrodes/kg per electrode rate 90% 111111

weld metal at90% I max

2.0x300mm 50-70A 23V 0.57 139 53s

2.5x300mm 65-95A 23V 0.57 76.9 63 s

3.2x350mm 90-130A 24V 0.56 1.0 kg/h

50.0 70 s

4.0x450mm 125-165 A 24V 0 .58 1.3 kg/h

33.3 80s

You might also like

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999No ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesKrishna VachaNo ratings yet

- ESABDocument1 pageESABXQNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel Electrodestarun kaushalNo ratings yet

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDocument2 pagesGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranNo ratings yet

- Ok 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 MpaDocument1 pageOk 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 Mpamitesh prajapatiNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesXQNo ratings yet

- Exaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageExaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodessergio jose morales perazaNo ratings yet

- Ficha Tecnica Esab Electrodos EspecialesDocument1 pageFicha Tecnica Esab Electrodos EspecialesStanley RamirezNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Esab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument1 pageEsab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesraghubhaimantra4136No ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Nimoten: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten: LOW ALLOY STEEL (Nimoten Series)satnamNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoNo ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- Electrode E8018 DetailsDocument1 pageElectrode E8018 DetailskapsarcNo ratings yet

- Electrode Booklet F Web 73Document1 pageElectrode Booklet F Web 73satnamNo ratings yet

- Electrode Booklet F Web 23Document1 pageElectrode Booklet F Web 23satnamNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- Pipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pagePipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesRys Multiventas SacNo ratings yet

- Wire Wound Fixed Resistors: FeaturesDocument7 pagesWire Wound Fixed Resistors: FeaturesteoilcaNo ratings yet

- WeartrodDocument1 pageWeartrodBhavik PatelNo ratings yet

- Industrial Relays of Small Dimensions: Contact DataDocument10 pagesIndustrial Relays of Small Dimensions: Contact DatalancenglotNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More Informationw elhaj abdallaNo ratings yet

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Esab 28: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pageEsab 28: Covered (Stick) Electrodes (Smaw) Mild Steel Electrodesraghubhaimantra4136No ratings yet

- Tenalloy 120G: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 120G: LOW ALLOY STEEL (High Strength)Devender NegiNo ratings yet

- OK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocument1 pageOK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing Electrodesraghubhaimantra4136No ratings yet

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNo ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- WB5525E ENiCrMo-5Document1 pageWB5525E ENiCrMo-5cwiksjNo ratings yet

- Electrode Booklet F Web 85Document1 pageElectrode Booklet F Web 85satnamNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- R100 R101Document2 pagesR100 R101Paulo CardosoNo ratings yet

- SOW 7018A11 8 SpecSheetDocument2 pagesSOW 7018A11 8 SpecSheetKmi GutierrezNo ratings yet

- Industrial Relays of Small Dimensions: Contact DataDocument10 pagesIndustrial Relays of Small Dimensions: Contact DataTarek KhafagaNo ratings yet

- Rele ElectromanecticoDocument7 pagesRele ElectromanecticoJULIO PORTILLONo ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesMohammad AdilNo ratings yet

- SR 350 Quick User GuideDocument13 pagesSR 350 Quick User GuideMuhammad SyaifulhaqNo ratings yet

- Industrial Relays of Small Dimensions: Contact DataDocument10 pagesIndustrial Relays of Small Dimensions: Contact DataNelson VillalbaNo ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- Aristo Rod 55Document1 pageAristo Rod 55joao guilhermeNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Relpol Serie r15 DatasheetsDocument9 pagesRelpol Serie r15 DatasheetsnnNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- OX/OY Series: Ceramic Composition 10% ToleranceDocument3 pagesOX/OY Series: Ceramic Composition 10% ToleranceAkashNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Resistance Welding: Indian Institute of Welding - ANB Refresher Course - Module 10Document40 pagesResistance Welding: Indian Institute of Welding - ANB Refresher Course - Module 10dayalramNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Catálogo PanWorld - enDocument16 pagesCatálogo PanWorld - enIsaias Exequiel Zapata GutierrezNo ratings yet

- NSK Linear Guide: Miniature PU Series/PE SeriesDocument7 pagesNSK Linear Guide: Miniature PU Series/PE Seriesjaime cerdaNo ratings yet

- Program Ampseca 2022Document23 pagesProgram Ampseca 2022khaoula-adelNo ratings yet

- Conduction Phenomena PDFDocument73 pagesConduction Phenomena PDFAnonymous 3tjJtJesoNo ratings yet

- Wrought Washers FlyerDocument2 pagesWrought Washers FlyerG.L. HuyettNo ratings yet

- Charcoal Production at Kiln Sites Affects C PDFDocument9 pagesCharcoal Production at Kiln Sites Affects C PDFJoao MinhoNo ratings yet

- Type of Company Ownership:: Forging ProcessDocument17 pagesType of Company Ownership:: Forging Processsureshkumar silvernitz100% (1)

- Methods of Purification of WaterDocument15 pagesMethods of Purification of WaterAbdullah Ansari Gunner100% (1)

- EnviroChem Additional PDFDocument503 pagesEnviroChem Additional PDFJane PollyNo ratings yet

- Laboratory Notes - Food TestsDocument6 pagesLaboratory Notes - Food TestsAbdul Ola IBNo ratings yet

- Pt. Binuma Widya Karsa Company Profile 2015Document14 pagesPt. Binuma Widya Karsa Company Profile 2015Anonymous H9Qg1iNo ratings yet

- Bioresource Technology: ReviewDocument14 pagesBioresource Technology: ReviewCan GülayinNo ratings yet

- CPC 2017Document3 pagesCPC 2017Harshith ShettyNo ratings yet

- Hempatex 46330Document2 pagesHempatex 46330Abah TeaNo ratings yet

- Fatigue and Static Crack GrowtDocument14 pagesFatigue and Static Crack GrowtKay WhiteNo ratings yet

- Atomic Radius and Effective Nuclear ChargeDocument8 pagesAtomic Radius and Effective Nuclear ChargeKisses EldswidthNo ratings yet

- The Application of Steam Quality Test LimitsDocument14 pagesThe Application of Steam Quality Test Limitspangaia100% (1)

- Journal of The Mechanics and Physics of Solids: Ryan S. Ginder, William D. Nix, George M. PharrDocument11 pagesJournal of The Mechanics and Physics of Solids: Ryan S. Ginder, William D. Nix, George M. PharrRaj Jung MahatNo ratings yet

- Astm e 1745Document2 pagesAstm e 1745Zahoor Ahmed Mohsan100% (1)

- Cetiol HeDocument4 pagesCetiol HeAleksandr FernandezNo ratings yet

- Magna-505-Display InforDocument2 pagesMagna-505-Display InforLee Chong EeNo ratings yet

- Grade 8 Integrated Science Schemes of Work Term Three 2018Document3 pagesGrade 8 Integrated Science Schemes of Work Term Three 2018Davies Masumba100% (3)

- Polymers NotesDocument55 pagesPolymers Notessamay gujratiNo ratings yet

- Materiales: Fenómenos FísicosDocument2 pagesMateriales: Fenómenos FísicosSandro Coz Martel100% (2)

- Natural Gas To BTXDocument505 pagesNatural Gas To BTXFrank Pocomucha GallardoNo ratings yet

- K01587 - 20200224174954 - Chapter 2 - OleochemicalDocument38 pagesK01587 - 20200224174954 - Chapter 2 - OleochemicalAisyah SidekNo ratings yet

- The Chemistry of Acids and BasesDocument68 pagesThe Chemistry of Acids and BasesHelpful Hand100% (1)

- Hydrolysis of Complexes: Functional Mimics of Metallo-: β-Lactam Antibiotics Catalyzed by Dinuclear Zinc (II) β-lactamasesDocument12 pagesHydrolysis of Complexes: Functional Mimics of Metallo-: β-Lactam Antibiotics Catalyzed by Dinuclear Zinc (II) β-lactamasesSubhecchha BaidyaNo ratings yet

- SAE BoltDocument1 pageSAE BoltAnuj ShahiNo ratings yet

- Andrade - Learning Activity-FinalDocument4 pagesAndrade - Learning Activity-Finalapi-257354113No ratings yet