Professional Documents

Culture Documents

Sandpiper s30nmdl2ds

Sandpiper s30nmdl2ds

Uploaded by

Yongfeng QianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sandpiper s30nmdl2ds

Sandpiper s30nmdl2ds

Uploaded by

Yongfeng QianCopyright:

Available Formats

Quality System

ISO9001 Certified

S30 Non-Metallic

Environmental

Design Level 2

Management System

ISO14001 Certified Ball Valve

Air Exhaust Side View

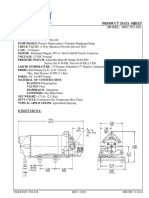

Air-Operated

Air Inlet Side View Double Diaphragm Pump

U.S. Patent #5,851,109; 5,996,627; 400,210 ENGINEERING, PERFORMANCE

& 6,241,487

Other U.S. Patents Applied for CE & CONSTRUCTION DATA

INTAKE/DISCHARGE PIPE SIZE CAPACITY AIR VALVE SOLIDS-HANDLING HEADS UP TO DISPLACEMENT/STROKE

3" ANSI Flange or 0 to 238 gallons per minute No-lube, no-stall Up to .71 in. (18mm) 100 psi or 231 ft. of water .9 Gallon / 3.41 liter

80mm DIN Flange (0 to 901 liters per minute) design (7 bar or 70 meters)

MODEL S30 Non-Metallic Performance Curve

Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions.

BAR

The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%.

PSI

20 (34)

40 (68)

60 (102)

7 100 100 80 (136)

PS I(6.8

Bar

90 )

100 (170)

6

80 80 P 120 (204)

NPSHR

SI (

5.44

5 70 Bar

)

140 (238)

60

4 60 P

HEAD

SI (4

.08 B

METERS

ar)

50

FEET

3

40

40 PS

I (2.72

Bar)

2 30 30 9.1

25 7.6

20 20 6

20 PSI (1

1 .36 Bar)

Air Inle 15 4.5

t Press

10 ure 10 3

5 1.5

0 0

0 20 40 60 80 100 120 140 160 180 200 220

U.S. Gallons per minute

50 150 250 350 450 550 650 750 850

Liters per minute

CAPACITY

SANDPIPER® pumps are designed to be powered only by compressed air.

s30nmdl2ds-REV0508 Model S30 Non-Metallic Page 1

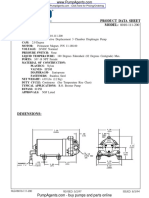

Explanation of Pump Nomenclature

S30 Non-Metallic · Design Level 2· Ball Valve

Check Diaphragm/ Check Non-Wetted Shipping

MODEL Pump Pump Valve Design Wetted Check Valve Valve Material Porting Pump Pump Kit Weight

Brand Size Type Level Material Materials Seat Options Options Style Options Options lbs. (kg)

S30B2P1PQAS000. S 30 B 2 P 1 P Q A S 0 00. 231 (105)

S30B2P2PQAS000. S 30 B 2 P 2 P Q A S 0 00. 231 (105)

S30B2K1KQAS000. S 30 B 2 K 1 K Q A S 0 00. 315 (143)

S30B2K2KQAS000. S 30 B 2 K 2 K Q A S 0 00. 315 (143)

S30B2P4PQAV000. S 30 B 2 P 4 P Q A V 0 00. 270 (122)

S30B2K4KQAV000. S 30 B 2 K 4 K Q A V 0 00. 354 (161)

Pump Brand Non-Wetted Material Options Pump Options Kit Options, Continued

S= SANDPIPER® A= Painted Aluminum 0= None E0.= Solenoid Kit with

J= Painted Aluminum PTFE 1= Sound Dampening Muffler 24VDC Coil

Pump Size Q= Epoxy Coated Aluminum 2= Mesh Muffler E1.= Solenoid Kit with 24VDC

30=3" K= PTFE Coated Aluminum 3= High temperature Air Explosion-Proof Coil

Check Valve Type L= PTFE Coated Aluminum with Valve w/Integral Muffler E2.= Solenoid Kit with

B= Ball PTFE Coated Hardware 4= High temperature Air 24VAC/12VDC Coil

R= Epoxy Coated Aluminum with Valve Sound Dampening E3.= Solenoid Kit with 12VDC

Design Level PTFE Coated Hardware Muffler Explosion-Proof Coil

2= Design Level 2 5= High temperature E4.= Solenoid Kit with 110VAC Coil

Porting Options Air Valve w/Mesh Muffler E5.= Solenoid Kit with 110VAC, 60

Wetted Material A= ANSI Flange

K= PVDF Hz Explosion-Proof Coil

D= DIN Flange Kit Options E6.= Solenoid Kit with 220VAC Coil

P= Polypropylene 7= Dual Porting (ANSI) 00.= None E7.= Solenoid Kit with 220VAC,

Diaphragm Check Valve Materials 8= Top Dual Porting (ANSI) P0.= 10-30VDC 60 Hz Explosion-Proof Coil

1= Santoprene/Santoprene 9= Bottom Dual Porting (ANSI) Pulse Output Kit E8.= Solenoid Kit with 110VAC, 50

2= PTFE-Santoprene Backup/PTFE P1.= Intrinsically-Safe Hz Explosion-Proof Coil

Pump Style 5-30VDC,110/120VAC,

3= PTFE Pumping, PTFE-Santoprene E9.= Solenoid Kit with 230VAC, 50

D= Spill Containment with Electronic 220/240VAC

Backup Driver/PTFE Hz Explosion-Proof Coil

Leak Detection (110V) Pulse Output Kit

4= Santoprene Pumping, Santoprene SP.= Stroke Indicator Pins

Driver/Santoprene E= Spill Containment with Electronic P2.=110/120 or 220/240VAC

Leak Detection (220V) Pulse Output Kit

Check Valve Seat M= Spill Containment with Mechanical

K= PVDF Leak Detection

P= Polypropylene S= Standard

U= Polyurethane/ Polyurethane V= Spill Containment with Visual

Leak Detection

CAUTION! Operating temperature limitations are as follows:

Operating Temperatures

Materials Maximum Minimum

Santoprene : Injection molded thermoplastic elastomer with no fabric layer. Long mechanical flex life.

®

212°F -10°F

Excellent abrasion resistance. 100°C -23°C

Virgin PTFE: Chemically inert, virtually impervious. Very few chemicals are known to react chemically

with PTFE molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such 212°F -35°F

as chlorine trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures. 100°C -37°C

Polypropylene: 150°F -40°F

65°C 5°C

PVDF: 200°F 10°F

93°C -13°C

Polyurethane: 210°F -40°F

99°C -40°C

For specific applications, always consult the Warren Rupp “Chemical Resistance Chart”

s30nmdl2ds-REV0508 Model S30 Non-Metallic Page 2

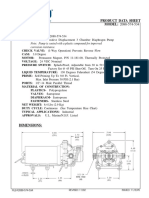

Dimensions: S30 Non-Metallic

Dimensions in Inches

Dimensional Tolerance: ±1/8"

DIMENSION A

Standard Pump 6 9/16”

Pulse Output Kit 6 9/16”

Sound Dampening Muffler 13 3/4”

Mesh Muffler 8 13/16”

Note: Porting Flanges are also available with PN10

80mm DIN bolting configuration.

Dimensions in Millimeters

Dimensional Tolerance: ± 3mm

DIMENSION A

Standard Pump 167mm

Pulse Output Kit 167mm

Sound Dampening Muffler 349mm

Mesh Muffler 225mm

s30nmdl2ds-REV0508 Model S30 Non-Metallic Page 3

Dimensions: S30 Non-Metallic with Containment Duty

Dimensions in Inches

Dimensional Tolerance: ±1/8"

DIMENSION A B

Standard Pump 6 9/16” 12 11/16”

Pulse Output Kit 6 9/16” 12 11/16”

Sound Dampening Muffler 13 3/4” 22 9/32”

Mesh Muffler 8 13/16” 14 15/16”

Note: Porting Flanges are also available with PN10

80mm DIN bolting configuration.

Dimensions in Millimeters

Dimensional Tolerance: ± 3mm

DIMENSION A B

Standard Pump 167mm 322mm

Pulse Output Kit 167mm 322mm

Sound Dampening Muffler 349mm 579mm

Mesh Muffler 225mm 380mm

Note: Porting Flanges are also available with PN10

80mm DIN bolting configuration.

s30nmdl2ds-REV0508 Model S30 Non-Metallic Page 4

You might also like

- SCI ConnectionsDocument9 pagesSCI ConnectionsMujjo SahbNo ratings yet

- Udimet Alloy 520Document1 pageUdimet Alloy 520Svetlana PerekopskayaNo ratings yet

- Guentner Material Selection 2011 EnglishDocument8 pagesGuentner Material Selection 2011 EnglishHoang100% (1)

- s30 SMetallic Data SheetDocument5 pagess30 SMetallic Data Sheetluis miguel velarde manrique100% (1)

- Bomba Neumatica Sandpiper Metalica Modelo S20Document8 pagesBomba Neumatica Sandpiper Metalica Modelo S20Edgar EncinaNo ratings yet

- Metallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpDocument6 pagesMetallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpCarlos Alberto OspinaNo ratings yet

- S07nmdl1ds ENDocument5 pagesS07nmdl1ds ENYongfeng QianNo ratings yet

- pb025 NM STANDARDDocument3 pagespb025 NM STANDARDAlvaro Iparraguirre NavarroNo ratings yet

- S1F Non-Metallic Pump: Technical Data SheetDocument3 pagesS1F Non-Metallic Pump: Technical Data SheetspattacutNo ratings yet

- Sandpiper Standard Duty Metallic Pumps s30 Data SheetDocument3 pagesSandpiper Standard Duty Metallic Pumps s30 Data Sheetjose manuel alvarez rodriguezNo ratings yet

- s20 Metalik Data Sheet Rev0817Document2 pagess20 Metalik Data Sheet Rev0817STEPF cryptoNo ratings yet

- S30 Non-Metallic Containment Duty Pump: Technical Data SheetDocument2 pagesS30 Non-Metallic Containment Duty Pump: Technical Data SheetMuhamad nurul aminNo ratings yet

- S20 Metallic Pump: Technical Data SheetDocument3 pagesS20 Metallic Pump: Technical Data SheetDang LucNo ratings yet

- Sandpiper s1f PumpDocument3 pagesSandpiper s1f PumpAdi PurnomoNo ratings yet

- s05 M StandardDocument3 pagess05 M Standardlaura.diazNo ratings yet

- Sump PumpDocument2 pagesSump PumpRAM SANNo ratings yet

- ADC3010 AF 484 Series RegulatorDocument3 pagesADC3010 AF 484 Series RegulatormiguesobeNo ratings yet

- Bomba de Agua Shurflo 8007-593-836 Sup SH 12V 35 MTSDocument2 pagesBomba de Agua Shurflo 8007-593-836 Sup SH 12V 35 MTSrocilic114No ratings yet

- Eaton 421 Pump Sheet Vers-BDocument2 pagesEaton 421 Pump Sheet Vers-Bdzakky syahputraNo ratings yet

- Ficha Tecnica Surflo 8090-212-246Document2 pagesFicha Tecnica Surflo 8090-212-246Fernando YepezNo ratings yet

- 152 Series RegulatorsDocument1 page152 Series RegulatorsScientific EquipmentNo ratings yet

- Typical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealDocument6 pagesTypical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealSonia Marcela AriasNo ratings yet

- Sandpiper S15 Bomba NeumaticaDocument3 pagesSandpiper S15 Bomba NeumaticaAlejandro AdriasolaNo ratings yet

- DS AddPak Injection Block R08Document4 pagesDS AddPak Injection Block R08eka pramudia santosoNo ratings yet

- Product Data Sheet MODEL: 8010-111-200 Specifications:: Permanent Magnet, P/N 11-188-00Document3 pagesProduct Data Sheet MODEL: 8010-111-200 Specifications:: Permanent Magnet, P/N 11-188-00MapleNo ratings yet

- Sandpiper hdf2Document3 pagesSandpiper hdf2alonsomoganNo ratings yet

- MastraisingcylindersDocument5 pagesMastraisingcylindersAyman AkrabNo ratings yet

- Valvula Serie F ParkerDocument3 pagesValvula Serie F ParkerRogelio ArandaNo ratings yet

- 6000 - Spec BooterDocument2 pages6000 - Spec BooterCasanova FernandoNo ratings yet

- Model DDV Diaphragm Deluge Valve: Table ADocument15 pagesModel DDV Diaphragm Deluge Valve: Table ACoordinador TecnicoNo ratings yet

- Curvas de DesempeñoDocument116 pagesCurvas de DesempeñoRene RodriguezNo ratings yet

- ADC 3010 AC 212 Series RegulatorDocument2 pagesADC 3010 AC 212 Series RegulatorkicsnerNo ratings yet

- High Pressure Check Valves: SHCV SeriesDocument8 pagesHigh Pressure Check Valves: SHCV SeriesToty DzNo ratings yet

- Service Operating - Model 8329 ALEMITEDocument19 pagesService Operating - Model 8329 ALEMITEMorales EduardoNo ratings yet

- Danfoss ERR100Document1 pageDanfoss ERR100Ayu AnnisaNo ratings yet

- 1 1/2" Elima-Matic Clamped Metallic: Performance SpecificationsDocument1 page1 1/2" Elima-Matic Clamped Metallic: Performance SpecificationsAldy DankersNo ratings yet

- Piping Class - GS70Document1 pagePiping Class - GS70Dmitriy RybakovNo ratings yet

- MODEL: 2088-514-145 Product Da Ta Sheet: Factory Set at 45 PSI Shut-Off, Turn On 25 PSI 5 PSIDocument2 pagesMODEL: 2088-514-145 Product Da Ta Sheet: Factory Set at 45 PSI Shut-Off, Turn On 25 PSI 5 PSIman1809No ratings yet

- Plot 01Document5 pagesPlot 01Muhammad Irfan ButtNo ratings yet

- 2" Ultra-Matic Non-Metallic Bolted: Performance SpecificationsDocument1 page2" Ultra-Matic Non-Metallic Bolted: Performance SpecificationsDaniel Andres Gonzalez CanedoNo ratings yet

- Regulators Edge 3 Series Regulators: Slam™Document1 pageRegulators Edge 3 Series Regulators: Slam™Dries VandezandeNo ratings yet

- SB 930Document8 pagesSB 930Mauricio Hermosilla OrellanaNo ratings yet

- TDS - Item 170Document1 pageTDS - Item 170YazanassiNo ratings yet

- Versamatic MetalicaDocument12 pagesVersamatic MetalicaJahaziel VegaNo ratings yet

- E-Sh Series: Erp 2009/125/ceDocument124 pagesE-Sh Series: Erp 2009/125/ceabedzNo ratings yet

- ESAB ExtractPage25-26cDocument8 pagesESAB ExtractPage25-26cDries VandezandeNo ratings yet

- CHDS Fchmber 141002 PDFDocument4 pagesCHDS Fchmber 141002 PDFVils ArabadzhievaNo ratings yet

- Estandar Disolucion LevoDocument5 pagesEstandar Disolucion LevoBrendapaez3No ratings yet

- Pages From E-MESW-MC001-EDocument2 pagesPages From E-MESW-MC001-EAshishNo ratings yet

- ExtractPage23 24B PDFDocument4 pagesExtractPage23 24B PDFDries VandezandeNo ratings yet

- MODEL: 2088-574-534 Product Data Sheet: Corrosion ResistanceDocument2 pagesMODEL: 2088-574-534 Product Data Sheet: Corrosion ResistanceLio LiverhNo ratings yet

- Experimental Investigation of Cyclic Vibration Morton Effect in The Bearing of A Double Overhung Compressor by Jim McGinley and Bill MarscherDocument28 pagesExperimental Investigation of Cyclic Vibration Morton Effect in The Bearing of A Double Overhung Compressor by Jim McGinley and Bill MarscherGang HANNo ratings yet

- LGH 25RVX e - 60Document5 pagesLGH 25RVX e - 60Qui documNo ratings yet

- Series B10-2 - Technical Information General Description Performance CurveDocument2 pagesSeries B10-2 - Technical Information General Description Performance CurveLuis Fernando Ramírez PromotorNo ratings yet

- Colorflow - Control Valves F PDFDocument3 pagesColorflow - Control Valves F PDFAlejandraNo ratings yet

- Scanjet Datasheet Bio7SBDocument2 pagesScanjet Datasheet Bio7SBGabriel TravassosNo ratings yet

- All-Flo 1.5 Inch Bolted AOD Pump Data SheetDocument4 pagesAll-Flo 1.5 Inch Bolted AOD Pump Data SheetfvcasadosNo ratings yet

- Bomba ABER de Pistão Acima de 17 LDocument2 pagesBomba ABER de Pistão Acima de 17 LGloria AlvesNo ratings yet

- Barksdale Valve 4 WayDocument2 pagesBarksdale Valve 4 WayDwiki RamadhaniNo ratings yet

- WW C30-C Product-Page English 1-2016 2Document4 pagesWW C30-C Product-Page English 1-2016 2rafaelcoserNo ratings yet

- Tecman TMB4-V5 Web Spec V160921Document1 pageTecman TMB4-V5 Web Spec V160921thomas.templierNo ratings yet

- Jofee - Catalogue 01Document11 pagesJofee - Catalogue 01Yongfeng QianNo ratings yet

- S 07 NMDL 1 SMDocument35 pagesS 07 NMDL 1 SMYongfeng QianNo ratings yet

- S 05 NMDL 2 SMDocument35 pagesS 05 NMDL 2 SMYongfeng QianNo ratings yet

- s10nmdl1sm ENDocument30 pagess10nmdl1sm ENYongfeng QianNo ratings yet

- S 20 NMDL 3 DsDocument6 pagesS 20 NMDL 3 DsYongfeng QianNo ratings yet

- S07nmdl1ds ENDocument5 pagesS07nmdl1ds ENYongfeng QianNo ratings yet

- Policarpio - BGT 5 - Research No.2Document21 pagesPolicarpio - BGT 5 - Research No.2Tracy PolicarpioNo ratings yet

- Amendmend TS 14 01 14Document17 pagesAmendmend TS 14 01 14Prakash BeheraNo ratings yet

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Document35 pagesDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainNo ratings yet

- ZN GrapheneDocument8 pagesZN GrapheneRahul kumarNo ratings yet

- NDT PDFDocument0 pagesNDT PDFAnthony CyrilNo ratings yet

- 23 11 23 Facility Natural-Gas PipingDocument19 pages23 11 23 Facility Natural-Gas PipingKak SofiNo ratings yet

- Curvas Antidesgaste para Silos de CementoDocument2 pagesCurvas Antidesgaste para Silos de CementoNarvaxisNo ratings yet

- Casting Processes: ME 4210: Manufacturing Processes and Engineering Prof. J.S. Colton © GIT 2006Document56 pagesCasting Processes: ME 4210: Manufacturing Processes and Engineering Prof. J.S. Colton © GIT 2006anand_lmlNo ratings yet

- DB Wiring DiagramDocument1 pageDB Wiring DiagrammhofuNo ratings yet

- Fuji Electric VFZ Series Operating Manual JEC PDFDocument25 pagesFuji Electric VFZ Series Operating Manual JEC PDFCarlos DavalosNo ratings yet

- Star S07FS32DR Water Softener Owners GuideDocument38 pagesStar S07FS32DR Water Softener Owners GuideBillNo ratings yet

- Worm GearsDocument4 pagesWorm GearsSp PatelNo ratings yet

- Masterroc Hca 20: Liquid Hydration Inhibitor For ConcreteDocument3 pagesMasterroc Hca 20: Liquid Hydration Inhibitor For Concretez_sheriNo ratings yet

- Scope of WorksDocument43 pagesScope of WorksbecpavanNo ratings yet

- MAI R32N&S 9851 2230 01cDocument2 pagesMAI R32N&S 9851 2230 01cesteban muñozNo ratings yet

- Steel 2D Analysis & Design (EN1993)Document4 pagesSteel 2D Analysis & Design (EN1993)Truong Phuoc TriNo ratings yet

- 168 Imi PolymatDocument4 pages168 Imi PolymatEngr KamalNo ratings yet

- Assignment 1Document11 pagesAssignment 1Luna LatisyaNo ratings yet

- Seismic Effects On Perofrmance of Bridges PDFDocument18 pagesSeismic Effects On Perofrmance of Bridges PDFkondaNo ratings yet

- Discussion: Analytical Investigation and Monitoring of The Alaskan Way Viaduct Super GirdersDocument13 pagesDiscussion: Analytical Investigation and Monitoring of The Alaskan Way Viaduct Super GirdersMongi Ben OuezdouNo ratings yet

- Durai PPT Mini 2Document42 pagesDurai PPT Mini 2rexdindigulNo ratings yet

- Pressure Vessel Design IS 2825Document1 pagePressure Vessel Design IS 2825sreenvasmallaNo ratings yet

- Construction of Toilets To The Skating Ring at Jewal AppartmentDocument45 pagesConstruction of Toilets To The Skating Ring at Jewal AppartmentprasadmvkNo ratings yet

- Computational Fluid Dynamics in Turbulent Flow Applications: August 2016Document25 pagesComputational Fluid Dynamics in Turbulent Flow Applications: August 2016kvvp94No ratings yet

- Design of Square FootingDocument4 pagesDesign of Square FootingLean BalingataNo ratings yet

- Unit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTDocument2 pagesUnit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTAnil KumarNo ratings yet

- Atlas: High Performance End MillsDocument12 pagesAtlas: High Performance End Millsmax8086No ratings yet