Professional Documents

Culture Documents

Purlin Design

Purlin Design

Uploaded by

Naveen Kumar PadmanabuniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Purlin Design

Purlin Design

Uploaded by

Naveen Kumar PadmanabuniCopyright:

Available Formats

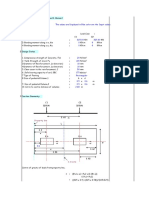

Design of Purlins

Design data

2

Yield strength of steel py = 275.0 N/mm

Slope of roof (to horizontal) = 10.0 o or 0.174 radians

Span of purlin l = 4.75 m

Spacing of purlins = 1.30 m

Sectional properties of purlin.

Member = RSC203x76x24

3 4

D = 203.2 B = 76.20 Z xx = 192.00 cm I xx = 1955.00 cm

3 4

t = 7.1 T = 11.20 Z yy = 27.7 cm Iyy = 152.0 cm

2

Gross area of cross section A = 30.4 cm r.min = 22.4 mm

PDL/PL

Loads

Dead load

Roofing sheet & accessories load PDL-1 = 0.25 kN/m PDL*cos(x)/

PLL*cos(x)/

Dead weight of purlin PDL-2 = 0.24 kN/m PWL

Total PDL = 0.49 kN/m PDL*sin(x)/

Live load PLL = 1.00 kN/m PLL*sin(x)

Wind load PWL = 4.67 kN/m

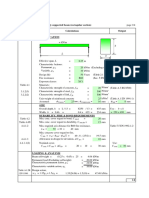

Load case I

a) Load combination 1.4DL+1.6LL x

W 1 = [1.4PDLcos(x)+ 1.6PLLcos(x)] = 2.3 kN/m

W 1y = [1.4PDLsin(x)+1.6 PLLsin(x)] = 0.4 kN/m

b) Load combination 1.4DL+1.4WL

W 2 = [PDLcos(x)+ PWLcos(x)] = 7.1 kN/m

W 2y = [1.4PDLsin(x)+1.4 PWLsin(x)] = 1.3 kN/m

c) Load combination 1.2DL+1.2LL+1.2WL

W 3 = [1.2PDLcos(x)+1.2PLLcos(x)+1.2 PWLcos(x)] = 7.3 kN/m

W 3y = [1.2PDLsin(x)+1.2 PLLsin(x)+1.2 PWLsin(x)] = 1.3 kN/m

Case a) and Case b) are critical, case a) adopted for deisgn.

Load combination 1.4DL+1.6LL

Applied moment at mid span of purlin

M xx = 6.35 kN-m

2

M xx = [P DLcos(x )+ P LLcos(x )]*leff /8

Effective length =1.0*L =leff l=leff = 4.75 m

Note: Sag rods are provided at mid span of every purlin. Hence, connection point of sag rod to purlin

will act as a support in y-y axis of purlin and the effective length in y-y axis will be 0.5 times the

spacing of truss.

M yy = 0.22 kN-m

2

M yy = ([P DLsin(x )+ P LLsin(x )]*(l /2) )/10

Moment capacity check:

Moment capacity of Mazor axis, Mcx = 63.36 kN-m

Moment capacity of Minor axis, Mcy = 9.14 kN-m

(Mc = 1.2 x py x Z)

Local capacity of check, Mxx/Mcx+Myy/Mcy < 1

Mxx/Mcx+Myy/Mcy = 0.12

Hence ok

Buckling capacity check:

Slenderness ratio, Leff/r.min = 212.05

Equivalent Slenderness ratio, lLT = uvw

buckling parameter, u = 0.90

Torsional index, x = D/T = 18.14

Ratio, w = 1.00

2 0.25

The slenderness factor, v = 0.60 (v = 1/(1+0.05x(/x) ) )

Equivalent Slenderness ratio, lLT = 114.09

Bending strength, pb = 100.00 N/mm2 (From table-16 of BS 5950-2000, part-1)

Buckling resisting moment, Mb = 1.2 x pb x Zx = 23.04 kN.m

The overall buckling check, mMx/Mb+mMyy/Mcy < 1

mMx/Mb+mMyy/Mcy = 0.30

Hence ok

Shear check:

Max. shear force, wL/2 = 0.94 kN

Shear area, Avx = 1442.72 mm2

Shear capacity, Pvx = 0.6 x py x Avx = 238.05 kN

2

Shear area, Avy = 0.9 x Ao = 1536.19 mm (Ao = area of flanges)

Shear capacity, Pvx = 0.6 x py x Avx = 253.47 kN

Hence ok

Check of deflection:

Deflection, dx = 2.43 mm

dx = (5 x wl4)/384EI

Deflection, dy = 0.34 mm

dy = (5 x wl4)/384EI

Allowable deflection, d.allow = 19.00 mm

(d.allow = L/250, as per SP-1275) Hence ok

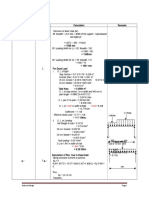

Cladding Purlin

Design data

2

Yield strength of steel py = 275.0 N/mm

Span of purlin l = 6.00 m

Spacing of purlins = 1.00 m

Sectional properties of purlin.

Member = RSC254x89x36

3 4

D = 254 B = 88.90 Z xx = 350.00 cm I xx = 4445.00 cm

3 4

t = 9.1 T = 13.60 Z yy = 46.7 cm Iyy = 3.2 cm

2

Gross area of cross section A = 45.4 cm r.min = 25.8 mm

Loads

PDL

Dead load

Roofing sheet & accessories load PDL-1 = 0.25 kN/m

Dead weight of purlin PDL-2 = 0.24 kN/m

Total PDL = 0.49 kN/m PWL

Wind load PWL = 3.59 kN/m

(1.1x0.826x1.5-Refer Wind load calculations on walls)

Load combination 1.4WL

Applied moment at mid span of purlin

2

M xx = P WL*leff /8 M xx = 22.61 kN-m

Effective length =1.0*L =leff l=leff = 6.00 m

Note: Sag rods are provided at mid span of every purlin. Hence, connection point of sag rod to purlin

will act as a support in y-y axis of purlin and the effective length in y-y axis will be 0.5 times the

spacing of truss. Calculations in this direction are negelected,hence Dead load is very small)

Moment capacity check:

Moment capacity of Mazor axis, Mcx = 115.50 kN-m

Moment capacity of Minor axis, Mcy = 15.41 kN-m

(Mc = 1.2 x py x Z)

Local capacity of check, Mxx/Mcx < 1

Mxx/Mcx = 0.20

Hence ok

Buckling capacity check:

Slenderness ratio, Leff/r.min = 232.56

Equivalent Slenderness ratio, lLT = uvw

buckling parameter, u = 0.90

Torsional index, x = D/T = 18.68

Ratio, w = 1.00

The slenderness factor, v = 0.58 (v = 1/(1+0.05x(/x)2)0.25)

Equivalent Slenderness ratio, lLT = 121.69

Bending strength, pb = 83.00 N/mm2 (From table-16 of BS 5950-2000, part-1)

Buckling resisting moment, Mb = pb x Zx = 29.05 kN.m

The overall buckling check, mMx/Mb

mMx/Mb+mMyy/Mcy = 0.78

Hence ok

Shear check:

Max. shear force, wL/2 = 1.47 kN

2

Shear area, Avx = 2311.40 mm

Shear capacity, Pvx = 0.6 x py x Avx = 381.38 kN

2

Shear area, Avy = 0.9 x Ao = 2176.27 mm (Ao = area of flanges)

Shear capacity, Pvx = 0.6 x py x Avx = 359.08 kN

Hence ok

Check of deflection:

Deflection, dx = 6.65 mm

dx = (5 x wl4)/384EI

Deflection, dy = 78.78 mm

dy = (5 x wl4)/384EI

Allowable deflection, d.allow = 24.00 mm

(d.allow = L/250, as per SP-1275) Hence not ok

You might also like

- Design of Floor JoistDocument5 pagesDesign of Floor JoistXDXDXDNo ratings yet

- Four Pile Caps StructvilleDocument6 pagesFour Pile Caps Structvillemabuhamd100% (1)

- Combined FootingDocument30 pagesCombined FootingThirumalesh100% (1)

- Wall FootingDocument11 pagesWall FootingJohn Paul Hilary EspejoNo ratings yet

- Superimposed Dead Loads and Live Loads Load MagnitudeDocument8 pagesSuperimposed Dead Loads and Live Loads Load MagnitudeLouieNo ratings yet

- Mathcad - 03-Design of Singly Reinforced BeamsDocument3 pagesMathcad - 03-Design of Singly Reinforced BeamsMrAlittle FingerNo ratings yet

- 7.continuous BeamsDocument35 pages7.continuous BeamsTareck BOU JAOUDENo ratings yet

- Beam-Design-R CDocument123 pagesBeam-Design-R CMarkNo ratings yet

- DESIGN OF COMBINED FOOTING (SlabDocument7 pagesDESIGN OF COMBINED FOOTING (SlabmeenuNo ratings yet

- Design of Eccentric Footing With StrapDocument11 pagesDesign of Eccentric Footing With StrapKrijan MaliNo ratings yet

- Design of Doubly Reinforced BeamsDocument21 pagesDesign of Doubly Reinforced BeamsBhaskar BabiNo ratings yet

- Pile Cap DesignDocument28 pagesPile Cap Designpwd2007No ratings yet

- Design of Column (With Biaxial Bending)Document4 pagesDesign of Column (With Biaxial Bending)Uttam Kumar GhoshNo ratings yet

- DRCS AssignmentDocument7 pagesDRCS AssignmentHarsh TiwariNo ratings yet

- Cantilever Method of Portal FrameDocument9 pagesCantilever Method of Portal FrameNikhilNo ratings yet

- Gulariya MC L 5m, B 4mDocument9 pagesGulariya MC L 5m, B 4mrashmi bhailaNo ratings yet

- Isolated FootingDocument59 pagesIsolated Footingsrinivasa raoNo ratings yet

- IAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanDocument29 pagesIAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanSrikanth ReddyNo ratings yet

- Design of Doubly Reinforced BeamDocument2 pagesDesign of Doubly Reinforced BeamZnake Von LucasNo ratings yet

- Raft Footing FlowchartDocument4 pagesRaft Footing FlowchartVinith Krishna100% (1)

- Isolated Corner Column FootingDocument6 pagesIsolated Corner Column FootingYorde KatapangNo ratings yet

- Slab DesignDocument10 pagesSlab DesignKeeperNo ratings yet

- Analysis (Beam)Document62 pagesAnalysis (Beam)Cypress Rovee FloresNo ratings yet

- Slab S2 @RD AnalysisDocument1 pageSlab S2 @RD AnalysisMark Christian Esguerra100% (1)

- Example 5.1-BeamDocument4 pagesExample 5.1-BeamNur Alia NajwaNo ratings yet

- Staircase Design: 8.28kN/m 15.57kN/mDocument3 pagesStaircase Design: 8.28kN/m 15.57kN/mBikki CyamaNo ratings yet

- Column Design - As Per BS CodeDocument16 pagesColumn Design - As Per BS CodeYam BalaoingNo ratings yet

- Roof Truss DesignDocument7 pagesRoof Truss DesignAnonymous sfkedkymNo ratings yet

- Prelims Solution Ce18Document6 pagesPrelims Solution Ce18Mark Lester LualhatiNo ratings yet

- Rectangular Combined Footing: Input DataDocument2 pagesRectangular Combined Footing: Input DataAnonymous 5pQf43AJwNo ratings yet

- Quiz 2Document4 pagesQuiz 2Jerome M. GuetaNo ratings yet

- Manual Design of One Way Slab (Continous Slab)Document5 pagesManual Design of One Way Slab (Continous Slab)Struct Soft CentreNo ratings yet

- RCII Column Design Solved Examples: Example 2.1. (Classification of Columns)Document18 pagesRCII Column Design Solved Examples: Example 2.1. (Classification of Columns)Dechas MohammedNo ratings yet

- Design of Combined FootingsDocument45 pagesDesign of Combined FootingsAnkit AgrawalNo ratings yet

- Steel Module 7Document5 pagesSteel Module 7dash1991No ratings yet

- Design of Truss 3Document22 pagesDesign of Truss 3Udat Hakeem Malang AmirNo ratings yet

- Design Retaining WallDocument15 pagesDesign Retaining WallAnindit MajumderNo ratings yet

- Tower STR ReportDocument18 pagesTower STR ReportRoshan KejariwalNo ratings yet

- Analysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCODocument25 pagesAnalysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCOV.m. RajanNo ratings yet

- Base Shear ComputationDocument5 pagesBase Shear ComputationAmante MorenoNo ratings yet

- Design of SlabDocument26 pagesDesign of SlabSumanth Sangem100% (1)

- Two Way SlabDocument9 pagesTwo Way SlabMehul Paþel100% (1)

- RC Beam Design Based On ACI 318 14Document2 pagesRC Beam Design Based On ACI 318 14ani145yadavNo ratings yet

- Raft DesignDocument8 pagesRaft Designramesh_madkatte1082No ratings yet

- Two Way SLabDocument22 pagesTwo Way SLabDevesh GuptaNo ratings yet

- One Way Continuous SlabDocument5 pagesOne Way Continuous SlabBia MughalNo ratings yet

- Design of Combined Footing With Strap Beam: Width of Interior Column 2aDocument6 pagesDesign of Combined Footing With Strap Beam: Width of Interior Column 2aLakmal JayashanthaNo ratings yet

- Combined FootingDocument2 pagesCombined FootingakhilNo ratings yet

- Staad Pro-Different Floor LoadsDocument28 pagesStaad Pro-Different Floor LoadsV.m. Rajan100% (1)

- Design of Two Pile Cap DATADocument4 pagesDesign of Two Pile Cap DATAhemanth funny100% (1)

- Chapter 2 ExercisesDocument4 pagesChapter 2 ExercisesMaxNo ratings yet

- Design ProjectDocument36 pagesDesign Projectveenabalu20No ratings yet

- Flat Slab DesignDocument2 pagesFlat Slab DesignKim ChanthanNo ratings yet

- Design of Purlins Design Data: XX XX Yy IyyDocument6 pagesDesign of Purlins Design Data: XX XX Yy IyyCorey CookNo ratings yet

- Steel Rafter Section For Eave Roof Section ReductionsDocument25 pagesSteel Rafter Section For Eave Roof Section ReductionsJanaka KarunarathnaNo ratings yet

- Purlin Design (YCP 1020) : Table 7 CL 4.2.3Document2 pagesPurlin Design (YCP 1020) : Table 7 CL 4.2.3JONAS NGNo ratings yet

- Design Purlin Girt FinalDocument14 pagesDesign Purlin Girt FinalcadsultanNo ratings yet

- Beam Analysis 1Document2 pagesBeam Analysis 1bayzuraNo ratings yet

- ASME Ch35 p629-644Document16 pagesASME Ch35 p629-644kapilnandwanaNo ratings yet

- ADP 2 Lab ManualDocument102 pagesADP 2 Lab ManualKishoremcNo ratings yet

- Guidelines For Pipe Support AnalysisDocument29 pagesGuidelines For Pipe Support AnalysisEarl John LugatimanNo ratings yet

- Pdisp Piled RaftwebinarDocument30 pagesPdisp Piled RaftwebinarBartosz ZaforemskiNo ratings yet

- CE16 Structural Timber Design Unit 3Document44 pagesCE16 Structural Timber Design Unit 3Czelsi Carlos NavarroNo ratings yet

- Ami Warp AnalysisDocument31 pagesAmi Warp AnalysisBittuNo ratings yet

- Bruton Etal 2006 SPEPFC106847Document10 pagesBruton Etal 2006 SPEPFC106847Souha Bali100% (1)

- Static Buckling of Moderately Thick, Anisotropic, Laminated and Sandwich Cylindrical Shell PanelsDocument12 pagesStatic Buckling of Moderately Thick, Anisotropic, Laminated and Sandwich Cylindrical Shell Panelsjunjie yiNo ratings yet

- Commentary and Recommendations On FEMA 350: Structural Engineers Association of California Seismology CommitteeDocument51 pagesCommentary and Recommendations On FEMA 350: Structural Engineers Association of California Seismology CommitteeDavid Alvarez MirandaNo ratings yet

- Rectangular Tank MathcadDocument37 pagesRectangular Tank Mathcadelixnz100% (1)

- 2019 02 20 ClearCalcs CF - OPTIMISED PDFDocument56 pages2019 02 20 ClearCalcs CF - OPTIMISED PDFIsaac PangNo ratings yet

- AU0701Document4 pagesAU0701bmdbmdbmdNo ratings yet

- BridgeDocument29 pagesBridgeSiva Krishna ReddyNo ratings yet

- Casing DesignDocument23 pagesCasing DesignDhiaa LaMi100% (1)

- Cohesive Fracture and Scaling: CE-430 & MS-441Document3 pagesCohesive Fracture and Scaling: CE-430 & MS-441MsmMostafaNo ratings yet

- Performance Indices Booklet Bokpeien22Document33 pagesPerformance Indices Booklet Bokpeien22b meryemNo ratings yet

- Cfs HelpDocument84 pagesCfs HelpmurdicksNo ratings yet

- Uj 36573+SOURCE1+SOURCE1.1Document9 pagesUj 36573+SOURCE1+SOURCE1.1Axole ThuthunjwayoNo ratings yet

- DLA Vessels Guide e May18Document68 pagesDLA Vessels Guide e May18tallerusacoNo ratings yet

- AISI - Direct Strength Method (DSM) Design GuideDocument184 pagesAISI - Direct Strength Method (DSM) Design GuidePaul KohanNo ratings yet

- Structural Design Optimization of A Wind Turbine Blade Using The Genetic AlgorithmDocument19 pagesStructural Design Optimization of A Wind Turbine Blade Using The Genetic AlgorithmGogyNo ratings yet

- Local and Post-Local Buckling of Fabricated High-Strength Steel and Composite Columns, 2019 (Zhichao Huang) PDFDocument15 pagesLocal and Post-Local Buckling of Fabricated High-Strength Steel and Composite Columns, 2019 (Zhichao Huang) PDFPhan Đào Hoàng HiệpNo ratings yet

- Ec3 Design 170412092432 PDFDocument65 pagesEc3 Design 170412092432 PDFKTMO100% (1)

- IITG Presentation 20-10-2017 by Prof KulkarniDocument63 pagesIITG Presentation 20-10-2017 by Prof KulkarniAmit Kumar BaghelNo ratings yet

- Steel Shear StrengthDocument12 pagesSteel Shear StrengthShekh Muhsen Uddin AhmedNo ratings yet

- CIVIL 210 - 2019 BundleDocument263 pagesCIVIL 210 - 2019 BundleVincent ChenNo ratings yet

- Steel Frame Design ManualDocument80 pagesSteel Frame Design ManualHaytham ZaghloulNo ratings yet

- Structural Mechanics 2-Lesson 4-Buckling (Complete Note)Document27 pagesStructural Mechanics 2-Lesson 4-Buckling (Complete Note)Janith amarawickramaNo ratings yet

- Concrete Institute of Australia - Recomended Practice - Z36 Formwork HandbookDocument164 pagesConcrete Institute of Australia - Recomended Practice - Z36 Formwork Handbooktim100% (2)

- WAN05 Shell HydroformingDocument7 pagesWAN05 Shell HydroformingAlejandroNo ratings yet