Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

12 views2010 - Us2010011782a1 - Vise For A Directional Drilling Machine

2010 - Us2010011782a1 - Vise For A Directional Drilling Machine

Uploaded by

Cường Nguyễn QuốcCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2011 Us20110137618a1 Geotechnical HorizontalDocument14 pages2011 Us20110137618a1 Geotechnical HorizontalCường Nguyễn QuốcNo ratings yet

- 2011 - Us7954558 - Devices and Methods For Power Control in Horizontal Directional DrillingDocument13 pages2011 - Us7954558 - Devices and Methods For Power Control in Horizontal Directional DrillingCường Nguyễn QuốcNo ratings yet

- 2012 - Us20120006597 - Drill HeadDocument7 pages2012 - Us20120006597 - Drill HeadCường Nguyễn QuốcNo ratings yet

- 2011 - US006276464B1 - Stake Coupler For A HDDDocument7 pages2011 - US006276464B1 - Stake Coupler For A HDDCường Nguyễn QuốcNo ratings yet

- 2011 - Us20110132665 - Electric Horizontal Directional Drilling Machine SystemDocument12 pages2011 - Us20110132665 - Electric Horizontal Directional Drilling Machine SystemCường Nguyễn QuốcNo ratings yet

- 2011 - Us7880336 - Electric Horizontal Directional Drilling Machine SystemDocument13 pages2011 - Us7880336 - Electric Horizontal Directional Drilling Machine SystemCường Nguyễn QuốcNo ratings yet

- 2005 - Us6910541 - Macro Assisted Control System and Method For A Horizontal Directional Drilling MachineDocument26 pages2005 - Us6910541 - Macro Assisted Control System and Method For A Horizontal Directional Drilling MachineCường Nguyễn QuốcNo ratings yet

- 2008 - US007461707B2 - Electric HDD Machine SystemDocument12 pages2008 - US007461707B2 - Electric HDD Machine SystemCường Nguyễn QuốcNo ratings yet

- 2013 - Us8365841b2 - Sectional Back Reamer Apparatus and Method For Horizontal Directional DrillingDocument11 pages2013 - Us8365841b2 - Sectional Back Reamer Apparatus and Method For Horizontal Directional DrillingCường Nguyễn QuốcNo ratings yet

- 2008 - Us7392858 - Remote Control For A Drilling MachineDocument17 pages2008 - Us7392858 - Remote Control For A Drilling MachineCường Nguyễn QuốcNo ratings yet

- 2005 - US006968735B2 - Long Range Data Transmitter For HDDDocument9 pages2005 - US006968735B2 - Long Range Data Transmitter For HDDCường Nguyễn QuốcNo ratings yet

- 2007 - Us20070294034a1 - Method For Designing and Optimizing Drilling and Completion Operations in Hydrocacrbon ReservoirsDocument38 pages2007 - Us20070294034a1 - Method For Designing and Optimizing Drilling and Completion Operations in Hydrocacrbon ReservoirsCường Nguyễn QuốcNo ratings yet

- 2006 - Us7066283 - Reverse Circulation Directional and Horizontal Drilling Using Concentric Coil TubingDocument19 pages2006 - Us7066283 - Reverse Circulation Directional and Horizontal Drilling Using Concentric Coil TubingCường Nguyễn QuốcNo ratings yet

- (Manual) StraightLine HDD 2462 Parts ManualDocument65 pages(Manual) StraightLine HDD 2462 Parts ManualCường Nguyễn QuốcNo ratings yet

- 2007 - Us20070021857 - Method For Selecting Bits and Drilling Tool AssembliesDocument39 pages2007 - Us20070021857 - Method For Selecting Bits and Drilling Tool AssembliesCường Nguyễn QuốcNo ratings yet

- 2007 - Us7251567 - Electronically Calibrated Beacon For A Horizontal Directional Drilling MachineDocument14 pages2007 - Us7251567 - Electronically Calibrated Beacon For A Horizontal Directional Drilling MachineCường Nguyễn QuốcNo ratings yet

- 2006 - Us7013991 - Obstacle Detection System For Underground OperationsDocument30 pages2006 - Us7013991 - Obstacle Detection System For Underground OperationsCường Nguyễn QuốcNo ratings yet

- 2004 - Us20040079553a1 - Reverse Circulation Directional and Horizontal Drilling Usin Concentric Drill StringDocument20 pages2004 - Us20040079553a1 - Reverse Circulation Directional and Horizontal Drilling Usin Concentric Drill StringCường Nguyễn QuốcNo ratings yet

- (Manual) StraightLine - HDD-2462-operators ManualDocument33 pages(Manual) StraightLine - HDD-2462-operators ManualCường Nguyễn QuốcNo ratings yet

- 2007 - Us7240744 - Rotary and Mud-Powered Percussive Drill Bit Assembly and MethodDocument15 pages2007 - Us7240744 - Rotary and Mud-Powered Percussive Drill Bit Assembly and MethodCường Nguyễn QuốcNo ratings yet

- 2005 - Us6979776 - Pipe Bundle For Underground InstallationDocument17 pages2005 - Us6979776 - Pipe Bundle For Underground InstallationCường Nguyễn QuốcNo ratings yet

- 2014 - Us20140353034 - Devices and Methods For Horizontal Directional Drilling With A Boring Tool LibraryDocument18 pages2014 - Us20140353034 - Devices and Methods For Horizontal Directional Drilling With A Boring Tool LibraryCường Nguyễn QuốcNo ratings yet

- 2014 - Us20140284111 - Horizontal Directional Drilling SystemDocument16 pages2014 - Us20140284111 - Horizontal Directional Drilling SystemCường Nguyễn QuốcNo ratings yet

- 2014 - Us8807241b2 - Devices and Method For Horizontal Directional Drilling With A Boring Tool LibraryDocument17 pages2014 - Us8807241b2 - Devices and Method For Horizontal Directional Drilling With A Boring Tool LibraryCường Nguyễn QuốcNo ratings yet

- 2016 - Us20160084016a1 - Horizontal Directional Drill Pipe Drive Connection With Locking FeatureDocument13 pages2016 - Us20160084016a1 - Horizontal Directional Drill Pipe Drive Connection With Locking FeatureCường Nguyễn QuốcNo ratings yet

- 2010 - US007810582B2 - Counterbalance Enabled Power Generator For HDDDocument20 pages2010 - US007810582B2 - Counterbalance Enabled Power Generator For HDDCường Nguyễn QuốcNo ratings yet

- Ring Spinning MachineDocument55 pagesRing Spinning MachineCường Nguyễn QuốcNo ratings yet

- 2009 - Us7500530 - Control SystemDocument9 pages2009 - Us7500530 - Control SystemCường Nguyễn QuốcNo ratings yet

- 2010 - US20100243326A1 - Common Interface Architecture For HDD MachineDocument17 pages2010 - US20100243326A1 - Common Interface Architecture For HDD MachineCường Nguyễn QuốcNo ratings yet

- 2010 - Us7721821 - Underground Boring Machine and Method For Controlling Underground BoringDocument13 pages2010 - Us7721821 - Underground Boring Machine and Method For Controlling Underground BoringCường Nguyễn QuốcNo ratings yet

2010 - Us2010011782a1 - Vise For A Directional Drilling Machine

2010 - Us2010011782a1 - Vise For A Directional Drilling Machine

Uploaded by

Cường Nguyễn Quốc0 ratings0% found this document useful (0 votes)

12 views11 pagesOriginal Title

2010_us2010011782a1_vise for a Directional Drilling Machine

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

12 views11 pages2010 - Us2010011782a1 - Vise For A Directional Drilling Machine

2010 - Us2010011782a1 - Vise For A Directional Drilling Machine

Uploaded by

Cường Nguyễn QuốcCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 11

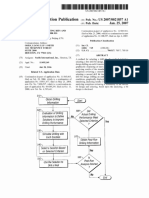

tion — 0) Pub. No.: US 2010/0117282 A1

US 20104

1001172821

«) United States

«2 Patent Application Publi

Rozendaal (43) Pub, Date: May 13, 2010

(54) VISE FOR A DIRECTIONAL DRILLING Related US. Applicaton Data

ee) (60) Provisional application No. 60/885,823, filed on Jan.

(7) Inventor Peter C, Rozendaal, Pella, IA (US) a

Publication Classifiat

Conespondence Adress (1) Ingen

MERCHANT & GOULD PC BIS 0 (2006.01)

20. BOX 2903 B2sB 124 (2006.01)

MINNEAPOLIS, MN 55402-0903 (US) @ wa aeoaui.g00257

(73) Assignee: ‘Vermeer Manufacturing on BES TRACE

‘Company, Pella, [A (US) A vise apparatus includes a vise die assembly that is pivotally

‘mounted to tng heads ofa vise mechanism. The vise die

(21) Appl 11s23.815, seb include platy of vise dean amounting block

iaving 2 ist fee and an oppositely disposed second fee.

(22) PCT Filed: San. 1, 2008 Fachof he pluraliy of vie die iacludes piping srice.

fis vise def the plu of vse dies mounted othe fist

(85) PCTNo PCTUsoRsi279 fae ofthe mounting block wiles second vse die ismonated

tothe eeond fice The fit and second vise dear mounted

S371 (0, Such thatthe prpping srfice of fit vse de fces opposite

(,(@)Dale: San. 15,2010 the gripping src ofthe second vse de

300

Patent Application Publication May 13, 2010 Sheet 1 of 5 US 2010/0117282 A1

FIG. 2

100 a fo

300

84 20

80, | a mo

22

O O} sdo ae

90

50

wonvoyqng uopeayddy juaped

$307 oN TOT ‘ET AEH

TV Z87L110/0107 SA.

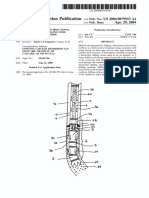

Patent Application Publication May 13, 2010 Sheet 3 of 5 US 2010/0117282 A1

FIG. 3

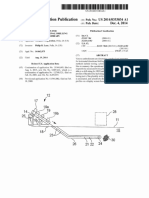

Patent Application Publication May 13, 2010 Sheet 4 of 5 US 2010/0117282 A1

FIG. 4

US 2010/0117282 A1

May 13, 2010 Sheet 5 of 5

Patent Application Publication

US 2010/0117282 AI

VISE FOR A DIRECTIONAL DRILLING

MACHIN

[0001] This applications being fled on 17 Jan. 2008, 8 2

PCT International Patent application inthe name of Vermeer

Manufacturing Company, U.S. national corporation, app

cant forthe designation of all countries except the US, and

Poter C. Rozendaal, a citizen of the US. applicant forthe

designation ofthe US only, and claims priority 1 US. Pro-

visional Patent Application Ser, No. O/885,825, ile Jan. 19,

2007. Such provisional application is incorporate herein by

reference

FIELD OF TECHNOLOGY

0002] Thepresentinventioa relates generally to horizontal

‘underground drilling machines, More particularly, the

present invention relates to a vise apparatus used. with

threaded dil pipe

BACKGROUND OF THE INVENTION

[0003] A verity of vise arrangements for use with borizon-

tal drilling machines exist, including vise jaws having two

‘opposing jaw halves. The jaws are arranged to clamp onto a

pipet citer thread or unread the pipe to another pipe. The

vise jaws are clamped tothe pipe by hydranlic actuators or

cylinders that provide engagement or clamping force.

[0004] In conventional jaw designs, the maximum torque

applied to the gripped pipe, without relative movement

between the pipe andthe jaws, is directly proportional othe

force applied by hydraulic cylinders. The tonue effected on

the pipe provides torque holding capacity ata threaded con-

rection between the to pipes. Larger pipes require greater

torque to effet sufficient torque holding capacity. The dll

pipe used in conjunction withthe coaventonal jaw design is

limited, typically ranging from 15 to 39 inches in outer

ameter.

10005] Deiling machines wilizing much larger dil pipe

‘ad dil tools are becoming available fr use in the industry.

Forexample, some dill pipecan range uptoabout 8 inches in

‘outer diameter. A design that provides greater engagement

force ta effet suficient torque holding capacity ata threaded

connection between anger pipes is needed.

[0006] Conventional designs incorporating latch door

arrangement for use on vertical drilling machines have been

‘used to provide sufficient engagemeat force oa lager dam-

ctr pipes, These designs, however, are particular to vertical

illng rigs wherein there is ample space inthe vicinity ofthe

latch dor vise arrangement. vise apparatus that accomaio-

dates large pipe is needed for use on a horizontal dling

‘machine where space between the ground and a ground sup

ports limited

SUMMARY OF THE INVENTION

10007] The disclosure describes a vise apparatus foruse on

‘horizontal drilling machine, The vise apparatus includes 3

vise die assembly that is pivotally mounted o tong heads of

vise mechanism, The vise die assembly includes a mounting

‘lock bavinga front fee anda second fae that are oppositely

May 13, 2010

isposed onthe mounting block. A vise die having gripping

surface is mounted to eachof theirs face athe second face

ofthe vise die assembly.

BRIEF DESCRIPTION OF THE DRAWINGS

{0008} The accompanying drains are inci © pro

vila fuer andrstendng ofthe preset invention an are

incorporated in and conte part of is specification The

deswngsiastate exemplary embodiments ofthe present

invention nd ogter with the description serve further

pls te principles ofthe invention, wher:

[009] FIG. 1s ont perspective view ofarackasembly

foreon a orion dnscona dling machine in seor-

dance wih he prinspls ofthis disclose;

[W010] FIG.2isaside view ofthereck assembly of FIG. ts

[W011] FIG. 3isefiontviewofavise assembly as shownin

G1

[WIZ] FIG. 4 isa rom penpetve view of vse die

sssenby and

[W913] FIG. send fragmentary front view ofthe

vise assembly of FIG. 3.

DETAILED DESCRIPTION OF THE PREFERRED

EMBODIMENT

[0014] With reference now to the various figures in which

identical elements are numbered identically thoughout, a

description vazious exemplary aspect othe present inven

‘ion will now be provides.

1. General Operation of the Vise Apparatus in Horizontal

Drilling

[0015] Thepresent invention is directed to a vise apparatus

for use on horizontal deiling machines, Horizontal dling

‘machines typically compse a rotational drive mechanism, 3

Tongitudinal drive mechanism, a vise apparatus, a ground

support, anda dill pipe storagetransfer apparatus. The dill.

ing process involves threading together leagths of threaded

rill pipe to form a drill sting extending from the dling

‘machine though a bored hole and terminating ata dil bit

assembly. The dil sting transfers rotational torque and lon-

stitudinal thrust from the drive mechanisms to the dil bit

assembly

0016} "To begin drilling a bore, the dil bit assembly is

located near the ground support of the horizontal dling

‘machine und is attached to 2 dill string. The deill sting

initially comprises « fist drill pipe that is attached w the

rotational drive mechanism and longitudinal deive mecha-

nism. The rotational dive mechanism and longitudinal dive

‘mechanism are typically located at an end apposite the bore

Jocation, The frst step of oring is thus oath the dil it

assembly othe fist dil pipe

{0017 "The dri bitassembly i generally larger in diameter

‘than the dil pipe. Conventional designs require hat the dll.

jt assembly be connected to the first drill pipe by manwal

‘wrenching. It would be beneficial to connect the dell bit

assembly tothe fist dil pipe by inserting the dill bit assem

bly into a vse apparatus to aid in the preparations of dling

the bore The vise apparatus according othe principles ofthis

selosure provide such uly inan open dimension oradapt-

able configuration that permits drill bit assemblies to be

inserted and clamped into the vise apparatus, as will be

deserbed later in detail

US 2010/0117282 AI

[0018] Once the dil bit assembly is connects to the fist

Gil pipe, the dil string (he cil it assembiy and the ist

il pipe) are rated and propelled into the ground. As the

ill string progresses, second dil pipes removed from he

siorageltansfer apparatus and positioned in alignment with

te dil string. Typically the storag'tanfer apparatus com-

prises a magazine wherein the longitudinal axis ofthe stored

Ail pipe is parallel to te dil string. Once positioned, the

second dil pie is thread to the dail string. The process

repeated to exten the length ofthe bored hol.

[0019] ‘The del stings subjects to high torque loads, In

Airectonally controlled applications, the dill tring is aso

subjected to significant bending leads. Proper mating of

tireaded joins between the drill pipes is eritial to the per-

formance of the drill string. To properly “make-up” the

threaded joints, significant torque loads mst be applied tothe

cuter diameters ofthe dil pipes.

[0020] When te bored hole sas long as desire, te dil

bitassembiy soften change or, fora variety of reasons, the

il sting is remove from the bored hoe. Inthe ater ease,

forexample the fixed length of il pipes are subsequenty

palledoutofthe bored hole, unthreaded, nd transferred back

to storage Removal ofthedl tring imolves“break-ont”of

te threaded connections or joints. The break-out tongue nec=

essary to break the threaded connections enerallysinilaror

arcater than the tongue required (0 initially make-up the

threaded joint

[0021] Vise configurations of conventional designs involve

‘lower clamp, an upper clamp, anda driver. The driver is 3

part ofthe driling machine that i longitudinally propelled,

‘ypically along track, and has a mule threaded end, opin

end, In make-up operations, the driver advances the drill

siringalonga longitinal axis until the driver reaches anend

ofthe tack. At that point, the ower clamp secures the dill

siring na stationary positon, The diverrotationally reverses

to unthrad from a box end (or female threaded area) of the

il string while reversing longitudinally along the rack. A

‘new dll pipes positioned wthina losing area citer manu

ally or witha ro loader mechanism. The driver changes

‘eiational direction and bexins to. apsin longitudinally

advan along the track owardthe new dil pipe. Thepinend

ofthe driver engages a box end (i.e. female threaded-end) of

the new drill pipe. Aste der continues to advance loaai-

‘oinaly a pin endo the new dil pipe engages the box end

ofthe clamped dil sting and repeats the process

[0022] Asawidervaretyftoolsusedin borizonta dailing

bocome aalable, the need to adapt the vise apparatus to

accommodate the various shapes and sizes of tools becomes

‘more important. For instance, some applications inser a rela

tively shor pipe section having te sme diameter as the fina

bored hole int section of the bored holo stabilize the sol

This pipe sections commonly known as a slip fining.

‘Because theslip ning hasa diameter lager than the diameter

ofthe il string th slip ining is typically difficult orimpos-

sibleto fit within the vise appara of eonventional designs

[0023] Another consideration with regards horizontal rill

{ng concems the overall arangement ofthe dilling machine

and vise apparatus in relation to ground. Placement of the

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2011 Us20110137618a1 Geotechnical HorizontalDocument14 pages2011 Us20110137618a1 Geotechnical HorizontalCường Nguyễn QuốcNo ratings yet

- 2011 - Us7954558 - Devices and Methods For Power Control in Horizontal Directional DrillingDocument13 pages2011 - Us7954558 - Devices and Methods For Power Control in Horizontal Directional DrillingCường Nguyễn QuốcNo ratings yet

- 2012 - Us20120006597 - Drill HeadDocument7 pages2012 - Us20120006597 - Drill HeadCường Nguyễn QuốcNo ratings yet

- 2011 - US006276464B1 - Stake Coupler For A HDDDocument7 pages2011 - US006276464B1 - Stake Coupler For A HDDCường Nguyễn QuốcNo ratings yet

- 2011 - Us20110132665 - Electric Horizontal Directional Drilling Machine SystemDocument12 pages2011 - Us20110132665 - Electric Horizontal Directional Drilling Machine SystemCường Nguyễn QuốcNo ratings yet

- 2011 - Us7880336 - Electric Horizontal Directional Drilling Machine SystemDocument13 pages2011 - Us7880336 - Electric Horizontal Directional Drilling Machine SystemCường Nguyễn QuốcNo ratings yet

- 2005 - Us6910541 - Macro Assisted Control System and Method For A Horizontal Directional Drilling MachineDocument26 pages2005 - Us6910541 - Macro Assisted Control System and Method For A Horizontal Directional Drilling MachineCường Nguyễn QuốcNo ratings yet

- 2008 - US007461707B2 - Electric HDD Machine SystemDocument12 pages2008 - US007461707B2 - Electric HDD Machine SystemCường Nguyễn QuốcNo ratings yet

- 2013 - Us8365841b2 - Sectional Back Reamer Apparatus and Method For Horizontal Directional DrillingDocument11 pages2013 - Us8365841b2 - Sectional Back Reamer Apparatus and Method For Horizontal Directional DrillingCường Nguyễn QuốcNo ratings yet

- 2008 - Us7392858 - Remote Control For A Drilling MachineDocument17 pages2008 - Us7392858 - Remote Control For A Drilling MachineCường Nguyễn QuốcNo ratings yet

- 2005 - US006968735B2 - Long Range Data Transmitter For HDDDocument9 pages2005 - US006968735B2 - Long Range Data Transmitter For HDDCường Nguyễn QuốcNo ratings yet

- 2007 - Us20070294034a1 - Method For Designing and Optimizing Drilling and Completion Operations in Hydrocacrbon ReservoirsDocument38 pages2007 - Us20070294034a1 - Method For Designing and Optimizing Drilling and Completion Operations in Hydrocacrbon ReservoirsCường Nguyễn QuốcNo ratings yet

- 2006 - Us7066283 - Reverse Circulation Directional and Horizontal Drilling Using Concentric Coil TubingDocument19 pages2006 - Us7066283 - Reverse Circulation Directional and Horizontal Drilling Using Concentric Coil TubingCường Nguyễn QuốcNo ratings yet

- (Manual) StraightLine HDD 2462 Parts ManualDocument65 pages(Manual) StraightLine HDD 2462 Parts ManualCường Nguyễn QuốcNo ratings yet

- 2007 - Us20070021857 - Method For Selecting Bits and Drilling Tool AssembliesDocument39 pages2007 - Us20070021857 - Method For Selecting Bits and Drilling Tool AssembliesCường Nguyễn QuốcNo ratings yet

- 2007 - Us7251567 - Electronically Calibrated Beacon For A Horizontal Directional Drilling MachineDocument14 pages2007 - Us7251567 - Electronically Calibrated Beacon For A Horizontal Directional Drilling MachineCường Nguyễn QuốcNo ratings yet

- 2006 - Us7013991 - Obstacle Detection System For Underground OperationsDocument30 pages2006 - Us7013991 - Obstacle Detection System For Underground OperationsCường Nguyễn QuốcNo ratings yet

- 2004 - Us20040079553a1 - Reverse Circulation Directional and Horizontal Drilling Usin Concentric Drill StringDocument20 pages2004 - Us20040079553a1 - Reverse Circulation Directional and Horizontal Drilling Usin Concentric Drill StringCường Nguyễn QuốcNo ratings yet

- (Manual) StraightLine - HDD-2462-operators ManualDocument33 pages(Manual) StraightLine - HDD-2462-operators ManualCường Nguyễn QuốcNo ratings yet

- 2007 - Us7240744 - Rotary and Mud-Powered Percussive Drill Bit Assembly and MethodDocument15 pages2007 - Us7240744 - Rotary and Mud-Powered Percussive Drill Bit Assembly and MethodCường Nguyễn QuốcNo ratings yet

- 2005 - Us6979776 - Pipe Bundle For Underground InstallationDocument17 pages2005 - Us6979776 - Pipe Bundle For Underground InstallationCường Nguyễn QuốcNo ratings yet

- 2014 - Us20140353034 - Devices and Methods For Horizontal Directional Drilling With A Boring Tool LibraryDocument18 pages2014 - Us20140353034 - Devices and Methods For Horizontal Directional Drilling With A Boring Tool LibraryCường Nguyễn QuốcNo ratings yet

- 2014 - Us20140284111 - Horizontal Directional Drilling SystemDocument16 pages2014 - Us20140284111 - Horizontal Directional Drilling SystemCường Nguyễn QuốcNo ratings yet

- 2014 - Us8807241b2 - Devices and Method For Horizontal Directional Drilling With A Boring Tool LibraryDocument17 pages2014 - Us8807241b2 - Devices and Method For Horizontal Directional Drilling With A Boring Tool LibraryCường Nguyễn QuốcNo ratings yet

- 2016 - Us20160084016a1 - Horizontal Directional Drill Pipe Drive Connection With Locking FeatureDocument13 pages2016 - Us20160084016a1 - Horizontal Directional Drill Pipe Drive Connection With Locking FeatureCường Nguyễn QuốcNo ratings yet

- 2010 - US007810582B2 - Counterbalance Enabled Power Generator For HDDDocument20 pages2010 - US007810582B2 - Counterbalance Enabled Power Generator For HDDCường Nguyễn QuốcNo ratings yet

- Ring Spinning MachineDocument55 pagesRing Spinning MachineCường Nguyễn QuốcNo ratings yet

- 2009 - Us7500530 - Control SystemDocument9 pages2009 - Us7500530 - Control SystemCường Nguyễn QuốcNo ratings yet

- 2010 - US20100243326A1 - Common Interface Architecture For HDD MachineDocument17 pages2010 - US20100243326A1 - Common Interface Architecture For HDD MachineCường Nguyễn QuốcNo ratings yet

- 2010 - Us7721821 - Underground Boring Machine and Method For Controlling Underground BoringDocument13 pages2010 - Us7721821 - Underground Boring Machine and Method For Controlling Underground BoringCường Nguyễn QuốcNo ratings yet