Professional Documents

Culture Documents

2016 - Us20160084016a1 - Horizontal Directional Drill Pipe Drive Connection With Locking Feature

2016 - Us20160084016a1 - Horizontal Directional Drill Pipe Drive Connection With Locking Feature

Uploaded by

Cường Nguyễn Quốc0 ratings0% found this document useful (0 votes)

9 views13 pagesOriginal Title

2016_US20160084016A1_HORIZONTAL DIRECTIONAL DRILL PIPE DRIVE CONNECTION WITH LOCKING FEATURE

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

9 views13 pages2016 - Us20160084016a1 - Horizontal Directional Drill Pipe Drive Connection With Locking Feature

2016 - Us20160084016a1 - Horizontal Directional Drill Pipe Drive Connection With Locking Feature

Uploaded by

Cường Nguyễn QuốcCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 13

AONE 0

‘US 2016008401681

cu») United States

cz) Patent Application Publication co) Pub. No.: US 2016/0084016 A1

Slaughter, JR. et al. (43) Pub. Dat Mar. 24, 2016

(54) HORIZONTAL DIRECTIONAL D ublication Clasifiation

DRIVE CONNECTION WITH LOCKING

FEATURE (50) In

E2IB 17046 (2006.01)

(71). Applicont: The Charles Machine Works, Ine. F168 X00 (2006.01)

Perry. OK (US) 2B 17082 (2006.01)

(2) US.CL

(72) Inventors: Greg L. Staughter, JR. Per, OK (US); che E218 17/046 201301), £200 177042

Floyd R. Gunsauls, Pore. OK (US) (2013.01), F768 400 (201301)

Max A. Metcalf, Stillwater, OK (US)

oN ABSTRACT

(21) Appl. Nos 149960,639 The present invention is directed to a spindle assembly for

connecting a drill string to a rotational drive for vse in a

Filed: Dee. 7.2018 horizontal directional drilling operation. The assembly com-

prises saver sub attached tothe rotational drive, and a drive

Related US. Application Data chuck for connection wo the dil siting. The drive ebuck and

Saver sub form a torguc-transmitting connection by engaging

‘hrougha seatin the saversuband an. engagement point onthe

drive chuck. Dowel pins may he used to eotationaly lock and

(60) Provisional application No. 61/823,015, filed on May provide the engagement hesween the saver suh and the drive

14, 2013, provisional application No. 61/683,968, chick. A collar may thread to the saver sub and emuse an

fled on Aug. 16, 2012, interference fit by engaging the dive chuek at a shoulder.

(63) Continuation of application No, 13/965,961, filed on

Aug. 13, 2013, sow Pat. No. 9.206851

Patent Application Publication Mar. 24, 2016 Sheet 1 of 8 US 2016/0084016 AI

15

16

FIG. |

7

Patent Application Publication Mar. 24, 2016 Sheet 2 of 8 US 2016/0084016 AI

FIG. 2

Patent Application Publication

Mar. 24, 2016 Sheet 3 of 8

72

20

34 -

44 / i:

TE

64

\ Le

30

46

70

32

al

US 2016/0084016 AI

FIG. 3

Patent Application Publication Mar. 24, 2016 Sheet 4 of 8

t

So

iL

US 2016/0084016 AI

Patent Application Publication Mar. 24, 2016 Sheet 5 of 8 US 2016/0084016 AI

A

48 o

: 7 Y L

92

2i

FIG. 5

Patent Application Publication Mar. 24, 2016 Sheet 6 of 8 US 2016/0084016 AI

FIG. 6

Patent Application Publication Mar. 24, 2016 Sheet 7 of 8 ‘US 2016/0084016 AL

18

40

102

100

26

30

Le

ea

FIG. 7

22

20

m\

Patent Application Publication Mar. 24, 2016 Sheet 8 of 8 US 2016/0084016 AI

FIG. 8

US 2016/0084016 AI

HORIZONTAL DIRECTIONAL DRILL PIPE,

DRIVE CONNECTION WITH LOCKING.

FEATURE

‘CROSS REFERENCE TO RELATED

"APPLICATION

[0001] This application is a continuation of U.S. patent

application Ser. No. 13/965,961, fled Aug. 13, 2013, now

US. Pat, No, 9,206 851, which claims the henefit of provi-

sional patent application Ser No, 61/823,015, filed May’ 14,

2013, and provisional patent application Ser No, 61/683,968,

Sled Aug. 16, 2012, the enire contents of which are incorpo”

rated herein by reference.

FIELD

10002] The present invention relates generally to eonnee-

tion mechanisms for tansferring torque to adil string in

horizontal directional dling processes

BACKGROUND

[0003] Horizontal boring machines are used to install i=

fay services oroher products underground. Horizontal dree-

tional drilling eliminates surface disruption along the length

‘ofthe project, except atthe entry and exit points, and rauces,

the likelihood of damaging previously buried products,

10004] The boring operation isa process of using a boring

‘machine to advance adel string through the ear along &

desired path, The boring machine generally comprises a

Jame, drive system mounted on the frame andl connected 10

‘one end ofthe dil string, and a boring tool connect the

‘other end ofthe drill string. The drive system provides thrust,

‘and rotation needed to advance the dil sting andthe boring

tool through the earth, The drill string is generally comprised

‘ofa plurality of dil pipe sections joined together at threaded.

‘connections. As the pilot bore operation proceeds, the dill,

‘rings lengthened by repeatedly adding pipe setions wo the

dil string

[0005] _ When he pilot bore operations completed, the dil

‘tring ispulled back through the borehole during a backream-

ing operation, generally with the uy line or prodiet to be

installed underground connected to the end ofthe drill tring.

uring this backreaming operation, pipe sections are

removed from the drill string asthe dil string gts shorter.

ach imea pipe section istaken from the drill string Asis the

‘case with the alton of pipe sections tothe dri string, the

process is repetity

[0006] A “Uriver" or “saver sub is used asaconnection to

transmit the tongue and thnistpallback forees generated by

the relational drive of an FIDD machine toa dil string. The

‘connection comes in contact with every pipe involved with 3

boring operation during both boring and pull-back and thus

‘encounters high rates of wear on the connection surfaces of

the component, Assueh, itis beneficial to make the part easily

replaceable. Further, iis beneficial to limit the wear points oF

the saver sub such that itis easy to replace, without requiring

‘excessive abort rebuild the saver sub

SUMMARY,

10007] The present invention comprises torgue-transmit-

ting assembly for use with a rotational drive used in a hori-

‘ontal directional drilling operation. The assembly comprises

8 siver sub and drive chick. The saver sub s rotationally

‘attached tothe rotational drive and comprises seat and 8

Mar. 24, 2016

‘threaded portion, The drive chuck comprises an engagemes

point to engage the sat and a connection member for atc

‘meat tothe cell string, The deve chuek and saver sub are

ationally locked.

[0008] In another embodiment of the invention, it is

directed 10 4 torque-transmitting assembly for use with a

‘ational drive used ina horizontal directional drilling per-

tion, Theassembly comprises saver sub, acive chuek, and

‘colar. The saver suis rotationally attached to the rotational

rive. The saver sub comprises seat and a threaded portion.

The drive chuck comprises a shoulder, an engagement pot

to engage the sea, and a connection member for attachment

to the dill string. The collar comprises threaded porioa and

an nteral shoulder. The interal shoulder contacts the shoul-

‘er of the drive chuck such that threading the collar onto the

saver sub roationally leks the saver sub to the drive chuck

[0009] In another embodiment, the invention is directed to

4 spindle assembly for rotating a drill sting. The spindle

assembly comprises a saver sub, a drive chuck, and a colar

The drivechuek is engazed with the saver sub in non-threaded

‘orque-ransmitting engagement. Te collar is disposed abe

both an outer surface of the saver sub and aa outer surface of

the drive chuck to secure the saver sub tothe drive chuck. The

colle is tread on the saver sub

BRIEE DESCRIPTION OF THE DRAWINGS.

[0010] FIG. 1is aside view of an HDD machine and drill

string for use with the spindle assembly of the invention

disclosed herein.

[0011] FIG. 2 is an exploded perspective view of compo-

‘ent parts ofa spindle assembly

[0012] FIG. 3 is a sectional side view of the assembled

spindle assembly of FIG. 2

[0013] FIG. 4a sectional exploded perspective view of a

cola drive chuck, anda wreach for use withthe spine

assembly of FIG. 2

[0014] FIG. Sis an exploded perspective view of an alter-

ative embodiment of a spindle assembly.

[0015] FIG. 6 is a perspective view of the assembled

spindle assembly of FIG. 5.

[0016] FIG. 7 is a soctiona side view of an altemative

‘embodiment of a spindle assembly.

[0017] FIG. 8 isan exploded perspective view of an alter-

‘ative embodiment of a spindle assembly.

DESCRIPTION OF THE PREFERRED

EMBODIMENT

[0018] ‘Thedisclosed inventionisdectedto atonque-trans-

:niting spindle assembly 10 for use in horizontal diretional

Grilling operations for boring under a surface of the ground

11. With reference to FIG. 1, the spindle assembly 10 con-

‘ects rotational deve 12 ofa horizontal directional dilling

(HDD) apparatus 14 to a dail ssing 16, The dell sting 16

comprises a plurality of segments which meet at pipe joints

18, The spindle assembly 10, when fully assembled

scribed in’ more detail below, is replaceable when the

repeated making up and breaking out sections of dell pipe

‘uses wear, Rotation of the rotational drive 12 eauses the

spindle assembly 10 to rotate, which transits torgue to the

Grill string 16 when the HDD apparatus 14 isin operation

This torque can make up or break loose the dill string 16

US 2016/0084016 AI

‘during sition oF removal of individual pipe sections, oF

‘eansiit thrust and rotation through the drill string to down-

hole tool 17,

10019] With reference to FIG. 2, the spindle assembly 10

‘comprises a saver sub 18, a dive chuck 20, a plurality of

‘dvsel pins 1, and 2 collar 22, The saver sub 18 comprises 9

fist end 24 and a second end 26. The frst end 24 is fixedly

attaehed to the rotational drive 12 (FIG. 1). The connection

may take place through a ange, a sliding spline connection,

‘4 Welded connection, frictional interference fit, or other

suitable methods of joining the tational drive 12 (othe saver

sub 18, As shown ia FIG. 2, the saver sub 18 comprises @

spline connection. The second end 26 comprises an opening

28,2 threaded portion 30 anda seat 32. The opening 28 may

be formes such that the ceive chuck 20 comes in contact with

the inner wall ofthe saver sub 18, oF may be clearance fit sch

thatthe saver sub and drive ehuek do not contact one anether

‘within the opening. As shown, the set 32 comprises a plus

rality of eastellaions 34 formed in the second end 26. The

‘astellations 34 are configured to engage a torque-camrying

Teature to transmit toque from the HDD apparatus 14 (FIG.

1) to the dil string 16 (FIG. 1), As shown herein, the castcl-

Jations 34 engage the plurality of dowel pins 21. As shown,

there are six dowel pins 2, though other numbers are pos”

sible. The eastellations 34 may be formed with a tapered

‘opening to ensure that the dowel pins 21 can slipeasiy inand,

‘out of position when the spindle assembly 10 is not

assembled. As shown, the spindle assembly 10 comprises six

‘castellations 34 and dowel pins 21

10020] The drive chuck 20 comprises a first end 40, 9 sec-

‘ond end 42, an engagement point 44 «plurality of depres-

sions 46, and a shoulder 48. The first end 40 extends within

the opening 28 of the saver sub 18. The first end 40) may

‘operate to transmit thrust between the saver sub 18 and drive

chuck 20, or may alternatively only seal the connection

between the saver sub and drive ehuek. The second end 42 is

4 connection member for thrust and rotation-transmitting

‘connection toa dill sting (FIG. 1). This connestion atthe

second end 42 may be a threaded connection. The threaded

‘connection of the second end 42 may be on the inside oF

‘outside of the drive ehuck 20, The engagement point 44 is

‘adapted t0 engage the seat 32 of the saver sub 18 for tans>

mission of rotation forces between the saver sub andthe drive

‘chuck 20, The engagement between the seat 32 and engage

‘ment point 44 also may transmit thnist between the dive

‘chuck 20 and saver sub 18,

{0021} The plurality of depressions 46 provide a foeation

Torte dowel pins 21 to be placed. Thedepressions 46 may be

formed with a tapered opening to allow the dowel pins 21 t0

‘easily slip into and out ofthe depressions. Altematively, the

‘depressions 46 may ave parallel walls o provide a press-fit

‘connection when the spindle assembly 10 is assembled. The

‘engagement point 44 may be machined such thatthe engage

‘ment point only engayes the seat 32 through the dowel pins

21-Inthis embodiment, no direct connection between the seat

32 and engagement point 4 takes place, and all the trque-

transmission and thrist-irnsmission occurs between the seat

andthe dowel pins 21 and the dowel pins and the engagement

Point. The depressions 46 may be evenly spaced or may be

Uunevenly spaced o allow for “clocking” orientation herieen

the saver sub 18 and the drive chuck 20, The shoulder 48

‘comprises a section ofthe drive chuck 20 where the diameter

Mar. 24, 2016

ofthe deve ehuek changes. Preferably the shoulder 8 con

Pisce aslopedsurlae for interaction wth internal eae of

the collar 1.

{0022] "The collar 22 comprises fist end 60 ala second

aid 62 The ist ed interact withthe thread portion 10

the sver sub 186 hold the elements othe spindle assembly

10 together. One shilled i the set will appreciate tht the

spindle assembly could transmit tongue without theuse of the

collar 22

(0023) With reference now to FIG. 3 the spindle assembly

10s showa formed together in eosssction. As shown, the

dowel pins 21 are located within the depressions 46 ofthe

dive chuck 20nd the castllatons M4 ofthe saver sub 18

The depressions 46 have tapered bottom to allow easy

removal when te spindle assembly 10 is disassembled. The

coll 22 or comprises an intemal shoulder 64 and 9

{hrcaded portion 66 fermen it interal Wal. The head

portion 66 is located at the fist end 60 ofthe collar 22 and

acts withthe threaded portion 30 ofthe saver sub 18 0

attach the collar to the saver sub. When fully foeme the

Jnteral shoulder 64 coatsets the shoulder 48 ofthe deve

chuck 20. Ths connection forees the engagement point 44

toward the seat 32.

{0024} One sill inthe at will appreciate hat an aneleof

contact between the intemal shoulder 6¢ and shoulder 48 ay

besetat acute angles, or angles below 48 degrees. This canes

a rail component in the preload three bet ees he collar 22

fn the deve chuck 200s the threaded setion 66 ofthe cllar

is tighteaod onto the threaded portion 30 of the saver su

‘Thus, during the assembly ofthe spindle assembly 10, some

ofthe rotational enemy used frees the diameter of the eallar

22 0 expand and the diameter of the ceive eck 201 con-

trae. This reduces relative movement between the saver sb

18 and drive chuck 20 and thus decreases wear on intemal

comportets othe spindle assembly 1

(0025) When fully formed, te spindle assembly 10 may

oamprise a internal chansel 70 located within the ceater of

the saver sub 8 and drive chuck 20. The intemal channel 70

allows ito be transite rom the HDD anachine 1G. 1)

{© the dill suing (FIG. 1), seal 72 is located about a

Perper ofthe drive eck 20 to prevent Mid rom escaping

the connection of the deve chuck and saver sub 18. Aer

‘ately, he seal ould be placed within the opening 28 the

Savers or mating wit the fist end 4 ofthe deve chuck

20-As shown, th sal 72 ian o-ring. Other elastomeric or

face seal mechanisms may be used to provide a Teak free

conncetin between the dive eck 20 ahd the saver sub 18

[0026] Withreteence now 1oF1G. 4 the collar 2 and dive

inc 20 are shown in croserctin with erench $0, The

‘wrench comprises handle 8 and locking feature 84. The

bande 82 allows an operstor to apply forge and tum the

‘wench 80. The locking feature is adap o mate withthe

‘cond ad 62th coll 22. The second end 62nd locking

eature 4 havea complementary polygonal profile. Ths, the

wrench 80 may bese Led nd tre the collar 20

to saver sub 18 FIG. 3), The operator may either rotate the

swrench 0, othe collar 22 my be eld place by the wrench

bravisewhiletherotational drive 12(F1G. 1) rotates the ver

sb 1

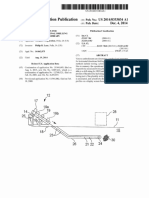

[0027] With reference to FIG. §, the colle 22 may alten

tively heattached tothe saver sob 18 tsi a plurality ofbots

90 though a Dange 92 inthe collar The plurality of bolts

apply a clamping load to the drive chuck 20 throwgh is

shoulder 48, The saver sub 18 comprises plurality of bolt

US 2016/0084016 AI

holes 94 adapted to receive the bolts 90, This embediaent

transfers torque between the saver sub 18 and drive chuck 20

«through dove pins 21 as deseribed with reference FIGS.2

‘and 3

10028] When fully connected to the rotational drive 12 of

the HDD machine 14, this embodiment of the spindle assem-

bly 10 appears as shown in FIG. 6, The spindle assembly 10

is attached tothe rotational drive 12 (FIG. Lat the sub saver

418 trough ange connection. The collar 22 is connected 10

the sub saver 18 through bolts 90. The drive chuck 20 is

‘engagestby the collar 2 at tsshoulder FIG. S)andis adapted

or connection toa dil string (not shown) st its sccond end

2.

10029] _Altemative embodiments ofthe spindle assembly

10 without the use of dowel pins are disclosed herein, Wi

reference 10 FIG. 7, the first end 40 of the drive chuck 20

‘comprises an external threaded portion 100. The second end

26 ofthe saver sub 18 comprises an internal threaded portion

4102 within the opening 28. The pitch of the intenal threaded

portion 102 may be slightly different than the pitch of the

threaded portion 30 of the saver sub 18, Alternatively, the

‘etna threaded portion may allow fora “right-hand” nea

While the dareaded portion 30 isa “left-hand” thread, o vice

versa As such, the forees generated on the intemal threaded

portion during make up and break out ofthe collar 22 on the

Ever sub 18 would no snthread the drive chuck 20

[0030] With reference to FIG. 8, another altemative

‘embovliment of the spindle assembly 10 is shown, Tn this

‘embodiment, the seat 32 of the saver sub 18 comprises as

tellaions 44. Those castelations 34 are adapted to dioetly

‘engage complementary castelatons 110 of the engagement

Point 44 ofthe drive chuck 20. Toryue transmission occurs

directly on the complementary eastellations 34, 119. The

‘eastllstions 34, 110 may be machined or casted. As shown,

the shoulder 48 ofthe drive chuck 20 is perpendicular, rather

than the angled surface of FIG. 3, but it will be appreciated

that these may altematively be angled as discussed above.

0031] In operation, the spindle assembly 10 js assembled

Joruse with HDD machine 14, The saver sub 18 is ixed tothe

rotational drive 12 ofthe HDD machine. The dowel rods 21

are placed within the depressions 46 of te drive chuck 20,

‘The drive chuck 20 s then placed int the saver sub 18 such

that the seat 32 is proximate the engagement point 44. As

shown in FIG. 2, the saver sub 18 engages the drive chuck 20

Jn tonue-transmitting arrangement through the dowel rods

21, Thecollar22isthen placed around perimeterof thedrive

‘chuck 20 and secured wo the saver sub 18 such thatthespindle

assembly is rationally locked. The cola 22 may be tight-

‘nex by sing weench 80, lteratively, the collar 22 may be

‘clamped by vice wrenches (901 shown) of the HDD machine

14, then tightened by rotating the rotational deve 12 of the

HDD machine 14 to tightea the eollar oa the sver sub 18.

Sections of drill sring 16 may then be threaded onto the drive

‘chuck 20. the spindle assembly is used o male upor break

‘out sections of dil string. and to transmit torque to a doven-

hole tool 17 for use in HDD operations,

10032} | While the dowel rods 21 have boon disclosed herein

2 seated in depressions 46 of the drive chuck 20 for interae=

tion withcastellationson the saver sub 1, itisanticipatod that

this may be reversed. The depressions may altematively be

placed onthe saver sub 18 forinteration withcastellaionson

the drive chuck 20. In this alternative arrangement, the com-

ponents wold sill be constrained by the tightening of the

collar 22

Mar. 24, 2016

[0033] One skilled ia the at will appreciate that the

‘embodiments herein are not limiting on the scope of this

invention. Altemative mechanisms for locking the spindle

assembly 10 together suc that tongue is transmitted between

the rotational deve 12 and del sting 16 aro possible with

slight variation. For example, the dowel mods 21 may be

‘ntgrally formed with the drive chuck 20. The dowel rods

‘may be replaced with ring that interacts withthe drive chuck

20 and saver sub 18 to transmit torgue

[0034] Further, dhe connection discussed herein could also

‘be used to connect the drill string 16 witha downhole tool or

culing epparats (aot showa) ata terminal end ofthe dell

string

[0035] The spindle assembly 10 disclosed may be modified

Tor use with a dal-membor dell string 16, for torgue tans-

sssion to the inner member, ouler member, oF both (not

shown)

What is claimed is:

1. torque-transmitting assembly for use ia @ horizontal

iretional operation, the assembly comprising:

‘saver sub having an end

8 drive chuck having an end;

‘an extemal collar that joins adjacent ends ofthe saver sub

‘and drive chuck at an interface where they are main-

‘ained in coaxial and non-costating relationship; and

‘an intemal key that locks the drive chuck and saver sub in

‘rotaionally-fied relationship,

2. The tongue-ransmiting assembly ofclaim I whereinthe

ey comprises at least one dowel pin,

3. Tho tongus-transmittingassembly’of claim 2 whersin the

drive chuck defines at least one depression for placement of

the at least one dowel

4 The torque-trans

key comprises six dowel pits.

'. The tonque-ransmiting assembly ofelaim 2 whereinthe

at feast one dowel pin is characterized by a circular cross-

section

‘6. The torque-ransmitting assembly ofclaim I whereinthe

ey is placed within atleast one recess formed adjacent the

interlace ofthe saver sub and the drive chuck.

7.The torque-trans ly of elsim A wherein the

rive chuck comprises al least one depression for placement

ofthe key.

8. Thelonque-trnsmiting assembly ofclaima 7 whercinthe

key i radially removable from the at leat one depression,

9. The torquestransmitting assembly of elim 1 further

comprising:

a shoulder disposed onthe drive eek; and

fan internal shoulder disposed within the collar,

‘wherein te intemal shoulder contacts the shoulder ofthe

deve chuck when the siver sub and the collar are

attached.

10, The torque-transmiting assembly of claim 9 wherein

thesaversub and collar ar attached ina threaded connection.

11, The torue-transmiting assembly of ela 9 wherein

the saver sub ad collar are attached with bots

12, The torque-transmiting assembly of claim 9 wherein

the drive chuck is attached to dal-member pipe string.

13. A spindle assembly for rotating # dill sting, the

spindle assembly comprising

saver sub:

‘drive chuck; and

‘akey disposed between thesaversub andthe drivechuck at

‘an engagement point

wherein the

US 2016/0084016 AI

‘wherein the saver sub nd dive chuck ae in nonthreaded

torjue-iransmilting engagement and are engaged a the

engagement point only rough the key.

14, The spindle wssembly of claim 13 further comprising @

collar disposed about the swer sub and the drive chuck,

wherein the colliis movable between a locked positon and

an unlocked position

15, The spindle assembly of claim 14 wherein the drive

‘chuck is interference ft between the collar and the key when,

the collars in the locked postion

16, The spindle assembly of claim 18 wherein the colar

‘comprises an inner shoulder and the deve chuck comprises

‘corresponding outer shoulder.

17. The spindle assembly of claim 13 wherein the drive

‘tuck comprises atleast one depression corresponding tothe

key,

18, The spindle assembly of claim 17 wherein the key is

radially removable Irom the at least one depression

19. The spindle sssembly of claim 13 wherein the key

‘comprises atleast one dowel pi

20. 4 kt comprising’

‘collar configured to suround interfacing ends ofa saver

‘ub an a drive chuck to maintain them in coaxial and

non-contacting relationship: and

1 plurality of dowel pins configured to lock the collard

‘ver sb and drive chuck in otationally-tixe rela

ship.

21 The kit of claim 20 in which each dove pin is regis:

trable with concavities formed in each ofthe saver suband the

drive chuck

Mar. 24, 2016

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2011 Us20110137618a1 Geotechnical HorizontalDocument14 pages2011 Us20110137618a1 Geotechnical HorizontalCường Nguyễn QuốcNo ratings yet

- 2011 - Us7954558 - Devices and Methods For Power Control in Horizontal Directional DrillingDocument13 pages2011 - Us7954558 - Devices and Methods For Power Control in Horizontal Directional DrillingCường Nguyễn QuốcNo ratings yet

- 2012 - Us20120006597 - Drill HeadDocument7 pages2012 - Us20120006597 - Drill HeadCường Nguyễn QuốcNo ratings yet

- 2011 - US006276464B1 - Stake Coupler For A HDDDocument7 pages2011 - US006276464B1 - Stake Coupler For A HDDCường Nguyễn QuốcNo ratings yet

- 2011 - Us20110132665 - Electric Horizontal Directional Drilling Machine SystemDocument12 pages2011 - Us20110132665 - Electric Horizontal Directional Drilling Machine SystemCường Nguyễn QuốcNo ratings yet

- 2011 - Us7880336 - Electric Horizontal Directional Drilling Machine SystemDocument13 pages2011 - Us7880336 - Electric Horizontal Directional Drilling Machine SystemCường Nguyễn QuốcNo ratings yet

- 2005 - Us6910541 - Macro Assisted Control System and Method For A Horizontal Directional Drilling MachineDocument26 pages2005 - Us6910541 - Macro Assisted Control System and Method For A Horizontal Directional Drilling MachineCường Nguyễn QuốcNo ratings yet

- 2008 - US007461707B2 - Electric HDD Machine SystemDocument12 pages2008 - US007461707B2 - Electric HDD Machine SystemCường Nguyễn QuốcNo ratings yet

- 2013 - Us8365841b2 - Sectional Back Reamer Apparatus and Method For Horizontal Directional DrillingDocument11 pages2013 - Us8365841b2 - Sectional Back Reamer Apparatus and Method For Horizontal Directional DrillingCường Nguyễn QuốcNo ratings yet

- 2008 - Us7392858 - Remote Control For A Drilling MachineDocument17 pages2008 - Us7392858 - Remote Control For A Drilling MachineCường Nguyễn QuốcNo ratings yet

- 2005 - US006968735B2 - Long Range Data Transmitter For HDDDocument9 pages2005 - US006968735B2 - Long Range Data Transmitter For HDDCường Nguyễn QuốcNo ratings yet

- 2007 - Us20070294034a1 - Method For Designing and Optimizing Drilling and Completion Operations in Hydrocacrbon ReservoirsDocument38 pages2007 - Us20070294034a1 - Method For Designing and Optimizing Drilling and Completion Operations in Hydrocacrbon ReservoirsCường Nguyễn QuốcNo ratings yet

- 2006 - Us7066283 - Reverse Circulation Directional and Horizontal Drilling Using Concentric Coil TubingDocument19 pages2006 - Us7066283 - Reverse Circulation Directional and Horizontal Drilling Using Concentric Coil TubingCường Nguyễn QuốcNo ratings yet

- (Manual) StraightLine HDD 2462 Parts ManualDocument65 pages(Manual) StraightLine HDD 2462 Parts ManualCường Nguyễn QuốcNo ratings yet

- 2007 - Us20070021857 - Method For Selecting Bits and Drilling Tool AssembliesDocument39 pages2007 - Us20070021857 - Method For Selecting Bits and Drilling Tool AssembliesCường Nguyễn QuốcNo ratings yet

- 2007 - Us7251567 - Electronically Calibrated Beacon For A Horizontal Directional Drilling MachineDocument14 pages2007 - Us7251567 - Electronically Calibrated Beacon For A Horizontal Directional Drilling MachineCường Nguyễn QuốcNo ratings yet

- 2006 - Us7013991 - Obstacle Detection System For Underground OperationsDocument30 pages2006 - Us7013991 - Obstacle Detection System For Underground OperationsCường Nguyễn QuốcNo ratings yet

- 2004 - Us20040079553a1 - Reverse Circulation Directional and Horizontal Drilling Usin Concentric Drill StringDocument20 pages2004 - Us20040079553a1 - Reverse Circulation Directional and Horizontal Drilling Usin Concentric Drill StringCường Nguyễn QuốcNo ratings yet

- (Manual) StraightLine - HDD-2462-operators ManualDocument33 pages(Manual) StraightLine - HDD-2462-operators ManualCường Nguyễn QuốcNo ratings yet

- 2007 - Us7240744 - Rotary and Mud-Powered Percussive Drill Bit Assembly and MethodDocument15 pages2007 - Us7240744 - Rotary and Mud-Powered Percussive Drill Bit Assembly and MethodCường Nguyễn QuốcNo ratings yet

- 2005 - Us6979776 - Pipe Bundle For Underground InstallationDocument17 pages2005 - Us6979776 - Pipe Bundle For Underground InstallationCường Nguyễn QuốcNo ratings yet

- 2014 - Us20140353034 - Devices and Methods For Horizontal Directional Drilling With A Boring Tool LibraryDocument18 pages2014 - Us20140353034 - Devices and Methods For Horizontal Directional Drilling With A Boring Tool LibraryCường Nguyễn QuốcNo ratings yet

- 2014 - Us20140284111 - Horizontal Directional Drilling SystemDocument16 pages2014 - Us20140284111 - Horizontal Directional Drilling SystemCường Nguyễn QuốcNo ratings yet

- 2014 - Us8807241b2 - Devices and Method For Horizontal Directional Drilling With A Boring Tool LibraryDocument17 pages2014 - Us8807241b2 - Devices and Method For Horizontal Directional Drilling With A Boring Tool LibraryCường Nguyễn QuốcNo ratings yet

- 2010 - US007810582B2 - Counterbalance Enabled Power Generator For HDDDocument20 pages2010 - US007810582B2 - Counterbalance Enabled Power Generator For HDDCường Nguyễn QuốcNo ratings yet

- 2010 - US20100243326A1 - Common Interface Architecture For HDD MachineDocument17 pages2010 - US20100243326A1 - Common Interface Architecture For HDD MachineCường Nguyễn QuốcNo ratings yet

- Ring Spinning MachineDocument55 pagesRing Spinning MachineCường Nguyễn QuốcNo ratings yet

- 2009 - Us7500530 - Control SystemDocument9 pages2009 - Us7500530 - Control SystemCường Nguyễn QuốcNo ratings yet

- 2010 - Us2010011782a1 - Vise For A Directional Drilling MachineDocument11 pages2010 - Us2010011782a1 - Vise For A Directional Drilling MachineCường Nguyễn QuốcNo ratings yet

- 2010 - Us7721821 - Underground Boring Machine and Method For Controlling Underground BoringDocument13 pages2010 - Us7721821 - Underground Boring Machine and Method For Controlling Underground BoringCường Nguyễn QuốcNo ratings yet