Professional Documents

Culture Documents

Filled WPS Single FCAW

Filled WPS Single FCAW

Uploaded by

Ahmad ShaheenCopyright:

Available Formats

You might also like

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Form Wps Saw BlankDocument1 pageForm Wps Saw BlankHamid Taghipour ArmakiNo ratings yet

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- Astm A36 - 1 Astm A36 - 1: Wps Form (Gtaw & Smaw) Welding Procedure Specification (WPS)Document4 pagesAstm A36 - 1 Astm A36 - 1: Wps Form (Gtaw & Smaw) Welding Procedure Specification (WPS)Adam Al Aufa100% (1)

- Prequalified Qualified by TestingDocument5 pagesPrequalified Qualified by Testingcarlosoliveros1967No ratings yet

- 4G Fcaw WPSDocument3 pages4G Fcaw WPSdjafourNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- WPS SMAW - PL en V Con GaugingDocument1 pageWPS SMAW - PL en V Con GaugingLuis MirandaNo ratings yet

- Annex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document2 pagesAnnex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Daniel ZapataNo ratings yet

- D17.1-D17.1M-2017-Sample-WPS-formDocument1 pageD17.1-D17.1M-2017-Sample-WPS-formMhmoudhaggagNo ratings yet

- WPS 1.1Document1 pageWPS 1.1Juan Diego Carvajal100% (1)

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)rabacet23No ratings yet

- P WPS Smaw Ceym 001 021Document1 pageP WPS Smaw Ceym 001 021juan carlos garavitoNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Base Metals Base Metal Thickness: Document IT-ME-XXX-XX/F-01 Rev. 0 DateDocument1 pageBase Metals Base Metal Thickness: Document IT-ME-XXX-XX/F-01 Rev. 0 Datehenry ayala100% (1)

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Document1 pageQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13No ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specification (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specification (WPS)ING HARRINSON FERREBUSNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- WPS Astm - A 53Document2 pagesWPS Astm - A 53S. K. M. ShujonNo ratings yet

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Ejemplo WpsDocument1 pageEjemplo WpsIsaac GutierrezNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorld100% (1)

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- WPS 1310Document2 pagesWPS 1310paulNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Document2 pagesWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- WPS Precalificado Aceros Moservin 2022Document2 pagesWPS Precalificado Aceros Moservin 2022Jonathan Espinoza MejiaNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Balkishan DyavanapellyNo ratings yet

- WPS - Is4923 SmawDocument2 pagesWPS - Is4923 SmawprudvirajsriujjwalaNo ratings yet

- Aws D1.1Document1 pageAws D1.1พันธุ์เทพ คําพองNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 pagesNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNo ratings yet

- Form Wps Gtaw Smaw BlankDocument1 pageForm Wps Gtaw Smaw BlankjezNo ratings yet

- BGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Document1 pageBGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Eswar Enterprises QcNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- WPS-30Document2 pagesWPS-30srinivas raoNo ratings yet

- Request For Welding Procedure ApprovalDocument13 pagesRequest For Welding Procedure ApprovalecsuperalNo ratings yet

- 07 SMAW 332 18 532 332 E7018 Prequalified WPSsDocument82 pages07 SMAW 332 18 532 332 E7018 Prequalified WPSsErick Vazquez100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- KPH 3033002 em 3 enDocument16 pagesKPH 3033002 em 3 enAhmad ShaheenNo ratings yet

- 2 Fcaw-AllDocument51 pages2 Fcaw-AllAhmad ShaheenNo ratings yet

- الكود السعوديDocument27 pagesالكود السعوديAhmad ShaheenNo ratings yet

- kwt2001 01Document12 pageskwt2001 01Ahmad ShaheenNo ratings yet

- Fcaw SSDocument5 pagesFcaw SSAhmad ShaheenNo ratings yet

- High-Performance and Cost-EfficientDocument12 pagesHigh-Performance and Cost-EfficientAhmad ShaheenNo ratings yet

- HTA Rev 5.00 Install GuideDocument240 pagesHTA Rev 5.00 Install GuideAhmad ShaheenNo ratings yet

- N° Codice / Code Descrizione Description Q.tà: VERSION 07/2012 From Serial 476Document3 pagesN° Codice / Code Descrizione Description Q.tà: VERSION 07/2012 From Serial 476Ahmad ShaheenNo ratings yet

- Expressway Plow - 11 Foot Carbon Steel Blade, Trip Edge, Drop Pin, 3 Inch CylindersDocument2 pagesExpressway Plow - 11 Foot Carbon Steel Blade, Trip Edge, Drop Pin, 3 Inch CylindersAhmad ShaheenNo ratings yet

- Split Shaft Pto: Installation InstructionsDocument12 pagesSplit Shaft Pto: Installation InstructionsAhmad ShaheenNo ratings yet

- ReferensiDocument4 pagesReferensiluluNo ratings yet

- Gout and Othercrystal-Associated ArthropathiesDocument31 pagesGout and Othercrystal-Associated ArthropathiesLia pramitaNo ratings yet

- Jayson Desear: 3. What Is The Importance of Legislation in The Development and Sustenance of Special Education Programs?Document2 pagesJayson Desear: 3. What Is The Importance of Legislation in The Development and Sustenance of Special Education Programs?Jayson Desear100% (3)

- Catalog DHF DSF enDocument2 pagesCatalog DHF DSF enRUTHNo ratings yet

- Neatecha 1Document20 pagesNeatecha 1cram retselNo ratings yet

- Environmental LeadershipDocument4 pagesEnvironmental LeadershipElpi FerrerNo ratings yet

- CertificateDocument1 pageCertificatefirebase fbNo ratings yet

- Part 1 Hydraulic Design Calculation 473Document13 pagesPart 1 Hydraulic Design Calculation 473shashi rajhansNo ratings yet

- End of Term 1 Physcis and Chemistry-2024Document14 pagesEnd of Term 1 Physcis and Chemistry-2024angellevitt520No ratings yet

- 415 V System Stage-1Document18 pages415 V System Stage-1raghavendran raghuNo ratings yet

- HIVDocument38 pagesHIVFarhan Herjanto100% (1)

- Practical Applications of Water Immersion Recovery.6Document13 pagesPractical Applications of Water Immersion Recovery.6GlendaNo ratings yet

- Queen Creek Queen Creek Barber School: Enroll Now Full Time or Part Time!!!!Document4 pagesQueen Creek Queen Creek Barber School: Enroll Now Full Time or Part Time!!!!reneeclancyNo ratings yet

- Borja-et-al.-2021-Final-Output-in-Practical Research 1Document237 pagesBorja-et-al.-2021-Final-Output-in-Practical Research 1Abigail MasotisNo ratings yet

- Vane Shear TestDocument10 pagesVane Shear TestManikyaMayankNo ratings yet

- Essentials and Pre-Requisites of Medical ResearchDocument3 pagesEssentials and Pre-Requisites of Medical ResearchArchisman Mukherjee FAPSIANNo ratings yet

- Scope of Work For The Supply and Installation of Solar Power SystemDocument12 pagesScope of Work For The Supply and Installation of Solar Power SystemAzizullah AlizayNo ratings yet

- CyclamenDocument50 pagesCyclamenLAUM1No ratings yet

- Load Cell C16ADocument88 pagesLoad Cell C16AShigilNo ratings yet

- The Group Remedy Prescriber 0 Compound Tablet by F.E. PowellDocument26 pagesThe Group Remedy Prescriber 0 Compound Tablet by F.E. Powellambertje1267% (3)

- MRD Guidline NABHDocument3 pagesMRD Guidline NABHharpreet kaur brarNo ratings yet

- Wa0001Document32 pagesWa0001shirou xNo ratings yet

- CISA Exam Prep Domain 2-2019Document122 pagesCISA Exam Prep Domain 2-2019poornima24100% (1)

- Iop DinDocument4 pagesIop DinDjannie AnneNo ratings yet

- Series E Environmental Coils: Coils and Electronic ControlsDocument18 pagesSeries E Environmental Coils: Coils and Electronic ControlsMMM-MMMNo ratings yet

- G8 Radial Groundwater Flow in Confined AquiferDocument12 pagesG8 Radial Groundwater Flow in Confined AquiferkurtieberberNo ratings yet

- Chapter 4 Investments in Debt Securities and Other Long-Term InvestmentDocument11 pagesChapter 4 Investments in Debt Securities and Other Long-Term Investmentpapajesus papaNo ratings yet

- Geduldig v. Aiello, 417 U.S. 484 (1974)Document17 pagesGeduldig v. Aiello, 417 U.S. 484 (1974)Scribd Government DocsNo ratings yet

- Lamesoft PO 65: Naturally Derived Lipid Layer EnhancerDocument1 pageLamesoft PO 65: Naturally Derived Lipid Layer Enhancerneha sahuNo ratings yet

- Leaves Can Also Store Food and WaterDocument5 pagesLeaves Can Also Store Food and WaterMaximos ManiatisNo ratings yet

Filled WPS Single FCAW

Filled WPS Single FCAW

Uploaded by

Ahmad ShaheenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filled WPS Single FCAW

Filled WPS Single FCAW

Uploaded by

Ahmad ShaheenCopyright:

Available Formats

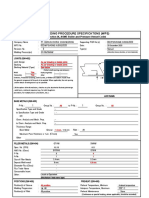

Sample Form (GMAW & FCAW)

WELDING PROCEDURE SPECIFICATION (WPS)

RED Inc. ______ ____________ 2010 pg 357 _____ __0__ 12/01/1987

Company Name WPS No. Rev. No. Date

J. Jones____ _____ 01/18/1988 231 __________________________ _

Authorized by Date Supporting PQR(s)

Type or AWS BASE METAL With

BASE METALS Specification Grade Group No. THICKNESS As-Welded PWHT

Base Material ASTM A131 A I CJP Groove Welds 3/4 -1 ½ “ -

Welded To ASTM A131 A I CJP Groove w/CVN - -

Backing Material ASTM A131 A I PJP Groove Welds - -

Other - Fillet Welds - -

DIAMETER - -

JOINT DETAILS JOINT DETAILS (Sketch)

Groove Type single V groove butt weld

Groove Angle 35° included

Root Opening 1/4”

Root Face -

Back Gouging none

Method -

POSTWELD HEAT TREATMENT

Temperature None

Time at Temperature -

Other -

PROCEDURE

Weld Layer(s) All

Weld Pass(es) All

Process FCAW

Type (Semi-Auto./Machine/Auto.) semi-auto.

Position OH

Vertical Progression -

Filler Metal AWS Spec. A5.20

AWS Classification E71T-1

Diameter 0.045”

Manufacture/Trade Name -

Shielding Gas (Composition) 100 % CO2

Flow Rate 45-55 cfh

Nozzle Size #4

Preheat Temperature 60° min.

Interpass Temperature 60°-350°

Electrical Characteristics ---

Current Type & Polarity DCEP

Transfer Mode -

Power Source Type -

Amps 180 - 220

Volts 25 - 26

Wire Feed Speed (Amps)

Travel Speed 8-12 ipm

Maximum Heat Input* -

Technique ---

Stringer or Weave stringer

Multi or Single Pass (per side) multipass

Oscillation (Machine/Automatic) -

Number of Electrodes 1

Contact Tube to Work Dist. ½-1"

Peening None

Interpass Cleaning wire brush

Other -

( see aws.org/forms for more examples )

Sample Form (GMAW & FCAW)

WELDING PROCEDURE SPECIFICATION (WPS)

RED Inc. ______ ____________ 2010 pg 357 _____ __1__ 12/01/1987

Company Name WPS No. Rev. No. Date

J. Jones____ _____ 01/18/1988 231 __________________________ _

Authorized by Date Supporting PQR(s)

Type or AWS BASE METAL With

BASE METALS Specification Grade Group No. THICKNESS As-Welded PWHT

Base Material ASTM A131 A I CJP Groove Welds 3/4 -1 ½ “ -

Welded To ASTM A131 A I CJP Groove w/CVN - -

Backing Material ASTM A131 A I PJP Groove Welds - -

Other - Fillet Welds - -

DIAMETER - -

JOINT DETAILS JOINT DETAILS (Sketch)

Groove Type single V groove butt weld

Groove Angle 35° included

Root Opening 1/4”

Root Face -

Back Gouging none

Method -

POSTWELD HEAT TREATMENT

Temperature None

Time at Temperature -

Other -

PROCEDURE

Weld Layer(s) All

Weld Pass(es) All

Process FCAW

Type (Semi-Auto./Machine/Auto.) semi-auto.

Position OH

Vertical Progression -

Filler Metal AWS Spec. A5.20

AWS Classification E71T-1

Diameter 0.045”

Manufacture/Trade Name -

Shielding Gas (Composition) 100 % CO2

Flow Rate 45-55 cfh

Nozzle Size #4

Preheat Temperature 60° min.

Interpass Temperature 60°-350°

Electrical Characteristics ---

Current Type & Polarity DCEP

Transfer Mode -

Power Source Type -

Amps 180 - 220

Volts 25 - 26

Wire Feed Speed (Amps)

Travel Speed 8-12 ipm

Maximum Heat Input* -

Technique ---

Stringer or Weave stringer

Multi or Single Pass (per side) multipass

Oscillation (Machine/Automatic) -

Number of Electrodes 1

Contact Tube to Work Dist. ½-1"

Peening None

Interpass Cleaning wire brush

Other -

( see aws.org/forms for more examples )

Sample Form (GMAW & FCAW)

WELDING PROCEDURE SPECIFICATION (WPS)

RED Inc. ______ ____________ 2010 pg 357 _____ __2__ 12/01/1987

Company Name WPS No. Rev. No. Date

J. Jones____ _____ 01/18/1988 231 __________________________ _

Authorized by Date Supporting PQR(s)

Type or AWS BASE METAL With

BASE METALS Specification Grade Group No. THICKNESS As-Welded PWHT

Base Material ASTM A131 A I CJP Groove Welds 3/4 -1 ½ “ -

Welded To ASTM A131 A I CJP Groove w/CVN - -

Backing Material ASTM A131 A I PJP Groove Welds - -

Other - Fillet Welds - -

DIAMETER - -

JOINT DETAILS JOINT DETAILS (Sketch)

Groove Type single V groove butt weld

Groove Angle 35° included

Root Opening 1/4”

Root Face -

Back Gouging none

Method -

POSTWELD HEAT TREATMENT

Temperature None

Time at Temperature -

Other -

PROCEDURE

Weld Layer(s) All

Weld Pass(es) All

Process FCAW

Type (Semi-Auto./Machine/Auto.) semi-auto.

Position OH

Vertical Progression -

Filler Metal AWS Spec. A5.20

AWS Classification E71T-1

Diameter 0.045”

Manufacture/Trade Name -

Shielding Gas (Composition) 100 % CO2

Flow Rate 45-55 cfh

Nozzle Size #4

Preheat Temperature 60° min.

Interpass Temperature 60°-350°

Electrical Characteristics ---

Current Type & Polarity DCEP

Transfer Mode -

Power Source Type -

Amps 180 - 220

Volts 25 - 26

Wire Feed Speed (Amps)

Travel Speed 8-12 ipm

Maximum Heat Input* -

Technique ---

Stringer or Weave stringer

Multi or Single Pass (per side) multipass

Oscillation (Machine/Automatic) -

Number of Electrodes 1

Contact Tube to Work Dist. ½-1"

Peening None

Interpass Cleaning wire brush

Other -

( see aws.org/forms for more examples )

You might also like

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Form Wps Saw BlankDocument1 pageForm Wps Saw BlankHamid Taghipour ArmakiNo ratings yet

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- Astm A36 - 1 Astm A36 - 1: Wps Form (Gtaw & Smaw) Welding Procedure Specification (WPS)Document4 pagesAstm A36 - 1 Astm A36 - 1: Wps Form (Gtaw & Smaw) Welding Procedure Specification (WPS)Adam Al Aufa100% (1)

- Prequalified Qualified by TestingDocument5 pagesPrequalified Qualified by Testingcarlosoliveros1967No ratings yet

- 4G Fcaw WPSDocument3 pages4G Fcaw WPSdjafourNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- WPS SMAW - PL en V Con GaugingDocument1 pageWPS SMAW - PL en V Con GaugingLuis MirandaNo ratings yet

- Annex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document2 pagesAnnex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Daniel ZapataNo ratings yet

- D17.1-D17.1M-2017-Sample-WPS-formDocument1 pageD17.1-D17.1M-2017-Sample-WPS-formMhmoudhaggagNo ratings yet

- WPS 1.1Document1 pageWPS 1.1Juan Diego Carvajal100% (1)

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)rabacet23No ratings yet

- P WPS Smaw Ceym 001 021Document1 pageP WPS Smaw Ceym 001 021juan carlos garavitoNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Base Metals Base Metal Thickness: Document IT-ME-XXX-XX/F-01 Rev. 0 DateDocument1 pageBase Metals Base Metal Thickness: Document IT-ME-XXX-XX/F-01 Rev. 0 Datehenry ayala100% (1)

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Document1 pageQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13No ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specification (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specification (WPS)ING HARRINSON FERREBUSNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- WPS Astm - A 53Document2 pagesWPS Astm - A 53S. K. M. ShujonNo ratings yet

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Ejemplo WpsDocument1 pageEjemplo WpsIsaac GutierrezNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorld100% (1)

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- WPS 1310Document2 pagesWPS 1310paulNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Document2 pagesWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- WPS Precalificado Aceros Moservin 2022Document2 pagesWPS Precalificado Aceros Moservin 2022Jonathan Espinoza MejiaNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Balkishan DyavanapellyNo ratings yet

- WPS - Is4923 SmawDocument2 pagesWPS - Is4923 SmawprudvirajsriujjwalaNo ratings yet

- Aws D1.1Document1 pageAws D1.1พันธุ์เทพ คําพองNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 pagesNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNo ratings yet

- Form Wps Gtaw Smaw BlankDocument1 pageForm Wps Gtaw Smaw BlankjezNo ratings yet

- BGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Document1 pageBGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Eswar Enterprises QcNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- WPS-30Document2 pagesWPS-30srinivas raoNo ratings yet

- Request For Welding Procedure ApprovalDocument13 pagesRequest For Welding Procedure ApprovalecsuperalNo ratings yet

- 07 SMAW 332 18 532 332 E7018 Prequalified WPSsDocument82 pages07 SMAW 332 18 532 332 E7018 Prequalified WPSsErick Vazquez100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- KPH 3033002 em 3 enDocument16 pagesKPH 3033002 em 3 enAhmad ShaheenNo ratings yet

- 2 Fcaw-AllDocument51 pages2 Fcaw-AllAhmad ShaheenNo ratings yet

- الكود السعوديDocument27 pagesالكود السعوديAhmad ShaheenNo ratings yet

- kwt2001 01Document12 pageskwt2001 01Ahmad ShaheenNo ratings yet

- Fcaw SSDocument5 pagesFcaw SSAhmad ShaheenNo ratings yet

- High-Performance and Cost-EfficientDocument12 pagesHigh-Performance and Cost-EfficientAhmad ShaheenNo ratings yet

- HTA Rev 5.00 Install GuideDocument240 pagesHTA Rev 5.00 Install GuideAhmad ShaheenNo ratings yet

- N° Codice / Code Descrizione Description Q.tà: VERSION 07/2012 From Serial 476Document3 pagesN° Codice / Code Descrizione Description Q.tà: VERSION 07/2012 From Serial 476Ahmad ShaheenNo ratings yet

- Expressway Plow - 11 Foot Carbon Steel Blade, Trip Edge, Drop Pin, 3 Inch CylindersDocument2 pagesExpressway Plow - 11 Foot Carbon Steel Blade, Trip Edge, Drop Pin, 3 Inch CylindersAhmad ShaheenNo ratings yet

- Split Shaft Pto: Installation InstructionsDocument12 pagesSplit Shaft Pto: Installation InstructionsAhmad ShaheenNo ratings yet

- ReferensiDocument4 pagesReferensiluluNo ratings yet

- Gout and Othercrystal-Associated ArthropathiesDocument31 pagesGout and Othercrystal-Associated ArthropathiesLia pramitaNo ratings yet

- Jayson Desear: 3. What Is The Importance of Legislation in The Development and Sustenance of Special Education Programs?Document2 pagesJayson Desear: 3. What Is The Importance of Legislation in The Development and Sustenance of Special Education Programs?Jayson Desear100% (3)

- Catalog DHF DSF enDocument2 pagesCatalog DHF DSF enRUTHNo ratings yet

- Neatecha 1Document20 pagesNeatecha 1cram retselNo ratings yet

- Environmental LeadershipDocument4 pagesEnvironmental LeadershipElpi FerrerNo ratings yet

- CertificateDocument1 pageCertificatefirebase fbNo ratings yet

- Part 1 Hydraulic Design Calculation 473Document13 pagesPart 1 Hydraulic Design Calculation 473shashi rajhansNo ratings yet

- End of Term 1 Physcis and Chemistry-2024Document14 pagesEnd of Term 1 Physcis and Chemistry-2024angellevitt520No ratings yet

- 415 V System Stage-1Document18 pages415 V System Stage-1raghavendran raghuNo ratings yet

- HIVDocument38 pagesHIVFarhan Herjanto100% (1)

- Practical Applications of Water Immersion Recovery.6Document13 pagesPractical Applications of Water Immersion Recovery.6GlendaNo ratings yet

- Queen Creek Queen Creek Barber School: Enroll Now Full Time or Part Time!!!!Document4 pagesQueen Creek Queen Creek Barber School: Enroll Now Full Time or Part Time!!!!reneeclancyNo ratings yet

- Borja-et-al.-2021-Final-Output-in-Practical Research 1Document237 pagesBorja-et-al.-2021-Final-Output-in-Practical Research 1Abigail MasotisNo ratings yet

- Vane Shear TestDocument10 pagesVane Shear TestManikyaMayankNo ratings yet

- Essentials and Pre-Requisites of Medical ResearchDocument3 pagesEssentials and Pre-Requisites of Medical ResearchArchisman Mukherjee FAPSIANNo ratings yet

- Scope of Work For The Supply and Installation of Solar Power SystemDocument12 pagesScope of Work For The Supply and Installation of Solar Power SystemAzizullah AlizayNo ratings yet

- CyclamenDocument50 pagesCyclamenLAUM1No ratings yet

- Load Cell C16ADocument88 pagesLoad Cell C16AShigilNo ratings yet

- The Group Remedy Prescriber 0 Compound Tablet by F.E. PowellDocument26 pagesThe Group Remedy Prescriber 0 Compound Tablet by F.E. Powellambertje1267% (3)

- MRD Guidline NABHDocument3 pagesMRD Guidline NABHharpreet kaur brarNo ratings yet

- Wa0001Document32 pagesWa0001shirou xNo ratings yet

- CISA Exam Prep Domain 2-2019Document122 pagesCISA Exam Prep Domain 2-2019poornima24100% (1)

- Iop DinDocument4 pagesIop DinDjannie AnneNo ratings yet

- Series E Environmental Coils: Coils and Electronic ControlsDocument18 pagesSeries E Environmental Coils: Coils and Electronic ControlsMMM-MMMNo ratings yet

- G8 Radial Groundwater Flow in Confined AquiferDocument12 pagesG8 Radial Groundwater Flow in Confined AquiferkurtieberberNo ratings yet

- Chapter 4 Investments in Debt Securities and Other Long-Term InvestmentDocument11 pagesChapter 4 Investments in Debt Securities and Other Long-Term Investmentpapajesus papaNo ratings yet

- Geduldig v. Aiello, 417 U.S. 484 (1974)Document17 pagesGeduldig v. Aiello, 417 U.S. 484 (1974)Scribd Government DocsNo ratings yet

- Lamesoft PO 65: Naturally Derived Lipid Layer EnhancerDocument1 pageLamesoft PO 65: Naturally Derived Lipid Layer Enhancerneha sahuNo ratings yet

- Leaves Can Also Store Food and WaterDocument5 pagesLeaves Can Also Store Food and WaterMaximos ManiatisNo ratings yet