Professional Documents

Culture Documents

Risk Assessment

Risk Assessment

Uploaded by

totA ahmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment

Risk Assessment

Uploaded by

totA ahmedCopyright:

Available Formats

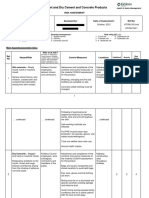

Total Concrete Ltd

Risk Assessment

Activity: Reference:

Concreting contact on site RA076

Task Description:

Assessor: Date:

Andrew Shaw 26/04/2017

Assessment of Risk

Hazard Likelihood Severity Risk

Exposure to cement dust Med Low Low

Shovelling materials Low Low Low

Handling heavy / bulky materials Med Med Med

Contact with rotating drum Low Med Low

Entanglement with blades when mixing / cleaning Low Med Low

Fall of loose concrete Med Med Med

Contact with wet concrete Med Low Low

Contact with machinery / components Low Med Med

Entanglement in reinforcement Med Low Low

Contact with sharp edges Med Low Low

L|M|H L|M|H L|M|H

People at Risk

Workers Adjacent Workers Site Wide Personnel Occupants

Visitors Members of Public

Concreting contact on site Risk Assessment pg. 1/4

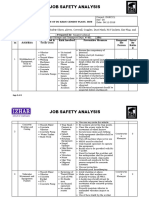

Total Concrete Ltd

Controls

Risk Control Measures

Gloves to be worn when handling cement / additives. COSHH

Reaction of skin to Assessment to be carried out and communicated to all operatives.

contact with cement / Hand washing facilities to be available on site.

additives Refer to COSHH assessment for details of hazards associated with

cement and additives.

Dust masks to be worn whilst loading cement into mixer unless

Inhalation of cement dust adequate ventilation is available. COSHH Assessment to be carried out

and communicated to all operatives.

All equipment to be serviced and maintained in line with manufacturers

recommendations. Any faults to be reported to management

immediately and the equipment taken out of use. Mixer to be placed in

area where others are kept away from rotating parts. All rotating parts

– belts, pulleys etc. to be guarded.

Contact with machinery /

No hand tools such as shovels, sticks etc to be used in drum whilst

components

mixing is in operation. Mixer to be stopped and disconnected from

power supply before cleaning is undertaken. Mixer to be sited on flat

level ground without resorting to packing of feet. Mixer to be mounted

on wheels to ease movement around site. All equipment to be 110 volt

and PAT tested regularly.

Two-man lift to be used when unloading mixer and putting onto stand.

All employees trained in manual handling techniques. Manual handling

assessment carried out for handling of wet and dry concrete materials,

e.g. when loading mixer and when pouring and shovelling concrete into

Handling heavy / bulky

position. Mixer to be mounted on wheels to ease movement around

materials

site.

Half bags to be used wherever possible – full bags to be split in two

before loading into mixer.

Two persons to undertake tipping of large mixes.

Doors, guards, formwork and falsework to be properly closed, guarded

and secured to prevent falls of loose concrete during lifting operations.

Falls of loose concrete / Do not overfill form/falsework with materials.

lifting operations Lifting plan to be in place when using cranes or other lifting equipment

to raise materials.

Segregate all areas where overhead work is in operation.

Only competent and trained operatives to carry out machine bending

and/or cropping of reinforcement materials.

Mechanical means of lifting and placing reinforcement to be used when

Entanglement / contact practicable.

with reinforcement Boards planed over reinforcement to provide access and working areas

with sufficient edge protection installed if required. Gloves, boots and

full leg and arm coverings to be worn when working near reinforcement

due to sharp edges.

Concreting contact on site Risk Assessment pg. 2/4

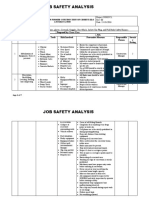

Total Concrete Ltd

Assessment of Remaining Risk

Very Low

safe to proceed work to control measures

Low

safe to proceed with caution

Medium

safe to proceed with further controls

High

proceed under further controls and supervised

Very High

unsafe DO NOT proceed - further action needed

Concreting contact on site Risk Assessment pg. 3/4

Total Concrete Ltd

Further Action Required

Action

Action Required Date Completed Completed By

Timeframe

Ensure adequate supervision is

provided and that control measures

Ongoing

remain valid for the duration of the

works.

Safe systems of work are provided and 1 Week

issued to all staff and training provided Refresh at

in their use. Inductions

All staff to be trained in the importance

1 Week

and use of correct Personal Protective

Refresh at

Equipment and wearing of the correct

Inductions

PPE a condition of employment

COSHH Assessment to be 2 Weeks

communicated to workforce for Refresh at

hazardous substances e.g. cement Inductions

Acknowledgement

By signing this form you confirm that you have read and understood the risk assessments outlined and associated safe methods of

work, are competent to undertake the work, and that you agree to comply with the safe working procedures in place to minimise

the hazards present for the activities undertaken.

Name Signature Date

Andrew Shaw 26/04/2017

Produced at www.darleypcm.com Concreting contact on site Risk Assessment pg. 4/4

You might also like

- Concreting Job Safety Analysis (JSA)Document2 pagesConcreting Job Safety Analysis (JSA)sudam kumar raut91% (22)

- Concrete & Form Work: Job Safety Analysis Pouring ConcreteDocument1 pageConcrete & Form Work: Job Safety Analysis Pouring ConcreteHortencio Samuel100% (4)

- Work Method Statement PDFDocument8 pagesWork Method Statement PDFUsiwo Abed Soteria Otowa100% (4)

- Risk Assessment For Waste Management: SL No Potential Hazard Risk Persons at Risk Control Measures Risk RatingDocument3 pagesRisk Assessment For Waste Management: SL No Potential Hazard Risk Persons at Risk Control Measures Risk Ratingطارق رضوان100% (1)

- Method Statement & Risk Assessment Hydrostatic Leak TestDocument7 pagesMethod Statement & Risk Assessment Hydrostatic Leak TestWalid AmdouniNo ratings yet

- Concrete Pouring (Risk Assessment)Document3 pagesConcrete Pouring (Risk Assessment)Ri Oz80% (5)

- Master Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDocument6 pagesMaster Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDaniel JulianNo ratings yet

- ERP Plaster CONMIXDocument2 pagesERP Plaster CONMIXAyubkhan250% (2)

- Recycled AggregatesDocument31 pagesRecycled Aggregatesshailesh goral56% (9)

- Risk AssessmentDocument8 pagesRisk AssessmentMohamed KatouraNo ratings yet

- HT RA 162 and HT RA 162 1working With Wet and Dry Cement and Concrete Products RedactedDocument10 pagesHT RA 162 and HT RA 162 1working With Wet and Dry Cement and Concrete Products RedactedjohnNo ratings yet

- HT RA 162 and HT RA 162 1working With Wet and Dry Cement and Concrete Products RedactedDocument10 pagesHT RA 162 and HT RA 162 1working With Wet and Dry Cement and Concrete Products RedactedMohamed KatouraNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- Hazard Analysis - Concrete, Cast-In-place (Curbstone)Document3 pagesHazard Analysis - Concrete, Cast-In-place (Curbstone)abdullah ashrafNo ratings yet

- Jha Batching Plant PlatformDocument5 pagesJha Batching Plant PlatformsoubhagyaNo ratings yet

- Safe - Work - Method - Statement - Roof - Truss - Installation V1.0Document8 pagesSafe - Work - Method - Statement - Roof - Truss - Installation V1.0hurairamughal666No ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentAkinbami Olorunnifemi100% (1)

- Risk Assessment: Method Statement Painting ActivitiesDocument11 pagesRisk Assessment: Method Statement Painting ActivitiesWalid Amdouni100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- Job Safety Analysis - Cement SiloDocument7 pagesJob Safety Analysis - Cement SiloArgi Bramantara100% (1)

- L4C - Working PlatfornDocument3 pagesL4C - Working PlatfornArif RizwanNo ratings yet

- Ritesh Ig2 Forms Electronic Submission v3 28.07.2021Document19 pagesRitesh Ig2 Forms Electronic Submission v3 28.07.2021NishanthNo ratings yet

- 7.5 Risk Assessment and Safety Measures:: 7.5.1 Classification of The Hazards in The Cement IndustryDocument28 pages7.5 Risk Assessment and Safety Measures:: 7.5.1 Classification of The Hazards in The Cement IndustryjohnNo ratings yet

- Method Statement Concrete Works 2019Document8 pagesMethod Statement Concrete Works 2019Derek obboNo ratings yet

- JSA Installation-Fire-Alarm-SystemDocument12 pagesJSA Installation-Fire-Alarm-Systemuz9143895No ratings yet

- MS-CV-001 - Excavation and BackfillingDocument6 pagesMS-CV-001 - Excavation and BackfillingHusam zayedNo ratings yet

- Pre-Task Planning: Describe Work To Be PerformedDocument3 pagesPre-Task Planning: Describe Work To Be PerformedMario MongeNo ratings yet

- Busduck Instalion JSADocument5 pagesBusduck Instalion JSAasifreza96No ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument5 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- JSA-Confined Space Activity - 05Document4 pagesJSA-Confined Space Activity - 05babjihanumanthuNo ratings yet

- FLHA'sDocument2 pagesFLHA'salthaherashNo ratings yet

- Safe Use of Site Dumpers On Construction SitesDocument4 pagesSafe Use of Site Dumpers On Construction SitesMusharaf ShahNo ratings yet

- Job Safety Analysis - Cement SiloDocument9 pagesJob Safety Analysis - Cement SiloMohammed Minhaj100% (1)

- ## PublicDocument1 page## PublicarjunkoiralaNo ratings yet

- Jha UtilityDocument4 pagesJha UtilityRavi thokalNo ratings yet

- 1 Earth WorksDocument5 pages1 Earth WorksMuhammad Shahid Iqbal100% (1)

- Risk Assessment Record: 5 4 3 2 1 1 2 3 4 5 SeverityDocument6 pagesRisk Assessment Record: 5 4 3 2 1 1 2 3 4 5 SeverityAfaan gani InamdarNo ratings yet

- JSA - Admin Building To Cafiteria BridgeDocument6 pagesJSA - Admin Building To Cafiteria BridgerjNo ratings yet

- Civil JSA Form Block WorkDocument3 pagesCivil JSA Form Block Workhaseebzaheer787No ratings yet

- Risk Assessment Working at HeightDocument3 pagesRisk Assessment Working at Heightpeace.mudauNo ratings yet

- RA INSTALLATION Electrical PannelDocument7 pagesRA INSTALLATION Electrical PannelAmrou Ben RjebNo ratings yet

- Bending Risk AssessmentDocument4 pagesBending Risk AssessmentAthar KhanNo ratings yet

- Lecturer Name: Section: 1 Date of Submission: 5: November 2020Document3 pagesLecturer Name: Section: 1 Date of Submission: 5: November 2020little projectNo ratings yet

- Y0 QNACN7 Risk Assessment ReportDocument16 pagesY0 QNACN7 Risk Assessment ReportShah MuzzamilNo ratings yet

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaNo ratings yet

- Carpentry, Forming, Framing or Wood WorkingDocument1 pageCarpentry, Forming, Framing or Wood Workingchirese2000No ratings yet

- Site DumpersDocument4 pagesSite DumpersDanijel PindrićNo ratings yet

- HMDS Monthly Risk Assessment BlankDocument3 pagesHMDS Monthly Risk Assessment BlankAli BelkhiriNo ratings yet

- Carpentry, Forming, Framing or Wood WorkingDocument1 pageCarpentry, Forming, Framing or Wood WorkingAlex DcostaNo ratings yet

- MS Vetonit Masonry Mortar MS7-PP003-03-21Document3 pagesMS Vetonit Masonry Mortar MS7-PP003-03-21Maha MuflehNo ratings yet

- Risk AssessmentDocument1 pageRisk AssessmentSiti Noor Rahimah IbarahimNo ratings yet

- Concrete Work - Truck PumpingDocument1 pageConcrete Work - Truck PumpingPrakash PavuralaNo ratings yet

- Working at Heights SwmsDocument11 pagesWorking at Heights Swmssyed khaja misbhuddinNo ratings yet

- Carpentry, Forming, Framing or Wood Working PDFDocument1 pageCarpentry, Forming, Framing or Wood Working PDFnaraNo ratings yet

- Carpentry Forming Framing or Wood WorkingDocument1 pageCarpentry Forming Framing or Wood WorkingPrakash PavuralaNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Penetrant Testing: Principles, Techniques, Applications and Interview Q&AFrom EverandPenetrant Testing: Principles, Techniques, Applications and Interview Q&ANo ratings yet

- Lenocean Plant DetailsDocument2 pagesLenocean Plant DetailsYahyaNo ratings yet

- Norma Astm C33Document11 pagesNorma Astm C33EliasTalaAllcaNo ratings yet

- TDS-Starfix C1-SLDocument3 pagesTDS-Starfix C1-SLYASHICA VAITTIANATHANNo ratings yet

- 16th NOCMAT 2015 Submission 95 PDFDocument13 pages16th NOCMAT 2015 Submission 95 PDFPatito Lisbhet Romero BuenoNo ratings yet

- Daily Production & Power Report - 31!03!2022Document9 pagesDaily Production & Power Report - 31!03!2022fjohnmajorNo ratings yet

- Helen Schedule 2Document182 pagesHelen Schedule 2Bruch G TadeNo ratings yet

- Plant Parts CatalogDocument40 pagesPlant Parts CatalogHuilber MartínezNo ratings yet

- Mix Design SheetDocument17 pagesMix Design SheetAmar WadoodNo ratings yet

- Revised Data (Buildings)Document95 pagesRevised Data (Buildings)sasidharkatari91572No ratings yet

- Crack in Concrete: by Feseha Sahile (DR.)Document22 pagesCrack in Concrete: by Feseha Sahile (DR.)Engida Gizachew WondimuNo ratings yet

- CEE 3020 Practice Exam 1Document9 pagesCEE 3020 Practice Exam 1CodyNo ratings yet

- Pariej Final Shedule - BDocument41 pagesPariej Final Shedule - BDouglas RobinsonNo ratings yet

- Problem Set No.2 - Ultimate Stress Design (USD)Document1 pageProblem Set No.2 - Ultimate Stress Design (USD)Catherine Shaina O. PasionNo ratings yet

- M205Document4 pagesM205FRANZ RICHARD SARDINAS MALLCO100% (1)

- System No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)Document2 pagesSystem No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)aNo ratings yet

- JacketingDocument9 pagesJacketingsp thipathiNo ratings yet

- Progress in Civil, Architectural and Hydraulic Engineering: Editor: Yun-Hae KimDocument1,447 pagesProgress in Civil, Architectural and Hydraulic Engineering: Editor: Yun-Hae KimLoo Wei Sung100% (1)

- Chapter 1: IntroductionDocument8 pagesChapter 1: IntroductionpraveennagarajanNo ratings yet

- UNIT-3 (Lecture-1) Types of PiersDocument23 pagesUNIT-3 (Lecture-1) Types of PiersSabbir hossain0% (1)

- Permissible Limit For SolidsDocument3 pagesPermissible Limit For SolidssabishanuNo ratings yet

- Research Paper On MetalsDocument5 pagesResearch Paper On Metalsfvg2005k100% (1)

- Silo PresentationDocument21 pagesSilo PresentationCrislynNo ratings yet

- Cement Composition and Special Cements - Part 2Document14 pagesCement Composition and Special Cements - Part 2Kaushal KumarNo ratings yet

- Bata Ringan, Beton Ringan, CLC Block, Foam Generator, Foam Concrete, Foaming Agent, Cetakan Plastik, Pompa Beton Ringan, Precast Panel Beton RinganDocument5 pagesBata Ringan, Beton Ringan, CLC Block, Foam Generator, Foam Concrete, Foaming Agent, Cetakan Plastik, Pompa Beton Ringan, Precast Panel Beton RingantakaraqigongNo ratings yet

- Methods of Test For Mortat For MasonryDocument10 pagesMethods of Test For Mortat For MasonryAndini Wijaya100% (1)

- GB 175 2007Document42 pagesGB 175 2007HCM Office NSCCNo ratings yet

- JK - Literature - 226 English PDFDocument4 pagesJK - Literature - 226 English PDFSantoshkumar GurmeNo ratings yet

- HARSCO Utility PDFDocument20 pagesHARSCO Utility PDFperacNo ratings yet