Professional Documents

Culture Documents

GSA Cordilleran MinSep Poster2013

GSA Cordilleran MinSep Poster2013

Uploaded by

Master Geologia UsalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GSA Cordilleran MinSep Poster2013

GSA Cordilleran MinSep Poster2013

Uploaded by

Master Geologia UsalCopyright:

Available Formats

Zircon and Apatite Separation Using a Spiral Panning Table: Evaluation of Time and Yield Efficiency May 21,

May 21, 2013

Student Researchers: Brittany Fagin and Ashley Edwards Abstract No: 219530

Type of Session: Poster

Research Advisor: Dr. Chris Mattinson Session Number 27: “T6. Using Detrital Zircon Age Data to Reassemble the Cordilleran Jigsaw Puzzle”

Session Start Time: 1:30 PM

Affiliation: Central Washington University, Ellensburg, WA Location: Radisson Hotel and Conference Center, Salon B/C

Poster Booth Number: 15

ABSTRACT METHODS SECOND - The control sample bag is processed with a Frantz Isodynamic Magnetic Separator. RESULTS

7) 8) 8) The non-magnetic

FIRST - All sample fractions received the same treatment before picking a control. portion was directed

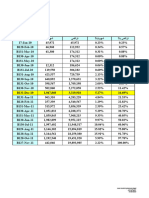

Mineral separations concentrate the heavy minerals apatite and zircon All values in graphs are normalized to 1 kg sample.

by gravity into the

necessary to accurately date rock samples, but current methods are 1) 2) 3) Dixie cup on the left

time-consuming, toxic, expensive, and have unknown yield efficiencies. To and the magnetic 13.34

evaluate and improve separation methods, I processed five, ~1.4 kg portion was directed

1388 min

samples (hornblende-biotite tonalite, 65.47 wt % SiO2, 137 ppm Zr, 0.138 by electromagnetism 37 Zircon and Apatite

113

wt % P2O5, collected from the Mt. Stuart Batholith near Leavenworth, WA; into the Dixie cup on Yield / Total Time for

16

expected yields per kg, calculated from CIPW-norm: 300 mg zircon; 3200 the right. Each Trial - This graph

mg apatite) with a new procedure using a spiral panning table (panner) to shows the relationship

wash and pre-concentrate heavy minerals before magnetic, lithium between the zircon and

7) The control (Bag #3), after apatite yields for each

polytungstate (LST) and methylene iodide (MEI) heavy liquid separations. handwashing, was magnetically

The control sample (#3) was hand washed, separated magnetically, and trial, cross-referenced 4.79 4.68

separated with a Frantz with the amount of

processed with LST and MEI, resulting in 33.5 mg zircon and 308.9 mg 1) Chunks of sample fresh from the 2) Sledge hammer, to break sample into 3) Sample pieces were then ground into Isodynamic Magnetic Separator. time for each step. 2.98

apatite. Panner trial #1 used a fast sample feed rate (58.4 g/min) and slow outcrop. ~1 in. diameter pieces (sieve at bottom >500 micron bits. 1099 1.77 1.74

1.43 1.65

rotation speed (13.7 rpm), resulting in 3.7 mg zircon and 1.0 mg apatite. of image). 9) 10) 0.81

0.39

Panner trial #2 used a slow sample feed rate (11.5 g/min), the same slow

rotation speed as trial #1, and yielded 6.1 mg zircon and 6.0 mg apatite. 4) 5) MEANWHILE - Thin section preparation +

Whole-rock geochemistry

Surfactant was used in panner trial #4 to cut surface tension along with a

slow feed rate of 9.1 g/min and the same slow rotation speed as trial #1,

6) 207 min

6 251 min

37

yielding 6.9 mg zircon and 3.4 mg apatite. Last, panner trial #5 used a faster 156 min

6 37 15 15

8

165 min

6 10 6 37

rotation speed (24.7 rpm) and a fast feed rate (36.2 g/min), which produced 9

37

21

22

125 21 4

8

308.9

87

38 126 44

the highest yields: 13.2 mg zircon, 12.9 mg apatite. Compared with the 46 46 46 46

expected yields (above), the yields from both control (~50% purity

separates containing 33.5 mg zircon, 308.9 mg apatite) and panner trials Total Zircon and

(high-purity separates containing 3.7-13.2 mg zircon, 1.0-12.9 mg apatite) Times per Step per Trial - This graph shows the individual times for each step of each Apatite Yields (mg) -

9) This rock sample fortuitously showed

method tested (shows only run-time; set-up and clean-up are assumed to be the same This graph shows the 33.5

were much less, likely due to the loss of small grains and inclusions. The a color difference between the

4) Then sieved to 250 microns. 5) Example of sample divided into for each process). amount of zircon and

panner technique yielded 10x the concentration of zircon than the control, non-magnetic minerals (beaker on the

so toxic MEI would ideally not be needed to separate apatite from zircon in fractions ~1.4 kg. Bag #3 was used as the left) and the magnetic minerals (Dixie 10) Inner processes of the Frantz magnet. apatite yielded from

future projects, making this project’s protocol safer than current methods. control. cup on the right). Also, the difference of Sample flows from right to left. Significant Zircon Purity Difference each method. Control

6) Researcher Brittany cutting a billet apatite yield is too

The experimental process took ~7 hours per sample, compared to ~38 amounts between the non-magnetic

for thin section preparation. large to fit the graph. 12.9 13.2

hours for the control. The greater speed, improved zircon concentration, and the magnetic portions is shown in

THIRD - SPIRAL PANNING - How does it work?

and avoidance of toxic heavy liquids are significant advantages of the this image. FINALLY - Control #3 Zrc Yield 6.9

6.0 6.1

methods in this project similar to the larger, more expensive Gemeni table, 11) 11) Pro-Camel 24 by Camel Heavy Liquid Separations 3.7 3.4

and further development will improve recovery efficiency. Mining Products. Samples Control trial MEI heavy mineral 1.0

Zrc

are fed through the yellow yield. Fewer discernible zircons

16) 16) Set up for lithium 18) alongside many unidentified

funnel and the rotation is polytungstate (LST)

clock-wise. “Lighter” minerals clear-to-white minerals. (Lower

THE PROCESS are washed away and

separation. Image

purity, ~50%).

shows control sample;

Common Beginning Steps collected in the blue bucket. note high quantity of Ttn?

-Hammering, crushing, grinding, sieving (500 µm) Copper bar has water sample remaining at

CONCLUSIONS

-De-magging (remove metal from sample after grinding) nozzles wetting the panner this step.

-Divide sample into ~1.4 kg bags during processing. 14) In conclusion:

14) Panner trials resulted in 1) We were able to improve yield quantity and purity with the use of

Control Panner Trials 13) the spiral panning table.

smaller concentrated portions of

-Sample processed on panner (each heavy minerals to be processed 18) Methylene iodide separation. 2) We were able to modify the panner process to significantly improve

later by the Frantz magnet. 17) Amount of samples and liquid are small. efficiency and yield with each progressive step.

trial varied parameters; feed-rate,

rotation-speed, water-nozzle flow 15) Panner #5 Zrc Yield 3) The control method yielded the largest amount of zircon, but the

-rate/direction, surfactant) quantity was less pure and the process required more time.

-250 µm sieve -Ultrasonic wash (DI water); small ZRC

-Ultrasonic wash (DI water); large volume Panner trials MEI heavy 4) For the majority of the samples, the spiral panning table is

volume -250 µm sieve

Ttn? mineral yield. Much higher preferred for its quicker time, higher yield purity, and the added

-Frantz Isodynamic Magnetic -Frantz Isodynamic Magnetic proportion of zircons to other bonus of possibly skipping the MEI step (this would improve safety

heavy minerals. (Higher purity,

Separator Separator

near ~100%). Note: zircon

because MEI is highly toxic).

-Ultrasonic wash (DI water) -Ultrasonic wash (DI water) 19) Zrc 5) Note that the times displayed in the results section do not include

-Lithium Polytungstate (LST) heavy -Lithium Polytungstate (LST) heavy grain size is larger, possibly due

liquid separation liquid separation

12) 19) Pipetting the final to preferential loss of smaller the time needed to recover the LST and MEI heavy liquids,

-Ultrasonic wash (Ultra-Pure water) -Ultrasonic wash (Ultra-Pure water) batch of heavy minerals grains during panning. contributing to the conclusion that the panner method is better

12) Fortunately, our rock 13) Heavies are transported up

-Methylene Iodide (MEI) heavy liquid -Methylene Iodide (MEI) heavy liquid 15) Microscopic view of heavy yield from the MEI into the filter (very large quantities of LST were needed to process the control

sample showed a prominent the grooves to the center hole

separation separation straight from the panner after drying. of a flask for collection.

color difference between the and depositied in a beaker. 17) Researcher Ashley is excited to see sample; the same amount of liquid was used to process all of the

-Ultrasonic wash (Acetone) -Ultrasonic wash (Acetone) Zircon grain present in the center.

“light” minerals and the zircons sinking through the next heavy panner samples).

-Weigh zircon and apatite yields -Weigh zircon and apatite yields “heavy” minerals. liquid. “It’s raining zircons!”

You might also like

- BSBPMG530 - Assessment Task 1Document13 pagesBSBPMG530 - Assessment Task 1luciana menghiniNo ratings yet

- BSBCMM511 - Assessment Task 1Document13 pagesBSBCMM511 - Assessment Task 1luciana menghini100% (1)

- Baseline Risk Assessment For Cable JointsDocument2 pagesBaseline Risk Assessment For Cable Jointskwanela koniNo ratings yet

- Vehicle Body Engineering and Safety NotesDocument143 pagesVehicle Body Engineering and Safety NotesRoney Mathew78% (9)

- Astm A131Document6 pagesAstm A131banglvhNo ratings yet

- As 2012326Document2 pagesAs 2012326wr5nsghsc9No ratings yet

- Analisis UAS PKN 6Document2 pagesAnalisis UAS PKN 6Aba BilNo ratings yet

- BEDD212DSTDocument152 pagesBEDD212DSTkhanmikail1994No ratings yet

- Transcript February 2021Document3 pagesTranscript February 2021api-495543740No ratings yet

- UTT Student HandbookDocument56 pagesUTT Student HandbookAriey MaQueenNo ratings yet

- (2016) Production of Cutaneous Vitamin D3 After UVB Radiation in Reptiles and AmphibiansDocument20 pages(2016) Production of Cutaneous Vitamin D3 After UVB Radiation in Reptiles and AmphibiansVulpesNo ratings yet

- BEDD107CCT July4Document80 pagesBEDD107CCT July4Mahesh RathoreNo ratings yet

- Characterising Early and Late Return To Work Following TbiDocument36 pagesCharacterising Early and Late Return To Work Following TbikhaledNo ratings yet

- H&R InsuranceDocument3 pagesH&R InsurancercbstocksNo ratings yet

- AsdfghjiklmnbvcxzDocument6 pagesAsdfghjiklmnbvcxzSampath KumarNo ratings yet

- Leflet PKB 77 Simpo - WorkshopDocument2 pagesLeflet PKB 77 Simpo - WorkshopAidaDesNo ratings yet

- Answer Sheet: P3 Credit 3B Book Unit 13 Page 38-46Document2 pagesAnswer Sheet: P3 Credit 3B Book Unit 13 Page 38-46Indah PuspitaNo ratings yet

- Answer Sheet: P3 Credit 3B Book Unit 13 Page 38-46Document2 pagesAnswer Sheet: P3 Credit 3B Book Unit 13 Page 38-46Indah PuspitaNo ratings yet

- Analisis Soal Sas 2 MuzdalifahDocument6 pagesAnalisis Soal Sas 2 Muzdalifahlelipd11No ratings yet

- Layout Karawang Parking LotDocument1 pageLayout Karawang Parking Lotjohanhsr5No ratings yet

- Diu Internship Report2 JK ReviewedDocument40 pagesDiu Internship Report2 JK ReviewedNguyen Thanh DiuNo ratings yet

- Tugas Utama (Nama Program / Aktiviti Tarikh SasaranDocument1 pageTugas Utama (Nama Program / Aktiviti Tarikh SasaranjulizaNo ratings yet

- National University of Study and Research in Law RanchiDocument25 pagesNational University of Study and Research in Law RanchiANIRUDHNo ratings yet

- Complete DissertationDocument240 pagesComplete DissertationAriSuandiNo ratings yet

- MBA ProjectDocument32 pagesMBA ProjectHemali RameshNo ratings yet

- Analisis UAS MTK 6Document2 pagesAnalisis UAS MTK 6Aba BilNo ratings yet

- Kaikaku in ManufacturingDocument83 pagesKaikaku in Manufacturingintelrams100% (1)

- ABSTRACT ART IN ABSTRACT REALITY Cecilia PDFDocument43 pagesABSTRACT ART IN ABSTRACT REALITY Cecilia PDFveekshiNo ratings yet

- Praxis ResultsDocument4 pagesPraxis Resultsapi-738568377No ratings yet

- Mpeomo 2022Document35 pagesMpeomo 2022arkondxNo ratings yet

- Setp 1 AdviceDocument101 pagesSetp 1 AdviceStorage Liz100% (1)

- Polifer - PT - Report 001 - Elias JarjouraDocument1 pagePolifer - PT - Report 001 - Elias JarjouraElias JarjouraNo ratings yet

- Ashraf Gabr: Cost Control Planning Dept 10/29/2023Document2 pagesAshraf Gabr: Cost Control Planning Dept 10/29/2023mr789918No ratings yet

- Installation Instruction of Outdoor Manifold (B) : Component ListDocument2 pagesInstallation Instruction of Outdoor Manifold (B) : Component ListLogistica FriochapNo ratings yet

- Redes de Desague 2Document1 pageRedes de Desague 2Kevin Pinedo LoayzaNo ratings yet

- AICTE Training and Learning (ATAL) Academy Sponsored Computational Biology and Algorithms Under Thrust Area Computational Science and BiologyDocument2 pagesAICTE Training and Learning (ATAL) Academy Sponsored Computational Biology and Algorithms Under Thrust Area Computational Science and BiologyBaponNo ratings yet

- Protocolo de manejo baseado em consenso (protocolo CREVICE) para o tratamento de lesão cerebral traumática grave com base em imagens e exame clínico para uso quando o monitoramento da pressão intracraniana não é empregadoDocument61 pagesProtocolo de manejo baseado em consenso (protocolo CREVICE) para o tratamento de lesão cerebral traumática grave com base em imagens e exame clínico para uso quando o monitoramento da pressão intracraniana não é empregadoMaiquiel MaiaNo ratings yet

- Neu.2017.5599 - NICE PaperDocument61 pagesNeu.2017.5599 - NICE PaperGregory MillánNo ratings yet

- BED105CCT July4Document100 pagesBED105CCT July4TAUSIF RAZANo ratings yet

- Cab - Dash Cab - Rear Interior Air Conditioner: Electrical System 798 AC HAA Off-Highway TruckDocument16 pagesCab - Dash Cab - Rear Interior Air Conditioner: Electrical System 798 AC HAA Off-Highway TruckAlejandro JaraNo ratings yet

- Village Status of VelpuruDocument7 pagesVillage Status of VelpuruAnonymous fC8a2AlwNo ratings yet

- Breaking Binge - Exploring The Effects of Binge Watching On TelevDocument88 pagesBreaking Binge - Exploring The Effects of Binge Watching On TelevGustavo PadovaniNo ratings yet

- Sentron: Technological Leader Amongst The Circuit-Breakers: SENTRON CommunicationDocument186 pagesSentron: Technological Leader Amongst The Circuit-Breakers: SENTRON Communicationsatelite54No ratings yet

- CannizzaroDocument1 pageCannizzaroMarcello Di LorenzoNo ratings yet

- Answered - in An Air Standard Brayton Cycle The - BartlebyDocument1 pageAnswered - in An Air Standard Brayton Cycle The - BartlebyGabriel TraceNo ratings yet

- Seeds Lesson Plan Template Revised2 2 1Document5 pagesSeeds Lesson Plan Template Revised2 2 1api-548717522No ratings yet

- Masters And: MethodsDocument102 pagesMasters And: MethodsHernán Mosquera100% (1)

- Action Observation and Mirror Neuron Network: A Tool For Motor Stroke RehabilitationDocument7 pagesAction Observation and Mirror Neuron Network: A Tool For Motor Stroke RehabilitationElias VillalonNo ratings yet

- Gambar D I BulelengDocument46 pagesGambar D I BulelengFadli FadliNo ratings yet

- Design and Construction of A Solar Water Purification System Usin PDFDocument39 pagesDesign and Construction of A Solar Water Purification System Usin PDFRajNo ratings yet

- Scorereport 29 - Rve ScoreDocument4 pagesScorereport 29 - Rve Scoreapi-486190068No ratings yet

- Karlien Vanhouteghem, Annelies Aerssens, Dirk Ommeslag, Jerina Boelens, Steven Callens, Anne-Marie Van Den AbeeleDocument1 pageKarlien Vanhouteghem, Annelies Aerssens, Dirk Ommeslag, Jerina Boelens, Steven Callens, Anne-Marie Van Den AbeeleAfien MuktiNo ratings yet

- BSBPMG633 Task 1 - BDocument12 pagesBSBPMG633 Task 1 - Bluciana menghiniNo ratings yet

- WEC Technical ProgramDocument3 pagesWEC Technical ProgramjulesjusayanNo ratings yet

- Fact Sheet 2015 2016: Exchange ProgramDocument6 pagesFact Sheet 2015 2016: Exchange ProgramdavidNo ratings yet

- 1 Interim ReportDocument29 pages1 Interim ReportPiyush sharmaNo ratings yet

- 12 HUMSS 1 Composite S.Y 2019-2020Document32 pages12 HUMSS 1 Composite S.Y 2019-2020Darwin RonquilloNo ratings yet

- Instructure Canvas Pilot Project Spring 2013 Final ReportDocument37 pagesInstructure Canvas Pilot Project Spring 2013 Final ReportP PNo ratings yet

- 3.3.1 & 3.3.2 F-138 Training Matrix and Record HSEDocument1 page3.3.1 & 3.3.2 F-138 Training Matrix and Record HSEAbuAbdullah KhanNo ratings yet

- Ethical Issues in Takata Airbag RecallDocument19 pagesEthical Issues in Takata Airbag RecallNadya TheodoraNo ratings yet

- Vi Sem Award Sheet Consolidated It-3rd YearDocument1 pageVi Sem Award Sheet Consolidated It-3rd Yearbhediya45No ratings yet

- Material System Analyses 9 Materials 10052021 Final-Version3Document66 pagesMaterial System Analyses 9 Materials 10052021 Final-Version3Master Geologia UsalNo ratings yet

- 1 s2.0 S0012821X19301979 MainDocument13 pages1 s2.0 S0012821X19301979 MainMaster Geologia UsalNo ratings yet

- Heavy Minerals and Magnetic SeparationDocument5 pagesHeavy Minerals and Magnetic SeparationMaster Geologia UsalNo ratings yet

- Tablas Frantz y DensidadesDocument10 pagesTablas Frantz y DensidadesMaster Geologia UsalNo ratings yet

- MC Clenaghan 2011 ProcessingmethodsDocument15 pagesMC Clenaghan 2011 ProcessingmethodsMaster Geologia UsalNo ratings yet

- Suma Bac Conc. D10 DSDocument2 pagesSuma Bac Conc. D10 DSMustafa AdelNo ratings yet

- Advancess in Traditional Indian Dairy Products AssignmentDocument18 pagesAdvancess in Traditional Indian Dairy Products AssignmentTULLIMILLI CHANIKYA VENKAT KRISHNA SAI 2200268No ratings yet

- Reversible Reactions QDocument3 pagesReversible Reactions QVictor DyzeNo ratings yet

- Thermaline 1248 PDSDocument3 pagesThermaline 1248 PDSGudang PagardewaNo ratings yet

- 4 Bonding P1Document19 pages4 Bonding P1mostafa barakatNo ratings yet

- Difference Between Meq and MmolDocument5 pagesDifference Between Meq and MmolAndrei LeuNo ratings yet

- Public Summary: 1 - Ashanti Exotic Ostrich Oil Spf30+ Lip Protection OintmentDocument2 pagesPublic Summary: 1 - Ashanti Exotic Ostrich Oil Spf30+ Lip Protection OintmentRadoNo ratings yet

- Kerakoll Bio Tile AdhesiveDocument5 pagesKerakoll Bio Tile AdhesivemaheshNo ratings yet

- FOB2-3 TS - Technical Manual - Section 5 - MaintenanceDocument100 pagesFOB2-3 TS - Technical Manual - Section 5 - MaintenancemaghraouiNo ratings yet

- Seats and Seals Selection Guide: Share ThisDocument4 pagesSeats and Seals Selection Guide: Share ThisArjed Ali ShaikhNo ratings yet

- LAL Kinetic-QCLDocument32 pagesLAL Kinetic-QCLSykat ZamanNo ratings yet

- E-Learning Program CH-1: "Food Processing"Document42 pagesE-Learning Program CH-1: "Food Processing"Rohit Ramesh KaleNo ratings yet

- FIRE Extinguisher / FIRE Igniter LAB: NAME - PER - MAILBOX # - DUE DATEDocument9 pagesFIRE Extinguisher / FIRE Igniter LAB: NAME - PER - MAILBOX # - DUE DATEMacaraeg, Janea MaeNo ratings yet

- 3M Scotchlite Reflective Material Fabrics - TDS April, 2018.Document8 pages3M Scotchlite Reflective Material Fabrics - TDS April, 2018.Ricardo GutiérrezNo ratings yet

- Grade 11 Science 2nd Term Test Paper 2019 English Medium - North Western ProvinceDocument23 pagesGrade 11 Science 2nd Term Test Paper 2019 English Medium - North Western ProvinceNethu NethuNo ratings yet

- IB Chemistry: Unit 4 Stoichiometry QuestionsDocument37 pagesIB Chemistry: Unit 4 Stoichiometry QuestionsmjohnmccNo ratings yet

- Building Life CycleDocument10 pagesBuilding Life CyclefarhanadNo ratings yet

- Organic Food and It's AdvantagesDocument6 pagesOrganic Food and It's AdvantagesIonicNo ratings yet

- Chemistry Holiday Homework Project For CBSE: Dry Fruit AnalysisDocument37 pagesChemistry Holiday Homework Project For CBSE: Dry Fruit AnalysisEkasNo ratings yet

- BS EN 3-7 - 2004 Poprtable Fire ExtinguishersDocument48 pagesBS EN 3-7 - 2004 Poprtable Fire ExtinguishersKamagara Roland AndrewNo ratings yet

- Model Answer: Important Suggestions To ExaminersDocument42 pagesModel Answer: Important Suggestions To Examinerskabir bodeleNo ratings yet

- Ion Transport in Solvent Free Polymers (Too Old)Document16 pagesIon Transport in Solvent Free Polymers (Too Old)Muhammad SajidNo ratings yet

- Removal of Heavy Metals From Sewage SludgeDocument8 pagesRemoval of Heavy Metals From Sewage SludgeCristian CarrascoNo ratings yet

- Eesh Paper PDFDocument4 pagesEesh Paper PDFEesh Kumar TanejaNo ratings yet

- 06 - To Compare The Enthalpies of Solution of A Salt in Its Anhydrous and Hydrated StatesDocument2 pages06 - To Compare The Enthalpies of Solution of A Salt in Its Anhydrous and Hydrated StatesBeyonce Noel100% (2)

- Composites C: Open Access: Jamileh Shojaeiarani, Dilpreet S Bajwa, Saptaparni ChandaDocument22 pagesComposites C: Open Access: Jamileh Shojaeiarani, Dilpreet S Bajwa, Saptaparni ChandaTami TomNo ratings yet

- 1225 TDS Process VespheneDocument4 pages1225 TDS Process VespheneDashh DNo ratings yet

- Weathering and Formation of Soil - PPT - 060751Document19 pagesWeathering and Formation of Soil - PPT - 060751NIKUNJ RAMASHANKAR TRIPATHINo ratings yet