Professional Documents

Culture Documents

Media Charge - Wear - Ball Mills

Media Charge - Wear - Ball Mills

Uploaded by

Pedro RodriguezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Media Charge - Wear - Ball Mills

Media Charge - Wear - Ball Mills

Uploaded by

Pedro RodriguezCopyright:

Available Formats

Moly-Cop Tools, Version 3.

0

About the Media Charge_Wear_Ball Mills Spreadsheet ...

Scope :

The Media Charge_Linear Wear_Ball Mills spreadsheet was designed to estimate the Linear Wear Rate

Constants for a ball charge in a Conventional Ball Mill, as a function of its known dimensions and basic operating

conditions. Also, the spreadsheet allows for the calculation of the typical Grinding Media Consumption Rate

indicators; that is, gr/ton, gr/kWh, kg/hr or tons/month.

Theoretical Framework :

The most widely accepted mathematical description of the gradual consumption process experienced by a grinding

ball inside a tumbling mill is known as the Linear Wear Theory, by which the mass rate of consumption of a grinding

ball is described as directly proportional to the surface area exposed by such ball to the various wear mechanisms

(abrasion and/or corrosion) active in the mill charge environment :

Wt = d(mb)/d(t) = - km Ab

where :

Wt = mass wear rate, kg/hr

mb = ball weight, kg; after t hours of being charged into the mill.

Ab = exposed ball area, m 2

km = mass wear rate constant, kg/hr/m2.

Equivalently, taking into account the geometry of the grinding body (sphere or cylinder), one obtains :

d(d)/d(t) = - 2 km / rb = - kd

where :

d = size (diameter) of the grinding ball, mm; after t hours of being charged into the mill.

rb = grinding ball density, ton/m3

kd = wear rate constant, mm/hr.

If kd is to remain unaffected by the extent of wear; that is, kd is not a function of the current ball size d - a condition

satisfied by most grinding media varieties and normally referred to as Linear Wear Kinetics - the above expression

may be simply integrated to obtain :

d = dR - kd t

where dR represents the initial size of the balls.

For any given grinding media variety, the constant kd becomes an indicator of its relative quality, as compared to

other alternative products.

Moly-Cop Tools / 625016131.xlsx 11/09/2022 / 15:17:09

Moly-Cop Tools, Version 3.0

About the Media Charge_Wear_Ball Mills Spreadsheet ...

By direct analogy to mineral particle breakage kinetics, it is postulated that an even more representative and

scaleable quality indicator is the Energy Specific Wear Rate Constant [kdE, mm/(kWh/ton)], defined through the

expression :

kd = kdE (Pb/Wb) / 1000

where the ratio (Pb/Wb) corresponds to the contribution (Pb) of every ton of balls in the charge (Wb) to the total power

draw (Pnet) of the mill. The underlying theoretical claim is that grinding balls will wear faster in a more energy

intensive environment. Therefore, kdE is expected to be more insensitive than kd to variations in mill operating

conditions (that may affect Pb and/or Wb). As a practical evaluation criterion, it should be then accepted that the

top quality grinding media, in any given application, will be the one that exhibits the lowest value of the

wear rate constant kdE.

The above expression creates the need for a theoretical representation of the Mill Power Draw and how each

component of the mill charge (balls, rocks and slurry) contribute to this power demand. The simple Hogg and

Fuerstenau model serves such purpose well (see Spreadsheet Mill Power_Ball Mills).

Then the traditional Grinding Media Consumption Indicators may be obtained from the expressions :

[4000 k W ]d b

Wt = ________________________

dR [ 1 – (dS/dR)4]

where dS represents the average size of the metal scrap being rejected by the mill. Also :

WE = 1000 Wt /Pgross , in gr/kWh

WM = WE E , in gr/ton

where E represents the Specific Energy Consumption of the operation, normally expressed in kWh per ton of ore

ground.

Recently, H. Benavente (Moly-Cop 2006 : X Simposio sobre Procesamiento de Minerales, Termas de Chillán, Chile)

proposed an empirical correlation for the calculation of kdE, as a function of the Bond's Abrasion Index (54th

Annual Meeting of AICHE, 1963) of the ore, the F80 feed size and the slurry pH :

kdE = kdB [(AI - 0.02)/0.2]0.331 (F80/5000)0.13 (pH/10)-0.677

where kdB is known as the Benavente Constant.

Moly-Cop Tools / 625016131.xlsx 11/09/2022 / 15:17:09

Moly-Cop Tools / 625016131.xlsx 11/09/2022 / 15:17:09

Moly-Cop Tools TM

(Version 3.0)

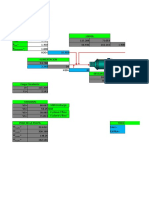

DETERMINATION OF WEAR RATE CONSTANTS

Special Case : BALL MILLS

Remarks Base Case Example

Power, kW

Mill Dimensions and Operating Conditions 3,348 Balls

Diameter Length Mill Speed Charge Balls Interstitial Lift 0 Overfilling

ft ft % Critical Filling,% Filling,% Slurry Filling,% Angle, (°) 536 Slurry

18.50 22.00 72.00 38.00 38.00 100.00 35.00 3,885 Net Total

rpm 12.82 10.00 % Losses

% Utilization hr/month 4,316 Gross Total

% Solids in the Mill 72.00 97.00 698 3,014 MWh/month

Ore Density, ton/m3 2.80

Slurry Density, ton/m3 1.86 Charge Mill Charge Weight, tons Apparent

Balls Density, ton/m3 7.75 Volume, Ball Slurry Density

m3 Charge Interstitial above Balls ton/m3

Ore Feedrate, ton/hr 400.0 63.76 296.48 47.48 0.00 5.395

ton/day 9,312

Energy, kWh/ton (ore) 10.79 Ball Recharge Rate

gr/ton gr/kWh (gross) gr/kWh (balls) Kg/hr tons/month

Make-up Ball Size, mm 75.0 625.4 57.96 74.72 250.2 175

Scrap Size, mm 12.0

Wear Rate Constants:

Spec. Area, m2/m3 (app) 63.78 kdE, mm/[kWh(balls)/ton(balls)] 1.400

Total Charge Area, m2 4067 kd, mm/hr 0.0158

Purge Time, hrs 3,985 Benavente

Bond's AI Feed Size, F80 Slurry pH Constant, kdB

0.302 5000 10.5 1.292

Moly-Cop Tools / 625016131.xlsx 11/09/2022 / 15:17:09

You might also like

- Toronto Construction Association Phone and Address DirectoryDocument806 pagesToronto Construction Association Phone and Address DirectoryDar Ger75% (4)

- Machin Dynamic Foundations Xe2ddDocument20 pagesMachin Dynamic Foundations Xe2ddSuresh nathanNo ratings yet

- Basic Drilling Calculations - FullDocument56 pagesBasic Drilling Calculations - FullMohamed Kamal100% (1)

- Activity Proposal - Trade Fair2018Document12 pagesActivity Proposal - Trade Fair2018Yuki Nakata100% (2)

- GR/KWH, KG/HR or Tons/Month.: ScopeDocument5 pagesGR/KWH, KG/HR or Tons/Month.: ScopeThaigroup CementNo ratings yet

- Media Charge - Linear Wear - Ball MillsDocument5 pagesMedia Charge - Linear Wear - Ball MillsLuis Katsumoto Huere AnayaNo ratings yet

- Media Charge - Linear Wear - Ball MillsDocument5 pagesMedia Charge - Linear Wear - Ball MillsLuis Katsumoto Huere AnayaNo ratings yet

- Media Charge - Wear - Non-LinearDocument85 pagesMedia Charge - Wear - Non-LinearPedro Rodriguez100% (1)

- Bond Mill ThroughputDocument5 pagesBond Mill ThroughputAnonymous TsKN7XZBNo ratings yet

- Bond Mill Throughput10X10Document5 pagesBond Mill Throughput10X10Flia Diaz Zuniga100% (1)

- Media Charge - Dynamics - SAG MillsDocument31 pagesMedia Charge - Dynamics - SAG Millsedwin javier valdivia guillenNo ratings yet

- Bonds Law ApplicationDocument1 pageBonds Law ApplicationDanny joaquinNo ratings yet

- Scope:: About The Mill Power - SAG Mills Spreadsheet ..Document4 pagesScope:: About The Mill Power - SAG Mills Spreadsheet ..percyNo ratings yet

- Mill Power - Ball MillsDocument6 pagesMill Power - Ball MillsPedro RodriguezNo ratings yet

- Bond - Op. Work Index (HGE SRL)Document3 pagesBond - Op. Work Index (HGE SRL)Pedro RodriguezNo ratings yet

- Media Charge Dynamics Ball MillsDocument31 pagesMedia Charge Dynamics Ball Millsedwin javier valdivia guillenNo ratings yet

- Especialización en Molienda de Minerales: Por: Moly-Cop Adesur S.ADocument100 pagesEspecialización en Molienda de Minerales: Por: Moly-Cop Adesur S.AHector Bolaños100% (1)

- Mill Power SAG MillsDocument7 pagesMill Power SAG MillsJheny MattaNo ratings yet

- Mill Power Ball MillsDocument5 pagesMill Power Ball MillsCarlos de la TorreNo ratings yet

- Mill Power - Rod MillsDocument4 pagesMill Power - Rod MillsFredy PeñaNo ratings yet

- Media Charge - Wear - PredictorDocument12 pagesMedia Charge - Wear - PredictorPedro RodriguezNo ratings yet

- RyB Group - Molycop IIIDocument114 pagesRyB Group - Molycop IIIBrianNo ratings yet

- Media Charge Wear Rod MillsDocument3 pagesMedia Charge Wear Rod MillspolsiemprealdoNo ratings yet

- Media Charge - Optimal Ball SizeDocument6 pagesMedia Charge - Optimal Ball SizeMetalurgia ProcesosNo ratings yet

- Mediacharge Wear PredictorDocument7 pagesMediacharge Wear PredictorHazem DiabNo ratings yet

- Mediacharge OptimalballsizeDocument4 pagesMediacharge OptimalballsizeHoàng HùngNo ratings yet

- Media Charge - Wear & Impact - SAG MillsDocument9 pagesMedia Charge - Wear & Impact - SAG MillsAldo PabloNo ratings yet

- Rotary Blast Hole DrillsDocument4 pagesRotary Blast Hole DrillsRodolfoNo ratings yet

- Overall MEB HI HJ HSCDocument61 pagesOverall MEB HI HJ HSCPhan SNo ratings yet

- 5.10 Ground Support Slab-TR34Document11 pages5.10 Ground Support Slab-TR34Vũ Hà Mai Lê100% (3)

- 106-E-01 (Netralizing Unit) - TEMA SheeDocument1 page106-E-01 (Netralizing Unit) - TEMA SheeMekar MeinaNo ratings yet

- Calculation Memory TailingsDocument13 pagesCalculation Memory TailingsjordanNo ratings yet

- BK 4 (CC 51400)Document9 pagesBK 4 (CC 51400)hasan arifNo ratings yet

- Sample Heat Exchanger Spec SheetDocument2 pagesSample Heat Exchanger Spec SheetKBNo ratings yet

- Heat Exchanger Rating Data Sheet SI Units: C:/Users/Berta/Desktop/Intercambiador E-101.htriDocument1 pageHeat Exchanger Rating Data Sheet SI Units: C:/Users/Berta/Desktop/Intercambiador E-101.htriEduardoNo ratings yet

- Storage Tank Foundation DesignDocument15 pagesStorage Tank Foundation DesignDeny AristyaNo ratings yet

- Htri PDFDocument1 pageHtri PDFLuigy L-a100% (1)

- Media Charge - Ball Size & DensityDocument3 pagesMedia Charge - Ball Size & DensityIrving Dirzo CarrilloNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetWael BadriNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoNo ratings yet

- Construction and Application of A New TPH Model For Caserones Concentrator - Magin TorresDocument11 pagesConstruction and Application of A New TPH Model For Caserones Concentrator - Magin TorresNicolas PerezNo ratings yet

- I-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Document5 pagesI-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Martin DanzeNo ratings yet

- Agitator - Ag-C8-102Document4 pagesAgitator - Ag-C8-102uttam prabhuNo ratings yet

- E. G. Brush: Burn UpDocument2 pagesE. G. Brush: Burn Uptanzil10No ratings yet

- Hydrogen BookletDocument250 pagesHydrogen Bookletjiji1183No ratings yet

- Weaver Heat Transfer Technologies DATA SHEET 1Document1 pageWeaver Heat Transfer Technologies DATA SHEET 1Bhavin PatelNo ratings yet

- File: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Document14 pagesFile: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Camila Florencia ScarlatoNo ratings yet

- Wood - EmissionsDocument1 pageWood - EmissionsRufus D SNo ratings yet

- ОЛ №3 от 12062020 PDFDocument3 pagesОЛ №3 от 12062020 PDFВалентин СелищевNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetWael BadriNo ratings yet

- 1 PDFDocument1 page1 PDFWael BadriNo ratings yet

- Steam Heater E-002Document2 pagesSteam Heater E-002vidyaNo ratings yet

- 3PPD ShaPhiDocument7 pages3PPD ShaPhiPhilip Anthony MasilangNo ratings yet

- Design (Metric) 5 (1) .37Document7 pagesDesign (Metric) 5 (1) .37Huy NguyenmbvNo ratings yet

- Data Sheet E41001Document6 pagesData Sheet E41001BFEVietnamNo ratings yet

- CBD For Crushed Aggregate (Mille-Galafi)Document13 pagesCBD For Crushed Aggregate (Mille-Galafi)Solomon MehariNo ratings yet

- Consub TemaDocument1 pageConsub TemaMAYANK AGRAWALNo ratings yet

- Material Stream: Propane & Butane: ConditionsDocument2 pagesMaterial Stream: Propane & Butane: Conditionsالم زمانNo ratings yet

- UntitledDocument235 pagesUntitledUsman HayderNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9: File: Printed: 24-08-2019 at 10:29:26 PM Overall SummaryDocument1 pageAspen Exchanger Design and Rating Shell & Tube V9: File: Printed: 24-08-2019 at 10:29:26 PM Overall Summarymohit kumarNo ratings yet

- BSP Plant Performance 60th TISCO JamshedpurDocument22 pagesBSP Plant Performance 60th TISCO JamshedpurBinod Kumar Padhi100% (1)

- Mill Power - Ball MillsDocument6 pagesMill Power - Ball MillsPedro RodriguezNo ratings yet

- Media Charge - Wear - Non-LinearDocument85 pagesMedia Charge - Wear - Non-LinearPedro Rodriguez100% (1)

- Media Charge - Wear - PredictorDocument12 pagesMedia Charge - Wear - PredictorPedro RodriguezNo ratings yet

- Balance ZarandaDocument4 pagesBalance ZarandaPedro RodriguezNo ratings yet

- Ba - Masa Con DensidadesDocument9 pagesBa - Masa Con DensidadesPedro RodriguezNo ratings yet

- Bond - Op. Work Index (HGE SRL)Document3 pagesBond - Op. Work Index (HGE SRL)Pedro RodriguezNo ratings yet

- Granulometrico Mod Hge FinalDocument50 pagesGranulometrico Mod Hge FinalPedro RodriguezNo ratings yet

- Unit 4 Basic CiduntDocument108 pagesUnit 4 Basic CiduntPedro RodriguezNo ratings yet

- Name: Luis Alberto Gonzalez Huaynacari: Hat Hat Hat HatDocument2 pagesName: Luis Alberto Gonzalez Huaynacari: Hat Hat Hat HatPedro RodriguezNo ratings yet

- Balance NodalDocument4 pagesBalance NodalPedro Rodriguez100% (1)

- O Joy That in Our EmbersDocument8 pagesO Joy That in Our Embersapi-302591593No ratings yet

- Products Techniques, Inc.: Aircraft Paint Application ManualDocument42 pagesProducts Techniques, Inc.: Aircraft Paint Application ManualOscar Cueva100% (2)

- MDG 1006 Spontaneous Combustion Management GuideDocument21 pagesMDG 1006 Spontaneous Combustion Management GuidedonnypsNo ratings yet

- Quantenoptik Vorlesung5 PDFDocument4 pagesQuantenoptik Vorlesung5 PDFErinSuttonNo ratings yet

- Course Outline Phy 193Document9 pagesCourse Outline Phy 193Akemi KeiNo ratings yet

- Los Temperamentos y Las Artes Magda Lissau PDFDocument221 pagesLos Temperamentos y Las Artes Magda Lissau PDFAni Arredondo100% (1)

- Red Hat Enterprise Linux-6-6.0 Release Notes-En-USDocument38 pagesRed Hat Enterprise Linux-6-6.0 Release Notes-En-USadio77No ratings yet

- Right To Information - Best BookDocument44 pagesRight To Information - Best Bookarvindthakur100% (1)

- Response Based Weather-Routing and Operation Planning of Heavy Transport VesselsDocument9 pagesResponse Based Weather-Routing and Operation Planning of Heavy Transport VesselsKuya Fabio VidalNo ratings yet

- Strength of MaterialsDocument9 pagesStrength of MaterialsAhmad WafiuddinNo ratings yet

- Math Revision Worksheet Grade 5Document3 pagesMath Revision Worksheet Grade 5Kaviya arunNo ratings yet

- (IJCST-V7I3P5) :ankur Baishya, Dr. Sangeeta KakotyDocument4 pages(IJCST-V7I3P5) :ankur Baishya, Dr. Sangeeta KakotyEighthSenseGroupNo ratings yet

- Causes of Resistance To ChangeDocument5 pagesCauses of Resistance To Changegaurav100% (1)

- Quality ControlDocument18 pagesQuality ControlNidaNo ratings yet

- Notes On SuccessionDocument118 pagesNotes On SuccessionWhere Did Macky Gallego100% (3)

- ISO 26000 PresentationDocument21 pagesISO 26000 PresentationcompartimentssmNo ratings yet

- Dropbox (Service) - WikipediaDocument15 pagesDropbox (Service) - WikipediaglennNo ratings yet

- Plastic Limit Test - 004Document8 pagesPlastic Limit Test - 004funky_jebonNo ratings yet

- Too Woomba NewDocument630 pagesToo Woomba NewAshish Bhalla0% (1)

- Special Doll Houses and Special DollsDocument20 pagesSpecial Doll Houses and Special Dollsstefi idlab100% (1)

- Mastering Advanced Analytics With Apache SparkDocument75 pagesMastering Advanced Analytics With Apache SparkAgMa HuNo ratings yet

- Understanding & Using Ansel Adam's Zone SystemDocument34 pagesUnderstanding & Using Ansel Adam's Zone Systemkbza969100% (1)

- De WALL, Martijn. The City As InterfaceDocument9 pagesDe WALL, Martijn. The City As InterfaceAilton de AndradeNo ratings yet

- Simón Armando-Text-Control Sample Insertion Rate-Is There An Industry StandardDocument9 pagesSimón Armando-Text-Control Sample Insertion Rate-Is There An Industry StandardvalyvedNo ratings yet

- NX InstallDocument18 pagesNX Installsukhpreet SinghNo ratings yet

- Chapter 9 Social Stratification Part 2 - PalmesDocument12 pagesChapter 9 Social Stratification Part 2 - PalmesEdgar PeninsulaNo ratings yet

- 4 Gabriele Guscyte & Jolanta Sinkuniene Full TextDocument25 pages4 Gabriele Guscyte & Jolanta Sinkuniene Full TextExamlNo ratings yet

- Tmsa2 PDFDocument34 pagesTmsa2 PDFChander Mehta100% (1)