Professional Documents

Culture Documents

As9100 Procedure 753

As9100 Procedure 753

Uploaded by

ankit75880 ratings0% found this document useful (0 votes)

9 views2 pagesThis document describes a company's process for identifying materials and products throughout production and delivery in 3 steps:

1. Materials and parts received are verified and identified upon receipt. Identification is maintained through production and delivery if required.

2. Products are identified during design to ensure traceability. Requirements are defined in configuration management and quality plans.

3. Unique identifications are applied to products, and processing records are maintained as quality records to provide traceability.

Original Description:

Original Title

as9100-procedure-753

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes a company's process for identifying materials and products throughout production and delivery in 3 steps:

1. Materials and parts received are verified and identified upon receipt. Identification is maintained through production and delivery if required.

2. Products are identified during design to ensure traceability. Requirements are defined in configuration management and quality plans.

3. Unique identifications are applied to products, and processing records are maintained as quality records to provide traceability.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

9 views2 pagesAs9100 Procedure 753

As9100 Procedure 753

Uploaded by

ankit7588This document describes a company's process for identifying materials and products throughout production and delivery in 3 steps:

1. Materials and parts received are verified and identified upon receipt. Identification is maintained through production and delivery if required.

2. Products are identified during design to ensure traceability. Requirements are defined in configuration management and quality plans.

3. Unique identifications are applied to products, and processing records are maintained as quality records to provide traceability.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

MP-753-A

Identification and Traceability

1.0 Purpose

1.1 This procedure describes the process for identifying materials and product

throughout production, service and delivery.

2.0 Responsibilities

2.1 Add your responsibilities here.

3.0 Definitions

3.1 None

4.0 Equipment/Software

4.1 No additional equipment or software required.

5.0 Instructions

5.1 Product identification

5.2 Describe your process for identifying raw materials, parts, product or service.

Companies processes for this procedure vary widely. The following is an

example of how a procedure may look.

5.3 Your Company products are identified and traceability (if required) is provided

through material receipt, production, and delivery.

5.4 During the design phase, product identification is established to ensure

traceability and maintenance of the configuration of the product in order to

identify any differences between the actual configuration and that specified by

contract. Product identification and traceability requirements are defined by a

Configuration Management Plan, Quality Plans or Customer Contract

requirements.

5.5 Materials and parts received by Your Company are verified/identified upon

receipt by means of individual part marking or container marking. Identification

is maintained though the production process and point of delivery as required by

Engineering drawings, work instructions, or contract requirement.

5.6 Your Company product traceability is provided though Production

Documentation, including work order routers, configuration data information for

control of product manufacture, test and inspection.

5.6.1 Product information includes part numbers, drawing revision levels, parts

list revision (as applicable), the project activity number and serialization

as required.

Identification and Traceability Page 1 of 2

Date printed 4/14/09 6:05 PM

MP-753-A

Identification and Traceability

5.6.2 Production Documentation provides a record of operation sequences

including assembly, test, and acceptance Inspection.

5.6.3 Configuration Management, Design Engineering, and/or Manufacturing

Planning define hardware product serialization control and maintenance.

5.6.4 A record of subassemblies and parts contained in the end item product

are identified and maintained as Quality Records.

5.7 A unique identification is applied to individual Your Company products providing

traceability of processing records which are maintained as Quality Records.

5.7.1 Product processing steps including acceptance test and inspection are

annotated by authorized stamps in accordance with documented stamp

control procedures, and controlled signatures, when required.

5.7.2 These records provide evidence that products have passed final

inspection/test with defined acceptance criteria.

5.8 Software product traceability is controlled through product plans and procedures,

and administered by a controlled library maintained by Configuration

Management.

6.0 Forms and Records

6.1 Example: F-xxx-001 Production Traveler

7.0 Attachments

7.1 Identify any attachments

8.0 Related Documents

8.1 Identify any related documents

9.0 References

9.1 None

Identification and Traceability Page 2 of 2

Date printed 4/14/09 6:05 PM

You might also like

- Design Control SOPDocument16 pagesDesign Control SOPMesut Deniz100% (1)

- Management of Product Safety: 6) Esclation Process & Information FlowDocument2 pagesManagement of Product Safety: 6) Esclation Process & Information FlowGiang Luu100% (2)

- Performing An Installation QualificationDocument8 pagesPerforming An Installation QualificationThomasNo ratings yet

- 1list of Procedures & Records As Required by API Q1 (9th Edition) Rev.01Document5 pages1list of Procedures & Records As Required by API Q1 (9th Edition) Rev.01pbalawin43900% (2)

- IATF 16949 Gap Assessment ChecklistDocument7 pagesIATF 16949 Gap Assessment ChecklistBharath100% (1)

- Autoclave Cleaning Log Sheet ExampleDocument23 pagesAutoclave Cleaning Log Sheet Exampleankit7588No ratings yet

- SOP 013 Product Identification and TraceabilityDocument7 pagesSOP 013 Product Identification and Traceabilityankit7588No ratings yet

- Internal Audit Checklist ProductionDocument9 pagesInternal Audit Checklist Productiondhir.ankur100% (2)

- Datasheet ModEva 15TDocument6 pagesDatasheet ModEva 15TGuilherme SousaNo ratings yet

- Quality Assurance Requirements For Licensees-07162010Document4 pagesQuality Assurance Requirements For Licensees-07162010Norma GarciaNo ratings yet

- Documented Procedures and Records Required by API Specification Q1 (9 Edition, June 2013)Document3 pagesDocumented Procedures and Records Required by API Specification Q1 (9 Edition, June 2013)Игорь100% (1)

- SOP - 0111 - 10 - Vendor Audit SOPDocument9 pagesSOP - 0111 - 10 - Vendor Audit SOPrana_ehsan1163100% (2)

- Product - Process ValidationDocument5 pagesProduct - Process ValidationalliceyewNo ratings yet

- Clause Matrix Iatf 16949Document10 pagesClause Matrix Iatf 16949ikesh mNo ratings yet

- LafargeDocument18 pagesLafargegviola1405No ratings yet

- ISO/TS16949-Self Audit ChecklistDocument14 pagesISO/TS16949-Self Audit ChecklistBharathNo ratings yet

- IVV HandbookDocument390 pagesIVV HandbookkingmajorNo ratings yet

- Master List of Quality Procedures IndexDocument71 pagesMaster List of Quality Procedures IndexLILIANAMAR100% (2)

- Leica Geosystems: Release NotesDocument13 pagesLeica Geosystems: Release NotesCamilo NiñoNo ratings yet

- Process ControlDocument5 pagesProcess ControlTuan Anh100% (1)

- IATF IA CHecklistDocument2 pagesIATF IA CHecklistDamodaran RajanayagamNo ratings yet

- On Site Assessment TemplateDocument8 pagesOn Site Assessment TemplatewentropremNo ratings yet

- Apqp Pro 8.3 Process Development PlanningDocument7 pagesApqp Pro 8.3 Process Development PlanningMattNo ratings yet

- SA-QA-SOP-01 Rev 3 SOP For Quality Assurance 01 Oct 20 NewDocument6 pagesSA-QA-SOP-01 Rev 3 SOP For Quality Assurance 01 Oct 20 NewdwarakababuNo ratings yet

- Guideline 2 FAIDocument16 pagesGuideline 2 FAIMohamed HassanNo ratings yet

- Iatf UpgradingDocument6 pagesIatf UpgradingAhmad AzrilNo ratings yet

- Checklist of Documentation For IATF 16949 - 2016Document11 pagesChecklist of Documentation For IATF 16949 - 2016Deepak kumarNo ratings yet

- AV-OP-06 Manufacturing Iss 1Document4 pagesAV-OP-06 Manufacturing Iss 1Kevin DeLimaNo ratings yet

- TS VDA ComparisonDocument9 pagesTS VDA ComparisonigorciNo ratings yet

- Sop Qa 038Document9 pagesSop Qa 038chalicevitalchemNo ratings yet

- VAL 005 Validation Concept and Procedure SampleDocument4 pagesVAL 005 Validation Concept and Procedure SampleSameh MostafaNo ratings yet

- Edition Section Question Answer Q1 9th 3.1.6 - 5.6.1.1Document6 pagesEdition Section Question Answer Q1 9th 3.1.6 - 5.6.1.1Ainura SakpireyevaNo ratings yet

- ISO 9001 Required Documentation and StepsDocument3 pagesISO 9001 Required Documentation and StepsganandmailNo ratings yet

- The Preparation of Validation Master Plan: Manual: 035Document6 pagesThe Preparation of Validation Master Plan: Manual: 035Rambabu komati - QA71% (7)

- VAL 125 Guideline For The Development of A Validation Project Plan Sample PDFDocument3 pagesVAL 125 Guideline For The Development of A Validation Project Plan Sample PDFsiva sankarNo ratings yet

- Checklist of Documentation As Per IATF 16949:2016Document10 pagesChecklist of Documentation As Per IATF 16949:2016Arun Kumar Sharma100% (2)

- Checklist of Mandatory Documentation Required by Iso 13485 2016Document3 pagesChecklist of Mandatory Documentation Required by Iso 13485 2016Ami Jariwala100% (1)

- Product Qualification Requirements 2.0Document3 pagesProduct Qualification Requirements 2.0Amit SinghNo ratings yet

- Template For Installation Qualification Protocol - Pharmaceutical GuidanceDocument6 pagesTemplate For Installation Qualification Protocol - Pharmaceutical GuidanceMSL IndiaNo ratings yet

- Magna Global Quality Standard: MQS 10 - Error Proofing and Detection Device VerificationDocument4 pagesMagna Global Quality Standard: MQS 10 - Error Proofing and Detection Device VerificationGonzalo MazaNo ratings yet

- PR Checklist Stage4 FinalDocument7 pagesPR Checklist Stage4 FinalAhmed SamirNo ratings yet

- ISO 9001 Required DocumentationDocument3 pagesISO 9001 Required Documentationdnmule100% (1)

- AS9100 Mandatory RecordsDocument3 pagesAS9100 Mandatory Recordsocardenas9160No ratings yet

- Production Part Approval ProcessDocument6 pagesProduction Part Approval ProcessleonardoNo ratings yet

- Iq Oq PQ SopDocument3 pagesIq Oq PQ Sopsafikul jamalNo ratings yet

- 3 - IM - F - 004 - Customer Shipping Label FormDocument8 pages3 - IM - F - 004 - Customer Shipping Label FormAvinash MalladhiNo ratings yet

- Validation Manual ME-21 900 937Document2 pagesValidation Manual ME-21 900 937Miguel Angel Pacahuala CristobalNo ratings yet

- 7 Product Realization RequirementsDocument10 pages7 Product Realization RequirementsArman Ul Nasar0% (1)

- ANPQP - 3.0 - Category 5Document27 pagesANPQP - 3.0 - Category 5jefry sitorusNo ratings yet

- Work Breakdown Structure: Pracovní Činnosti Podle IEEE/EIA 12207 (WBS)Document10 pagesWork Breakdown Structure: Pracovní Činnosti Podle IEEE/EIA 12207 (WBS)Jan HornychNo ratings yet

- Management of Product Safety: 6) Esclation Process & Information FlowDocument2 pagesManagement of Product Safety: 6) Esclation Process & Information FlowrajarajanNo ratings yet

- WI-H-003 Inspection and Acceptance Work Instruction Rev ADocument8 pagesWI-H-003 Inspection and Acceptance Work Instruction Rev AAnil Chowadary Anil ChowadaryNo ratings yet

- Production Part Approval Process: PurposeDocument6 pagesProduction Part Approval Process: Purposefabroto88No ratings yet

- 0.2 ProductionDocument4 pages0.2 ProductionadityaNo ratings yet

- QS9000 Check ListDocument16 pagesQS9000 Check ListAngelo ZerellaNo ratings yet

- Checklist Audit ISO TS 16949Document14 pagesChecklist Audit ISO TS 16949Demi RamaNo ratings yet

- ISO Checklist of Mandatory Documentation Required by IATF 16949 en YES OKDocument20 pagesISO Checklist of Mandatory Documentation Required by IATF 16949 en YES OKroelly100% (2)

- QSP Format Product SafetyDocument4 pagesQSP Format Product Safetydhir.ankurNo ratings yet

- P-750 Control of Production and Service ProvisionNEWDocument3 pagesP-750 Control of Production and Service ProvisionNEWnice guyNo ratings yet

- PRC0502Document5 pagesPRC0502John Thompson100% (2)

- Mission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsFrom EverandMission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsRating: 5 out of 5 stars5/5 (1)

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Structured Software Testing: The Discipline of DiscoveringFrom EverandStructured Software Testing: The Discipline of DiscoveringNo ratings yet

- Iso 14469-2017Document44 pagesIso 14469-2017ankit7588No ratings yet

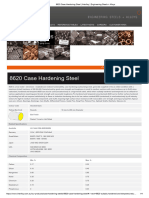

- 8620 Case Hardening Steel - Interlloy - Engineering Steels + AlloysDocument4 pages8620 Case Hardening Steel - Interlloy - Engineering Steels + Alloysankit7588No ratings yet

- PED 2014 68 Eu Classification and CategoriesDocument36 pagesPED 2014 68 Eu Classification and Categoriesankit7588No ratings yet

- SOP WeldingDocument3 pagesSOP Weldingankit7588No ratings yet

- 15 FmeaDocument43 pages15 Fmeaankit7588No ratings yet

- 2.workshop ScheduleDocument1 page2.workshop Scheduleankit7588No ratings yet

- 2-15 Corr&SimpRegDocument72 pages2-15 Corr&SimpRegankit7588No ratings yet

- 4-8 SPC - Variables DataDocument59 pages4-8 SPC - Variables Dataankit7588No ratings yet

- 3-4 Full FactorialDocument111 pages3-4 Full Factorialankit7588No ratings yet

- 18 Measurement Systems AnalysisDocument118 pages18 Measurement Systems Analysisankit7588No ratings yet

- 2-11 ANOVA Analysis of VarianceDocument81 pages2-11 ANOVA Analysis of Varianceankit7588No ratings yet

- 0220 - Sop AutoclaveDocument6 pages0220 - Sop Autoclaveankit7588No ratings yet

- Preventive Maintenance Checking ParametersDocument7 pagesPreventive Maintenance Checking Parametersankit7588No ratings yet

- 16.10 Cryogenic Material SafetyDocument5 pages16.10 Cryogenic Material Safetyankit7588No ratings yet

- Lean Six Sigma Green Belt Training CourseDocument14 pagesLean Six Sigma Green Belt Training Courseankit7588No ratings yet

- PT Acceptance CriteriaDocument8 pagesPT Acceptance Criteriaankit7588No ratings yet

- 0575 User ManualDocument28 pages0575 User Manualankit7588No ratings yet

- Re-Certification 2018Document1 pageRe-Certification 2018ankit7588No ratings yet

- Lockout Tagout - Train The Trainer - 4 HOURSDocument1 pageLockout Tagout - Train The Trainer - 4 HOURSankit7588No ratings yet

- Ocp PpeDocument3 pagesOcp Ppeankit7588No ratings yet

- DS2063 Inox Eu enDocument28 pagesDS2063 Inox Eu enankit7588No ratings yet

- Diaphragm Valve ChineseDocument76 pagesDiaphragm Valve Chineseankit7588No ratings yet

- DX58XXXXXX - 4 Child Part 2 RMDocument1 pageDX58XXXXXX - 4 Child Part 2 RMankit7588No ratings yet

- IFPMA PP Traceability 03 - 2021Document7 pagesIFPMA PP Traceability 03 - 2021ankit7588No ratings yet

- Licences: 154. Application For Licence.Document7 pagesLicences: 154. Application For Licence.ankit7588No ratings yet

- Quadcopter With Arduino Uno Running MultiWiiDocument5 pagesQuadcopter With Arduino Uno Running MultiWiileorio88No ratings yet

- Az 104 MayDocument222 pagesAz 104 MaytherockamitbaghelNo ratings yet

- Functional CoverageDocument36 pagesFunctional CoverageBalakumaran DurairajNo ratings yet

- Manaul ASXXDocument105 pagesManaul ASXXFábio CardosoNo ratings yet

- Comparing The Architectures of ComponentDocument26 pagesComparing The Architectures of ComponentManuel Arroyo JuanNo ratings yet

- bq2014 Controlador de Carga para BateriaDocument26 pagesbq2014 Controlador de Carga para BateriaLucas dos Santos LuizNo ratings yet

- Parv File Java 20Document35 pagesParv File Java 20Aditya KashyapNo ratings yet

- Class 12 CS Revision Tour MCQDocument5 pagesClass 12 CS Revision Tour MCQAryan Parikh100% (1)

- ESP-WROOM-32 - Datasheet (Mar 2017)Document24 pagesESP-WROOM-32 - Datasheet (Mar 2017)StefanoViganóNo ratings yet

- F12 13 Eeng410 FinDocument2 pagesF12 13 Eeng410 FinHYTHAMNo ratings yet

- Java Platform Standard Edition 8 DocumentationDocument2 pagesJava Platform Standard Edition 8 DocumentationCarlos AvenilNo ratings yet

- Optix Osn9800 M: BrochureDocument2 pagesOptix Osn9800 M: BrochureAlexander PischulinNo ratings yet

- Program Maintenance - TutorialspointDocument2 pagesProgram Maintenance - TutorialspointMc Gemrick SantosNo ratings yet

- Process Model For ATM SimulatorDocument5 pagesProcess Model For ATM SimulatorKumar rNo ratings yet

- HEC Pakistan - Recommendations - 28 - JULY - 2021Document160 pagesHEC Pakistan - Recommendations - 28 - JULY - 2021Alia KhanNo ratings yet

- CED19I032Document13 pagesCED19I032Pranavram VNo ratings yet

- Pro Azure Administration and AutomationDocument14 pagesPro Azure Administration and Automationsethii_ankushNo ratings yet

- OS DL TF TestDocument8 pagesOS DL TF TestA060yashswi chaturvediNo ratings yet

- Pli PPT ExtraDocument20 pagesPli PPT ExtraNagfaceNo ratings yet

- Brief Details About 3G-RNCDocument11 pagesBrief Details About 3G-RNCAthi NarayananNo ratings yet

- Clevo W350SSQDocument114 pagesClevo W350SSQMatias MareNo ratings yet

- Zonal-Architecture-White-Paper (Tendencias Automotrices)Document24 pagesZonal-Architecture-White-Paper (Tendencias Automotrices)JESUS JUAREZ PEÑUELANo ratings yet

- IEEE Paper (DEVELOPMENT OF PROGRAMMING LANGUAGE PYTHON)Document16 pagesIEEE Paper (DEVELOPMENT OF PROGRAMMING LANGUAGE PYTHON)MayureshNo ratings yet

- AutomationDocument82 pagesAutomationPratik GhodakeNo ratings yet

- YMA (Penetration Methods of Hackers and Preventing Hacking)Document326 pagesYMA (Penetration Methods of Hackers and Preventing Hacking)zawlwin oo100% (1)

- Open Source Monitoring System For It Infrastructures Incorporating Iot-Based SensorsDocument3 pagesOpen Source Monitoring System For It Infrastructures Incorporating Iot-Based SensorsAdrian RubicoNo ratings yet

- Catalog KD3800EDocument1 pageCatalog KD3800Echenguiti mohamedNo ratings yet