Professional Documents

Culture Documents

244564-Article Text-571036-1-10-20211223

244564-Article Text-571036-1-10-20211223

Uploaded by

Demir YurdakulOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

244564-Article Text-571036-1-10-20211223

244564-Article Text-571036-1-10-20211223

Uploaded by

Demir YurdakulCopyright:

Available Formats

Water and Water Purification Technologies.

Scientific and Technical News ISSN 2218-9300

REMOVAL OF BERYLLIUM (Be2+) FROM WATER SAMPLES BY

SORPTION PROCESS: A REVIEW

Ö. Arar

Ege University, Faculty of Science, Department of Chemistry, 35040, Izmir, Turkey,

ozgur.arar@ege.edu.tr

DOI: https://doi.org/10.20535/2218-930032021244564

Beryllium (Be2+) is an important industrial metal because of its unusual material properties: it is

lighter than aluminium and six times stronger than steel. Beryllium is a strategic metal due to its

low density combined with its strength, low neutron absorption, high melting point and high

modulus of elasticity. Beryllium is often alloyed with other metals such as copper and is an

important component of materials used in the aerospace, automotive, energy, defense, medical, and

electronics industries. However, beryllium and its compounds are very toxic, especially to the

lungs, skin, and eyes. Beryllium compounds are known carcinogens based on sufficient evidence of

carcinogenicity in humans from human studies. Toxic effects of beryllium include immunotoxic,

allergic, mutagenic, and carcinogenic effects. Mammalian tissues do not excrete it, so the effects

are cumulative and can lead to death at high concentrations. Therefore, removal of Be2+ is

important. In this review, the removal of Be2+ from water samples by sorption processes using

different sorbents was summarized. The effects of process parameters on the removal of Be2+ have

been summarized. The work discussed showed that ion exchange resins, various modified

biosorbents metal oxides can be used for the removal of Be2+. The results showed that the pH of the

solution has an important effect on the removal rate. Sorption kinetics vary from 3 minutes to 48h.

When the functional groups are on the surface of the sorbent, the sorption process is rapid.

However, if the surface of the sorbent is covered with oxides such as magnetite, it takes longer to

reach equilibrium. Published work shows that more than 99 % of Be2+ can be removed from

solution.

Keywords: adsorption, beryllium, toxicity, biosorbent, ion exchanger, water treatment

Received: 23 November 2021 Revised: 13 December 2021 Accepted: 21 December 2021

1. Introduction of 1551 K (1287 °C) is consistent with its

position in the periodic table [1,2].

Beryllium (Be) is a steel-grey, brittle

metal with an atomic number of 4 and an 1.1. Beryllium in the environment

atomic weight of 9.01. Its ground-state Beryllium is the 47th most abundant

electronic structure is given as ls22s2. It has an element in the earth's crust and is widely

outer shell with two s electrons, characteristic distributed in many types of rocks. Beryllium

of members of group IIA of the periodic table. behaves like a lithophile element in that it

Beryllium's position between lithium and readily combines with oxygen to form light

boron in the periodic table explains its low beryllium oxide compounds, resulting in its

density of 1.85 g/cm3. The density is the enrichment in the Earth's crust rather than in

second lowest of all metals. Its melting point its core. The concentration in the primitive

mantle is estimated to be about 60 parts per

PHYSICO-CHEMICAL BASES OF WATER TREATMENT 3

Water and Water Purification Technologies. Scientific and Technical News ISSN 2218-9300

billion (ppb) beryllium, while estimates of the Be3Al2[Si6O18]. It is also present in many

concentration of beryllium in the upper natural minerals, including bertrandite,

continental crust range from 1.9 to 3.1 ppm Be4Si2O7(OH)2 [3,4]. The properties of some

beryllium. Beryllium occurs mainly in the Beryllium minerals is listed in Table 1 [3,5].

form of the silicate mineral beryl,

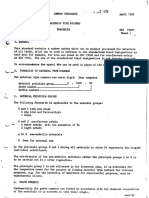

Table 1. Name, formula and properties of some Beryllium minerals

Name Formula Colour BeO (percent) Transparency

Barylite BaBe2Si2O7 Colourless, 16 Transparent-

white, yellow Translucent

Bertrandite Be4Si2O7(OH)2 Colourless, 42 Transparent

white, pale-

yellow

Beryl Be3Al2Si6O18 White, pale- 14 Transparent-

yellow, Green Translucent

Chrysobery BeAl2O4 Green, yellow, 20 Transparent-

red Translucent

Helvite Mn4Be3Si3O12S Brown, yellow, 14 Transparent-

grey Translucent

Phenakite Be2SiO4 Colourless, 45 Transparent

white

Beryllium is a metallic element found in is one-third lighter than aluminum, making it

about 50 minerals. These minerals occur one of the lowest density metals. It is also one

mainly in pegmatites, granites, syenites, and of the stiffest with six times the stiffness of

occasionally in gneisses and mica schists. steel. It has a high heat absorption capacity

When they occur in heterogeneous and is dimensionally stable over a wide range

pegmatites, the crystals attain a large size and of temperatures.

a good to excellent hexagonal crystal form; Beryllium is a strategic metal due to its

such crystals occasionally reach a diameter of low density combined with its strength, low

0.66 to 1 m, a length of several meters, and a neutron absorption, high melting point and

weight of several tons. Crystals growing in high modulus of elasticity, which makes it

cavities and druses in the parent rock are attractive for electrical components, aerospace

often quite transparent and of gem quality [6]. and nuclear energy. As a result, beryllium

1.2 Application of beryllium metal is used in aircraft disk brakes, X-ray

Pure beryllium and its metal alloys transmission windows, nuclear reactor

(e.g., Cu, Al, Mg, Ni) are an indispensable neutron reflectors, and heat shields.

material in the manufacture of products for Beryllium oxide is used in high-tech

the aerospace, automotive, energy, defense, ceramics, electronic heat sinks, and crucibles.

medical, and electronics industries. Beryllium Beryllium alloys are used in electrical

ФІЗИКО-ХІМІЧНІ ОСНОВИ ВОДОПІДГОТОВКИ 4

Water and Water Purification Technologies. Scientific and Technical News ISSN 2218-9300

connectors and relays, computers, underwater considered necessary to set a formal

cable housings, aircraft engine parts, and guideline value [1].

dental applications [7–9].

2. Removal of beryllium

1.3 Toxicity of beryllium

Beryllium exhibits a broad spectrum of Although both beryllium and beryllium

toxic effects and is classified as a Group 1 compounds are classified as carcinogens,

carcinogen, meaning that beryllium and beryllium and its compounds are used in

beryllium compounds are known carcinogens various industries. Because of the widespread

based on sufficient evidence of use of beryllium and its known harmful

carcinogenicity in humans from human effects on health and the environment, it is

studies. Toxic effects of beryllium include important to remove the potential risks. There

immunotoxic, allergic, mutagenic, and are few studies dealing with the removal of

carcinogenic effects. The primary health beryllium ions from aqueous environments. In

problem associated with beryllium is Be- this review, the removal of beryllium from

associated lung disease (also called chronic water samples by sorption methods has been

beryllium disease or berylliosis); however, summarized.

other health problems are also being 2.1. Removal of Be2+ by ion exchange

considered. An important feature of beryllium resins

toxicity is a considerable latency period, Ion exchangers are insoluble materials

usually lasting up to 6-10 years. Because most that carry reversibly bound ions. These ions

of the attention related to beryllium has been can be exchanged stoichiometrically for other

devoted to occupational exposure, the ions of the same sign. Ion exchange polymers,

mechanisms of beryllium toxicity are not yet especially ion exchange resins, are cross-

clear [10–12]. linked polymers carrying fixed functional

Studies on the carcinogenicity of groups or sites [13].

beryllium in experimental animals are Othman et al. used a strongly acidic

available for the inhalation, intratracheal, oral, cation exchange resin, Amberlite IR-120, to

and parenteral routes of exposure. Inhalation remove Be2+ from aqueous solutions. The

exposure to beryllium (metal, ores, and authors reported that the initial pH of the

sulfate compounds) resulted in a significant solution had an important effect on the

increase in lung cancer in rats and monkeys. removal rate and the optimum removal was

These observations support the possible achieved in a pH range of 3-3.5. In addition,

causal relationship found in the occupational increasing the solution temperature increased

studies. the sorption rate. Kinetic models showed that

Beryllium (metal, alloys and liquid film diffusion controlled the process in

compounds) has also been shown to cause the early phase of adsorption, followed by

lung cancer in rats by intratracheal instillation matrix diffusion, which controlled the process

and osteosarcoma in rabbits by intravenous in the final phase [14].

and intramedullary injection [1]. Demerdash et al. investigated the effect

WHO also reports that beryllium is of flow rate and bed thickness on the removal

rarely, if ever, found in drinking water in of Be2+ in a fixed-bed reactor loaded with

concentrations of concern. Therefore, it is not Amberlite IR-120. The authors reported that

PHYSICO-CHEMICAL BASES OF WATER TREATMENT 5

Water and Water Purification Technologies. Scientific and Technical News ISSN 2218-9300

the sorption of Be2+ to the resin increased 2.2. Biosorption

when the feed flow rate was decreased. The Biosorption can be defined as the

authors also found that as the bed height removal of desired substances from an

increased, the sorption of beryllium to aqueous solution by biological material. The

Amberlite IR-120 increased at both fast and removal of contaminants occurs by various

slow flow rates [15]. mechanisms such as absorption, adsorption,

Ramesh et al. used inorganic ion ion exchange, surface complexation and

exchangers, zeolite 4A, zeolite 13X and precipitation [18,19]. It may not be possible to

bentonite for the removal of Be2+ from find a sorbent that has such functional groups.

aqueous solutions. The effect of sorbent dose, Oxidation or various polymeric techniques

solution pH and contact time on the removal have been used to attach functional groups to

of Be2+ was studied. The optimum sorbent the surface of biosorbents.

dose was found to be 5 g for a solution Abu El-Soad et al. modified chitosan

containing 3 mg-Be/L. The pH of the solution with sulfonic acid and used it to remove Be2+

was given as another important parameter for from aqueous solutions. Chitosan was first

the sorption of Be2+. The removal rate of Be2+ cross-linked with glutaraldehyde to decrease

was low at pH 1 and increasing the pH of the the solubility of chitosan and later they used

solution improved the removal rate and the chlorosulfonic acid to introduce sulfonic acid

optimum pH for Be2+ sorption was found to groups into chitosan. The prepared sorbent

be ≥ 5. was tested under different experimental

The presence of interfering ions, such as conditions. The pH of the solution affected

Ca, Mg and Fe, was also tested for the the removal rate of Be2+ and the optimum

removal of Be2+ and the results showed that removal was achieved at pH 4. The sorption

Mg had the greatest effect on the sorption of of Be2+ reached equilibrium in 40 minutes and

Be2+ on both zeolite 4A and bentonite. The the sorption kinetics obeyed the pseudo-

decreasing order of effect of the counterions second order kinetic model. The

is Mg > Fe > Ca. However, all counterions thermodynamic studies showed that the

showed less effect on bentonite than on sorption of Be2+ was exothermic and

zeolite 4A. Be- loaded zeolite 4A and spontaneous. The exhausted sorbent was

benthonite were regenerated with different regenerated with various solutions. It was

concentrations of NaCl. The regeneration rate found that the maximum desorption of

of zeolite 4A is higher than that of benthonite beryllium ions from the sorbent loaded with

and the optimum NaCl concentration was Be with 1.5 M urea acidified with 0.6 M

found to be 10 % NaCl for both ion H2SO4 desorbed about 65% of beryllium ions

exchangers [16]. within 30 minutes [20].

Das and Pobi prepared a resin Abd El-Magied et al. prepared acetate-

containing N-benzoylphenylhydroxylamine containing chitosan and used it to remove

for the separation of Be2+ from other Be2+ from aqueous solutions. The authors

elements. Be2+ was significantly sorbed found that the removal of Be2+ was pH

between pH 1.0 and 7.0. The loaded resin was dependent and the maximum removal was

regenerated with 2.0 M H2SO4 solution [17]. achieved at pH 1 and pH 5. At pH values

between 1-5, the removal rate decreased. The

ФІЗИКО-ХІМІЧНІ ОСНОВИ ВОДОПІДГОТОВКИ 6

Water and Water Purification Technologies. Scientific and Technical News ISSN 2218-9300

authors explained that this difference was due equilibrium in 6 h for MWBI (0.8 g

to the presence of Be(H2O)42+ in acidic media FeSO4·7H2O was used to prepare the sorbent)

and, at pH 5, to the dissociation of carboxylic and 48 h for MWBII (1.4 g FeSO4-7H2O was

acid and the electrostatic interaction of acetate used to prepare the sorbent). The calculated

groups with [Be3(OH)3]3+ ions. The kinetic kinetic parameters showed that the pseudo-

test showed that 80 % of the total uptake of second-order kinetic model fitted better to the

Be2+ was achieved within 40 minutes and that experimental results. Regeneration tests

the pseudo-second order model is most showed that 0.01 M HCl or H2SO4 desorbed

favourable for describing the biosorption more than 95 % of Be2+ from the prepared

process. The authors conclude that the sorbents [23].

sorption of Be2+ is exothermic and 2.3. Metal oxides and other composite

spontaneous. A 3 M H2SO4 solution can sorbents

regenerate the sorbent with an efficiency of In addition to the ion exchanger and

86 % [21]. biosorbents, various types of organic-

Acetate-containing cellulose was inorganic composites or metal oxides have

prepared by a two-step oxidation process and been used to remove Be2+.

used to remove Be2+. NaIO4 was used to Porschova and Parschova impregnated

break the carbon-carbon bond of the polymeric sorbents XAD4-A33 and XAD16-

glucopyranose ring to generate aldehyde A33 with magnetite and used them for the

groups, and NaClO2 was used to oxidize the removal of Be2+ from aqueous solutions. The

aldehyde groups to carboxylic acid groups. prepared sorbents were placed in a column

The authors reported that maximum removal and the metal ion-containing solution was

was achieved at a pH of ≥ 5. At a low pH, the added to the column. The loaded sorbents

removal rate was low, which was due to the were regenerated in a multistep process. First,

conversion of the acetate groups to a it was rinsed with an alkaline salt solution

molecular form so that there was no (2 % NaOH and 2 % NaCl), then conditioned

interaction between Be2+ and the functional with demineralized water, and finally with

groups. The sorption kinetics was very fast demineralized CO2-saturated water. 84 % of

and reached equilibrium within 3 minutes. the Be from XAD4-A33 and 91 % of the Be

The authors also found that the sorption of from XAD16-A33 were desorbed [24].

Be2+ was exothermic and spontaneous. The Katsuta et al. tested Al2O3, SiO2, TiO2,

sorbent loaded with Be can be regenerated and CoO nanoparticles for the sorption of

with more than 99 % efficiency by 0.1 M HCl Be2+ from an aqueous solution. The authors

or H2SO4 solution [22]. found that the partition ratio of Be2+ between

Tokarcikova et al. prepared biochar aqueous solution and nanoparticles increased

from low-grade wheat and modified it with with increasing pH. The authors also reported

two different ratios of magnetite to remove that the adsorption of Be2+ on the oxide

Be2+ from aqueous solutions. The authors nanoparticles was evaluated based on the

reported that the removal of Be2+ increased surface complexation model, in which the

with increasing pH of the solution and the hydroxyl groups on the surface of the oxide

maximum sorption capacity was reached at deprotonate and form complexes with Be2+ in

pH = 6 for both sorbents. Sorption reached water [25].

PHYSICO-CHEMICAL BASES OF WATER TREATMENT 7

Water and Water Purification Technologies. Scientific and Technical News ISSN 2218-9300

The capacities of the various sorbents functional groups available for Be2+ sorption,

are summarised in Table 2. The capacities of the size of the sorbent, and the nature of the

the sorbents varied from 1.5 to 45 mg/g. The functional groups. The available binding site

variations in the capacity of the sorbent are during the preparation/modification of the

related to the method of preparation, the sorbent.

Table 2. The comparison of capacities of different types of sorbents for the removal of Be2+

Sorbent Capacity References

Zeolite 4A 3.3 [16]

Zeolite 13X 3.2

Amberlite IR-120 11.9* [14]

Aerobic granule 14.0 [26]

Ion-exchange resin with 31.2 [17]

Nbenzoylphenylhydroxylamine

Sulfated chitosan 40.6 [20]

Magnetically Modified biochar 1.4 [23]

Acetate modified chitosan 45.0 [21]

Polystyreneazo3,4dihydroxybenzene 22.5 [27]

* obtained from the pseudo-first-order kinetic model at 31 °C

3. Effect of process parameters of the sorbent. Another parameter is the

on sorption performance precipitation of Be2+ as Be(OH)2. The

working pH range should be lower than the

As summarized various process precipitation pH. In addition, when metal

parameters have been tested on Be2+ removal. oxides are used for the removal of Be2+, the

3.1 Sorbent dose point of zero charge (pzc) of the metal oxide

The removal of Be2+ increased with should be found and the pH of the solution

increasing sorbent dose, which can be should be adjusted to pH values at which the

attributed to the increase in available surface of the oxide becomes negative.

functional groups with increasing 3.3 Temperature

sorbent dose. The temperature of a solution has two

3.2 Solution pH main effects on adsorption. First, the rate of

The pH of the solution affects the rate sorption generally increases at higher

of sorption in different ways. If the functional temperatures. This is primarily due to the

groups are weak acid functional groups such increased rate of diffusion of the sorbate

as acetate, at an acidic pH or at a pH < pKa of through the solution to the sorbent. Since

a weak acid, the functional groups convert to solubility and adsorption rate are inversely

their molecular form and the interaction related and temperature affects solubility, it

between Be2+ and the functional groups does also affects the extent of sorption or the

not occur, decreasing the removal efficiency capacity of the sorbent for sorbate [28].

ФІЗИКО-ХІМІЧНІ ОСНОВИ ВОДОПІДГОТОВКИ 8

Water and Water Purification Technologies. Scientific and Technical News ISSN 2218-9300

The sorption of Be2+ is normally Be-rich solution or the disposal of this waste

exothermic; therefore, the extent of sorption should be planned.

generally increases with decreasing The disposal of the spent sorbent should

temperature. also be investigated in future studies.

4. Conclusions and future work References

The removal of Be2+ from water 1. World Health Organization. Beryllium in

Drinking-Water: Background Document for

samples by sorption methods was

Development of WHO Guidelines for Drinking-Water

investigated. The work discussed showed that Quality; Geneva: World Health Organization, 2009.

ion exchange resins, various modified 2. Walsh, K. A. Beryllium Chemistry and

biosorbents metal oxides can be used for the Processing. In; Vidal, E. E.; Goldberg, A.;

removal of Be2+. The results showed that the Dalder, E. N. C.; Olson, D. L.; Mishra, B., Eds.; ASM

international: Ohio, 2009; pp. 1–5.

pH of the solution has an important effect on

3. Foley, N.K.; Jaskula, B.W.; Piatak, N.M.;

the removal rate. At pH 1 or 2, the removal of Schulte, R.F. Beryllium; US Geological Survey, 2017.

Be2+ is low, and increasing the pH of the 4. Housecroft, C.E.; Sharpe, A.G. Inorganic

solution increases the removal rate, however, Chemistry; Fourth.; Pearson Publisher, Harlow,

precipitation of Be2+ can be observed at England: Harlow, England, 2012.

5. Christie, T.; Brathwaite, B. Mineral

higher pH values. The optimum removal is

Commodity Report 19-Beryllium, Gallium, Lithium,

achieved at different pH ranges and is related Magnesium, Uranium and Zirconium, 2008.

to the speciation of Be2+ as well as the nature 6. Walsh, K. A.; Vidal, E. E. Sources of

of the functional groups of the sorbent. Beryllium. In Beryllium Chemistry and Processing;

Sorption kinetics vary from 3 minutes to 2020.

7. Ma, Y.; Qiu, K. Fluorine Removal from

48 h. When the functional groups are on the

High-Fluorine Beryllium Ore by Roasting and

surface of the sorbent, the sorption process is Leaching Pretreatment. Int. J. Miner. Process. 2015,

rapid. However, if the surface of the sorbent 141, 1–7. https://doi.org/10.1016/j.minpro.2015.06.001

is covered with oxides such as magnetite, it 8. Yavuz, E.; Tokalıoğlu, Ş.; Patat, Ş.

takes longer to reach equilibrium. Dispersive Solid-Phase Extraction with Tannic Acid

Functionalized Graphene Adsorbent for the

The sorbent loaded with Be can be

Preconcentration of Trace Beryllium from Water and

regenerated with HCl, H2SO4, NaCl, or urea- Street Dust Samples. Talanta 2018, 190, 397–402.

containing H2SO4 solution. The regeneration https://doi.org/10.1016/j.talanta.2018.08.001

efficiency varied from 65 % to 99 %, which 9. Kolanz, M. E. Introduction to Beryllium:

can be attributed to the nature of the Uses, Regulatory History, and Disease. Appl. Occup.

Environ. Hyg. 2001, 16, 559–567.

functional groups.

https://doi.org/10.1080/10473220119088

The presence of interfering ions such as 10. Drobyshev, E.; Kybarskaya, L.; Dagaev, S.;

Na , K+, Ca2+ and Mg2+, and other cations that

+

Solovyev, N. New Insight in Beryllium Toxicity

may be present with Be should be Excluding Exposure to Beryllium-Containing Dust:

investigated. The effect of the concentration Accumulation Patterns, Target Organs, and

Elimination. Arch. Toxicol. 2019, 93, 859–869.

of interfering ions on the removal rate should

https://doi.org/10.1007/s00204-019-02432-7

also be studied in detail. 11. U.S. Department of Health and Human

After regeneration of the sorbent, Services. Report on Carcinogens, 14th Edition. Natl.

a Be-rich waste is produced. The reuse of the Toxicol. Progr. 2016.

PHYSICO-CHEMICAL BASES OF WATER TREATMENT 9

Water and Water Purification Technologies. Scientific and Technical News ISSN 2218-9300

12. Islam, M. R.; Sanderson, P.; Naidu, R.; for Beryllium Recovery. Int. J. Biol. Macromol. 2019,

Payne, T. E.; Johansen, M. P.; Bari, A. S. M. F.; 139, 153–160.

Rahman, M. M. Beryllium in Contaminated Soils: https://doi.org/10.1016/j.ijbiomac.2019.07.162

Implication of Beryllium Bioaccessibility by Different 21. Abd El-Magied, M. O.; Mansour, A.;

Exposure Pathways. J. Hazard. Mater. 2022, 421, Alsayed, F. A. A. G.; Atrees, M. S.; Abd Eldayem, S.

126757. https://doi.org/10.1016/j.jhazmat.2021.126757 Biosorption of Beryllium from Aqueous Solutions onto

13. Zagorodni, A. A. Ion Exchange Materials: Modified Chitosan Resin: Equilibrium, Kinetic and

Properties and Applications; First.; Elsevier: Thermodynamic Study. J. Dispers. Sci. Technol. 2018,

Amsterdam, London, 2007. 39, 1597–1605.

14. Othman, S. H.; Shabaan, M.; https://doi.org/10.1080/01932691.2018.1452757

Demerdash, M.; Saleh, M. M. Experimental and 22. Özdemir, V. T.; Tuğaç, H. M.; Arar, Ö.

Theoretical Investigation of Sorption Kinetics of Two-Pot Oxidative Preparation of Dicarboxylic Acid

Beryllium on Amberlite-IR-120 Sorbent. J. Nucl. Containing Cellulose for the Removal of Beryllium

Mater. 2009, 392, 427–433. (Be2+) from Aqueous Solution. Curr. Anal. Chem.

https://doi.org/10.1016/j.jnucmat.2009.04.001 2020, 16.

15. Demerdash, M.; Saleh, M. M.; Shabaan, M.; 23. Tokarčíková, M.; Motyka, O.;

Othman, S. H.; El-Anadouli, B. E. Experimental Peikertová, P.; Gabor, R.; Seidlerová, J. Magnetically

Validation for a Mathematical Model Describing Modified Biosorbent for Rapid Beryllium Elimination

Beryllium Retention on Flow-through Fixed Bed from the Aqueous Environment. Materials (Basel).

Reactor of Amb-IR-120. Hydrometallurgy 2011, 108, 2021, 14, 6610. https://doi.org/10.3390/ma14216610

136–142. 24. Porschová, H.; Parschová, H. Preparation

https://doi.org/10.1016/j.hydromet.2011.03.009 and Properties of Iron Oxide Composite Sorbents for

16. Ramesh, A.; Mohan, K. R.; Seshaiah, K.; Removing Arsenic, Beryllium and Uranium from

Choudary, N. V. Removal of Beryllium from Aqueous Aqueous Solutions. Ion Exch. Lett. 2013, 6(4), 5–7.

Solutions by Zeolite 4A and Bentonite. Sep. Sci. https://doi.org/10.3260/iel.2013.11.002

Technol. 2002, 37, 1123–1134. 25. Katsuta, S.; Kanaya, N.; Bessho, K.;

https://doi.org/10.1081/SS-120002245 Monjushiro, H. Adsorption Behavior of Trace

17. Das, J.; Pobi, M. Separation of Beryllium Beryllium (II) onto Metal Oxide Nanoparticles

and Aluminium from Other Elements Using an Ion- Dispersed in Water. Int. J. Chem. 2017, 9(4), 62–70.

Exchange Resin with N-Benzoylphenylhydroxylamine https://doi.org/10.5539/ijc.v9n4p62

as a Functional Group. Anal. Chim. Acta 1991, 242, 26. Sun, F.; Sun, W. L.; Sun, H. M.; Ni, J. R.

107–111. https://doi.org/10.1016/0003-2670(91)87053- Biosorption Behavior and Mechanism of Beryllium

a from Aqueous Solution by Aerobic Granule. Chem.

18. Gadd, G. M. Biosorption: Critical Review of Eng. J. 2011, 172, 783–791.

Scientific Rationale, Environmental Importance and https://doi.org/10.1016/j.cej.2011.06.062

Significance for Pollution Treatment. J. Chem. 27. Basargin, N. N.; Miroshnichenko, O. V.

Technol. Biotechnol. 2009, 84, 13–28. Beryllium(II) Sorption from Aqueous Solutions by

https://doi.org/10.1002/jctb.1999 Polystyrene-Based Chelating Polymer Sorbents. Russ.

19. Michalak, I.; Chojnacka, K.; Witek- J. Inorg. Chem. 2012, 57, 758–762.

Krowiak, A. State of the Art for the Biosorption https://doi.org/10.1134/S0036023612050026

Process — a Review. Appl. Biochem. Biotechnol. 2013, 28. Bernardin, F. E. Experimental Design and

170, 1389–1416. https://doi.org/10.1007/s12010-013- Testing of Adsorption and Adsorbates. In Adsorption

0269-0 technology: a step-by-step approach to process

20. Abu El-Soad, A. M.; Abd El-Magied, M. O.; evaluation and application; Slejko, F. L., Ed.; Marcel

Atrees, M. S.; Kovaleva, E. G.; Lazzara, G. Synthesis Dekker Inc.: New York, 1985; pp. 37–90.

and Characterization of Modified Sulfonated Chitosan

ФІЗИКО-ХІМІЧНІ ОСНОВИ ВОДОПІДГОТОВКИ 10

Water and Water Purification Technologies. Scientific and Technical News ISSN 2218-9300

ВИДАЛЕННЯ БЕРИЛІЮ (Be2+) ІЗ ПРОБ ВОДИ СОРБЦІЙНИМ

МЕТОДОМ: ОГЛЯД

Арар О.

Егейський університет, Факультет природничих наук, кафедра хімії,

35040, Ізмір, Туреччина, ozgur.arar@ege.edu.tr

Берилій (Be2+) є важливим промисловим металом завдяки своїм незвичайним властивостям:

він легший за алюміній та в шість разів міцніший за сталь. Берилій є стратегічно важливим

металом по причині його низької густини у поєднанні з міцністю, низьким поглинанням

нейтронів, високою температурою плавлення і високим модулем пружності. Берилій часто

сплавляють з іншими металами, такими як мідь, він є важливим компонентом матеріалів,

що використовуються в аерокосмічній, автомобільній, енергетичній, оборонній, медичній

та електронній промисловості. Однак берилій та його сполуки дуже токсичні, особливо для

легень, шкіри та очей. Канцерогенний вплив сполук берилію по відношенню до людського

органіму є давно доведеною і добре відомою. Токсичні ефекти берилію включають

імунотоксичну, алергічну, мутагенну та канцерогенну дії. Тканини ссавців не пристосовані

до виведення сполук берилію, тому спостерігається кумулятивний ефект, і, як наслідок, за

високих концентраціяй це може призвести до смерті. Тому видалення Be2+ має велике

значення. У даному огляді узагальнено дані щодо видалення Be2+ із водних розчинів з

використанням різних сорбентів. В статті узагальнено вплив параметрів процесу на

видалення Be2+. Встановлено, що для видалення Be2+ можна використовувати іонообмінні

смоли, різні модифіковані біосорбенти, оксиди металів. Результати показали, що рН

розчину має значний вплив на швидкість видалення. Кінетика сорбції змінюється від 3

хвилин до 48 годин. Коли функціональні групи знаходяться на поверхні сорбенту, процес

сорбції відбувається швидко, однак, якщо поверхня сорбенту покрита такими оксидами, як

магнетит, для досягнення рівноваги потрібно більше часу. Згідно опублікованих робіт, з

розчину можна видалити більше ніж 99 % Be2+.

Ключові слова: адсорбція, берилій, біосорбент, іонообмінник, водопідготовка

PHYSICO-CHEMICAL BASES OF WATER TREATMENT 11

You might also like

- AP Chemistry Chapter 2 Practice TestDocument20 pagesAP Chemistry Chapter 2 Practice TestbonnniiiNo ratings yet

- Design Criteria For Gaseous Oxygen Piping Systems 3PI60001: Ngineering TandardDocument43 pagesDesign Criteria For Gaseous Oxygen Piping Systems 3PI60001: Ngineering TandardKom NakNo ratings yet

- B&acompoundsDocument32 pagesB&acompoundstd_paulsonNo ratings yet

- ELEMENTS 2ndDocument7 pagesELEMENTS 2ndMIRIAM MUHINo ratings yet

- BerelimDocument5 pagesBerelimalirezayusufyarNo ratings yet

- Beryllium and Beryllium Compounds: CAS No. 7440-41-7 (Beryllium) PropertiesDocument3 pagesBeryllium and Beryllium Compounds: CAS No. 7440-41-7 (Beryllium) PropertiesMeera TripathiNo ratings yet

- Beryllium: Handbook On The Toxicology of Metals 4EDocument19 pagesBeryllium: Handbook On The Toxicology of Metals 4EChanWingSanNo ratings yet

- Open Journal of MetalDocument14 pagesOpen Journal of MetalMamadou FAYENo ratings yet

- Biosorption of Heavy Metals From Aqueous Solutions by Chemically ModifiedDocument6 pagesBiosorption of Heavy Metals From Aqueous Solutions by Chemically ModifiedEswin Hernandez ObregonNo ratings yet

- Adsorption Behavior of Na Bentonite and Nano Cloisite Na 2019 Journal of enDocument12 pagesAdsorption Behavior of Na Bentonite and Nano Cloisite Na 2019 Journal of enFabiola Patricia Perry HaroNo ratings yet

- Agua Residuales - 2021Document16 pagesAgua Residuales - 2021Sofía BárcenasNo ratings yet

- The Chemistry of Boron and Its Speciation in PlantsDocument13 pagesThe Chemistry of Boron and Its Speciation in PlantsCelismarNo ratings yet

- Bab I Pendahuluan: 1.1 Latar BelakangDocument11 pagesBab I Pendahuluan: 1.1 Latar BelakangRatih PratiwiNo ratings yet

- Periodic Table of The ElementsDocument15 pagesPeriodic Table of The ElementsEmanuel GuzmanNo ratings yet

- Chemistry Quiz 3 Reporte de Presentacion Con VikyDocument3 pagesChemistry Quiz 3 Reporte de Presentacion Con VikyRebeca BenavidesNo ratings yet

- BoronDocument120 pagesBoronErnesto Karlos100% (1)

- Jurnal InternasionalDocument26 pagesJurnal Internasionalmelina andrianiNo ratings yet

- Ozdemir Et Al. 2009Document12 pagesOzdemir Et Al. 2009Jhonny PinayaNo ratings yet

- Heavy Metal Adsorption Onto Agro-Based Waste Materials: A ReviewDocument10 pagesHeavy Metal Adsorption Onto Agro-Based Waste Materials: A ReviewAnnisa Fadhila RamadhaniNo ratings yet

- M. Ku ̈cu ̈K) - Chronic Lead Poisoning Affects The Central Nervous System, The GastrointestinalDocument46 pagesM. Ku ̈cu ̈K) - Chronic Lead Poisoning Affects The Central Nervous System, The GastrointestinalPriya Vijay kumaarNo ratings yet

- Removal of Lead (II) From Water by Agro-Industrial By-Products AdsorbentDocument11 pagesRemoval of Lead (II) From Water by Agro-Industrial By-Products AdsorbentJose EscobarNo ratings yet

- 1 s2.0 S2590123021000220 MainDocument12 pages1 s2.0 S2590123021000220 MainAulia Sukma HutamaNo ratings yet

- Comparative Study of Lead Sorption Onto Natural Perlite, Dolomite and DiatomiteDocument7 pagesComparative Study of Lead Sorption Onto Natural Perlite, Dolomite and DiatomitesedaNo ratings yet

- Turkish Po BioadsorbenteDocument5 pagesTurkish Po BioadsorbenteErick TsujiNo ratings yet

- Akira 21Document3 pagesAkira 21glenn_banaybanayNo ratings yet

- Bismuth Economic Geology and Value Chains - 2022 - Ore Geology ReviewsDocument20 pagesBismuth Economic Geology and Value Chains - 2022 - Ore Geology ReviewsPEDRO HERRERANo ratings yet

- Ahmad 2009Document11 pagesAhmad 2009dian widiyaningsihNo ratings yet

- Zeeshanmahdi Lab ReportsDocument112 pagesZeeshanmahdi Lab ReportsZeeshanMahdiNo ratings yet

- J Cej 2012 01 032Document9 pagesJ Cej 2012 01 032Priya Vijay kumaarNo ratings yet

- Thermodynamic and Kinetic Study of PB (II) Amputation by River SedimentDocument14 pagesThermodynamic and Kinetic Study of PB (II) Amputation by River SedimentIsna NurhidayatiNo ratings yet

- Ic Iii-T1Document5 pagesIc Iii-T1AYUSH SHARMANo ratings yet

- Yu - 2020 - RareMat - Recent Progress in Plant-Derived Hard Carbon Anode Materials For Sodium Ion Batteries A ReviewDocument15 pagesYu - 2020 - RareMat - Recent Progress in Plant-Derived Hard Carbon Anode Materials For Sodium Ion Batteries A ReviewvituruchNo ratings yet

- Biosorption of Lead (II), Chromium (III) and Copper (II) by R. Opacus: Equilibrium and Kinetic StudiesDocument11 pagesBiosorption of Lead (II), Chromium (III) and Copper (II) by R. Opacus: Equilibrium and Kinetic StudiestereNo ratings yet

- Comparative Chemistry of B, Al, Ga, In, TLDocument13 pagesComparative Chemistry of B, Al, Ga, In, TLMmadu CcyNo ratings yet

- Cobalt: Olivier Pourret, Michel-Pierre FauconDocument8 pagesCobalt: Olivier Pourret, Michel-Pierre FauconShafffNo ratings yet

- Case Study: Bioavailability of Tin and Tin Compounds: Article in PressDocument10 pagesCase Study: Bioavailability of Tin and Tin Compounds: Article in PressVictor FarinellaNo ratings yet

- Removal of Heavy Metals Using Bentonite Clay and Inorganic CoagulantsDocument20 pagesRemoval of Heavy Metals Using Bentonite Clay and Inorganic CoagulantsВладислав ГазинNo ratings yet

- Restaurator, 2009, Pp. 96 - 130 Printed in Germany - All Rights ReservedDocument35 pagesRestaurator, 2009, Pp. 96 - 130 Printed in Germany - All Rights ReservedMala Tecka100% (1)

- 1 s2.0 S0273230022001143 MainDocument10 pages1 s2.0 S0273230022001143 MainDzaky Sabrina Djulianra (Kio Bakri)No ratings yet

- Concept PaperDocument10 pagesConcept PaperMONICA BAUTISTANo ratings yet

- Journal of Environmental Chemical EngineeringDocument11 pagesJournal of Environmental Chemical EngineeringRiza Nur FajriatiNo ratings yet

- Metallic BiomaterialsDocument26 pagesMetallic BiomaterialspufarinaaNo ratings yet

- Adsorption of Ag, Cu and HG From Aqueous Solutions Using Expanded Perlite - UnlockedDocument6 pagesAdsorption of Ag, Cu and HG From Aqueous Solutions Using Expanded Perlite - UnlockedAMPamasengiNo ratings yet

- B TiO2 AntibacterialDocument6 pagesB TiO2 AntibacterialmarcomtnNo ratings yet

- Biosorpsi 26Document6 pagesBiosorpsi 26Chrysty ElesaNo ratings yet

- G3 - OutlineDocument4 pagesG3 - OutlineMarielle PonterasNo ratings yet

- J Cej 2011 01 069Document9 pagesJ Cej 2011 01 069Priya Vijay kumaarNo ratings yet

- Acidofilo EspecificoDocument6 pagesAcidofilo EspecificoMIRANDA ALEXANDRA ESPINOZA URBINANo ratings yet

- Lead in The OceanDocument18 pagesLead in The OceanKaRenGalaRzaNo ratings yet

- Molecules 28 05031Document18 pagesMolecules 28 05031xingzhehaoNo ratings yet

- 1 s2.0 S138589471100355X MainDocument8 pages1 s2.0 S138589471100355X MainZIZU79No ratings yet

- "Bioremediation Lead (PB) WTH Plants" by Kuni Nurul Khasanah (4301416035)Document11 pages"Bioremediation Lead (PB) WTH Plants" by Kuni Nurul Khasanah (4301416035)kuni nurul khasanahNo ratings yet

- Includes Beryllium, Magnesium, Calcium, Strontium, Barium, and RadiumDocument15 pagesIncludes Beryllium, Magnesium, Calcium, Strontium, Barium, and Radiumpink_music_loveNo ratings yet

- 4 DCDocument13 pages4 DCSaad LiaqatNo ratings yet

- TD PublishedDocument9 pagesTD PublishedSeptian Perwira YudhaNo ratings yet

- BoronDocument22 pagesBoronzidaaanNo ratings yet

- 164 JMES 1454 2015 AbdiDocument14 pages164 JMES 1454 2015 AbdiIslam LakatNo ratings yet

- Bismuth Based MaterialsDocument7 pagesBismuth Based MaterialsdebmallyNo ratings yet

- Kimia Unsur Logam Study Question 1. Explain The Finding History of Earth Alkali Metals!Document4 pagesKimia Unsur Logam Study Question 1. Explain The Finding History of Earth Alkali Metals!Diantari SaraswatiNo ratings yet

- 郭非凡CC 一堆硼化物Document4 pages郭非凡CC 一堆硼化物orangewings翅橙No ratings yet

- Adsorption of Heavy Metal Ions, Dyes and Proteins byDocument9 pagesAdsorption of Heavy Metal Ions, Dyes and Proteins bySundoro YogaNo ratings yet

- Modern Rhodium-Catalyzed Organic ReactionsFrom EverandModern Rhodium-Catalyzed Organic ReactionsP. Andrew EvansNo ratings yet

- Final ExamDocument14 pagesFinal ExamDemir YurdakulNo ratings yet

- Vervoort Et Al-2017-Polymer Engineering ScienceDocument7 pagesVervoort Et Al-2017-Polymer Engineering ScienceDemir YurdakulNo ratings yet

- CHM 408 Polymer Chemistry UneditedDocument73 pagesCHM 408 Polymer Chemistry UneditedDemir YurdakulNo ratings yet

- Lead Oxide - 20210714-1 (Dönüştürüldü)Document1 pageLead Oxide - 20210714-1 (Dönüştürüldü)Demir YurdakulNo ratings yet

- Pobu D 22 00413Document20 pagesPobu D 22 00413Demir YurdakulNo ratings yet

- Rev21EFFECTS and DEFECTS Doymamış Polyester-WO3.2H2O ParticlesDocument19 pagesRev21EFFECTS and DEFECTS Doymamış Polyester-WO3.2H2O ParticlesDemir YurdakulNo ratings yet

- 01.10.2021 Doymamış Polyester-WO3.2H2O Nanoparticles Radiation MeasurementDocument23 pages01.10.2021 Doymamış Polyester-WO3.2H2O Nanoparticles Radiation MeasurementDemir YurdakulNo ratings yet

- Examination of The Effect of Melamine As A Filler in Paper Coatings On Print QualityDocument8 pagesExamination of The Effect of Melamine As A Filler in Paper Coatings On Print QualityDemir YurdakulNo ratings yet

- Cea 14827748 HDocument10 pagesCea 14827748 HDemir YurdakulNo ratings yet

- Acsapm 0c00317Document10 pagesAcsapm 0c00317Demir YurdakulNo ratings yet

- Rev 11.06.2022 Ece Berna Yayin Polymer BultennnDocument19 pagesRev 11.06.2022 Ece Berna Yayin Polymer BultennnDemir YurdakulNo ratings yet

- 22.02.2022Rev21EFFECTS AND DEFECTS Doymamış polyester-WO3.2H2O Particles DüzeltmeDocument21 pages22.02.2022Rev21EFFECTS AND DEFECTS Doymamış polyester-WO3.2H2O Particles DüzeltmeDemir YurdakulNo ratings yet

- SECTION 07 92 00 Joint SealantsDocument14 pagesSECTION 07 92 00 Joint SealantsDemir YurdakulNo ratings yet

- 1 Heat Flow and Temperature Distribution in WeldingDocument24 pages1 Heat Flow and Temperature Distribution in Weldingডঃ শুভম চ্যাটার্জীNo ratings yet

- Seminar Topics NameDocument10 pagesSeminar Topics NameNilesh ThanviNo ratings yet

- לימבורג 2009Document312 pagesלימבורג 2009Yair Doram LightingNo ratings yet

- Hazardous Wastes (Management, Handling and Transboundary Movement) Rules, 2008Document63 pagesHazardous Wastes (Management, Handling and Transboundary Movement) Rules, 2008Mahesh MenonNo ratings yet

- 1629866207-Xam Idea Science Solutions Class 10 Chapter 3 Metal and Non MetalsDocument25 pages1629866207-Xam Idea Science Solutions Class 10 Chapter 3 Metal and Non MetalsHetal ChudasamaNo ratings yet

- MEP ME Crank Pin Bearing OHDocument30 pagesMEP ME Crank Pin Bearing OHSuhas KassaNo ratings yet

- Gbtâ 3524-2015 enDocument11 pagesGbtâ 3524-2015 enMohanrajMJNo ratings yet

- SB-462 - ASME BPVC 2021 Sección II Part BDocument6 pagesSB-462 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- BS 2874-1986 - (2021-05-03 - 09-38-52 Am)Document26 pagesBS 2874-1986 - (2021-05-03 - 09-38-52 Am)AkshayBhatkandeNo ratings yet

- Hardfacing Overview MeltolitDocument1 pageHardfacing Overview MeltolitmercyNo ratings yet

- Saravanan Wpq-5g 50nbDocument1 pageSaravanan Wpq-5g 50nbDeepakNo ratings yet

- Alloying Elements and Alloys (1) - 17471991 - 2023 - 05 - 31 - 18 - 57Document27 pagesAlloying Elements and Alloys (1) - 17471991 - 2023 - 05 - 31 - 18 - 57Anoop AnuNo ratings yet

- Comflor Floordecking PDFDocument39 pagesComflor Floordecking PDFing urbanNo ratings yet

- An Overview of The Automated Pouring ProcessDocument9 pagesAn Overview of The Automated Pouring ProcesskarthikkandaNo ratings yet

- 3.1 Work Book Chemistry Chapter 3 IB DPDocument29 pages3.1 Work Book Chemistry Chapter 3 IB DPSemwezi EnockNo ratings yet

- Modified Manganese Phosphate Conversion CoatingDocument24 pagesModified Manganese Phosphate Conversion Coatinggacm98No ratings yet

- 액화수소저장탱크용스테인리스소재의레이저용접적용을위한기초연구Document8 pages액화수소저장탱크용스테인리스소재의레이저용접적용을위한기초연구Sungwook KangNo ratings yet

- Api 510 Exam 2021Document14 pagesApi 510 Exam 2021eng_far100% (2)

- Din 17007Document8 pagesDin 17007Aditya Pratap100% (1)

- Marking Machine Options(无价格)Document7 pagesMarking Machine Options(无价格)maderacreativaboliviaNo ratings yet

- Feeney Catalogue - 1 - 51Document50 pagesFeeney Catalogue - 1 - 51socrates_10No ratings yet

- Gold RefiningDocument6 pagesGold Refiningelizaldesf50% (2)

- RFID Automotive Metal Mount TagsDocument1 pageRFID Automotive Metal Mount TagsBalluff SensorsNo ratings yet

- Francis OSDocument46 pagesFrancis OSBenjy Mathew0% (1)

- Dental CastingDocument139 pagesDental CastingSF QuadriNo ratings yet

- AQA Chemistry Bonding Structure and The Properties of Matter KnowIT GCSE1Document76 pagesAQA Chemistry Bonding Structure and The Properties of Matter KnowIT GCSE1Stone ZhongNo ratings yet

- X-Ray Diffraction Investigation of Alloys: R. A. Butera and D. H. WaldeckDocument5 pagesX-Ray Diffraction Investigation of Alloys: R. A. Butera and D. H. WaldeckDanielleNo ratings yet

- 4003 Chemistry Section Topic by TopicDocument32 pages4003 Chemistry Section Topic by Topicpercymtetwa25No ratings yet