Professional Documents

Culture Documents

E0002a I O Assignment Iris

E0002a I O Assignment Iris

Uploaded by

pedroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E0002a I O Assignment Iris

E0002a I O Assignment Iris

Uploaded by

pedroCopyright:

Available Formats

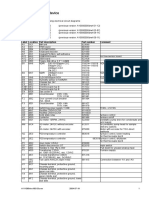

KRONES AG Dept.

EW - Internal Documentation IO assignment

I/O-assignment Inspector

controller with ACT2 und PC-

cameras

Linatronic version

Author:

Date 27.03.00

Project EP9732

File /conversion/tmp/activity_task_scratch/625390829.doc

Date Change:

1 15.03.00 Colour rejection on EA10_1

2 20.03.00 Stroboscope malfunctions on EA17 removed,

EA10_2 divided up for camera relays and rejection indicator

3 27.03.00 Inputs for KPS malfunctions removed

4

5

6

7

8

9

10

Netzteil 5V 30A

EA10_1

EA10_2

EA13_2

EA13_1

EA17

EA12

MC6

IO assignment of inspector controller with ACT2 - Linatronic 1/8

KRONES AG Dept. EW - Internal Documentation IO assignment

MC6

EA VG AP KB Signal

E1 X30.A10 X20.13 X11.13 Clock pulse bottle present signal 2

E2 X30.A9 X20.25 X11.25

E3 X30.A8 X20.12 X11.12 Fine clock pulse conveyor clock pulse

E4 X30.A7 X20.24 X11.24

E5 X30.A6 X20.11 X11.11

E6 X30.8A5 X20.23 X11.23 Reset AK 1

E7 X30.A4 X20.10 X11.10 Reset AK 2.3.4

E8 X30.A3 X20.22 X11.22 Reset general (not assigned)

E9 X30.B10 X20.9 X11.9

E10 X30.B9 X20.21 X11.21 2nd acknowledgement P.E. cell assembly pusher 1

E11 X30.B8 X20.8 X11.8 PEC AK4

E12 X30.B7 X20.20 X11.20

E13 X30.B6 X20.7 X11.7 Acknowledgement P.E. cell assembly Pusher 1

E14 X30.B5 X20.19 X11.19 Acknowledgement P.E. cell assembly Pusher 2

E15 X30.B4 X20.6 X11.6 Acknowledgement P.E. cell assembly Pusher 3

E16 X30.B3 X20.18 X11.18 Acknowledgement P.E. cell assembly Pusher 4

A1 X30.C10 X20.5 X11.5 Hasp lock 1

A2 X30.C9 X20.17 X11.17 Hasp lock 2

A3 X30.C8 X20.4 X11.4 Hasp lock 3

A4 X30.C7 X20.16 X11.16 Hasp lock 4

A5 X30.C6 X20.3 X11.3 Pusher 1

A6 X30.C5 X20.15 X11.15 Pusher 2

A7 X30.C4 X20.2 X11.2 Pusher 3

A8 X30.C3 X20.14 X11.14 Pusher 4

IO assignment of inspector controller with ACT2 - Linatronic 2/8

KRONES AG Dept. EW - Internal Documentation IO assignment

EA17

EA VG AP KB Signal

E1 X31.C4 X23.13 X10.13 Trigger colour sensor

E2 X31.A5 X23.25 X10.25

E3 X31.B5 X23.12 X10.12

E4 X31.C5 X23.24 X10.24 Input progr. Trigger

E5 X31.A6 X23.11 X10.11

E6 X31.B6 X23.23 X10.23

E7 X31.C6 X23.10 X10.10

E8 X31.A7 X23.22 X10.22

E9 X31.B7 X22.20 X13.20

E10 X31.C7 X22.21 X13.21

E11 X31.A8 X22.22 X13.22

E12 X31.B8 X22.23 X13.23

E13 X31.C8 X22.24 X13.24

E14 X31.C11 X23.9 X10.9

E15 X31.A12 X23.21 X10.21

E16 X31.B12 X23.8 X10.8

A1 X31.A2 X23.5 X10.5

A2 X31.B2 X23.17 X10.17

A3 X31.C2 X23.4 X10.4

A4 X31.A3 X23.16 X10.16 Valve bottle base blowoff device

A5 X31.B3 X22.10 X13.10 Progr. Trigger output 1

A6 X31.C3 X22.11 X13.11 Progr. Trigger output 2

A7 X31.A4 X22.12 X13.12 progr. Trigger output 3

A8 X31.B4 X22.13 X13.13 progr. Trigger output 4

AE4 X31.A9 X22.3 X13.3 Red colour sensor

AE5 X31.B9 X22.5 X13.5 Green colour sensor

AE6 X31.C9 X22.8 X13.8 Blue colour sensor

AE7 X31.A10 X22.9 X13.9

AE8 X31.B10 X22.4 X13.4 External temperature sensor

AE9 X31.C10 X9.12 Caustic 1 tank analogue

AE10 X31.A11 X10.12 Caustic 2 tank analogue

AE11 X31.B11 X11.12 Caustic 3 tank analogue

IO assignment of inspector controller with ACT2 - Linatronic 3/8

KRONES AG Dept. EW - Internal Documentation IO assignment

EA10_1

EA VG AP KB Signal

A1 X32.A2 X16.4 X8.4 U/D support for potentiometer

A2 X32.B2 X16.22 X8.22 Clk serial control board for caustic tanks-

A3 X32.C2 X16.5 X8.5 Synchronous -Dac back panels

A4 X32.A3 X16.23 8.23 CS support for potentiometer

A5 X32.B3 X16.6 X8.6

A6 X32.C3 X16.24 X8.24

A7 X32.A4 X16.7 X8.7

A8 X32.B4 X16.25 X8.25

A9 X32.C4 X16.8 X8.8 General machine stop

A10 X32.A5 X16.26 X8.26 Stop using brake

A11 X32.B5 X16.9 X8.9 Stop using conveyor

A12 X32.C5 X16.27 X8.27 Clock pulse for BLOC synchronisation

A13 X32.A6 X16.10 X8.10 Rejection during BLOC synchronisation

A14 X32.B6 X16.28 X8.28

A15 X32.C6 X16.11 X8.11 Colour rejection

A16 X32.A7 X16.29 X8.29

A17 X32.B7 X16.12 X8.12

A18 X32.C7 X16.30 X8.30 Delete counter

A19 X32.A8 X16.13 X8.13

A20 X32.B8 X16.31 X8.31

A21 X32.C8 X16.14 X8.14

A22 X32.A9 X16.32 X8.32

A23 X32.B9 X16.15 X8.15 Lamp reset push-button AK1

A24 X32.C9 X16.33 X8.33 Lamp reset push-button AK2.3.4

A25 X32.A10 X16.16 X8.16

A26 X32.B10 X16.34 X8.34

A27 X32.C10 X16.17 X8.17 Static outputs

A28 X32.A11 X16.35 X8.35 Depends on bottle type

A29 X32.B11 X16.18 X8.18

A30 X32.C11 X16.36 X8.36

A31 X32.A12 X16.19 X8.19

A32 X32.B12 X16.37 X8.37

IO assignment of inspector controller with ACT2 - Linatronic 4/8

KRONES AG Dept. EW - Internal Documentation IO assignment

EA10_2

EA VG AP KB Signal

A1 X33.A2 X18.1

A2 X33.B2 X18.20

A3 X33.C2 X18.2

A4 X33.A3 X18.21

A5 X33.B3 X18.3

A6 X33.C3 X18.22

A7 X33.A4 X18.4

A8 X33.B4 X18.23

A9 X33.C4 X18.5

A10 X33.A5 X18.24 Illustration of the rejection signals

A11 X33.B5 X18.6 from stations 1 to 16

A12 X33.C5 X18.25 Synchronised at counter level

A13 X33.A6 X18.7

A14 X33.B6 X18.26

A15 X33.C6 X18.8

A16 X33.A7 X18.27

A17 X33.B7 X18.9

A18 X33.C7 X18.28

A19 X33.A8 X18.10

A20 X33.B8 X18.29

A21 X33.C8 X18.11

A22 X33.A9 X18.30

A23 X33.B9 X18.12 Outputs for camera relays

A24 X33.C9 X18.31

A25 X33.A10 X18.13

A26 X33.B10 X18.32

A27 X33.C10 X18.14

A28 X33.A11 X18.33

A29 X33.B11 X18.15

A30 X33.C11 X18.34

A31 X33.A12 X18.16

A32 X33.B12 X18.35

IO assignment of inspector controller with ACT2 - Linatronic 5/8

KRONES AG Dept. EW - Internal Documentation IO assignment

EA13_1

EA VG AP KB Signal Standard assignment

E1 X36.A2 X1.4 CIS_1 rejection 1 Bottle base

E2 X36.B2 X1.5 CIS_1 rejection 2

E3 X36.C2 X2.4 CIS_2 rejection 1 Neck finish

E4 X36.A3 X2.5 CIS_2 rejection 2

E5 X36.B3 X3.4 CIS_3 rejection 1 Screw thread

E6 X36.C3 X3.5 CIS_3 rejection 2

E7 X36.A4 X4.4 CIS_4 rejection 1 Bottle base DF

E8 X36.B4 X4.5 CIS_4 rejection 2

E9 X36.C4 X5.4 CIS_5 rejection 1 Side-wall inspection unit 1

E10 X36.A5 X5.5 CIS_5 rejection 2

E11 X36.B5 X5.6 CIS_5 rejection 3

E12 X36.C5 X6.4 CIS_6 rejection 1 Side-wall inspection unit 2

E13 X36.A6 X6.5 CIS_6 rejection 2

E14 X36.B6 X6.6 CIS_6 rejection 3

E15 X36.C6 X7.4 CIS_7 rejection 1 Bottle contour detection unit camera

E16 X36.A7 X7.5 CIS_7 rejection 2

E17 X36.B7 X7.6 CIS_7 rejection 3

E18 X36.C7 X8.4 CIS_8 rejection 1 Reserve system

E19 X36.A8 X8.5 CIS_8 rejection 2

E20 X36.B8 X8.6 CIS_8 rejection 3

E21 X36.C8 X9.4 CIS_9 rejection 1

E22 X36.A9 X10.4 CIS_10 rejection 1

E23 X36.B9 X11.4 CIS_11 rejection 1

E24 X36.C9 X19.10 X9.10 External rejection signal Too low

1

E25 X36.A10 X19.9 X9.9 External rejection signal Too high 1

2

E26 X36.B10 X19.8 X9.8 External rejection signal Too high 2

3

E27 X36.C10 X19.7 X9.7 External rejection signal Teflon film

4

E28 X36.A11 X19.6 X9.6 External rejection signal Bottle contour detection unit 1

5

E29 X36.B11 X19.5 X9.5 External rejection signal Bottle contour detection unit 2

6

E30 X36.C11 X19.4 X9.4 External rejection signal Clogged neck inspection unit

7

E31 X36.A12 X19.3 X9.3 External rejection signal Leakage

8

E32 X36.B12 X19.2 X9.2 External rejection signal

9

IO assignment of inspector controller with ACT2 - Linatronic 6/8

KRONES AG Dept. EW - Internal Documentation IO assignment

EA13_2

EA VG AP KB Signal

E1 X35.A2 X17.2 12.2 “Bottle present” signal 1

E2 X35.B2 X16.21 8.21

E3 X35.C2 X16.3 8.3 Reject monitoring input

E4 X35.A3 X16.20 8.20 Reject monitoring output 1

E5 X35.B3 X16.2 8.2 Reject monitoring output 2

E6 X35.C3 X1.8 CIS_1 ready

E7 X35.A4 X2.8 CIS_2 ready

E8 X35.B4 X3.8 CIS_3 ready

E9 X35.C4 X4.8 CIS_4 ready

E10 X35.A5 X5.8 CIS_5 ready

E11 X35.B5 X6.8 CIS_6 ready

E12 X35.C5 X7.8 CIS_7 ready

E13 X35.A6 X8.8 CIS_8 ready

E14 X35.B6 X9.8 CIS_9 ready

E15 X35.C6X X10.8 CIS_10 ready

E16 X35.A7 X11.8 CIS_11 ready

E17 X35.B7 X19.26 X9.26 Lateral neck finish inspection unit 1 lamp

E18 X35.C7 X19.25 X9.25 Lateral neck finish inspection unit 2 lamp

E19 X35.A8 X19.24 X9.24

E20 X35.B8 X19.23 X9.23

E21 X35.C8 X19.22 X9.22 TFL stop

E22 X35.A9 X19.21 X9.21

E23 X35.B9 X19.20 X9.20 Coolant malfunction

E24 X35.C9 X19.19 X9.19 Malfunction to recooling unit

E25 X35.A10 X19.18 X9.18 TFL code 1

E26 X35.B10 X19.17 X9.17 TFL code 2

E27 X35.C10 X19.16 X9.16 TFL code 3

E28 X35.A11 X19.15 X9.15 TFL code 4

E29 X35.B11 X19.14 X9.14

E30 X35.C11 X19.13 X9.13

E31 X35.A12 X19.12 X9.12 Stroboscope lamp 1 malfunction

E32 X35.B12 X19.11 X9.11 Stroboscope lamp 2 malfunction

IO assignment of inspector controller with ACT2 - Linatronic 7/8

KRONES AG Dept. EW - Internal Documentation IO assignment

EA12

EA VG AP KB Signal

E1 X34.A3 X17.5 12.5 Encoder chain A

E2 X34.A4 X17.9 12.9 Encoder chain B

E3 X34.A5 X17.4 12.4 Encoder indexing signal 1

E4 X34.A6 X17.8 12.8 Encoder indexing signal 1 / reference clock pulse

proximity detector

E5 X34.A7 X17.3 12.3 Initiator ½ pitch

E6 X34.A8 X17.7 12.7

E7 X34.A9

E8 X34.A10 X17.6 12.6

A1 X34.C3 Clock pulse

A2 X34.C4 Fine clock pulse (256 / pitch) / conveyor clock pulse

A3 X34.C5 X17.21 12.21 Clock pulse

A4 X34.C6 X17.22 12.22 Fine clock pulse (16 / pitch)

A5 X34.C7 X17.23 12.23

A6 X34.C8 X17.24 12.24

A7 X34.C9 X17.25 12.25

A8 X34.C10 X19.37 12.37

IO assignment of inspector controller with ACT2 - Linatronic 8/8

You might also like

- MAN TGS-TGX Wiring Diagrams Electrical System K100 (2nd Edition) (097-152)Document56 pagesMAN TGS-TGX Wiring Diagrams Electrical System K100 (2nd Edition) (097-152)Леонид Коваль100% (3)

- SM Asta18lcc Aotr18lccDocument18 pagesSM Asta18lcc Aotr18lccLuk KaluznyNo ratings yet

- AC 60 Service NotesDocument21 pagesAC 60 Service Notes15101980100% (1)

- Cambridge Secondary Checkpoint - Science (1113) PastPapers 2009-2019Document375 pagesCambridge Secondary Checkpoint - Science (1113) PastPapers 2009-2019Harini Bharani100% (8)

- Manufacturer: Suzuki Model: Grand Vitara (05-) 2,0 Engine Code: J20A Output: 103 (140) 6000 - Tuned For: R-Cat Year: 2005-11 V9.200Document4 pagesManufacturer: Suzuki Model: Grand Vitara (05-) 2,0 Engine Code: J20A Output: 103 (140) 6000 - Tuned For: R-Cat Year: 2005-11 V9.200Jorge Martinez33% (3)

- Ricoh Mp2500 - PartsDocument105 pagesRicoh Mp2500 - PartsEdon SurfistNo ratings yet

- John Carroll University Magazine Spring 2012Document54 pagesJohn Carroll University Magazine Spring 2012johncarrolluniversityNo ratings yet

- Ricoh Aficio 2015, 2018 (Model K-C2 B121-B122-B123) Parts CatalogDocument90 pagesRicoh Aficio 2015, 2018 (Model K-C2 B121-B122-B123) Parts Catalogingmar_sNo ratings yet

- EN Freecurve ServiceguideDocument28 pagesEN Freecurve ServiceguideCarlos FuentesNo ratings yet

- A111080doc100 03Document2 pagesA111080doc100 03Jabulani2010No ratings yet

- DB en Axl F BP Se6 Axl F BP Se4 108759 en 09Document17 pagesDB en Axl F BP Se6 Axl F BP Se4 108759 en 09mehmet emin sarıNo ratings yet

- Boss DD-7 Service NotesDocument24 pagesBoss DD-7 Service NotesFernando GómezNo ratings yet

- RICOH Aficio MPC 2030 Parts ManualDocument154 pagesRICOH Aficio MPC 2030 Parts ManualkingveliNo ratings yet

- Ricoh Skylark A183 A184 Parts ManualDocument41 pagesRicoh Skylark A183 A184 Parts ManualstevanreljicNo ratings yet

- Stylus SX110 SX115 TX110-115 TX117 TX119 NX110 NX115 Parts List and DiagramDocument7 pagesStylus SX110 SX115 TX110-115 TX117 TX119 NX110 NX115 Parts List and Diagramhakom74No ratings yet

- Esquema Elétrico Tacógrafo (TCO)Document5 pagesEsquema Elétrico Tacógrafo (TCO)Helio67% (3)

- PART LIST Adventurer - AX Series - 07032015Document26 pagesPART LIST Adventurer - AX Series - 07032015Cristian David Celis RamirezNo ratings yet

- Service Manual LCD Television: Model No. LCD-23XL2Document32 pagesService Manual LCD Television: Model No. LCD-23XL2FEDE514No ratings yet

- LEXMARK x204n Parts MaanualDocument12 pagesLEXMARK x204n Parts MaanualTiberiu RotilăNo ratings yet

- DENON Stereo CD Player DCM280 - 380 - SM PDFDocument35 pagesDENON Stereo CD Player DCM280 - 380 - SM PDFLeslie MirasoleNo ratings yet

- GlenHuntlyDocument17 pagesGlenHuntlyHirushan MenukaNo ratings yet

- L32W831 L37W8311Document97 pagesL32W831 L37W8311Litman Bocanegra anguloNo ratings yet

- RXD-A55/A75: Service ManualDocument35 pagesRXD-A55/A75: Service ManualRichard T Hord JrNo ratings yet

- Dau Terminal MK112 31012024Document1 pageDau Terminal MK112 31012024Lê Trọng ThànhNo ratings yet

- AGYF Floor Service ManualDocument22 pagesAGYF Floor Service ManualAmanda Mack100% (1)

- Pioneer Deh-3750mpDocument61 pagesPioneer Deh-3750mpElena Palacios GalecioNo ratings yet

- RATL-SCC61E PMDocument26 pagesRATL-SCC61E PMLuis RamirezNo ratings yet

- RATIONAL Model# SCC WA 201Document30 pagesRATIONAL Model# SCC WA 201shanali766766No ratings yet

- Reproductora Manual PioneerDocument48 pagesReproductora Manual PioneerYuniel Serrano MilianNo ratings yet

- 1bintray Bn3000 PCDocument7 pages1bintray Bn3000 PCsalih65No ratings yet

- Drager Narkomed Field Service Procedure Julian Pfgf-Psys Pressure PCB 8603361 InstallationDocument8 pagesDrager Narkomed Field Service Procedure Julian Pfgf-Psys Pressure PCB 8603361 InstallationAmirNo ratings yet

- Service Manual Asyg12lecaDocument22 pagesService Manual Asyg12lecaWai LaiNo ratings yet

- SPARE PARTS 2U Indium Series-Senza - Prezzi-WebDocument44 pagesSPARE PARTS 2U Indium Series-Senza - Prezzi-WebLuis SanchezNo ratings yet

- AC33Document37 pagesAC33GersonMGNo ratings yet

- Krc2 Perifery enDocument21 pagesKrc2 Perifery enOkoNo ratings yet

- Pioneer VSX-418Document27 pagesPioneer VSX-418Tom TalicniNo ratings yet

- Catalogo Fornos RationalDocument31 pagesCatalogo Fornos RationalPaulo IjanoNo ratings yet

- AVIC Z2 - Service ManualDocument317 pagesAVIC Z2 - Service ManualHenry AlvarezNo ratings yet

- Fujitsu ASYB18LDC - AOYS18LDCDocument19 pagesFujitsu ASYB18LDC - AOYS18LDCPablos Augoustis100% (1)

- XR-A550 XR-A330: Stereo CD Cassette Deck ReceiverDocument82 pagesXR-A550 XR-A330: Stereo CD Cassette Deck ReceiverAlexandre S. CorrêaNo ratings yet

- 056 TS-2000 Service Manual SupplementDocument97 pages056 TS-2000 Service Manual SupplementVictor ClashNo ratings yet

- Penmount 1610 Control Board Data SheetDocument2 pagesPenmount 1610 Control Board Data Sheetnelson david pineda higueraNo ratings yet

- T6A36S, JT6A36X-AS CMOS Single-Chip LSI For LCD CalculatorDocument24 pagesT6A36S, JT6A36X-AS CMOS Single-Chip LSI For LCD Calculatorjp149No ratings yet

- C 2 NfsDocument4 pagesC 2 Nfs2JZ-GENo ratings yet

- Despiece MP2000 PDFDocument83 pagesDespiece MP2000 PDFAnonymous UHcbrUNo ratings yet

- VAMP 255 / 245 / 230 Technical Data SheetDocument38 pagesVAMP 255 / 245 / 230 Technical Data SheetOSunTzuONo ratings yet

- Ricoh A171 ARDF - PCDocument33 pagesRicoh A171 ARDF - PCdesechableNo ratings yet

- Service Manual: CFD-C1000Document20 pagesService Manual: CFD-C1000Giovanni MendozaNo ratings yet

- Acorn Computers United, 4a Market Cambridge C82 3NJ, England. Telephone 0223 312772Document24 pagesAcorn Computers United, 4a Market Cambridge C82 3NJ, England. Telephone 0223 312772zbytiNo ratings yet

- AxialFans BifurcatedDocument25 pagesAxialFans Bifurcatedblindjaxx100% (1)

- Boss PW-10 Service NotesDocument14 pagesBoss PW-10 Service NotesFernando GómezNo ratings yet

- Acson Service Guide Book 2010Document90 pagesAcson Service Guide Book 2010Fiza IjaNo ratings yet

- WM FX277Document22 pagesWM FX277london335No ratings yet

- Parts Catalog: First Edition October 1995Document77 pagesParts Catalog: First Edition October 1995Iftikhar MughalNo ratings yet

- 8997 6613 00 Diagrams and Drawings PDFDocument106 pages8997 6613 00 Diagrams and Drawings PDFMiguel PaucarNo ratings yet

- Conector LocationsDocument27 pagesConector Locationsroberto jose vergara gilNo ratings yet

- Stack Bypass B1 Parts ListDocument38 pagesStack Bypass B1 Parts ListTecnica CPY Copiadoras del ParaguayNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- Digital Signal Processing Using the ARM Cortex M4From EverandDigital Signal Processing Using the ARM Cortex M4Rating: 1 out of 5 stars1/5 (1)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Digital Compensation for Analog Front-Ends: A New Approach to Wireless Transceiver DesignFrom EverandDigital Compensation for Analog Front-Ends: A New Approach to Wireless Transceiver DesignNo ratings yet

- UntitledDocument21 pagesUntitledpedro100% (1)

- P & PLC E C T: PpendixDocument42 pagesP & PLC E C T: PpendixpedroNo ratings yet

- Water Rechiller / Heat ExchangerDocument2 pagesWater Rechiller / Heat ExchangerpedroNo ratings yet

- Adaptomode Inlet Pressure Regulators: ® Types: A4AS, A4AB, A4AD, A4AZDocument16 pagesAdaptomode Inlet Pressure Regulators: ® Types: A4AS, A4AB, A4AD, A4AZpedroNo ratings yet

- Appointment ConfirmationDocument4 pagesAppointment ConfirmationpedroNo ratings yet

- Writing Results in A Research PaperDocument6 pagesWriting Results in A Research Paperafedpmqgr100% (1)

- Wings of FireDocument5 pagesWings of FireJitendra AsawaNo ratings yet

- Advance Data StructuresDocument184 pagesAdvance Data StructureskamsiNo ratings yet

- Grade 9 Social Studies Textbook CbseDocument3 pagesGrade 9 Social Studies Textbook CbseKurtNo ratings yet

- Beta-4 Manual SupplementDocument10 pagesBeta-4 Manual SupplementDAVI VIANANo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetFahad NaveedNo ratings yet

- ALMMDocument16 pagesALMMJigar PatelNo ratings yet

- Model 200-30A200P-31-21A Solenoid ValveDocument4 pagesModel 200-30A200P-31-21A Solenoid Valveemuno008No ratings yet

- Meeting Minutes of 17th Departmental MeetingDocument3 pagesMeeting Minutes of 17th Departmental Meetingmyousafzai67No ratings yet

- Mechanical Engineering Machine Design Important MCQ PDF: All Exam Review AddaDocument24 pagesMechanical Engineering Machine Design Important MCQ PDF: All Exam Review AddaJatan DeepNo ratings yet

- cmsc420 Fall2020 LectsDocument156 pagescmsc420 Fall2020 LectsAnthony-Dimitri ANo ratings yet

- Presented By-Anshul Kumbhare Siddhant Mhatre: Boiler AccessoriesDocument10 pagesPresented By-Anshul Kumbhare Siddhant Mhatre: Boiler AccessoriesHarshvardhan Singh ChauhanNo ratings yet

- Estonian Foreign Intelligence Service Annual Report - 2020Document82 pagesEstonian Foreign Intelligence Service Annual Report - 2020Silviu TanaseNo ratings yet

- R Data Visualization Cookbook Sample ChapterDocument25 pagesR Data Visualization Cookbook Sample ChapterPackt PublishingNo ratings yet

- ENGLISH 9 DLP For DEMODocument9 pagesENGLISH 9 DLP For DEMOMary Joy Corpuz100% (2)

- Metaphors and Similes Lesson PlanDocument4 pagesMetaphors and Similes Lesson Planapi-242439128No ratings yet

- Performance TaskDocument6 pagesPerformance TaskPrinces Aliesa Bulanadi100% (1)

- THZ Rectangular Slitted Microstrip Patch Antenna Design For Biomedical Applications, Security Purposes & Drug DetectionDocument4 pagesTHZ Rectangular Slitted Microstrip Patch Antenna Design For Biomedical Applications, Security Purposes & Drug DetectionGreeni MarcoNo ratings yet

- Mark SheetDocument1 pageMark SheetLokeshNo ratings yet

- Kingair 350i Wiring - 21 Air ConditionedDocument68 pagesKingair 350i Wiring - 21 Air ConditionedLaboratorio01 AvionicsNo ratings yet

- Suppliers Assessment ChecklistDocument3 pagesSuppliers Assessment ChecklistRonnel LeanoNo ratings yet

- Photoshop Cheat Sheet Print Friendly 2018Document1 pagePhotoshop Cheat Sheet Print Friendly 2018Jefferson VelonzaNo ratings yet

- Boq Ipal Pasar Sukamaju2019Document3 pagesBoq Ipal Pasar Sukamaju2019tiopen5ilhamNo ratings yet

- Bar Bending Schedule (Service BLDG)Document20 pagesBar Bending Schedule (Service BLDG)Rania SaiedNo ratings yet

- Proforma Architect - Owner Agreement: Very Important NotesDocument11 pagesProforma Architect - Owner Agreement: Very Important NotesJean Erika Bermudo BisoñaNo ratings yet

- 5.5 CBM Waste Skip Open Top - POWER BearDocument1 page5.5 CBM Waste Skip Open Top - POWER Bearqtia71133No ratings yet

- Hitachi Data Systems Foudations ModularDocument378 pagesHitachi Data Systems Foudations ModularZhenhai WeiNo ratings yet

- Feature: SFP Optical Module 1 .25G Double Optical Fiber 20kmDocument2 pagesFeature: SFP Optical Module 1 .25G Double Optical Fiber 20kmDaniel Eduardo RodriguezNo ratings yet