Professional Documents

Culture Documents

Nozzle Clogging For Si' Killed Steel: Continuous Casting 32

Nozzle Clogging For Si' Killed Steel: Continuous Casting 32

Uploaded by

Can ERTANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nozzle Clogging For Si' Killed Steel: Continuous Casting 32

Nozzle Clogging For Si' Killed Steel: Continuous Casting 32

Uploaded by

Can ERTANCopyright:

Available Formats

32 CONTINUOUS CASTING

Nozzle clogging for ‘Si’ killed steel

Billet casting through the metering nozzle for ‘Si’ killed steel is an established practice. At one stage

Si killed steel for metering nozzle casting was considered to be quite free from nozzle clogging. The

steelmaker only had to keep the Al level low. Nozzle clogging was more of an issue with Al killed steel,

says PK Ghosh*

HOWEVER, with demand for quality, yield, level (>0.007%) is the reason for nozzle

and lower alloy consumption, nozzle clogging, which is true in many cases but

clogging can occur for ‘Si’ killed steel. For it was not the case for this plant (Plant A).

a plant, it may not be for all the heats and The Al level was always below 0.004% and

that baffles and influences the perception nozzle clogging occurred in the Al range of

and remedial measures. 0.002 % - 0.004%. It was suspected that

This paper describes how the problem ‘CaS’ formation could be a reason behind

of nozzle clogging was solved for two the clogging. However, SEM analysis did

different grades of steel in two different not show any CaS presence in the steel

Plants – Plant A for 0.80% carbon and Plant sample. Finally, it was ascertained that the

B for 0.15% Carbon. incidences of nozzle clogging were closely

The root cause of the problem was connected with the final oxygen level of the

established as low soluble oxygen at the steel at the end of ladle refining.

end of the treatment. All high carbon steel grades are ‘Si-

A unique programme was established killed’ and the main inclusions are MnO(x)

for ‘Ca’ addition for high carbon grade. SiO2(y) type. The values of subscripts x and

This programme was worked out after y depend on the chemistry of the steel or

identifying the crucial process parameters rather the relative molar percentages of Mn

and coming up with a ‘Ca’ treatment and Si in the steel. From the casting angle,

programme to ensure 100% success. the values of Mn and Si are important

To eliminate nozzle clogging for because they decide the subscripts x and y

low carbon grade, ‘Ca’ treatment was and whether the inclusion shall be liquid at

eliminated with a unique non-metallurgical 84 Grade. This led to a quality problem, casting temperature. There are two rules of

action. slowing down the productivity and rejection thumb that can be used.

of billet. One rule envisages that the Mn2/Si

Discussion Typical failures are shown in the Figs. 1 should be more than 1.60 and in another, it

Plant A - Nozzle clogging of high carbon and 2. is estimated that Mn/Si should be minimum

steel: 3.00.

This plant encountered nozzle clogging Insight in to nozzle clogging The main constituents of Si killed steel

with a maximum severity for AISI 1080- The most common belief is that a high Al are Fe are C, Mn and Si, but if the steel is

Fig 1. Speed Graph of Clogging Heats Fig 2. Speed Graph of Clogging Heats

* President, Steeltap International LLC, New Jersey, USA

March 2019 www.steeltimesint.com

Cont casting - GOSH AIST.indd 1 13/03/2019 10:14:43

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- BS en Iso 13919-1-2019Document24 pagesBS en Iso 13919-1-2019Can ERTAN100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Historical Steel Beams 1873 To 1952Document137 pagesHistorical Steel Beams 1873 To 1952darkwing888100% (14)

- ASTM A903 - 12 Standard Specification For Steel Castings, Surface Acceptance Standards, Magnetic Particle and Liquid Penetrant InspectionDocument2 pagesASTM A903 - 12 Standard Specification For Steel Castings, Surface Acceptance Standards, Magnetic Particle and Liquid Penetrant InspectionCan ERTANNo ratings yet

- Post-Mortem Ladle Shroud Analysis From The Casting of Al-Killed Steel: Microstructures and Origin of Alumina Clogging DepositsDocument15 pagesPost-Mortem Ladle Shroud Analysis From The Casting of Al-Killed Steel: Microstructures and Origin of Alumina Clogging DepositsCan ERTANNo ratings yet

- ASTM D4289-03 Standard Test Method For Elastomer Compatibility of Lubricating Greases and FluidsDocument8 pagesASTM D4289-03 Standard Test Method For Elastomer Compatibility of Lubricating Greases and FluidsCan ERTANNo ratings yet

- ASTM E45-18 Standard Test Methods For Determining The Inclusion Content of SteelDocument19 pagesASTM E45-18 Standard Test Methods For Determining The Inclusion Content of SteelCan ERTANNo ratings yet

- Test Ink Blue 30-58 English FTTDocument11 pagesTest Ink Blue 30-58 English FTTCan ERTANNo ratings yet

- MSF 730-732 733Document7 pagesMSF 730-732 733Can ERTANNo ratings yet

- The Chord Reset (4 Variations)Document8 pagesThe Chord Reset (4 Variations)Can ERTANNo ratings yet

- General Presentation: Chemical Composition C Si MN Ni CR Cu Mo N P SDocument7 pagesGeneral Presentation: Chemical Composition C Si MN Ni CR Cu Mo N P SCan ERTANNo ratings yet

- Fast Pulse Width Modulation (FPWM) Technology For DC-DC Converter, Featuring High-Speed Response With A Clock-Synchronized Comparator Control MethodDocument2 pagesFast Pulse Width Modulation (FPWM) Technology For DC-DC Converter, Featuring High-Speed Response With A Clock-Synchronized Comparator Control MethodCan ERTANNo ratings yet

- Ger SS 114-94201 A2Document7 pagesGer SS 114-94201 A2Can ERTANNo ratings yet

- Hydrochloric Acid SDSDocument15 pagesHydrochloric Acid SDSCan ERTANNo ratings yet

- Nitric Acid 65% SDS PDFDocument22 pagesNitric Acid 65% SDS PDFCan ERTANNo ratings yet

- Struers Application Note - Metallographic Preparation of High Alloy Tool SteelDocument6 pagesStruers Application Note - Metallographic Preparation of High Alloy Tool SteelCan ERTANNo ratings yet

- Struers Application Note - Metallographic Preparation of TitaniumDocument6 pagesStruers Application Note - Metallographic Preparation of TitaniumCan ERTANNo ratings yet

- Selection Guide For Hot MountingDocument1 pageSelection Guide For Hot MountingCan ERTANNo ratings yet

- Effect of Forging Surface On Fatigue Behavior of Steels A Literature ReviewDocument56 pagesEffect of Forging Surface On Fatigue Behavior of Steels A Literature ReviewCan ERTANNo ratings yet

- Liquid Rubber Base (LRB) : Technical Data SheetDocument2 pagesLiquid Rubber Base (LRB) : Technical Data SheetMilko Cataldo VegaNo ratings yet

- Cement Mineral Constituents of CementDocument2 pagesCement Mineral Constituents of CementSojol Saha SojolNo ratings yet

- بحث جدا مهم مركبات الكبريت العضوية في البترولDocument292 pagesبحث جدا مهم مركبات الكبريت العضوية في البترولعلاء كريم كاظمNo ratings yet

- Major Material Requirement: Ruwanpura Expressway Project - Phase 01Document2 pagesMajor Material Requirement: Ruwanpura Expressway Project - Phase 01Shamitha KanchanaNo ratings yet

- Chemie Ingenieur Technik Volume 73 Issue 6 2001 (Doi 10.1002/1522-2640 (200106) 73:6-605::aid-Cite6054444-3.0.Co 2-g) Görge Baltin Heinz Köser Klaus-Peter Wendlandt - Reactive DesorDocument1 pageChemie Ingenieur Technik Volume 73 Issue 6 2001 (Doi 10.1002/1522-2640 (200106) 73:6-605::aid-Cite6054444-3.0.Co 2-g) Görge Baltin Heinz Köser Klaus-Peter Wendlandt - Reactive Desorlili purwasihNo ratings yet

- BOC Gases Handbook: September 2001Document20 pagesBOC Gases Handbook: September 2001usman_hafeez86No ratings yet

- Alchemy 2005Document347 pagesAlchemy 2005timop100% (4)

- GN 01Document9 pagesGN 01Sohag114No ratings yet

- Chart Móc Trái Tim Ôm NhauDocument12 pagesChart Móc Trái Tim Ôm NhauHeir ĐàNo ratings yet

- Costing of H3S CuencaDocument5 pagesCosting of H3S CuencaJomin Dennis MiembroNo ratings yet

- Science G7 SUMMATIVE 2021 EDITEDDocument2 pagesScience G7 SUMMATIVE 2021 EDITEDedwin dumopoyNo ratings yet

- Evaluation of Resilient Characteristics of Stone Matrix Asphalt (Sma)Document4 pagesEvaluation of Resilient Characteristics of Stone Matrix Asphalt (Sma)Nikhil GuptaNo ratings yet

- Comparison of ASTM C311 Strength Activity Index Testing vs. Testing Based On Constant Volumetric ProportionsDocument22 pagesComparison of ASTM C311 Strength Activity Index Testing vs. Testing Based On Constant Volumetric ProportionsAnkur BarsainyaNo ratings yet

- Nomenclature AnsDocument8 pagesNomenclature Ansdlc352-sc1No ratings yet

- Conductivity of Solutions - Chem 101 Lab - 1Document8 pagesConductivity of Solutions - Chem 101 Lab - 1Erin Twomey50% (2)

- Sf6 Gas and The EnvironmentDocument3 pagesSf6 Gas and The EnvironmentmohammedNo ratings yet

- 8 - Glass and TimberDocument17 pages8 - Glass and TimberSyed Muzamil AhmedNo ratings yet

- Overview of Zirconia Application As Denture Base Material Substituting For MetalDocument4 pagesOverview of Zirconia Application As Denture Base Material Substituting For MetalNur IbrahimNo ratings yet

- Klingerit 1000 PDFDocument2 pagesKlingerit 1000 PDFindrapatiwNo ratings yet

- En - Wykaz Towarów - CN Od 20230812Document8 pagesEn - Wykaz Towarów - CN Od 20230812Юрий АндреевNo ratings yet

- Schedule of Rates, Zone Contracts - General Building Works BHRDocument38 pagesSchedule of Rates, Zone Contracts - General Building Works BHRnadeeshlakmalNo ratings yet

- Ep 300Document2 pagesEp 300mathewsujith31No ratings yet

- GenChem2 Q4 MELC 7-9 Week-5Document7 pagesGenChem2 Q4 MELC 7-9 Week-5BSED FIL 1- Ashley Romarie A. LactaotaoNo ratings yet

- Activity Sheet - Grade 8 PeriodicTable - Final As of April 19, 2018Document105 pagesActivity Sheet - Grade 8 PeriodicTable - Final As of April 19, 2018Daphnie Serate Nunez100% (1)

- ChemistryDocument26 pagesChemistryfaisalNo ratings yet

- Wang 2020Document19 pagesWang 2020Nguyễn Thái CôngNo ratings yet

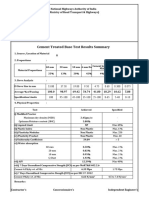

- Cement Treated Base Test Results Summary: National Highways Authority of India (Ministry of Road Transport & Highways)Document61 pagesCement Treated Base Test Results Summary: National Highways Authority of India (Ministry of Road Transport & Highways)Fariha Azad100% (2)

- Gypsum Plaster: Advantages and DisadvantagesDocument35 pagesGypsum Plaster: Advantages and DisadvantagesadkNo ratings yet

- ACO-Buildine BALCONY AND CORRIDOR DRAINDocument1 pageACO-Buildine BALCONY AND CORRIDOR DRAINJohnnattan De GuzmanNo ratings yet