Professional Documents

Culture Documents

Notifier Explosion Proof Smoke Detector 30 3003

Notifier Explosion Proof Smoke Detector 30 3003

Uploaded by

Tee RixOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Notifier Explosion Proof Smoke Detector 30 3003

Notifier Explosion Proof Smoke Detector 30 3003

Uploaded by

Tee RixCopyright:

Available Formats

DN-3846:C1

30-3003

Explosion-Proof Smoke Detector

Conventional Initiating Devices

General

The Pyrotector Model 30-3003 Explosion Proof Smoke Detec-

tor is a sensitive yet rugged protection device that is designed

for use in hazardous industrial and commercial locations. The

detector is designed to operate effectively with both slow smol-

dering and fast burning fires.

Features

• Rugged construction.

30-3003C.jpg

• Self checking and compensating circuitry maintains desired

sensitivity.

• Heightened sensitivity triggered when smoke is increasing,

3846cros.tif

but has not yet reached the preset sensitivity setting.

• Form A (SPST) N.O. contacts for connection to alarm out-

put circuitry.

• SPST N.C. contacts for supervision of input power.

• 2.3% fixed sensitivity.

Applications

• Combustible storage facilities.

• Munitions manufacturing.

• Volatile chemical storage.

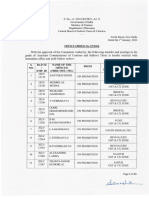

• Chemical processing plants. Cross Section of Sensing Chamber Assembly

• Petroleum refineries.

circuit. An increase in smoke within the detection chamber

• Turbine enclosures.

that exceeds a preset rate causes the rate-compensation cir-

cuit to increase the intensity of the light source, which

Construction & Operation increases detector sensitivity. If the smoke continues to build

The photoelectric smoke detector uses a solid-state infrared- at this rate, an amplifier circuit is triggered and the unit gener-

emitting diode (IRED) and a light-sensing photovoltaic cell ates an alarm. If not, the detector reverts to normal sensitivity.

arranged in a labyrinth assembly. The labyrinth permits free In normally smoky atmospheres, the detector will not go into

access to smoke but restricts external light. Because of its alarm as long as the concentration is less than the fixed sensi-

critical function to the operation of the detector, each IRED is tivity of the detector. This results in a sensitive and positive

selected with extreme care and is subjected to rigorous pre- response with a very low potential for unwanted alarms.

production testing to ensure long-term reliability and perfor-

The main enclosure of the detector contains the electronic cir-

mance.

cuitry, alarm relay, and supervision relay.

During normal operation (no smoke), the detector samples the

Fail-safe Operation. To ensure reliable operation, the Model

air approximately every four seconds for a period of less than

30-3003 is equipped with self-checking circuitry. A regulation

one millisecond. The photovoltaic smoke cell, which is placed

photodiode, which is matched to the smoke detection circuit,

at an angle to the pulsed invisible light source, is sensitive to

continuously monitors the output intensity of the IRED and

the infrared light in the specified frequency emitted by the

adjusts it as necessary to compensate for an accumulation of

IRED light source and is designed to receive a signal only

dust or other contaminants, or any other variation that can

when the pulsed IRED source is activated. See “Cross Sec-

occur with temperature and time. A power supervision relay in

tion of Sensing Chamber Assembly” at top of opposite column.

the detector provides a trouble output signal in the event of an

When smoke enters the chamber, the light from the IRED input power failure.

reflects off the smoke particles and reaches the photovoltaic

The detector uses extensive filtering against RF and transient

smoke cell. When the amount of light reflected by smoke

interference. In addition, there is a two-second time delay

reaches the factory-set threshold level, the smoke alarm circuit

before an alarm is generated.

is actuated.

The printed circuit board inside the detector is coated to mini-

The detector will respond to a slow smoldering fire when

mize the possibility of problems caused by moisture accumula-

smoke in the chamber reaches the preset sensitivity setting,

tion.

typically 2.3%.

Detector Outputs. The detector provides a set of Form A

If a fast-burning fire should occur, including fires in flammable

(SPST) N.O. contacts for connection to the alarm output cir-

liquids and other materials such as plastics that generate black

cuitry and a set of SPST N.C. contacts for supervision of input

smoke, the abnormally rapid movement of smoke into the

power. An auxilliary set of Form C (SPDT) NO/NC alarm relay

detection chamber is sensed by a special rate-compensating

contacts is also provided for controlling remote annunication

DN-3846:C1 • 03/21/2012 — Page 1 of 2

devices. The alarm output latches on in the event of an alarm Engineering Specifications

and an LED located on the outer surface of the housing is illu-

minated to provide a visual indication that an alarm condition The detector shall be a 2.3% fixed sensitivity photoelectric

has occurred. The detector is reset by momentarily interrupt- smoke detector, providing minimum response time to all fire

ing input power. types.

Classification. The Model 30-3003 is designed to meet NEC The detection chamber shall extend beyond the main housing

requirements for Class I, Division 2, Groups A,B, C and D; into the area to be protected, to provide maximum smoke entry

hazardous areas. CSA certified for use in Class 1, Division 2, capability into the chamber from any direction.

Groups A,B, C, and D hazardous locations. The detector light source shall be an IRED (Infrared Emitting

Explosion-Proof Certification. The Model 30-3003 is certi- Diode). Typical detector current consumption in the standby

fied by the German Electric Industry Association, VDE, to condition shall be 10 milliamperes.

meet Standards 0171/ “Special Protection” (Ex)sG5 (sand The detector shall lock in on alarm and have a visible alarm

encapsulated), and PTB/CENELEC approved as EEx q II T5. indicator LED.

The detector shall have SPST alarm relay contacts for connec-

Specifications tion to the fire alarm control panel and also power supervision

Operating Voltage: 20 to 28 volts DC. contacts.

Operating Current: Standby: 10 milliamperes. Alarm: 35 The detector enclosure shall be an explosion-proof flanged

milliamperes. housing designed to meet CSA certification for use in Class 1,

Division 2, Groups A, B, C and D hazardous locations.

Temperature Range: –13°F to +140°F (–25°C to +60°C).

The detector shall be intended for surface mounting and con-

Alarm and Supervisory Relay Contact Rating: 1.0 ampere nection to the system wiring shall be within a rated enclosure

at 30 vdc. SPST. (furnished).

Auxiliary Alarm Relay Contact Rating: 2.0 amperes at 30

vdc. Form C. SPDT. Product Line Information

Dimensions: Diameter: 5-5/16". Depth: 3-1/2". 30-3003: Explosion-Proof Smoke Detector.

Junction Box: Body Material: Copper-free aluminum,

Cover: Feraloy, Conduit Fitting: 25 mm (female).

Installation

The Model 30-3003 is intended for surface mounting. The

mounting screw holes are counterbored for No. 8 flat-head

screws. Electrical equipment that is used in conjunction with

the smoke detector is connected to the detector using a termi-

nal strip located in the junction box that is furnished with the

unit.

NOTE: For maintenance information see your product documenta-

tion.

Detector Location

The smoke detector is normally mounted on the ceiling not

less than six inches from a side wall. The exact location of the

detector must be determined by an evaluation based on engi-

neering judgment supplemented, if possible, by field tests.

For additional information on detector location and spacing,

contact the National Fire Protection Association, Battery-

march Park, Quincy, Massachusetts 02269, and request a

copy of NFPA Number 72, the Standard on Automatic Fire

Detectors.

Detector Connections

The Model 30-3003 contains two sets of relay contacts.

1. One set of N.O. Alarm contacts close upon detection of

smoke.

2. One set of N.C. Trouble contacts close when the detector

is powered. Notifier® is a registered trademark of Honeywell International Inc.

©2012 by Honeywell International Inc. All rights reserved. Unauthorized use

of this document is strictly prohibited.

This document is not intended to be used for installation purposes.

We try to keep our product information up-to-date and accurate.

We cannot cover all specific applications or anticipate all requirements.

All specifications are subject to change without notice.

Made in the U.S. A.

For more information, contact Notifier. Phone: (203) 484-7161, FAX: (203) 484-7118.

www.notifier.com

Page 2 of 2 — DN-3846:C1 • 03/21/2012

You might also like

- Vogue USA - January 2021Document94 pagesVogue USA - January 2021Andreea Dana100% (6)

- Laboratory Report (For Online Lab Class Only) : ECTE333: Microcontroller Architecture and Application Spring 2020 SessionDocument8 pagesLaboratory Report (For Online Lab Class Only) : ECTE333: Microcontroller Architecture and Application Spring 2020 SessionSaad KamranNo ratings yet

- MX Spark Detectors FUX 3001 DL FUX 3001 DL Ex PDFDocument2 pagesMX Spark Detectors FUX 3001 DL FUX 3001 DL Ex PDFNarendra Reddy BhumaNo ratings yet

- Explosion-Proof Smoke Detector: GeneralDocument2 pagesExplosion-Proof Smoke Detector: GeneralBambang Sigit PriyantoNo ratings yet

- U5005 Humo A Prueba de ExplosionDocument4 pagesU5005 Humo A Prueba de ExplosionJuan Carlos Oliva OrtizNo ratings yet

- V9006 Haz Loc Smoke Detronics InstallDocument4 pagesV9006 Haz Loc Smoke Detronics InstallIsaac VelasquezNo ratings yet

- Technical Manual: Explosion Proof Triple Infrared Flame Detector Model No.: AS-E302-IR3Document5 pagesTechnical Manual: Explosion Proof Triple Infrared Flame Detector Model No.: AS-E302-IR3Emre YıldırımNo ratings yet

- Acc V - 12 2017Document2 pagesAcc V - 12 2017Anas Ibrahim RaafatNo ratings yet

- I-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01Document2 pagesI-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01HiteshgangeleNo ratings yet

- Sensor Anti Chamas Hosokawa PDFDocument1 pageSensor Anti Chamas Hosokawa PDFCristiano FariasNo ratings yet

- Nova-5000 Detection & Control SystemDocument2 pagesNova-5000 Detection & Control Systemmubs73No ratings yet

- 5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorDocument4 pages5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorcembozNo ratings yet

- Model S270 Intrinsically Safe Smoke Detector: Nova-5000 Detection & Control SystemDocument2 pagesModel S270 Intrinsically Safe Smoke Detector: Nova-5000 Detection & Control SystemStephanie Reyes HdezNo ratings yet

- Standard Features: Series 65A Photoelectric Smoke DetectorDocument2 pagesStandard Features: Series 65A Photoelectric Smoke DetectorMostafa AliNo ratings yet

- 3-Receptor Haz de Luz 23901-01, Ec-LltDocument4 pages3-Receptor Haz de Luz 23901-01, Ec-Lltcrscardona.2024No ratings yet

- Đầu Báo Khói Kết Hợp Nhiệt Địa Chỉ Acc-V - 09-2015Document2 pagesĐầu Báo Khói Kết Hợp Nhiệt Địa Chỉ Acc-V - 09-2015Nguyễn Kỳ TúNo ratings yet

- Soc-24V Conventional Photoelectric Smoke Detector: ApplicationsDocument2 pagesSoc-24V Conventional Photoelectric Smoke Detector: Applicationsuygar öztürkNo ratings yet

- Https Hochiki - VN Uploads Plugin File 135 1590594717-270100149-Soc-24v-Photoelectric-Smoke-DetectorDocument2 pagesHttps Hochiki - VN Uploads Plugin File 135 1590594717-270100149-Soc-24v-Photoelectric-Smoke-DetectorTráng Nguyễn VănNo ratings yet

- Fire Alarm Control Panel 4-16 Zones: User & Installation ManualDocument17 pagesFire Alarm Control Panel 4-16 Zones: User & Installation ManualAje kakaNo ratings yet

- 10.0.3 - Smoke DetectorDocument2 pages10.0.3 - Smoke DetectorGopinath SekarNo ratings yet

- Minerva Marine: M600Ex Intrinsically Safe Fire DetectorsDocument4 pagesMinerva Marine: M600Ex Intrinsically Safe Fire DetectorsBrillyanNo ratings yet

- K85001-0560 - Reflective Beam DetectorDocument4 pagesK85001-0560 - Reflective Beam DetectorDauXuan HuynhNo ratings yet

- ApolloFire XP95 MultisensorDocument2 pagesApolloFire XP95 MultisensorfasiwiNo ratings yet

- FLAME DETECTION & PROTN - MS9001FA+eDocument2 pagesFLAME DETECTION & PROTN - MS9001FA+eShivam SinghNo ratings yet

- m600 DatasheetDocument4 pagesm600 DatasheetCost RootsNo ratings yet

- Instructions 95-8527: Protect - IR Multispectrum IR Flame Detector X3301Document32 pagesInstructions 95-8527: Protect - IR Multispectrum IR Flame Detector X3301OrtegampNo ratings yet

- Fuente Fcps 24s6eDocument12 pagesFuente Fcps 24s6eGuido RuizNo ratings yet

- Fire Alarm Control Panel 4-16 Zones User & Installation ManualDocument12 pagesFire Alarm Control Panel 4-16 Zones User & Installation Manualاسلام محمدNo ratings yet

- Module 7 - Fire Alarm and Detection SystemDocument86 pagesModule 7 - Fire Alarm and Detection SystemegrtacnengNo ratings yet

- 601P Install ManualDocument2 pages601P Install ManualDanut Stefan100% (2)

- Aln-V Photoelectric Smoke Sensor: ApplicationsDocument2 pagesAln-V Photoelectric Smoke Sensor: ApplicationsrjucNo ratings yet

- ProjectDocument18 pagesProjectGayathri RokkamNo ratings yet

- Datasheet Discovery EngelsDocument2 pagesDatasheet Discovery EngelsfloriskooimanbeveiligingNo ratings yet

- Depliant Iris Enea Inim 1.10 ENGDocument4 pagesDepliant Iris Enea Inim 1.10 ENGKnjigescribdNo ratings yet

- Flame Detector System: PurchaserDocument2 pagesFlame Detector System: PurchaserDenis Jimenez100% (1)

- Project Name Fire Alarm Security System: Submitted by MD - Rubel Mia ROLL:161116Document13 pagesProject Name Fire Alarm Security System: Submitted by MD - Rubel Mia ROLL:161116Rubel RiadNo ratings yet

- VAR TEC FDR Series User ManualDocument2 pagesVAR TEC FDR Series User ManualmicrajacutNo ratings yet

- Fire AlarmDocument13 pagesFire Alarmmnry414No ratings yet

- Truealarm Smoke Detectors: FeaturesDocument4 pagesTruealarm Smoke Detectors: FeaturescostaNo ratings yet

- Đầu Báo Khói Quang Địa ChỉDocument2 pagesĐầu Báo Khói Quang Địa ChỉLe Quang AnNo ratings yet

- Installation Manual EnUS 16566339211Document6 pagesInstallation Manual EnUS 16566339211Hoằng PhạmNo ratings yet

- Spc-24 Projected Beam Smoke Detector: ApplicationDocument2 pagesSpc-24 Projected Beam Smoke Detector: ApplicationDauXuan HuynhNo ratings yet

- Fire Detection and Alarm System Ijariie16692Document8 pagesFire Detection and Alarm System Ijariie16692Sibi SurendranNo ratings yet

- DUR-4047 Manual de Instalare - ENGDocument11 pagesDUR-4047 Manual de Instalare - ENGDorin SimioanaNo ratings yet

- GSM Based Industrial Security System: Abstract: Security and Automation Is A PrimeDocument6 pagesGSM Based Industrial Security System: Abstract: Security and Automation Is A PrimeMuhammed JaleelNo ratings yet

- Fire Safety: Building Management SystemsDocument85 pagesFire Safety: Building Management SystemssriNo ratings yet

- OptimDocument2 pagesOptimpieterdefrereNo ratings yet

- Ir3-Flame-Sensor-2-Page KopyasıDocument7 pagesIr3-Flame-Sensor-2-Page KopyasıNazim YesilkayaNo ratings yet

- Siemens Photoelectric Smoke DetectorDocument5 pagesSiemens Photoelectric Smoke DetectorEngineering TFINo ratings yet

- Intelia Fire Detectors: Tech Data Sheet Fire DetectionDocument3 pagesIntelia Fire Detectors: Tech Data Sheet Fire DetectionLado RostiashviliNo ratings yet

- SPEC. FGS Rev.2 - 11-15Document5 pagesSPEC. FGS Rev.2 - 11-15kepuren loro0% (1)

- Series: Conventional Detector RangeDocument4 pagesSeries: Conventional Detector RangearunNo ratings yet

- 0000944-Salwico Ac-Ir-3fq PDFDocument2 pages0000944-Salwico Ac-Ir-3fq PDFТарас АртюхNo ratings yet

- Detector de Llama (U7652) PDFDocument4 pagesDetector de Llama (U7652) PDFari78No ratings yet

- User Manual of Explosion Proof Smoke Detector AS-SD801EXDocument5 pagesUser Manual of Explosion Proof Smoke Detector AS-SD801EXEmre YıldırımNo ratings yet

- SD Op921Document4 pagesSD Op921Mohammad FathiNo ratings yet

- Photoelectric Smoke Detector P.1.18.01-4Document2 pagesPhotoelectric Smoke Detector P.1.18.01-4Pedro Caminos BolanosNo ratings yet

- IRD 1020 Infra-Red Flicker Detector: Flame Detection Device For Oil and Gas FlamesDocument4 pagesIRD 1020 Infra-Red Flicker Detector: Flame Detection Device For Oil and Gas FlamesJorge Gustavo GoyecheaNo ratings yet

- Caram Vs LauretagDocument1 pageCaram Vs LauretagALLYSSA JANE R. RUALLONo ratings yet

- Iot Project ProposalDocument7 pagesIot Project ProposalJames MondeloNo ratings yet

- Setting Up An Inventory Valuation Report in Dynamics AX Part 1 & 2Document18 pagesSetting Up An Inventory Valuation Report in Dynamics AX Part 1 & 2Fathy TahaNo ratings yet

- Basic Computer Hardware Quiz Questions and AnswerDocument10 pagesBasic Computer Hardware Quiz Questions and Answerkipassevone-1601100% (1)

- Step by Step GuideDocument5 pagesStep by Step GuideSourav SahaNo ratings yet

- Refiners Rhapsody 49 TheobatDocument80 pagesRefiners Rhapsody 49 TheobatIyere GiftNo ratings yet

- Tentree'sDocument6 pagesTentree's陈皎月No ratings yet

- Process Planning and Cost Estimation Nov / Dec 2013 Important Questions Unit-I (Workstudy and Ergonomics)Document2 pagesProcess Planning and Cost Estimation Nov / Dec 2013 Important Questions Unit-I (Workstudy and Ergonomics)RajeshKumarNo ratings yet

- Acer Ferrari 3400 Laptop ManualDocument113 pagesAcer Ferrari 3400 Laptop Manualmoming1No ratings yet

- Crafting Goals Objectives Vision and MisDocument19 pagesCrafting Goals Objectives Vision and MisJC Viacrucis JuaneroNo ratings yet

- Aem 805 - Aa - HW1Document28 pagesAem 805 - Aa - HW1AdefemiNo ratings yet

- DRUG FREE WORKPLACE Private - Public With ChartDocument26 pagesDRUG FREE WORKPLACE Private - Public With ChartKristi Lou TamingNo ratings yet

- Q3 Week2 Custom AnimationDocument28 pagesQ3 Week2 Custom AnimationEmee Grace RamonalNo ratings yet

- Office Order 07 of 2024 - 240101 - 200240Document32 pagesOffice Order 07 of 2024 - 240101 - 200240Hemant SinhmarNo ratings yet

- 2 - Picture Supported Writing Prompts - FEELINGS For SpEd or Autism UnitsDocument51 pages2 - Picture Supported Writing Prompts - FEELINGS For SpEd or Autism UnitsWake UpNo ratings yet

- Case Accounting - Air Asia BerhadDocument15 pagesCase Accounting - Air Asia BerhadWahyutri IndonesiaNo ratings yet

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)RMNo ratings yet

- ISE II Sample Paper 4 (With Answers)Document13 pagesISE II Sample Paper 4 (With Answers)Marta Navarro LópezNo ratings yet

- BSSE FYP Project ProposalDocument10 pagesBSSE FYP Project Proposal20014198-085No ratings yet

- 21st Century Literature From The Philippines and The World 1.1Document4 pages21st Century Literature From The Philippines and The World 1.1Kiefer SebastianNo ratings yet

- Benítez Et Al 2012Document7 pagesBenítez Et Al 2012Gladys González GonzálezNo ratings yet

- Utility CatalogDocument40 pagesUtility CatalogMilagros Mercedes Olmos CervantesNo ratings yet

- Proclimb Procross Torsional Conversion KitDocument8 pagesProclimb Procross Torsional Conversion KitcpcracingNo ratings yet

- Solutions Manual Elementary Surveying An Introduction To Geomatics - CompressDocument5 pagesSolutions Manual Elementary Surveying An Introduction To Geomatics - CompressHannah CiprianoNo ratings yet

- Otg Buying Guide CompressedDocument11 pagesOtg Buying Guide CompressedAreeba RahmanNo ratings yet

- North South University: Assignment Cover Page Department of Public HealthDocument2 pagesNorth South University: Assignment Cover Page Department of Public HealthRupak IslamNo ratings yet

- Moeller Datasheet NZM-XHI11L 266098Document3 pagesMoeller Datasheet NZM-XHI11L 266098Aziz Fauzi .No ratings yet

- 2006 T300 Body Builders ManualDocument76 pages2006 T300 Body Builders ManualСергей Орлов100% (1)