Professional Documents

Culture Documents

MS-DD-KMY01-MEC-GA-0002 (Shell) R3-1

MS-DD-KMY01-MEC-GA-0002 (Shell) R3-1

Uploaded by

Muhammad Rizky ImaduddinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS-DD-KMY01-MEC-GA-0002 (Shell) R3-1

MS-DD-KMY01-MEC-GA-0002 (Shell) R3-1

Uploaded by

Muhammad Rizky ImaduddinCopyright:

Available Formats

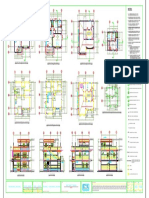

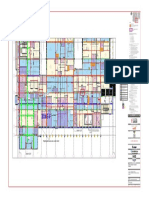

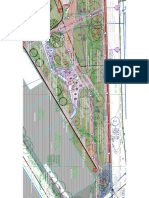

Ø1942 25 20 α BILL OF MATERIAL

SHELL

Outside

16+3 16 +3 R : Max. 4 mm

-0 -0

f : Max. 3 mm NO DESCRIPTION MATERIAL SIZE QTY

20

f T1 : See base metal

155 Inside β=α : 60°±5

27 28 40 FLANGE 16 +3

R

β

1 BASE PLATE A36 OD1994xID1486-Thk 30 1

-0 DETAIL A

PCD Ø1842

DETAIL C DETAIL B 2 FLANGE 1 A36 OD1994xID1740-Thk 30 1

Ø1740

Ø1942

65

224

175

DETAIL E DETAIL D 3 PLATE ANCHOR A36 127x245 - Thk 12 40

N1 4 SHELL 1 A36 Ø1740 x 2400-Thk 20 4

Ø14 0° 1200

72 340° 255

10° 5 SHELL 2 A36 Ø1740 x 2373-Thk 20 1

DETAIL SUPPORT LUG 325° 235

DETAIL 6 Ø23x40 Holes 24

FOR SCAFFOLDING 315° 120 1/4"NPT 6 FLANGE 2 A36 OD1942xID1740-Thk 25 1

310° 25

12

6 25 26 26 1 7 FLANGE 3 A36 OD1440xID1240-Thk 25 2

140

330

280

290° 8 SUPPORT PERSONNEL PROTECTION A36 60x75 - Thk 10 28

PCD Ø1842

20 Ø45 2

245

TYP

Ø1740

Ø1942

R115 9 EARTHING PIECE A36 130x38 - Thk 12 2

20 75 Ø150 DETAIL F

1486

1994

270° 90°

M1 24 200 25 10 DELETED

32" DETAIL TAILING LUG 11 DELETED

2-LIFTING TAILING

Ø23x40 Holes LUGS LUGS 127 12 12 DELETED

N4 234°

2" N2 DETAIL 3

1200 Section A-A 13 DELETED

OD Ø1942 0°

180° 270° 225° 180° 135° 90° 340° Flange 2 14 DELETED

OD Ø1740 6 45°

287° 234° 315° 30

B Ø1994 15 BLIND PLATE A36 ID1700-Thk 10 1

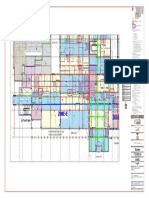

B

192.5

16

CW6 DETAIL G

CW6 CW6

16 NECK N1 A36 Ø1200 - Thk 20 1

800

784

784

1300

17 NECK N2 A36 Ø1200 - Thk 20 1

1826.5

5

LW5

PCD Ø1867

2367.5

2351.5

500

SHELL

18 MANHOLE A36 ID 32" - Thk 20 1

Ø1740

Ø1994

A 27 10 +3

-0

3122.5

542.5

19 NOZZLE DRAIN A 106 Gr. B 2" SCH 40 SMLS 1

1092.5

1000

28 800

FLANGE

LW5

10 +3

-0 20 REINFORCEMENT PAD LIFTING ASTM A36 375 x 375 x 20t 2

A A 800 A DETAIL H

CW5 CW5 CW5

21 END PLATE LIFTING LUG ASTM A36 Ø 325 x 20t 2

Ø58x20 Holes

8

1900

DETAIL 2

A 22 LIFTING LUG A106 GRr.B PIPE 8" SCH 80 2

Ø1994 30 16+3

10 +3

-0 23 STIFFENER RING ASTM A36 Ø 325 x 20t 2

2400

2400

-0

LW4

24 REINFORCEMENT PAD TAILING ASTM A36 200 x 330 x 20t 1

1645

LW4

1145

1145

1025

25 TAILING LUG ASTM A36 280 x 235 x 25t 1

1370

PROTECTION 2

LW4

PCD Ø1867

A CW4

DETAIL I 26 RING PLATE TAILING ASTM A36 Ø 150 x 12t 2

CW4 CW4 A

Ø1486

Ø1994

345

355

A 27 REINFORCEMENT PAD SUPPORT LUG ASTM A36 225 x 72 x 10t 16

75

3000

683 425 150 28 SUPPORT LUG PLATE ASTM A36 155 x 175 x 12t 16

11951.5

11997.5

2400

2400

29 DELETED

1970

A

LW3

Ø58x20 Holes 30 DELETED

DETAIL 1

800

135 31 DELETED

A CW3 A A 22 375

00

CW3 1/4" NPT

21

325 32 DELETED

CW3

21

CW

30°

7

6 A 33 DELETED

LW

1754

2945

325

375

375

7 25 34 DELETED

2400

2400

8

3000

35 RECTANGULAR WASHER ASTM A36 126 x 96 x 20t 20

1590

N1 N1

CW

1200

R173

1200 23

8

4 36 DELETED

1380 200 20

LW2

LW2

LW2

16 A DETAIL LIFTING LUG

4900

CW2 CW2 A CW2

17

55

A

2000

Nameplate 7 300 800

9 A M1

1027

N2 Ø800 M1 6 +3

LW7 1200

19 32" -0

N2 32"

12

2095

2660

1380

2690

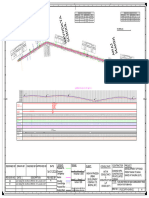

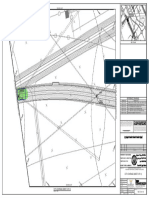

STEAM DRYER EXHAUST GAS STACK STEAM DRYER EXHAUST GAS STACK

CODE ASME STS-1 SIZE I.D.1700 x 30 mtr H CODE ASME STS-1 SIZE I.D.1700 x 30 mtr H

ITEM NO. 4821-STC-0001 THICKNESS 20 mm THK. ITEM NO. 4821-STC-0001 THICKNESS 20 mm THK.

3 mm 3 mm

SERVICE EXHAUST GAS CORR.ALLOW SERVICE EXHAUST GAS CORR.ALLOW

1200

DESIGN CAP. 120,000 Nm³/hr NDT UT & MT SPOT DESIGN CAP. 120,000 Nm³/hr NDT UT & MT SPOT

PROTECTION 1 1500

30.500 Kgs 30.500 Kgs

OPERATING CAP. 86,760 Nm³/hr NET WEIGHT. OPERATING CAP. 86,760 Nm³/hr NET WEIGHT.

DESIGN TEMP. 180 °C YEAR BUILT 2022 DESIGN TEMP. 180 °C YEAR BUILT 2022

FGE-STC-0001 FGE-STC-0001

OPERATING TEMP 130 °C SERIAL NO. OPERATING TEMP 130 °C SERIAL NO.

2400

DESIGN PRESS.

FABRICATOR

50 psig

PT.FACO Global Engineering

MANYAR SMELTER PROJECT

DESIGN PRESS.

FABRICATOR

50 psig

PT.FACO Global Engineering

MANYAR SMELTER PROJECT

2400

2375

PT. KOTAMINYAK INTERNUSA PT. Chiyoda International Indonesia PT. FREEPORT INDONESIA PT. KOTAMINYAK INTERNUSA PT. Chiyoda International Indonesia PT. FREEPORT INDONESIA

1240

LW1

LW1

1500

A A Top

Ø11

1183

CW10

CW9

Baseplate 30

2 18

1153

1183

1070

1100

6 +3

-0

H

675

570

CW1

515

545

560

305

245

305

C B CW1

38

N3

N4 Ø1994 30 2" 380 30

Ø1994 35

2" 260 683 1366 423.3 Bottom Baseplate

1 LEFT VIEW

3 1366 1366 130 20

15 FRONT VIEW

5464 DETAIL EARTHING PIECE (125° & 305°)

SHELL ORIENTATION

PT. FREEPORT INDONESIA

PT. Chiyoda International Indonesia

PT. KOTAMINYAK INTERNUSA

FLARE INTERNUSA

PT. FACO Global Engineering

You might also like

- P8 Fisico PDFDocument2 pagesP8 Fisico PDFazul mesaNo ratings yet

- AWS Vs Azure Vs Google Cloud - A Detailed Comparison of The Cloud Services Giants PDFDocument10 pagesAWS Vs Azure Vs Google Cloud - A Detailed Comparison of The Cloud Services Giants PDFSakthivel PNo ratings yet

- Machine Design Ebook1Document184 pagesMachine Design Ebook1Hew LetNo ratings yet

- Chachu Majra: Sector - 66 BetaDocument1 pageChachu Majra: Sector - 66 Betapujan77No ratings yet

- Combined AC Dwgs-31Document1 pageCombined AC Dwgs-31ibrahimsirpiNo ratings yet

- Limite de Frentes de TrabajosDocument1 pageLimite de Frentes de TrabajosJohann Nick Flores AparicioNo ratings yet

- Villa Madrid: Veintiuno de AbrilDocument1 pageVilla Madrid: Veintiuno de AbrilMel RiszeNo ratings yet

- Bloc BDocument1 pageBloc Bيو ليلNo ratings yet

- 3060 Map IS & Clan CircaDocument1 page3060 Map IS & Clan CircaWolfSpiderXNo ratings yet

- 3055 Map IS & Clan CircaDocument1 page3055 Map IS & Clan CircaWolfSpiderXNo ratings yet

- Ubic - Loc 3DDocument1 pageUbic - Loc 3DRolan Yañez ParionaNo ratings yet

- Total Parking Slot - 67 Cars: Entry & ExitDocument1 pageTotal Parking Slot - 67 Cars: Entry & ExitriteshNo ratings yet

- Unidad Educativa Cota ReferenciaDocument1 pageUnidad Educativa Cota ReferenciaHENRY CHOQUE GONZALONo ratings yet

- Acad-plot-Arazi CH Ali - V 2-Layout2Document1 pageAcad-plot-Arazi CH Ali - V 2-Layout2sssmajiksssNo ratings yet

- Osnova Dvojke Recover-Layout1Document1 pageOsnova Dvojke Recover-Layout1Миша МилановNo ratings yet

- Ra-020474 001Document1 pageRa-020474 001instqc001No ratings yet

- Steel Construction Example PDFDocument1 pageSteel Construction Example PDFArmin ŠehićNo ratings yet

- Location of Building BlocksDocument1 pageLocation of Building Blocks10Aboli MahajanNo ratings yet

- φDocument1 pageφantonisdachliNo ratings yet

- Bland LogoTitle Back - Final Fantasy Tactics PS1 Hitoshi SakimotoDocument2 pagesBland LogoTitle Back - Final Fantasy Tactics PS1 Hitoshi SakimotoCaio mantovani AlvesNo ratings yet

- Sector 03: Consultor Ubicación Proyecto: PlanoDocument1 pageSector 03: Consultor Ubicación Proyecto: PlanoeeeNo ratings yet

- MCC Room - Mezzanine Ac ReqtDocument1 pageMCC Room - Mezzanine Ac ReqtMark Magadia IpaNo ratings yet

- 1Document1 page1Engr M.Arshad KhalidNo ratings yet

- IBMD - MKD Layout 02.12.2019 PDFDocument1 pageIBMD - MKD Layout 02.12.2019 PDFManoj DasNo ratings yet

- K 2Document1 pageK 2assis alihNo ratings yet

- 3067 CcsDocument1 page3067 CcsKovács AttilaNo ratings yet

- La Madrugá Clarinete Principal PDFDocument1 pageLa Madrugá Clarinete Principal PDFChristianNo ratings yet

- NGP Con BRG Gad 836 2 - V15Document1 pageNGP Con BRG Gad 836 2 - V15PadmalavMahatoNo ratings yet

- YMCADocument1 pageYMCAOliver Hahn100% (1)

- Drilled Shaft Details: Common FoundationDocument2 pagesDrilled Shaft Details: Common FoundationSukrit GhoraiNo ratings yet

- Proposed Land Use 228 Sheet-1Document1 pageProposed Land Use 228 Sheet-1Shashi KumarNo ratings yet

- CPT Sagragao 2-A1Document1 pageCPT Sagragao 2-A1Ralph Emmerson BalaneNo ratings yet

- H16 Comprehensive Detailed Area Plan On Rs Mauza MapDocument1 pageH16 Comprehensive Detailed Area Plan On Rs Mauza MapMd Omor FarukNo ratings yet

- Desague (1) - Planta GeneralDocument1 pageDesague (1) - Planta Generalkristian MéndezNo ratings yet

- Eamco DMJ RS SD 001Document1 pageEamco DMJ RS SD 001libin513No ratings yet

- Selecione Um Bitmap: Observações ServiçosDocument1 pageSelecione Um Bitmap: Observações ServiçosFernando SantosNo ratings yet

- Huawei P30 Pro SchematicDocument77 pagesHuawei P30 Pro Schematicmaciej.gugol100% (1)

- DRIVEWAY ModelDocument1 pageDRIVEWAY ModelaxecubertoneNo ratings yet

- Kamc MT DWG 005 00 CommentsDocument2 pagesKamc MT DWG 005 00 Commentssaiidaahmed91No ratings yet

- Crisis Core - Final Fantasy VII - The Price of FreedomDocument2 pagesCrisis Core - Final Fantasy VII - The Price of FreedomRodokusuNo ratings yet

- Larissa Zigovski OrtofotoDocument1 pageLarissa Zigovski OrtofotoLarissa ZigovskiNo ratings yet

- The Blackink: Key Plan-Typical Floor Option - 2Document1 pageThe Blackink: Key Plan-Typical Floor Option - 2Aayushi GoyalNo ratings yet

- Clinica Hospital PDFDocument1 pageClinica Hospital PDFJenifer Diaz MejiaNo ratings yet

- Kshethra Farms - Westwoods Phase - 2 - Plots Layout With Areas and Dim - Dated 015.12.2023-ModelDocument1 pageKshethra Farms - Westwoods Phase - 2 - Plots Layout With Areas and Dim - Dated 015.12.2023-Modelmanan.maheshwari298No ratings yet

- Drawing Notes: R.Ground &first Floor Plan Ground Floor Plan R.First & Terrace Floor PlanDocument1 pageDrawing Notes: R.Ground &first Floor Plan Ground Floor Plan R.First & Terrace Floor PlanShreya SutarNo ratings yet

- Ra-025718 001Document1 pageRa-025718 001instqc001No ratings yet

- Plano 4 Perfiles Geológicos-PERFILES GEOLOGICOSDocument1 pagePlano 4 Perfiles Geológicos-PERFILES GEOLOGICOSLuis DuRan RíosNo ratings yet

- OR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE FDocument1 pageOR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE FAhmed SolankiNo ratings yet

- OR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE EDocument1 pageOR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE EAhmed SolankiNo ratings yet

- 5076-Al Wasl-Plot - 38 - 3000 SERIES - ELEVATIONSDocument2 pages5076-Al Wasl-Plot - 38 - 3000 SERIES - ELEVATIONSdubai eyeNo ratings yet

- CP Drawings 091220Document8 pagesCP Drawings 091220Chethan GowdaNo ratings yet

- Alcantarill 9+140.53Document1 pageAlcantarill 9+140.53melcvmfotosNo ratings yet

- Waltz No. 2Document4 pagesWaltz No. 2SherylNo ratings yet

- Zona 5 Gimnasio Piso Caucho - MariposaDocument1 pageZona 5 Gimnasio Piso Caucho - MariposaJuan Sebastian Gamboa CaceresNo ratings yet

- 4.e L-Section-2Document1 page4.e L-Section-2AATVIK SHRIVASTAVANo ratings yet

- Planta Perfil Long.-3Document1 pagePlanta Perfil Long.-3Dennis GomezNo ratings yet

- Plano 01 FundacionDocument1 pagePlano 01 FundacionVetzy VediaNo ratings yet

- Reference Drawings: Key PlanDocument1 pageReference Drawings: Key PlanTalha BurnyNo ratings yet

- DWG Additional-Twin Pod Filter-Rev 1-ModelDocument1 pageDWG Additional-Twin Pod Filter-Rev 1-ModelMuhammad Rizky ImaduddinNo ratings yet

- MS-DD-KMY01-MEC-GA-0002 (Shell) R3-4Document1 pageMS-DD-KMY01-MEC-GA-0002 (Shell) R3-4Muhammad Rizky ImaduddinNo ratings yet

- MS-DD-KMY01-MEC-GA-0002 (Shell) R3-3Document1 pageMS-DD-KMY01-MEC-GA-0002 (Shell) R3-3Muhammad Rizky ImaduddinNo ratings yet

- 4821-STC-0001 Platform 1D Type 2 Frame Only Fix-SignedDocument7 pages4821-STC-0001 Platform 1D Type 2 Frame Only Fix-SignedMuhammad Rizky ImaduddinNo ratings yet

- MS-DD-KMY01-MEC-GA-0002 (Shell) R3-2Document1 pageMS-DD-KMY01-MEC-GA-0002 (Shell) R3-2Muhammad Rizky ImaduddinNo ratings yet

- MS-DD-KMY01-MEC-GA-0029 - Rev3 4221-SignedDocument4 pagesMS-DD-KMY01-MEC-GA-0029 - Rev3 4221-SignedMuhammad Rizky ImaduddinNo ratings yet

- 4841-STC-0001 Platform 1B Type 2 Frame Only Fix-SignedDocument7 pages4841-STC-0001 Platform 1B Type 2 Frame Only Fix-SignedMuhammad Rizky ImaduddinNo ratings yet

- 4823-STC-0001 Platform DETAIL-signedDocument9 pages4823-STC-0001 Platform DETAIL-signedMuhammad Rizky ImaduddinNo ratings yet

- 4843-STC-0001 Platform DETAIL-signedDocument5 pages4843-STC-0001 Platform DETAIL-signedMuhammad Rizky ImaduddinNo ratings yet

- Magazines ListDocument11 pagesMagazines ListSheshadri Kattepur NagarajNo ratings yet

- ESD122 2-Channel ESD Protection Diode For USB Type-C and HDMI 2.0Document27 pagesESD122 2-Channel ESD Protection Diode For USB Type-C and HDMI 2.0H tavangarNo ratings yet

- Interest InventoriesDocument7 pagesInterest Inventoriesandrewwilliampalileo@yahoocomNo ratings yet

- Foreign Body Airway ObstructionDocument16 pagesForeign Body Airway ObstructionKatNo ratings yet

- Vizsgaanyag PDFDocument30 pagesVizsgaanyag PDFSipka GergőNo ratings yet

- General Properties of Engineering MaterialsDocument9 pagesGeneral Properties of Engineering MaterialsRoderick VillanuevaNo ratings yet

- Torrent WorkingDocument7 pagesTorrent WorkingsirmadamstudNo ratings yet

- Analytical Chem Chap11Document18 pagesAnalytical Chem Chap11Nicole Ann PedriñaNo ratings yet

- En 13237-2003 Terms and Definitions For Equipment and Protective Systems Intended For Use in Potentially Explosive AtmospheresDocument26 pagesEn 13237-2003 Terms and Definitions For Equipment and Protective Systems Intended For Use in Potentially Explosive AtmospheresGargiulo AnitaNo ratings yet

- Marketing Channels and Supply Chain ManagementDocument28 pagesMarketing Channels and Supply Chain ManagementGangadhar MamadapurNo ratings yet

- 02TP PrelimExam MITDocument2 pages02TP PrelimExam MITSnapShop by AJNo ratings yet

- 1000mm BOPP Tape Coating Machine Two Color Printing 40 Speed TangerangDocument6 pages1000mm BOPP Tape Coating Machine Two Color Printing 40 Speed TangerangJaja JamaludinNo ratings yet

- Book Review For: One Up On Wall StreetDocument22 pagesBook Review For: One Up On Wall StreetSenthil KumarNo ratings yet

- Global Wine IndustryDocument134 pagesGlobal Wine IndustrySaifur Rahman Steve100% (2)

- 1884 Journey From Heraut To Khiva Moscow and ST Petersburgh Vol 2 by Abbott S PDFDocument342 pages1884 Journey From Heraut To Khiva Moscow and ST Petersburgh Vol 2 by Abbott S PDFBilal AfridiNo ratings yet

- KaizenDocument8 pagesKaizenGigih SetijawanNo ratings yet

- Tone and MoodDocument8 pagesTone and MoodKristine PanalNo ratings yet

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- Irda Jun10Document96 pagesIrda Jun10ManiNo ratings yet

- Unit 4 ListeningDocument3 pagesUnit 4 ListeningAnh TamNo ratings yet

- St. John Adaptive Montessori School Magsaysay, Alicia, Isabela Monthly Exam in Science September Grade VI Name: - DateDocument3 pagesSt. John Adaptive Montessori School Magsaysay, Alicia, Isabela Monthly Exam in Science September Grade VI Name: - Date渡辺正平No ratings yet

- Filt Ers: 2 ElectrofiltersDocument8 pagesFilt Ers: 2 ElectrofiltersElancheran RengaNo ratings yet

- Learning Action Cell Implementation Plan (Tle Department)Document4 pagesLearning Action Cell Implementation Plan (Tle Department)AlmaRoxanneFriginal-TevesNo ratings yet

- Marked Fake Deck Tricks3Document7 pagesMarked Fake Deck Tricks3Tito Banerjee100% (1)

- Cookie Experimental DesignDocument2 pagesCookie Experimental Designapi-293314791No ratings yet

- 2021 HhhhhhhterqasdwqwDocument1 page2021 HhhhhhhterqasdwqwHassan KhanNo ratings yet

- NIDAR, Franced Haggai G. The Brain Is The Vehicle of The MindDocument1 pageNIDAR, Franced Haggai G. The Brain Is The Vehicle of The MindHaggai NidarNo ratings yet

- Mafia Ii 360 Download Manual EngDocument21 pagesMafia Ii 360 Download Manual EngJuan Camilo Payan GuerreroNo ratings yet