Professional Documents

Culture Documents

Technical Support HIRA

Technical Support HIRA

Uploaded by

Peter Sare WolloOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Support HIRA

Technical Support HIRA

Uploaded by

Peter Sare WolloCopyright:

Available Formats

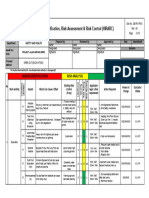

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA)

Department: Technical Support RA TEAM NAME SIGNATURE REVIEW & APPROVED BY:

Process: Commissioning & Service RA Leader: Andi Aziz

Signature:

Activity Location: Main Office RA Member 1:

Original Assessment Reference No.

RA Member 2: Name: Petrus Sare Wolo

Date: HIRA-

RA Member 3: Designation

Last Review Date: HSE Coordinator

:

Next Review Date: RA Member 4: Date:

Personal Protective Equipment

(PPE):

Safety helmet Glove Eye protection Safety Shoe Respirator Safety

Belt/Harness

Hazard Identification Risk Evaluation Risk Control

Risk Level

Risk Level

Due

Likelihoo

Likelihoo

Severity

Severity

Potential Possible Injury / Implementation Remark

No. Work Activity Existing Risk Control Additional Control Dat

Hazard Ill Health Person s

e

1 Menarik Kabel Bahaya Luka lecet, keseleo, Pekerja TIDAK BOLEH 2 1 2 Pertahankan

Tersandung memar di badan BERJALAN pada kabel yang pengendalian risiko

Pulling Cable dipasang atau diletakkan saat ini.

Tripping Hazard Scratches, sprain, selama penarikan kabel.

bruises on body Kabel harus DIJAUHKAN dari Maintain current risk

lalu lintas pejalan kaki dan control

peralatan.

Bahan-bahan yang disimpan

harus dibarikade dan

dilengkapi dengan tanda-

tanda.

Hindari menyimpan bahan di

jalur jalan

Workers shall NOT RUN on

installed or laid cables during

cable pulling.

Cables shall be KEPT AWAY

CM-FM-HSE-01-01 Rev.01 Page 1 of 7 Issued 26/03/2020

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA)

from foot and equipment

traffic.

Stored materials shall be

barricaded and provided with

signs.

Avoid storing materials on

walkways

Jatuh dari Patah tulang, Pelindung jatuh harus 5 1 5 Terapkan ALARP

Ketinggian Kematian dikenakan (body harness) (mengacu pada

Pelatihan/kesadaran bekerja Penilaian dan

Fall from Height Fracture, fatality di ketinggian harus diberikan Pengendalian

Identifikasi Risiko CM-

Fall protection must be worn HSE-SWP-11, nilai

(body harness) ulang secara teratur

Awareness/training must

provided

Implement ALARP

(refer to SWP Risk

Identification

Assessment and

Control – CM-HSE-

SWP-11, Re-assess

regularly

Pengangkatan Cidera Punggung Ikuti prosedur penanganan 3 1 3 Pertahankan

Manual manual. pengendalian risiko

Back injuries Tidak melakukan manual lift saat ini.

Manual Handling melebihi 25kg/orang

Maintain current risk

Follow the manual handling control

procedure

Perform manual lift Not

exceeded 25kg/person

Benda jatuh Cidera fisik Sediakan pagar pembatas & 3 1 3 Pertahankan

papan kaki untuk mencegah pengendalian risiko

Falling object Bodily injury jatuhnya alat / benda saat ini.

Jangan simpan bahan/alat

yang tidak perlu di platform Maintain current risk

kerja control

Sediakan keranjang untuk

menangani material selama

pemindahan dari ke elevasi

CM-FM-HSE-01-01 Rev.01 Page 2 of 7 Issued 26/03/2020

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA)

tinggi.

Jika diperlukan barikade area

selama akses yang jelas dari

bahan bekas

Amankan material dengan tali

Provide guardrail & toe board

to prevent falling of tools

/objects

Don’t keep the unnecessary

materials/tools on the work

platform

Provide basket for handling

material during transfer from

to high elevation.

If required barricade the area

during clear access from used

material

Secure material with lashing

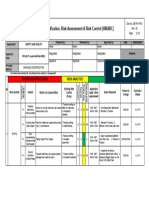

2 Pengetesan kabel Sengatan listrik Kulit terbakar, Tidak Teknisi listrik yang terlatih dan 5 1 5 Terapkan ALARP

sadarkan diri, kompeten harus melakukan (mengacu pada

Cable Test Electrical Shock kematian pengujian kabel Penilaian dan

Tentukan posisi aman Pengendalian

Localized skin burn, pengukuran Megger Identifikasi Risiko CM-

Unconscious, Arus debit ke grounding HSE-SWP-11, nilai

Fatality Objek uji pembumian ulang secara teratur

Pemeriksaan sistem

Pasang barikade di area Implement ALARP

pengujian (refer to SWP Risk

Aktifkan proteksi flashover Identification

pada Tes kontrol HV Assessment and

Penempatan & komunikasi Control – CM-HSE-

dengan beberapa supervisor SWP-11, Re-assess

selama pengujian untuk regularly

menjaga batas barikade

Trained and competent

electricians shall carry out the

cable testing

Determine the safe position of

Megger measurement

CM-FM-HSE-01-01 Rev.01 Page 3 of 7 Issued 26/03/2020

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA)

Discharge current to grounding

Grounding test object System

checking

Install barricade at testing

area

Activate the flashover

protection onHV control test

Placement & communication

with several supervisors during

testing to maintain barricade

boundaries

Jatuh dari Patah tulang, Pelindung jatuh harus 5 1 5 Terapkan ALARP

Ketinggian Kematian dikenakan (body harness) (mengacu pada

Pelatihan/kesadaran bekerja Penilaian dan

Fall from Height Fracture, fatality di ketinggian harus diberikan Pengendalian

Identifikasi Risiko CM-

Fall protection must be worn HSE-SWP-11, nilai

(body harness) ulang secara teratur

Awareness/training must

provided Implement ALARP

(refer to SWP Risk

Identification

Assessment and

Control – CM-HSE-

SWP-11, Re-assess

regularly

3 Penyelesaian Tertimpa/ Memar, tangan Berkoordinasi dengan 3 1 3 Pertahankan

pengetesan kabel terjepit benda tertusuk, patah supervisor/pengelola lokasi di pengendalian risiko

(Transfer & berat. tulang lokasi saat ini.

Penempatan Alat Uji Menggunakan APD yang tepat

HV ke Pengepakan) Stricken / Bruises, Lakukan housekeeping untuk Maintain current risk

pinched by hands pierced, menjaga area bersih dari control

Finishing cable Test heavy objects. fracture bahaya tersandung

Transfer & Placement Teknisi listrik yang terlatih dan

of HV Test Equipment kompeten harus melakukan

to Packing pengujian kabel

Coordinate with the supervisor

/ site manager at the location

Wearing proper PPE

Perform housekeeping to

CM-FM-HSE-01-01 Rev.01 Page 4 of 7 Issued 26/03/2020

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA)

maintain area clear from

tripping hazard

Trained and competent

electricians shall carry out the

cable testing

4 Pemasangan Katup & Pengangkatan Cidera Punggung Ikuti prosedur penanganan 3 1 3 Pertahankan

Instrumen Manual manual. pengendalian risiko

Back injuries Tidak melakukan manual lift saat ini.

Valve Installation & Manual Handling melebihi 25kg/orang

Instrument Maintain current risk

Follow the manual handling control

procedure

Perform manual lift Not

exceeded 25kg/person

Jatuh dari Patah tulang, Pelindung jatuh harus 5 1 5 Terapkan ALARP

Ketinggian Kematian dikenakan (body harness) (mengacu pada

Pelatihan/kesadaran bekerja Penilaian dan

Fall from Height Fracture, fatality di ketinggian harus diberikan Pengendalian

Identifikasi Risiko CM-

Fall protection must be worn HSE-SWP-11, nilai

(body harness) ulang secara teratur

Awareness/training must

Implement ALARP

provided (refer to SWP Risk

Identification

Assessment and

Control – CM-HSE-

SWP-11, Re-assess

regularly

Benda jatuh Cidera fisik Sediakan pagar pembatas & 3 1 3 Pertahankan

papan kaki untuk mencegah pengendalian risiko

Falling object Bodily injury jatuhnya alat / benda saat ini.

Jangan simpan bahan/alat

yang tidak perlu di platform Maintain current risk

kerja control

Sediakan keranjang untuk

menangani material selama

pemindahan dari ke elevasi

tinggi.

Jika diperlukan barikade area

selama akses yang jelas dari

CM-FM-HSE-01-01 Rev.01 Page 5 of 7 Issued 26/03/2020

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA)

bahan bekas

Amankan material dengan tali

Provide guardrail & toe board

to prevent falling of tools

/objects

Don’t keep the unnecessary

materials/tools on the work

platform

Provide basket for handling

material during transfer from

to high elevation.

If required barricade the area

during clear access from used

material

Secure material with lashing

Titik Jepit Cidera jari Gunakan sarung tangan 3 1 3 Pertahankan

Inspeksi sebelum kerja: pengendalian risiko

Pinch point Finger injury Identifikasi potensi titik jepit saat ini.

sebelum memulai pekerjaan

Maintain current risk

Wear safety gloves control

Pre-work inspection: Identify

potential pinch points before

starting work

A GUIDE TO SEVERITY RATING RISK MATRIX WITH NUMERIC RATINGS

CM-FM-HSE-01-01 Rev.01 Page 6 of 7 Issued 26/03/2020

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA)

A GUIDE TO LIKELIHOOD RATING RECOMMENDED ACTION FOR RISK LEVELS

CM-FM-HSE-01-01 Rev.01 Page 7 of 7 Issued 26/03/2020

You might also like

- HIRA Template 200912Document107 pagesHIRA Template 200912MOHAMMAD FIROZE0% (1)

- EAI-02 OfficeDocument2 pagesEAI-02 OfficePeter Sare WolloNo ratings yet

- Bird Netting & Pipe Gantry JSADocument1 pageBird Netting & Pipe Gantry JSAShakinah As SaadNo ratings yet

- Library Books AmendedDocument4 pagesLibrary Books Amendedbittu692No ratings yet

- VDA FMEA TemplateDocument53 pagesVDA FMEA Templatewatna0% (2)

- HIRA EngineeringDocument5 pagesHIRA EngineeringPeter Sare WolloNo ratings yet

- HIRA-22 Logistic & Commissioning Activity OKDocument8 pagesHIRA-22 Logistic & Commissioning Activity OKadityajailani19No ratings yet

- HIRA - Purchasing ActivityDocument4 pagesHIRA - Purchasing ActivityPeter Sare Wollo50% (2)

- HIRA-22 Logistic & Commissioning Activity OKDocument8 pagesHIRA-22 Logistic & Commissioning Activity OKadityajailani19No ratings yet

- HIRA-01 Store ActivityDocument7 pagesHIRA-01 Store ActivityPeter Sare WolloNo ratings yet

- HSE Risk Assessment Form: Risk/significance Evaluation Risk/significance EvaluationDocument1 pageHSE Risk Assessment Form: Risk/significance Evaluation Risk/significance EvaluationSachi AnandNo ratings yet

- C4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachineDocument2 pagesC4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachinePankaj PandeyNo ratings yet

- C3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Document1 pageC3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Pankaj PandeyNo ratings yet

- C6. #Hiradec For Vibration AnalysisDocument1 pageC6. #Hiradec For Vibration AnalysisPankaj PandeyNo ratings yet

- C5. HIRADEC - #Cutting and WeldingDocument2 pagesC5. HIRADEC - #Cutting and WeldingPankaj PandeyNo ratings yet

- Hira-Pilling WorkDocument3 pagesHira-Pilling WorkPrithika Anbu100% (1)

- Risk Assessment For NDTDocument14 pagesRisk Assessment For NDTNestor Mijares100% (1)

- 31.# Hiradec-CSTDocument2 pages31.# Hiradec-CSTPankaj PandeyNo ratings yet

- Moving Convoy Wide Load - RA-R9-01-014-01Document2 pagesMoving Convoy Wide Load - RA-R9-01-014-01cmrig74No ratings yet

- Manhole Construction - ExcavationDocument1 pageManhole Construction - Excavationasr.engineering2023No ratings yet

- Nipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01Document1 pageNipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01cmrig74No ratings yet

- Risk Assessment Register: Prepared By: Toolpusher / Hse AdvisorDocument1 pageRisk Assessment Register: Prepared By: Toolpusher / Hse Advisorcmrig740% (1)

- Department: List of Workcentre: S.No Workcentre Name Process Involved No. of Employees VLJDocument12 pagesDepartment: List of Workcentre: S.No Workcentre Name Process Involved No. of Employees VLJabhrrajjit SANo ratings yet

- Conducting Drop Object Inspection - RA-R9-01-017-01Document1 pageConducting Drop Object Inspection - RA-R9-01-017-01cmrig74No ratings yet

- KS-DS-HSES-NR-001 Working Inside Confined Space 15jul2021Document3 pagesKS-DS-HSES-NR-001 Working Inside Confined Space 15jul2021Richmond AntwiNo ratings yet

- Hira - Risk Assessment - Merakes - Provision of Subsea Tructures FabricatioonDocument943 pagesHira - Risk Assessment - Merakes - Provision of Subsea Tructures FabricatioonFariz Fatahillah AlbugisiNo ratings yet

- 24.DG Hiradec CDocument2 pages24.DG Hiradec CPankaj PandeyNo ratings yet

- 5 HirarcDocument5 pages5 HirarcTashriq ZakariaNo ratings yet

- Risk Assessment Register: Prepared By: Toolpusher / Hse AdvisorDocument1 pageRisk Assessment Register: Prepared By: Toolpusher / Hse Advisorcmrig74No ratings yet

- Construction Risk Assessments361241720220223Document2 pagesConstruction Risk Assessments361241720220223Afaan gani Inamdar100% (1)

- RMH-RA-GP-1001-Marking Penetration, Support Bracket Location (Reviewed 01042019)Document3 pagesRMH-RA-GP-1001-Marking Penetration, Support Bracket Location (Reviewed 01042019)Kumar sssssNo ratings yet

- ROAAP SPPF HospitalDocument3 pagesROAAP SPPF Hospitalrubiecabs12No ratings yet

- Manhole Construction - ShoringDocument1 pageManhole Construction - Shoringasr.engineering2023No ratings yet

- Working at Same Levels (High Risk Areas) RA-R9-01-001-02Document1 pageWorking at Same Levels (High Risk Areas) RA-R9-01-001-02cmrig74No ratings yet

- CHP HiraDocument57 pagesCHP HiraPankaj PandeyNo ratings yet

- 25.# Hiradec-EH Filter & Cooling PumpsDocument1 page25.# Hiradec-EH Filter & Cooling PumpsPankaj PandeyNo ratings yet

- HHB 58CFR RA-6 Working at HeightsDocument8 pagesHHB 58CFR RA-6 Working at HeightsSelwyn GohNo ratings yet

- HIRA ExcavationDocument2 pagesHIRA ExcavationPrithika AnbuNo ratings yet

- Sample Work Activity Ra Template 2016Document13 pagesSample Work Activity Ra Template 2016deboy90832No ratings yet

- HIRA - MS Staircase ErectionDocument7 pagesHIRA - MS Staircase ErectionRamNo ratings yet

- RA - EIA GeneratorDocument4 pagesRA - EIA GeneratorعمروNo ratings yet

- Utility Mapping and Site SurveyDocument1 pageUtility Mapping and Site Surveyasr.engineering2023No ratings yet

- Risk Assessment DewateringDocument6 pagesRisk Assessment DewateringFaizan Amer100% (1)

- 08 Hirarc Form (r02)Document2 pages08 Hirarc Form (r02)Aizat Sera SuwandiNo ratings yet

- HIRA-Rig Maintenance WORKDocument2 pagesHIRA-Rig Maintenance WORKPrithika AnbuNo ratings yet

- Living in Camp Accommodation RA-R9-01-010-01Document1 pageLiving in Camp Accommodation RA-R9-01-010-01cmrig74No ratings yet

- 28.# Hiradec-SUMP Pit PumpsDocument1 page28.# Hiradec-SUMP Pit PumpsPankaj PandeyNo ratings yet

- Annexure3 HIRA 2Document5 pagesAnnexure3 HIRA 2kanna gNo ratings yet

- Concrete Risk AssessmentDocument1 pageConcrete Risk AssessmentTariq saifiNo ratings yet

- C2.Hiradec - ONLINE SEALING ON PIPES (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Document2 pagesC2.Hiradec - ONLINE SEALING ON PIPES (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Pankaj PandeyNo ratings yet

- Hydra HiradecDocument1 pageHydra HiradecPankaj PandeyNo ratings yet

- Risk Assesment - FormatDocument3 pagesRisk Assesment - FormatSIBINNo ratings yet

- Confined Space - RA-R9-01-002-01Document1 pageConfined Space - RA-R9-01-002-01cmrig74No ratings yet

- HIRAC Utility and Swiss Miss 2023Document17 pagesHIRAC Utility and Swiss Miss 2023Queenie Chelan FloresNo ratings yet

- Hazard Identification & Risk Assessment (Hira) /jsa: Hira & Jsa For Tri Butyl Phosphate (TBP) PlantDocument6 pagesHazard Identification & Risk Assessment (Hira) /jsa: Hira & Jsa For Tri Butyl Phosphate (TBP) PlantShariq KhanNo ratings yet

- RA - EIA Neon LampsDocument2 pagesRA - EIA Neon Lampsعمرو100% (1)

- 3.2 HIRA Register - BlankDocument3 pages3.2 HIRA Register - Blankshobha shelarNo ratings yet

- RISK ASSESSMENT FORM - رــــطاخملــا ـمييقــت جذوــمــنDocument8 pagesRISK ASSESSMENT FORM - رــــطاخملــا ـمييقــت جذوــمــنAlper SaltaşNo ratings yet

- 001.hira - Proj - April23Document42 pages001.hira - Proj - April23Vinay PandeyNo ratings yet

- RA Leader: Approved by Reference NumberDocument2 pagesRA Leader: Approved by Reference NumberHasan WaqarNo ratings yet

- Risk Register: Design For Safety Project Name: Date of ReviewDocument4 pagesRisk Register: Design For Safety Project Name: Date of ReviewAzmi NordinNo ratings yet

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument3 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- CM-PR-DSG-01 Rev.02 Design ProcedureDocument10 pagesCM-PR-DSG-01 Rev.02 Design ProcedurePeter Sare WolloNo ratings yet

- HIRA EngineeringDocument5 pagesHIRA EngineeringPeter Sare WolloNo ratings yet

- HIRA-01 Store ActivityDocument7 pagesHIRA-01 Store ActivityPeter Sare WolloNo ratings yet

- HIRA - Purchasing ActivityDocument4 pagesHIRA - Purchasing ActivityPeter Sare Wollo50% (2)

- EAI-05 WarehouseDocument2 pagesEAI-05 WarehousePeter Sare WolloNo ratings yet

- Eai Technical SupportDocument3 pagesEai Technical SupportPeter Sare WolloNo ratings yet

- Form Imo Gisis (New)Document2 pagesForm Imo Gisis (New)Peter Sare WolloNo ratings yet

- EAI - PurchasingDocument2 pagesEAI - PurchasingPeter Sare WolloNo ratings yet

- Manhours - July 2022Document120 pagesManhours - July 2022Peter Sare WolloNo ratings yet

- Monthly Ladder Inspection ChecklistDocument4 pagesMonthly Ladder Inspection ChecklistPeter Sare WolloNo ratings yet

- Incident Accident Investigation Report - EriadiDocument2 pagesIncident Accident Investigation Report - EriadiPeter Sare WolloNo ratings yet

- Tda18250hn SdsDocument8 pagesTda18250hn SdsHedenarol Ramirez RojasNo ratings yet

- Case Analysis VandelayDocument20 pagesCase Analysis VandelaySapna Sharma100% (2)

- Test PDFDocument4 pagesTest PDFsupreethNo ratings yet

- Full Air SuspensionDocument5 pagesFull Air Suspensionmonikaneha123No ratings yet

- ANGLO GOLD Maintenance ManualDocument150 pagesANGLO GOLD Maintenance ManualAlberto LobonesNo ratings yet

- D92-1001 Tarea 2 ArranqueDocument4 pagesD92-1001 Tarea 2 ArranquemarioNo ratings yet

- SSS 2020 Business Plan RHB BankDocument29 pagesSSS 2020 Business Plan RHB BankMichael MyintNo ratings yet

- SQL Queries To Get Requisition, PO and PO Receipt DetailsDocument4 pagesSQL Queries To Get Requisition, PO and PO Receipt Detailsmjaga09No ratings yet

- Drone Certification Study GuidesDocument5 pagesDrone Certification Study GuidesSSNo ratings yet

- Pricing Sample All PetrochemicalsDocument18 pagesPricing Sample All Petrochemicalsrbrijeshgbiresearch100% (1)

- PS Demo Script - Forecast PositionsDocument8 pagesPS Demo Script - Forecast Positionsnaveenkumar7754918No ratings yet

- Cloud ComputingDocument39 pagesCloud Computinggmurugananth100% (2)

- HE10044 RW MedicalBrochure E 02Document12 pagesHE10044 RW MedicalBrochure E 02Th NattapongNo ratings yet

- 10120AM Motor Operated Electro-Mechanical DeadlineDocument2 pages10120AM Motor Operated Electro-Mechanical DeadlinePablo ToscanoNo ratings yet

- Click BondDocument4 pagesClick BondstaedtlerpNo ratings yet

- Registered ContractorsDocument19 pagesRegistered ContractorsAnuraj VakavayalilNo ratings yet

- Condensed Checklist F 86F 35Document6 pagesCondensed Checklist F 86F 35Juan Francisco Sanchez MassadiNo ratings yet

- SAP Sales Document TypesDocument30 pagesSAP Sales Document TypesSaurabh KumarNo ratings yet

- UKROI-KPC Kerb and Gully Range SmallDocument12 pagesUKROI-KPC Kerb and Gully Range SmallMihaela TodiricaNo ratings yet

- AIA-Design and Construction Delivery Methods For Public Projects PDFDocument1 pageAIA-Design and Construction Delivery Methods For Public Projects PDFGeorge AlexiadisNo ratings yet

- Calibration of Pressure GaugeDocument5 pagesCalibration of Pressure GaugeVarun SinghNo ratings yet

- Resuma AdzdinDocument2 pagesResuma AdzdinMuhamad Syarizal YusniNo ratings yet

- Additive Manufacturin Module 1 PPT NotesDocument46 pagesAdditive Manufacturin Module 1 PPT NotesMaaz AK100% (1)

- B2B Marketing Management - Project Proposal - Group - A11Document5 pagesB2B Marketing Management - Project Proposal - Group - A11Ishant SainiNo ratings yet

- Fpso OtcDocument7 pagesFpso OtcMartinus LuckyantoNo ratings yet

- J2534 Reprogramming User Guide For Version 4.6 and Higher: Updated December 18, 2012Document21 pagesJ2534 Reprogramming User Guide For Version 4.6 and Higher: Updated December 18, 2012totoymola8No ratings yet

- EN - 206 Work Demarcation MatrixDocument5 pagesEN - 206 Work Demarcation MatrixRaman KumarNo ratings yet

- Training Report at BMWDocument34 pagesTraining Report at BMWRajinder Singh50% (2)