Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

101 viewsJsa D. G. INSTALLATION

Jsa D. G. INSTALLATION

Uploaded by

Ravi thokalThe document is a job safety analysis for the installation of a diesel generator set at the Avalon City project site by Madhure Infra Engineering Pvt. Ltd. It identifies potential hazards for each job step, including vehicle movement, material falling, personal injury, improper work platform, electrocution, air pollution, and fire hazards. It also lists control measures to eliminate the hazards, such as using lifting equipment and personal protective equipment, restricting access, providing earthing and circuit breakers, maintaining good housekeeping, and more. The analysis was reviewed by key personnel from the contractor.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You might also like

- Rules of An GentlemanDocument16 pagesRules of An Gentlemanstole90% (1)

- JHA Fabrication WorkDocument4 pagesJHA Fabrication WorkRavi thokalNo ratings yet

- Jsa - Cable Termination: Job Step No. Step Description Hazards Control Measure(s) Responsible PersonDocument7 pagesJsa - Cable Termination: Job Step No. Step Description Hazards Control Measure(s) Responsible PersonMon Trang NguyễnNo ratings yet

- DOD-MST-INS-008 (Rev-1) Installation, Splicing and Testing of Fiber Optic CableDocument8 pagesDOD-MST-INS-008 (Rev-1) Installation, Splicing and Testing of Fiber Optic CableProfessional Trust100% (1)

- Cash Receipts System Narrative 2010 v3Document4 pagesCash Receipts System Narrative 2010 v3cristel jane FullonesNo ratings yet

- Evicence Outline 1Document68 pagesEvicence Outline 1krys10938No ratings yet

- Jsa CompressorDocument9 pagesJsa CompressorRavi thokalNo ratings yet

- Operation: Electrical Installation Risk Assessment Assessor: DateDocument4 pagesOperation: Electrical Installation Risk Assessment Assessor: Dateم.عبدالرحيم سلمان100% (1)

- Risk Assessment On Demolition Work - CompressDocument8 pagesRisk Assessment On Demolition Work - CompressAbegail Manuel GatusNo ratings yet

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- Panels Erection at Station: Ehs Risk AssessmentDocument4 pagesPanels Erection at Station: Ehs Risk AssessmentRohit SinghNo ratings yet

- RA Excavation For Site Establish LEW-ALLDocument7 pagesRA Excavation For Site Establish LEW-ALLChoubi ChoubacaNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- Tendernotice 1-2Document296 pagesTendernotice 1-2sachinrane5No ratings yet

- J S A Electrical Distributaton Board MaintenenceDocument4 pagesJ S A Electrical Distributaton Board MaintenenceASLAM MULANINo ratings yet

- Risk Assessment For Curtain Wall & Glazing InstallationDocument4 pagesRisk Assessment For Curtain Wall & Glazing InstallationBulent AkNo ratings yet

- JSA Gate Installation - 1 ProjectDocument4 pagesJSA Gate Installation - 1 ProjectMuhammad Umar GondalNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- Job Safety & Environment Analysis: Revision NoDocument3 pagesJob Safety & Environment Analysis: Revision NonishanthNo ratings yet

- JSA Backfilling, Leveling, (Night Shift)Document14 pagesJSA Backfilling, Leveling, (Night Shift)Mohammad Al Masa'dehNo ratings yet

- SWMSDocument21 pagesSWMSJ.j.JijoNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Job Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Document2 pagesJob Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Nishad MuhammedNo ratings yet

- 2014 Energized Electrical Work Permit - ByU-IdahoDocument2 pages2014 Energized Electrical Work Permit - ByU-Idahocarrot123456No ratings yet

- Job Risk Assessment Design and Installation of New Scada SystemDocument17 pagesJob Risk Assessment Design and Installation of New Scada Systemzee khanNo ratings yet

- HIRARC - Working at HeightDocument3 pagesHIRARC - Working at HeightAmpala Vanan100% (1)

- 23 JSA For Block WorkDocument2 pages23 JSA For Block WorkWakil AhmadNo ratings yet

- JSA E&I 6.tubing System InstallationDocument3 pagesJSA E&I 6.tubing System InstallationAmyNo ratings yet

- Safety Data Sheet: ARDROX 907PB AerosolDocument11 pagesSafety Data Sheet: ARDROX 907PB Aerosolabdulbaset alselwi100% (1)

- HIRA No. 05 Erecation WorkDocument4 pagesHIRA No. 05 Erecation WorkAttaullah AnsariNo ratings yet

- Cable TestingDocument2 pagesCable Testinglalmani bhusalNo ratings yet

- Jsa For Site EstablishmentDocument8 pagesJsa For Site EstablishmentBenasher IbrahimNo ratings yet

- Mobile Scaffolding Inspection Checklist: Project Name: DateDocument1 pageMobile Scaffolding Inspection Checklist: Project Name: DateMehtab Uddin mmNo ratings yet

- JSA Painting RM StoreDocument4 pagesJSA Painting RM StoreKhalid NaseemNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- SWMS - ConcreteDocument10 pagesSWMS - ConcreteMuhammadNo ratings yet

- Mie Hse Jha 004 Installation of TransformerDocument5 pagesMie Hse Jha 004 Installation of TransformerMd Gulam SafiNo ratings yet

- Al-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Document7 pagesAl-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Numan SaleemNo ratings yet

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDocument3 pagesLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINNo ratings yet

- Safe Work Method Statement For Erection of All Works:: Client ConsultantDocument4 pagesSafe Work Method Statement For Erection of All Works:: Client ConsultantsoubhagyaNo ratings yet

- Application To Perform Work - Grass CuttingDocument2 pagesApplication To Perform Work - Grass CuttingRauf Huseynov0% (1)

- JSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTDocument6 pagesJSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTshaibaz chafekar100% (1)

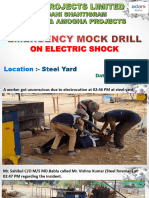

- Mock Drill Electric Shock 22.06.22Document15 pagesMock Drill Electric Shock 22.06.22sonu sharmaNo ratings yet

- SS JSP - 063 Testing and Pre-Commissioning WorksDocument9 pagesSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahNo ratings yet

- CTRA TK 64 003 Scaffolding Inside OutsideDocument6 pagesCTRA TK 64 003 Scaffolding Inside OutsideMohamed RizwanNo ratings yet

- Gas Cylinders RADocument5 pagesGas Cylinders RAalla malikNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- Height Pass FormatDocument1 pageHeight Pass Formatamit kumarNo ratings yet

- Risk Assessment PDFDocument4 pagesRisk Assessment PDFAnonymous iI88LtNo ratings yet

- Jha Lighting ArrestorDocument3 pagesJha Lighting ArrestorRavi thokalNo ratings yet

- RA Flushing &Hydro-TestingDocument8 pagesRA Flushing &Hydro-Testingalla malikNo ratings yet

- 18 SOP CBL Trench DiggingDocument10 pages18 SOP CBL Trench DiggingMd Gulam SafiNo ratings yet

- 1 23 Forklift SafetyDocument4 pages1 23 Forklift SafetykhurramNo ratings yet

- Asm Risk Assesment fv2 PDFDocument3 pagesAsm Risk Assesment fv2 PDFshijadNo ratings yet

- Rock Breaker Self ChecklistDocument1 pageRock Breaker Self ChecklistNair R RakeshNo ratings yet

- Risk Assessment For Structural Cabling System Testing and CommissioningDocument5 pagesRisk Assessment For Structural Cabling System Testing and CommissioningInfas YahyaNo ratings yet

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Qcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEDocument75 pagesQcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEbryanpastor106100% (1)

- Jsa Cooling TowerDocument5 pagesJsa Cooling TowerRavi thokalNo ratings yet

- Draft TC T K EnterprisesDocument1 pageDraft TC T K EnterprisesRavi thokalNo ratings yet

- CL-30. Pre Entry Welding MachineDocument1 pageCL-30. Pre Entry Welding MachineRavi thokalNo ratings yet

- OHSE PPE CHK ListDocument1 pageOHSE PPE CHK ListRavi thokalNo ratings yet

- Induction FormDocument2 pagesInduction FormRavi thokalNo ratings yet

- 39 Near Miss ReportDocument1 page39 Near Miss ReportRavi thokalNo ratings yet

- CL-27. 14'' Cutting MachineDocument1 pageCL-27. 14'' Cutting MachineRavi thokalNo ratings yet

- CL-22 - Static Boom PlacerDocument1 pageCL-22 - Static Boom PlacerRavi thokalNo ratings yet

- MSDS Polyplus CP Sefty Data 777Document4 pagesMSDS Polyplus CP Sefty Data 777Ravi thokalNo ratings yet

- CL-24. Mobile CraneDocument1 pageCL-24. Mobile CraneRavi thokalNo ratings yet

- CL-20. Crane HOOKDocument1 pageCL-20. Crane HOOKRavi thokalNo ratings yet

- CL-28. Boom PlacerDocument1 pageCL-28. Boom PlacerRavi thokalNo ratings yet

- Jsa CompressorDocument9 pagesJsa CompressorRavi thokalNo ratings yet

- CL-29. Concrete BucketDocument1 pageCL-29. Concrete BucketRavi thokalNo ratings yet

- Jsa ConcretingDocument4 pagesJsa ConcretingRavi thokalNo ratings yet

- Jsa Cooling TowerDocument5 pagesJsa Cooling TowerRavi thokalNo ratings yet

- Jsa CladdingDocument3 pagesJsa CladdingRavi thokalNo ratings yet

- Jsa CompoundDocument4 pagesJsa CompoundRavi thokalNo ratings yet

- Job Safety Procedure - TSEILDocument13 pagesJob Safety Procedure - TSEILRavi thokalNo ratings yet

- Jsa Brick ShiftingDocument4 pagesJsa Brick ShiftingRavi thokalNo ratings yet

- Jsa Brick WorkDocument4 pagesJsa Brick WorkRavi thokalNo ratings yet

- Jsa 112Document7 pagesJsa 112Ravi thokalNo ratings yet

- Jha 110Document7 pagesJha 110Ravi thokalNo ratings yet

- Daily Site Inspection ChecklistDocument2 pagesDaily Site Inspection ChecklistRavi thokalNo ratings yet

- Jha UnloadingDocument4 pagesJha UnloadingRavi thokalNo ratings yet

- Jha UtilityDocument4 pagesJha UtilityRavi thokalNo ratings yet

- JHA For Concreting WorkDocument3 pagesJHA For Concreting WorkRavi thokalNo ratings yet

- Jha Lighting ArrestorDocument3 pagesJha Lighting ArrestorRavi thokalNo ratings yet

- Job Discerption For Cluster Level Federation (CLF) ConsultantDocument3 pagesJob Discerption For Cluster Level Federation (CLF) ConsultantRavi thokalNo ratings yet

- Daily Checklist - Hindi Format - Draft2Document2 pagesDaily Checklist - Hindi Format - Draft2Ravi thokalNo ratings yet

- Employee Relationship ManagementDocument42 pagesEmployee Relationship Managementsupriyanair80% (5)

- Histtory and Importance of HadithDocument31 pagesHisttory and Importance of HadithAbdullah AhsanNo ratings yet

- TED Taiye SelasiDocument4 pagesTED Taiye SelasiMinh ThuNo ratings yet

- Florida Et Al v. Dept. of Health & Human Services Et AlDocument304 pagesFlorida Et Al v. Dept. of Health & Human Services Et AlDoug MataconisNo ratings yet

- 1941Document8 pages1941Zharieya AmaraNo ratings yet

- Teaching The SchwaDocument5 pagesTeaching The SchwaStarr BlueNo ratings yet

- Kurt LewinDocument6 pagesKurt Lewinfotiadis100% (2)

- The CPP/NPA/NDF Constitute The Local Communist Movement in The Philippines Beforehand, ItDocument19 pagesThe CPP/NPA/NDF Constitute The Local Communist Movement in The Philippines Beforehand, Itzy_tanNo ratings yet

- Kansai International Airport, Seawall, GyronesDocument13 pagesKansai International Airport, Seawall, GyronesIzzuddin ShahidanNo ratings yet

- Award Certificates EDITABLE 1Document7 pagesAward Certificates EDITABLE 1Ruby Ann Gervacio GimenezNo ratings yet

- Born Again of The People: Luis Taruc and Peasant Ideology in Philippine Revolutionary PoliticsDocument43 pagesBorn Again of The People: Luis Taruc and Peasant Ideology in Philippine Revolutionary PoliticsThania O. CoronicaNo ratings yet

- Bloomberg Training 2Document8 pagesBloomberg Training 2rahzzy100% (1)

- Analysis of Credit Risk Measurement UsinDocument6 pagesAnalysis of Credit Risk Measurement UsinDia-wiNo ratings yet

- Sp-Ishares-Nasdaq-Biotechnology-Etf-3-31 02-13-2023Document20 pagesSp-Ishares-Nasdaq-Biotechnology-Etf-3-31 02-13-2023jorge huerta durazoNo ratings yet

- Asphyxial DeathDocument17 pagesAsphyxial DeathSisca ChearzNo ratings yet

- Iqwq-Ft-Rspds-00-120103 - 1 Preservation During Shipping and ConstructionDocument31 pagesIqwq-Ft-Rspds-00-120103 - 1 Preservation During Shipping and Constructionjacksonbello34No ratings yet

- Week 1 Origins of Hospitality and HousekeepingDocument12 pagesWeek 1 Origins of Hospitality and HousekeepingEmmanuel CherianNo ratings yet

- Q3 2019 Management Review SHEQ Presentation-1Document23 pagesQ3 2019 Management Review SHEQ Presentation-1Warren KabichiNo ratings yet

- The Israel Lobby ControversyDocument2 pagesThe Israel Lobby ControversysisinjhaaNo ratings yet

- 14-128 MTR Veh Appraisal FormDocument2 pages14-128 MTR Veh Appraisal FormJASONNo ratings yet

- 3310-Ch 10-End of Chapter solutions-STDocument30 pages3310-Ch 10-End of Chapter solutions-STArvind ManoNo ratings yet

- Customer Satisfaction On TATA Motors-7Document40 pagesCustomer Satisfaction On TATA Motors-7VampsiukNo ratings yet

- Ee NewDocument1 pageEe Newhsbibahmed091No ratings yet

- Manual On Settlement of Land DisputesDocument120 pagesManual On Settlement of Land Disputescookbooks&lawbooks100% (1)

- Bounty Hunter CreationDocument3 pagesBounty Hunter CreationdocidleNo ratings yet

- Module MAPEH 8 4thDocument21 pagesModule MAPEH 8 4thEdnell VelascoNo ratings yet

- 31-07-2020 - The Hindu Handwritten NotesDocument16 pages31-07-2020 - The Hindu Handwritten NotesnishuNo ratings yet

Jsa D. G. INSTALLATION

Jsa D. G. INSTALLATION

Uploaded by

Ravi thokal0 ratings0% found this document useful (0 votes)

101 views5 pagesThe document is a job safety analysis for the installation of a diesel generator set at the Avalon City project site by Madhure Infra Engineering Pvt. Ltd. It identifies potential hazards for each job step, including vehicle movement, material falling, personal injury, improper work platform, electrocution, air pollution, and fire hazards. It also lists control measures to eliminate the hazards, such as using lifting equipment and personal protective equipment, restricting access, providing earthing and circuit breakers, maintaining good housekeeping, and more. The analysis was reviewed by key personnel from the contractor.

Original Description:

Original Title

jsa D. G. INSTALLATION

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a job safety analysis for the installation of a diesel generator set at the Avalon City project site by Madhure Infra Engineering Pvt. Ltd. It identifies potential hazards for each job step, including vehicle movement, material falling, personal injury, improper work platform, electrocution, air pollution, and fire hazards. It also lists control measures to eliminate the hazards, such as using lifting equipment and personal protective equipment, restricting access, providing earthing and circuit breakers, maintaining good housekeeping, and more. The analysis was reviewed by key personnel from the contractor.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

101 views5 pagesJsa D. G. INSTALLATION

Jsa D. G. INSTALLATION

Uploaded by

Ravi thokalThe document is a job safety analysis for the installation of a diesel generator set at the Avalon City project site by Madhure Infra Engineering Pvt. Ltd. It identifies potential hazards for each job step, including vehicle movement, material falling, personal injury, improper work platform, electrocution, air pollution, and fire hazards. It also lists control measures to eliminate the hazards, such as using lifting equipment and personal protective equipment, restricting access, providing earthing and circuit breakers, maintaining good housekeeping, and more. The analysis was reviewed by key personnel from the contractor.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 5

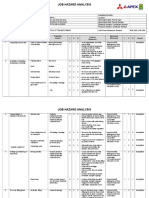

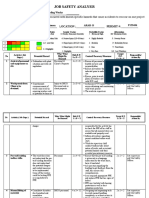

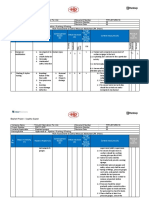

Madhure Infra Engineering Pvt.Ltd.

Job Safety Analysis

PROJECT / TASK :Installation of D. G. NO. 1 CONTRACTOR: MIEPL JOB No.:

SUPERVISOR : Devidas Sonkamble LOCATION : Avalon City Dapodi DATE: 10/09/2022

JOB STEP HAZARDS Control Measure ACTION

Break the job into steps. List the hazard or type of harm List the necessary control measures to be followed to Person who will ensure

Listing work which may be hazardous. identified with each step eliminate the identified hazards this happens

Shifting of ready Truss from Vehicle movement / toppling / Vehicle to be inspected & valid document to

fabrication yard to Ware House. run over hazards. be checked before start the job.

Valid license check for the operators and

signal man arrangement to be done .

Access to be placed from unwanted materials of

movement of trffic for vehicle movement.

Vehicle to be placed with the help of helper from

the gate.

Material fall hazard

Lifting equipment, tools & tackles to be certified by

unloading a competent person.

Only trained person is allowed to operate the lifting

equipment.

Valid documents to be checked & certified.

SWL to be followed before lifting the equipment.

Madhure Infra Engineering Pvt.Ltd.

Job Safety Analysis

Only one person is allowed to give signal for lifting

equipment.

Continuous supervision to be provided.

Area will be checked from all type of movements

with the help of supervisor till the end of work.

Personal injury PPE`S – helmet, shoes, goggles & jacket to be

provided.

Improper platform (for D. G. ,

DISEL & PANEL) PROPER PLATFORM IN A LEVEL SHOULD BE

Installation of D. G. set MADE & kept under a canopy or shed with proper

ventilation.

Charging of D. G. set

electrocution Entry to be restricted inside D. G. room for all other

than electrician/ operator.

Rubber mat to be provided below the panel.

Earthing to be provided for alternator, engine,

neutral earthing & panel earthing.

Circuits brakers to be provided.

Authorised electritian is allowed to worik on the

same .

Electritian will use rubber hand gloves (tested &

trade mark) while doing local test & all.

Area should be isolated/ barricaded to avoid

Madhure Infra Engineering Pvt.Ltd.

Job Safety Analysis

unauthorised entry.

Identification boards to be displayed.

Air pollution

Silencere (smoke emission pipe ) to be extended

above the root so that the smoke emitting from D.

G. set will not affect the surrounding.

Fire hazard

Check the oil leakage or short circuit daily &

electrian should fulfill the checklist for the same.

Area to be checked from all unwanted materials

(combustible or flammable) & maintain good

housekeeping.

Fire extinguisher (CO2/DCP type) & sand buckets

to be provided near by the area.

Madhure Infra Engineering Pvt.Ltd.

Job Safety Analysis

Job Hazard Analysis Attendees: Devidas Sonkamble, Ashok Phad, Ravikumar

Thokal,Vijaykumar Lohiya.

Name Signature Date

Written by: Ravikumar Thokal

Reviewed by: Vijaykumar Lohiya

Madhure Infra Engineering Pvt.Ltd.

Job Safety Analysis

Score TABLE OF CONSEQUENCE Score LIKELIHOOD

People Plant Environment

5 – Very High/ Multiple Fatalities Greater than Catastrophe, destruction of sensitive environment, worldwide 5 – Almost The event is expected to occur in most

Catastrophic $10Million Loss attention. Likely EPA prosecution. More than 30 days delay. certain circumstances. Likely to occur frequently-

More than 1 per year

4 – High/ Major Fatality or Permanent Disabilities $1Million to Disaster, high levels of media attention, high cost of clean 4 – likely/ The event will probably occur in most

$10Million Loss up. Offsite environmental harm, more than 10 days delay. probable circumstances. Likely to occur several tines.

1 per year

3 – Moderate Major Injuries - Incapacitations or $100Thousand to Major spills, onsite release, substantial environmental 3– The event should occur at some time. Likely

requiring time of work $1Million Loss nuisance, more than 1day delay. (Leads to an additional moderate/ to occur some time. 1 per 5 years

resources call out i.e. SES) occasional

2 – Low/ Minor Significant Injuries – Medical $10Thousand to Significant spills (leads to a call out of Site Emergency 2 – remote/ The event could occur at some time. Unlikely

Treatments, non-permanent injury $100Thousand Loss Response Group) unlikely but possible. 1 per 10 years

1 – Very Low/ Minor Injuries – First Aid Treatments Less than Low environmental impact. Minor Spills less than 80 Litres. 1 – rare/ The event may occur only in exceptional

Insignificant (cuts/bruises) $10Thousand Loss very circumstances. Assumed it may not be

unlikely experienced. 1 per 100 years

Risk Rating = Consequence + Likelihood Risk Rating - Definitions

Consequence Risk Rating Risk Rating Definitions Action Required

Intolerable Task not to start till the risk is eliminated or reduced. Bring to the immediate attention of

5 6 7 8 9 10 8 - 10

management. Formal assessment required. MUST reduce the risk as a matter of priority.

High Bring to the immediate attention of management. Task not to start till the risk is eliminated or

4 5 6 7 8 9 7

reduced. Further Assessment required. MUST reduce the risk as a matter of priority.

Significant Risk Bring to the attention of supervision. Review risks and ensure that they are reduced to as low as

3 4 5 6 7 8 6 reasonably practicable. To be dealt with as soon as possible, preferably before the task

commences. Introduce some form of hardware to control risk.

Moderate Risk Needs to be controlled but not necessarily immediately, an action plan to control the risk should be

2 3 4 5 6 7 5 drawn up. Review effectiveness of controls. Ensure responsibilities for control are specified.

Low Risk If practical reduce the risk. Ensure personnel are competent to do the task. Manage by routing

1 2 3 4 5 6 2-4

procedure. Monitor for change

1 2 3 4 5 A JHA considers a variety of activities/tasks involved in a job scope and analyses the key hazards (sources of harm) and their

consequences (types of harm) eg. Sources of harm – lifting a heavy pipe, which is manual handling. Types of harm – Back strain.

Likelihood

Main Points – On how to write a JHA. Hierarchy of Hazard Management – Control Measures

1. Define the task – what is to be done. These steps outline what should be planned for when deciding what control measures are to be put in

2. Review previous JHA if any – have we done it before? place. Whenever possible the highest step should be used first and then progress down the list.

3. Identify the steps – what is to be done. 1. Eliminate the hazard.

4. Identify the hazards of each step. 2. Substitution.

5. Identify who or what could be harmed. 3. Reducing the frequency of a hazardous task.

6. Give the task a risk rating – Consequence + Frequency 4. Enclosing the hazard.

7. Develop solutions to eliminate or control hazards in each step. 5. Additional procedures.

8. Review the risk rating after the control system has been implemented. 6. Additional supervision.

9. If risk rating unacceptable review the solutions till risk rating acceptable. 7. Additional training.

10. Agree who will implement the control system. 8. Instructions / information.

11. Document the JHA and discuss with the relevant personnel. 9. Some personal protective equipment.

You might also like

- Rules of An GentlemanDocument16 pagesRules of An Gentlemanstole90% (1)

- JHA Fabrication WorkDocument4 pagesJHA Fabrication WorkRavi thokalNo ratings yet

- Jsa - Cable Termination: Job Step No. Step Description Hazards Control Measure(s) Responsible PersonDocument7 pagesJsa - Cable Termination: Job Step No. Step Description Hazards Control Measure(s) Responsible PersonMon Trang NguyễnNo ratings yet

- DOD-MST-INS-008 (Rev-1) Installation, Splicing and Testing of Fiber Optic CableDocument8 pagesDOD-MST-INS-008 (Rev-1) Installation, Splicing and Testing of Fiber Optic CableProfessional Trust100% (1)

- Cash Receipts System Narrative 2010 v3Document4 pagesCash Receipts System Narrative 2010 v3cristel jane FullonesNo ratings yet

- Evicence Outline 1Document68 pagesEvicence Outline 1krys10938No ratings yet

- Jsa CompressorDocument9 pagesJsa CompressorRavi thokalNo ratings yet

- Operation: Electrical Installation Risk Assessment Assessor: DateDocument4 pagesOperation: Electrical Installation Risk Assessment Assessor: Dateم.عبدالرحيم سلمان100% (1)

- Risk Assessment On Demolition Work - CompressDocument8 pagesRisk Assessment On Demolition Work - CompressAbegail Manuel GatusNo ratings yet

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- Panels Erection at Station: Ehs Risk AssessmentDocument4 pagesPanels Erection at Station: Ehs Risk AssessmentRohit SinghNo ratings yet

- RA Excavation For Site Establish LEW-ALLDocument7 pagesRA Excavation For Site Establish LEW-ALLChoubi ChoubacaNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- Tendernotice 1-2Document296 pagesTendernotice 1-2sachinrane5No ratings yet

- J S A Electrical Distributaton Board MaintenenceDocument4 pagesJ S A Electrical Distributaton Board MaintenenceASLAM MULANINo ratings yet

- Risk Assessment For Curtain Wall & Glazing InstallationDocument4 pagesRisk Assessment For Curtain Wall & Glazing InstallationBulent AkNo ratings yet

- JSA Gate Installation - 1 ProjectDocument4 pagesJSA Gate Installation - 1 ProjectMuhammad Umar GondalNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- Job Safety & Environment Analysis: Revision NoDocument3 pagesJob Safety & Environment Analysis: Revision NonishanthNo ratings yet

- JSA Backfilling, Leveling, (Night Shift)Document14 pagesJSA Backfilling, Leveling, (Night Shift)Mohammad Al Masa'dehNo ratings yet

- SWMSDocument21 pagesSWMSJ.j.JijoNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Job Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Document2 pagesJob Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Nishad MuhammedNo ratings yet

- 2014 Energized Electrical Work Permit - ByU-IdahoDocument2 pages2014 Energized Electrical Work Permit - ByU-Idahocarrot123456No ratings yet

- Job Risk Assessment Design and Installation of New Scada SystemDocument17 pagesJob Risk Assessment Design and Installation of New Scada Systemzee khanNo ratings yet

- HIRARC - Working at HeightDocument3 pagesHIRARC - Working at HeightAmpala Vanan100% (1)

- 23 JSA For Block WorkDocument2 pages23 JSA For Block WorkWakil AhmadNo ratings yet

- JSA E&I 6.tubing System InstallationDocument3 pagesJSA E&I 6.tubing System InstallationAmyNo ratings yet

- Safety Data Sheet: ARDROX 907PB AerosolDocument11 pagesSafety Data Sheet: ARDROX 907PB Aerosolabdulbaset alselwi100% (1)

- HIRA No. 05 Erecation WorkDocument4 pagesHIRA No. 05 Erecation WorkAttaullah AnsariNo ratings yet

- Cable TestingDocument2 pagesCable Testinglalmani bhusalNo ratings yet

- Jsa For Site EstablishmentDocument8 pagesJsa For Site EstablishmentBenasher IbrahimNo ratings yet

- Mobile Scaffolding Inspection Checklist: Project Name: DateDocument1 pageMobile Scaffolding Inspection Checklist: Project Name: DateMehtab Uddin mmNo ratings yet

- JSA Painting RM StoreDocument4 pagesJSA Painting RM StoreKhalid NaseemNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- SWMS - ConcreteDocument10 pagesSWMS - ConcreteMuhammadNo ratings yet

- Mie Hse Jha 004 Installation of TransformerDocument5 pagesMie Hse Jha 004 Installation of TransformerMd Gulam SafiNo ratings yet

- Al-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Document7 pagesAl-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Numan SaleemNo ratings yet

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDocument3 pagesLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINNo ratings yet

- Safe Work Method Statement For Erection of All Works:: Client ConsultantDocument4 pagesSafe Work Method Statement For Erection of All Works:: Client ConsultantsoubhagyaNo ratings yet

- Application To Perform Work - Grass CuttingDocument2 pagesApplication To Perform Work - Grass CuttingRauf Huseynov0% (1)

- JSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTDocument6 pagesJSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTshaibaz chafekar100% (1)

- Mock Drill Electric Shock 22.06.22Document15 pagesMock Drill Electric Shock 22.06.22sonu sharmaNo ratings yet

- SS JSP - 063 Testing and Pre-Commissioning WorksDocument9 pagesSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahNo ratings yet

- CTRA TK 64 003 Scaffolding Inside OutsideDocument6 pagesCTRA TK 64 003 Scaffolding Inside OutsideMohamed RizwanNo ratings yet

- Gas Cylinders RADocument5 pagesGas Cylinders RAalla malikNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- Height Pass FormatDocument1 pageHeight Pass Formatamit kumarNo ratings yet

- Risk Assessment PDFDocument4 pagesRisk Assessment PDFAnonymous iI88LtNo ratings yet

- Jha Lighting ArrestorDocument3 pagesJha Lighting ArrestorRavi thokalNo ratings yet

- RA Flushing &Hydro-TestingDocument8 pagesRA Flushing &Hydro-Testingalla malikNo ratings yet

- 18 SOP CBL Trench DiggingDocument10 pages18 SOP CBL Trench DiggingMd Gulam SafiNo ratings yet

- 1 23 Forklift SafetyDocument4 pages1 23 Forklift SafetykhurramNo ratings yet

- Asm Risk Assesment fv2 PDFDocument3 pagesAsm Risk Assesment fv2 PDFshijadNo ratings yet

- Rock Breaker Self ChecklistDocument1 pageRock Breaker Self ChecklistNair R RakeshNo ratings yet

- Risk Assessment For Structural Cabling System Testing and CommissioningDocument5 pagesRisk Assessment For Structural Cabling System Testing and CommissioningInfas YahyaNo ratings yet

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Qcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEDocument75 pagesQcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEbryanpastor106100% (1)

- Jsa Cooling TowerDocument5 pagesJsa Cooling TowerRavi thokalNo ratings yet

- Draft TC T K EnterprisesDocument1 pageDraft TC T K EnterprisesRavi thokalNo ratings yet

- CL-30. Pre Entry Welding MachineDocument1 pageCL-30. Pre Entry Welding MachineRavi thokalNo ratings yet

- OHSE PPE CHK ListDocument1 pageOHSE PPE CHK ListRavi thokalNo ratings yet

- Induction FormDocument2 pagesInduction FormRavi thokalNo ratings yet

- 39 Near Miss ReportDocument1 page39 Near Miss ReportRavi thokalNo ratings yet

- CL-27. 14'' Cutting MachineDocument1 pageCL-27. 14'' Cutting MachineRavi thokalNo ratings yet

- CL-22 - Static Boom PlacerDocument1 pageCL-22 - Static Boom PlacerRavi thokalNo ratings yet

- MSDS Polyplus CP Sefty Data 777Document4 pagesMSDS Polyplus CP Sefty Data 777Ravi thokalNo ratings yet

- CL-24. Mobile CraneDocument1 pageCL-24. Mobile CraneRavi thokalNo ratings yet

- CL-20. Crane HOOKDocument1 pageCL-20. Crane HOOKRavi thokalNo ratings yet

- CL-28. Boom PlacerDocument1 pageCL-28. Boom PlacerRavi thokalNo ratings yet

- Jsa CompressorDocument9 pagesJsa CompressorRavi thokalNo ratings yet

- CL-29. Concrete BucketDocument1 pageCL-29. Concrete BucketRavi thokalNo ratings yet

- Jsa ConcretingDocument4 pagesJsa ConcretingRavi thokalNo ratings yet

- Jsa Cooling TowerDocument5 pagesJsa Cooling TowerRavi thokalNo ratings yet

- Jsa CladdingDocument3 pagesJsa CladdingRavi thokalNo ratings yet

- Jsa CompoundDocument4 pagesJsa CompoundRavi thokalNo ratings yet

- Job Safety Procedure - TSEILDocument13 pagesJob Safety Procedure - TSEILRavi thokalNo ratings yet

- Jsa Brick ShiftingDocument4 pagesJsa Brick ShiftingRavi thokalNo ratings yet

- Jsa Brick WorkDocument4 pagesJsa Brick WorkRavi thokalNo ratings yet

- Jsa 112Document7 pagesJsa 112Ravi thokalNo ratings yet

- Jha 110Document7 pagesJha 110Ravi thokalNo ratings yet

- Daily Site Inspection ChecklistDocument2 pagesDaily Site Inspection ChecklistRavi thokalNo ratings yet

- Jha UnloadingDocument4 pagesJha UnloadingRavi thokalNo ratings yet

- Jha UtilityDocument4 pagesJha UtilityRavi thokalNo ratings yet

- JHA For Concreting WorkDocument3 pagesJHA For Concreting WorkRavi thokalNo ratings yet

- Jha Lighting ArrestorDocument3 pagesJha Lighting ArrestorRavi thokalNo ratings yet

- Job Discerption For Cluster Level Federation (CLF) ConsultantDocument3 pagesJob Discerption For Cluster Level Federation (CLF) ConsultantRavi thokalNo ratings yet

- Daily Checklist - Hindi Format - Draft2Document2 pagesDaily Checklist - Hindi Format - Draft2Ravi thokalNo ratings yet

- Employee Relationship ManagementDocument42 pagesEmployee Relationship Managementsupriyanair80% (5)

- Histtory and Importance of HadithDocument31 pagesHisttory and Importance of HadithAbdullah AhsanNo ratings yet

- TED Taiye SelasiDocument4 pagesTED Taiye SelasiMinh ThuNo ratings yet

- Florida Et Al v. Dept. of Health & Human Services Et AlDocument304 pagesFlorida Et Al v. Dept. of Health & Human Services Et AlDoug MataconisNo ratings yet

- 1941Document8 pages1941Zharieya AmaraNo ratings yet

- Teaching The SchwaDocument5 pagesTeaching The SchwaStarr BlueNo ratings yet

- Kurt LewinDocument6 pagesKurt Lewinfotiadis100% (2)

- The CPP/NPA/NDF Constitute The Local Communist Movement in The Philippines Beforehand, ItDocument19 pagesThe CPP/NPA/NDF Constitute The Local Communist Movement in The Philippines Beforehand, Itzy_tanNo ratings yet

- Kansai International Airport, Seawall, GyronesDocument13 pagesKansai International Airport, Seawall, GyronesIzzuddin ShahidanNo ratings yet

- Award Certificates EDITABLE 1Document7 pagesAward Certificates EDITABLE 1Ruby Ann Gervacio GimenezNo ratings yet

- Born Again of The People: Luis Taruc and Peasant Ideology in Philippine Revolutionary PoliticsDocument43 pagesBorn Again of The People: Luis Taruc and Peasant Ideology in Philippine Revolutionary PoliticsThania O. CoronicaNo ratings yet

- Bloomberg Training 2Document8 pagesBloomberg Training 2rahzzy100% (1)

- Analysis of Credit Risk Measurement UsinDocument6 pagesAnalysis of Credit Risk Measurement UsinDia-wiNo ratings yet

- Sp-Ishares-Nasdaq-Biotechnology-Etf-3-31 02-13-2023Document20 pagesSp-Ishares-Nasdaq-Biotechnology-Etf-3-31 02-13-2023jorge huerta durazoNo ratings yet

- Asphyxial DeathDocument17 pagesAsphyxial DeathSisca ChearzNo ratings yet

- Iqwq-Ft-Rspds-00-120103 - 1 Preservation During Shipping and ConstructionDocument31 pagesIqwq-Ft-Rspds-00-120103 - 1 Preservation During Shipping and Constructionjacksonbello34No ratings yet

- Week 1 Origins of Hospitality and HousekeepingDocument12 pagesWeek 1 Origins of Hospitality and HousekeepingEmmanuel CherianNo ratings yet

- Q3 2019 Management Review SHEQ Presentation-1Document23 pagesQ3 2019 Management Review SHEQ Presentation-1Warren KabichiNo ratings yet

- The Israel Lobby ControversyDocument2 pagesThe Israel Lobby ControversysisinjhaaNo ratings yet

- 14-128 MTR Veh Appraisal FormDocument2 pages14-128 MTR Veh Appraisal FormJASONNo ratings yet

- 3310-Ch 10-End of Chapter solutions-STDocument30 pages3310-Ch 10-End of Chapter solutions-STArvind ManoNo ratings yet

- Customer Satisfaction On TATA Motors-7Document40 pagesCustomer Satisfaction On TATA Motors-7VampsiukNo ratings yet

- Ee NewDocument1 pageEe Newhsbibahmed091No ratings yet

- Manual On Settlement of Land DisputesDocument120 pagesManual On Settlement of Land Disputescookbooks&lawbooks100% (1)

- Bounty Hunter CreationDocument3 pagesBounty Hunter CreationdocidleNo ratings yet

- Module MAPEH 8 4thDocument21 pagesModule MAPEH 8 4thEdnell VelascoNo ratings yet

- 31-07-2020 - The Hindu Handwritten NotesDocument16 pages31-07-2020 - The Hindu Handwritten NotesnishuNo ratings yet