Professional Documents

Culture Documents

Service Parts List: Bulletin No

Service Parts List: Bulletin No

Uploaded by

Jose GonzalezCopyright:

Available Formats

You might also like

- An Interview With Elon MuskDocument2 pagesAn Interview With Elon MuskGiselle Medina Maximiano67% (3)

- Step 2 CK BibleDocument435 pagesStep 2 CK Biblewilksebas100% (13)

- g240 16a11a7 0a69 PDFDocument9 pagesg240 16a11a7 0a69 PDFlenin67% (3)

- Jangho Philippines Projects Presentation PDFDocument46 pagesJangho Philippines Projects Presentation PDFHao LiNo ratings yet

- DevaCurl Class Action LawsuitDocument135 pagesDevaCurl Class Action LawsuitmashablescribdNo ratings yet

- Service Manual: © MARCH 2016, Mercury Marine. All Rights Reserved. 90-8M0107213Document94 pagesService Manual: © MARCH 2016, Mercury Marine. All Rights Reserved. 90-8M0107213fabianoNo ratings yet

- G240 (16 Speeds) CEI MERCEDES-4-307-231-242Document12 pagesG240 (16 Speeds) CEI MERCEDES-4-307-231-242عبدالغني القباطي100% (3)

- g240 16a11a7 0a69 PDFDocument9 pagesg240 16a11a7 0a69 PDFlenin100% (1)

- Previous Screen: Generator Set C4.4 Generator Set S1M C4.4 Marine Gen Set S1M00001-UPDocument3 pagesPrevious Screen: Generator Set C4.4 Generator Set S1M C4.4 Marine Gen Set S1M00001-UPPaulvi MankouNo ratings yet

- JV3-160SP Mechanical Drawing V1.01 PDFDocument56 pagesJV3-160SP Mechanical Drawing V1.01 PDFErnestoNo ratings yet

- Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogDocument15 pagesAllison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogZafiro Feliz GalanNo ratings yet

- The Fusion Marketing Bible: Fuse Traditional Media, Social Media, & Digital Media to Maximize MarketingFrom EverandThe Fusion Marketing Bible: Fuse Traditional Media, Social Media, & Digital Media to Maximize MarketingRating: 5 out of 5 stars5/5 (2)

- BPT Targha Instalation ManualDocument12 pagesBPT Targha Instalation ManualFernando Manon100% (1)

- Overview of Functions and Operations BSPDocument2 pagesOverview of Functions and Operations BSPKarla GalvezNo ratings yet

- Service Parts List: 54-38-2600 J49A 2648-20 M18™ Random Orbit Sander See Page 2Document2 pagesService Parts List: 54-38-2600 J49A 2648-20 M18™ Random Orbit Sander See Page 2Daniel SierraNo ratings yet

- Service Parts List: Bulletin NoDocument2 pagesService Parts List: Bulletin NoRao ANo ratings yet

- Service Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillDocument2 pagesService Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillAmjad AlQasrawiNo ratings yet

- Service Parts List M12 Fuel 3" Compact Cut Off ToolDocument1 pageService Parts List M12 Fuel 3" Compact Cut Off TooljmzclrsNo ratings yet

- Service Parts List: M18™ Switch Tank™Document2 pagesService Parts List: M18™ Switch Tank™Ori umNo ratings yet

- Service Parts List: Bulletin NoDocument1 pageService Parts List: Bulletin NoEmmanuel Polledo TrujilloNo ratings yet

- Blue Star 145dx 185dx Part ManualDocument12 pagesBlue Star 145dx 185dx Part ManualGhislain ClicheNo ratings yet

- 6148-30 TYPE B71B MilwaukeeDocument3 pages6148-30 TYPE B71B MilwaukeeanibaltinoNo ratings yet

- MilwaukeeDocument2 pagesMilwaukeeLeoSolanoNo ratings yet

- Williams F98 Pump Parts ListDocument1 pageWilliams F98 Pump Parts Listbadawai sallamNo ratings yet

- Milwaukee PartsDocument1 pageMilwaukee PartsAmiet ChatterpalNo ratings yet

- SR-60 Kelly Bar FrictionDocument5 pagesSR-60 Kelly Bar Frictionاياد القباطيNo ratings yet

- Paramount Parts List Weed Eater Parts List Poulan Parts List Parts ListDocument2 pagesParamount Parts List Weed Eater Parts List Poulan Parts List Parts ListUNIMATE UNIMATENo ratings yet

- Parts Sheet: Electric Rod-Style ActuatorDocument18 pagesParts Sheet: Electric Rod-Style ActuatorSakahi SharmaNo ratings yet

- 1107-2740 hd4 1463084984Document12 pages1107-2740 hd4 1463084984ravenhotrods64No ratings yet

- Parts List ABYA30GATHDocument6 pagesParts List ABYA30GATHDino wowowNo ratings yet

- To Parts Spares Poulan p3500Document2 pagesTo Parts Spares Poulan p3500hdellarteNo ratings yet

- IntelliFloXF Variable Speed Pump After August 2015Document1 pageIntelliFloXF Variable Speed Pump After August 2015marlenetapiaarmentaNo ratings yet

- Vue Eclatee Mac GBV 325Document4 pagesVue Eclatee Mac GBV 325GegeNo ratings yet

- Service Parts List: M12™ HackzallDocument3 pagesService Parts List: M12™ Hackzallashtaroths1005sNo ratings yet

- Type 1: Paramount Parts List Weed Eater Parts List Poulan Parts List R Parts ListDocument5 pagesType 1: Paramount Parts List Weed Eater Parts List Poulan Parts List R Parts ListchiliwillyNo ratings yet

- Service Parts List: Cordless M12™ 3/8" Driver-DrillDocument3 pagesService Parts List: Cordless M12™ 3/8" Driver-DrillSergio BernalNo ratings yet

- Service Parts List: Cordless M12™ 3/8" Driver-DrillDocument3 pagesService Parts List: Cordless M12™ 3/8" Driver-DrillAmjad AlQasrawiNo ratings yet

- A Part 58Document1 pageA Part 58betabet GeorgeNo ratings yet

- Kassia Brochure Unit Floor PlansDocument19 pagesKassia Brochure Unit Floor PlansRonnie TanNo ratings yet

- Poluan 4218 Parts DiagDocument2 pagesPoluan 4218 Parts DiagJeffrey FarrowNo ratings yet

- LLAVE INALAMBRICA DE 3-4 MILWAUKEElgyc KyxcdluytflufvDocument2 pagesLLAVE INALAMBRICA DE 3-4 MILWAUKEElgyc Kyxcdluytflufvalejandro.morenoNo ratings yet

- 2606 20 (F24A) Milwaukee PBDocument3 pages2606 20 (F24A) Milwaukee PBhiramfgarciaNo ratings yet

- BAYLX - ULP Parts Manual NADocument24 pagesBAYLX - ULP Parts Manual NAJonah RagleNo ratings yet

- Skidding Winch Parts Manual fx90Document12 pagesSkidding Winch Parts Manual fx90iQuABoBNo ratings yet

- Mercedes: Actros Mp2 Actros Mp3 Actros Mp4 G330 - 16 SpeedsDocument73 pagesMercedes: Actros Mp2 Actros Mp3 Actros Mp4 G330 - 16 SpeedsJonathan TDS ZFNo ratings yet

- Olb Page20 20101002Document1 pageOlb Page20 20101002OutlookMagazineNo ratings yet

- Options: CatalogueDocument4 pagesOptions: CataloguessinokrotNo ratings yet

- 34 PartsDocument24 pages34 Partskirk sutherlandNo ratings yet

- P278215D - Miller Big Blue 400 PartsbookDocument19 pagesP278215D - Miller Big Blue 400 Partsbookalif.radinaNo ratings yet

- Char-Lynn 10000 Series Repair ManualDocument12 pagesChar-Lynn 10000 Series Repair Manualmillers roblesNo ratings yet

- Ecr Change Description 1229 Updated Title Block, Sheet Size Was B, Drawing Number Was Uldc-011, at A2 Add Dimension 320Document1 pageEcr Change Description 1229 Updated Title Block, Sheet Size Was B, Drawing Number Was Uldc-011, at A2 Add Dimension 320JBladonegNo ratings yet

- Allison at 500, at 1500 Series Parts CatalogDocument7 pagesAllison at 500, at 1500 Series Parts Catalogamin chaabenNo ratings yet

- Miller BIG BLUE 400 PRO Part ManualDocument19 pagesMiller BIG BLUE 400 PRO Part ManualWahyu Sriharja100% (2)

- Illustrated Parts Manual: Transmatic Lawn Tractor - Models 760-779Document28 pagesIllustrated Parts Manual: Transmatic Lawn Tractor - Models 760-779joeladamsNo ratings yet

- Poulan p4018wt Parts Manual 718469Document3 pagesPoulan p4018wt Parts Manual 718469Armando Lopez GonzalezNo ratings yet

- 54-24-3310 Milwaukee Service ManualDocument2 pages54-24-3310 Milwaukee Service ManualCarlos Salcedo100% (1)

- Des-J-1360-001-01-0 (Mto - Sketch - Form)Document1 pageDes-J-1360-001-01-0 (Mto - Sketch - Form)Yawar AliNo ratings yet

- Instructions For Parts Books: Note About Country CodesDocument12 pagesInstructions For Parts Books: Note About Country Codes12345ace12345No ratings yet

- Service Manual: ECM-MS907Document8 pagesService Manual: ECM-MS907imoon63No ratings yet

- Spare Parts List Ersatzteilliste Liste de Pièces Détachées Lista de Piezas de RepuestoDocument16 pagesSpare Parts List Ersatzteilliste Liste de Pièces Détachées Lista de Piezas de RepuestoDani.ZNo ratings yet

- Poulan Pro 4218Document3 pagesPoulan Pro 4218AlexNo ratings yet

- Dorsu MapDocument2 pagesDorsu Mapoffhegoes2No ratings yet

- ES5162 - RSPL - Rev - 5 PDFDocument63 pagesES5162 - RSPL - Rev - 5 PDFOkidata Impresoras0% (1)

- UT08017L Thru UT080119Document12 pagesUT08017L Thru UT080119Andreas ChristakosNo ratings yet

- Service Parts List: 54-00-2723 M18 FUEL Compact Router K91A Bulletin NoDocument5 pagesService Parts List: 54-00-2723 M18 FUEL Compact Router K91A Bulletin NoAmjad AlQasrawiNo ratings yet

- VIS30Document4 pagesVIS30Chali AndresNo ratings yet

- The Power of Scarcity: Leveraging Urgency and Demand to Influence Customer DecisionsFrom EverandThe Power of Scarcity: Leveraging Urgency and Demand to Influence Customer DecisionsNo ratings yet

- M.H. Saboo Siddik College of Engineering: CertificateDocument55 pagesM.H. Saboo Siddik College of Engineering: Certificatebhanu jammu100% (1)

- Dispersion PollutantsDocument18 pagesDispersion PollutantsAmira GogoantaNo ratings yet

- Hypersep: Centrifugal Water SeparationDocument4 pagesHypersep: Centrifugal Water SeparationClaudio TurlherNo ratings yet

- Carrier Air Cooled Liquid Chillers 30GH GZ Series DatasheetDocument16 pagesCarrier Air Cooled Liquid Chillers 30GH GZ Series DatasheetQazertNo ratings yet

- Earthquake Resistance BuildingDocument62 pagesEarthquake Resistance BuildingTGODA_13No ratings yet

- Vector XIIDocument2 pagesVector XIIShreeNo ratings yet

- PE PipesDocument28 pagesPE Pipesmanar rafikNo ratings yet

- Bio Kertas 2 - SkemaDocument11 pagesBio Kertas 2 - SkemaHaslinda SheikhNo ratings yet

- Acids and BasesDocument26 pagesAcids and BasesGaayathiriNo ratings yet

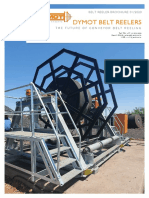

- Belt Reeler BrochureDocument4 pagesBelt Reeler BrochureRestuNo ratings yet

- Flatland Lets Think About ItDocument6 pagesFlatland Lets Think About Itpj_lastkissNo ratings yet

- Beverage Purchasing ControlDocument51 pagesBeverage Purchasing ControlMoses Mwah Muraya100% (2)

- DIM100D283490 (1) - 7.5MVA - CommentsDocument1 pageDIM100D283490 (1) - 7.5MVA - CommentsnisarbashaNo ratings yet

- BW010En Plastic Mould SteelsDocument20 pagesBW010En Plastic Mould SteelsFarid Impact TubesNo ratings yet

- Achasta Bear Paw RidgeDocument1 pageAchasta Bear Paw RidgeC Bombin'No ratings yet

- TZL1D L96 6000LM FST Mvolt 50K 80cri WHDocument6 pagesTZL1D L96 6000LM FST Mvolt 50K 80cri WHSolidNo ratings yet

- Assessment: Facial ShavingDocument2 pagesAssessment: Facial ShavingA CNo ratings yet

- Shop Manual: 97F21409 Backhoe Loader WB97R-2Document570 pagesShop Manual: 97F21409 Backhoe Loader WB97R-2Teknik Makina100% (1)

- 3D Geoscience Modeling, Computer Techniques For Geological Characterization (Simon W. Houlding, 1994) - (Geo Pedia) PDFDocument309 pages3D Geoscience Modeling, Computer Techniques For Geological Characterization (Simon W. Houlding, 1994) - (Geo Pedia) PDFbeku_ggs_beku100% (1)

- Bajaj Electricals Limited: Head of R & D AB Square Navi Mumbai Executive DirectorDocument2 pagesBajaj Electricals Limited: Head of R & D AB Square Navi Mumbai Executive DirectorabhijitNo ratings yet

- Ise Human Genetics Concepts and Applications 13Th Edition Ricki Lewis Full ChapterDocument65 pagesIse Human Genetics Concepts and Applications 13Th Edition Ricki Lewis Full Chapterkatelyn.willis396100% (4)

- Optimizing HPLC Methods 1684601740Document46 pagesOptimizing HPLC Methods 1684601740AlexandreLuizdeSouzaNo ratings yet

- General Pre Stress and ElasticDocument28 pagesGeneral Pre Stress and ElasticJorge Nickolai NavalesNo ratings yet

Service Parts List: Bulletin No

Service Parts List: Bulletin No

Uploaded by

Jose GonzalezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Parts List: Bulletin No

Service Parts List: Bulletin No

Uploaded by

Jose GonzalezCopyright:

Available Formats

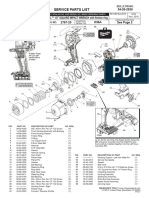

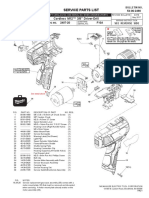

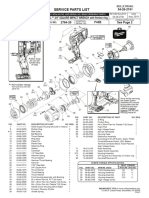

BULLETIN NO.

SERVICE PARTS LIST 54-05-0805

SPECIFY CATALOG NO. AND SERIAL NO. WHEN ORDERING PARTS REVISED BULLETIN DATE

Nov. 2013

CORDLESS M18™ COMPACT BLOWER

WIRING INSTRUCTION

CATALOG NO. 0884-20 STARTING

SERIAL NO. F74A See Page 2

33

(1x)

9 10 11 39 11

9 10 NOTE: Place a little grease

on the Spring #10 and the

Pin #9 to help retain

2 38 the parts in the small

cavity of the Speed

4(2x) Button

1 35

(7x)

37

41 35 36

37 38 EXAMPLE:

00 0 Component Parts (Small #) Are Included

3 When Ordering The Assembly (Large #).

7

6

8 12

36 40 12

1 2

33

14

27

13

26(4x)

42 13 14

15 25

15

44 23 24

25 32

31

22

19 24

17 23

16

43 21 22

27 31

32

20

45 16

19

17

21

(4x)

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

1 06-81-0016 M3 x 9 Pan Hd. Plastite T-10 Screw (7)

2 --------------- Handle/Motor Housing Halve-Right (1) FIG. PART NO. DESCRIPTION OF PART NO. REQ.

3 31-17-0130 Wire Trap (1) 26 06-81-0066 M4.0 x 10 Pan Hd. Plastite Phillips Screw (4)

4 06-81-0026 M2.3 x 6 Pan Hd. Plastite Phillips Screw (2) 27 --------------- Fan Housing Halve-Right (1)

6 42-42-0805 Switch Lock Button (1) 31 12-20-0884 Service Nameplate (1)

7 40-50-0206 Switch Lock Spring (1) 32 06-97-0040 Lock Washer (1)

8 06-81-0046 M2.3 x 6 Pan Hd. Washer Screw-Phillips (1) 33 06-81-0017 M3 x 15 Pan Hd. Plastite T-10 Screw (1)

9 --------------- Speed Button Detent Pin (1) 35 --------------- On-Off Switch (1)

10 --------------- Speed Button Spring (1) 36 --------------- Battery Connector Block (1)

11 --------------- Speed Button (1) 37 --------------- Main PCBA (1)

12 --------------- Handle Housing Halve-Left (1) 38 --------------- Switch PCBA (1)

13 44-34-0450 Lower Motor Support (1) 39 31-01-1010 Blower Speed Button Assembly (1)

14 --------------- Motor with Spindle (1) 40 14-34-1025 Handle/Motor Housing Assembly (1)

15 44-34-0455 Upper Motor Support (1) 41 14-20-2000 Electronics Assembly

16 43-24-0510 Nozzle (1) Consists of On-Off Switch, Main PCBA,

17 44-90-1040 Nozzle Ring (1) PCBA Switch, Battery Terminal Block (1)

19 43-24-0155 Extension Tube (1) 42 14-50-1300 Motor Assembly with Spindle (1)

20 45-80-0020 Inflator/Deflator Valves (1) 43 14-38-1010 Fan Housing Assembly (1)

21 06-81-0056 M4 x 18 Pan Hd. Plastite T-20 Screw (4) 44 22-84-0080 Blower Fan Kit (1)

22 --------------- Fan Housing Halve-Left (1) 45 43-24-0520 Nozzle/Extension Assembly (1)

23 05-83-0400 M5.0 x 8 Pan Hd. Phillips Machine Screw (1)

MILWAUKEE ELECTRIC TOOL CORPORATION

24 45-88-0013 Washer (1) 13135 W. LISBON RD., BROOKFIELD, WI 53005

25 --------------- Fan (1) Drwg. 3

AS AN AID TO REASSEMBLY, TAKE

Switch PCBA NOTICE OF WIRE ROUTING AND

POSITION IN WIRE GUIDES AND

TRAPS WHILE DISMANTLING TOOL.

Wire Trap #3 BE CAREFUL AND AVOID PINCHING

WIRES BETWEEN HANDLE HALVES

WHEN ASSEMBLING.

= WIRE TRAPS

or GUIDES

Channel in On-Off Switch

Lower Motor

Support for

red motor wire

Main PCBA

Rubber lugs

Rubber Motor

lugs

Battery Terminal

Block

Channel in Lower Motor

Rubber lugs Support for black motor wire

When reinstalling a new Motor Assembly, be sure that the red and black motor

#2 Handle/Motor leads are fed through the large opening in the back of the Lower Motor Support

Housing Halve before soldering wires to the On-Off Switch.

Slide the lower motor support onto the rear of the motor, orienting it as shown

and making sure it is firmly pressed into place.

Be sure that the Upper Motor Support is oriented as shown and firmly seated on

the spindle end of the Motor.

Press the motor leads into the channels of the lower motor support and remove

most of the slack from the rear of the motor. Line up the rubber lugs of the upper

and lower motor supports with the channels in the motor cavity of the Handle/

Motor Housing Halve. Install the assembly into the handle/motor housing halve.

NOTE:

#13 Lower For ease of installation, the upper motor support can be left off the spindle end

Motor Support of the motor until the lower motor support and motor are pressed into place. At

that time, the upper motor support can be assembled onto the motor, orienting

#14 Motor the rubber lugs with the corresponding channels in the motor cavity and firmly

seated.

#15 Upper

Motor Support

You might also like

- An Interview With Elon MuskDocument2 pagesAn Interview With Elon MuskGiselle Medina Maximiano67% (3)

- Step 2 CK BibleDocument435 pagesStep 2 CK Biblewilksebas100% (13)

- g240 16a11a7 0a69 PDFDocument9 pagesg240 16a11a7 0a69 PDFlenin67% (3)

- Jangho Philippines Projects Presentation PDFDocument46 pagesJangho Philippines Projects Presentation PDFHao LiNo ratings yet

- DevaCurl Class Action LawsuitDocument135 pagesDevaCurl Class Action LawsuitmashablescribdNo ratings yet

- Service Manual: © MARCH 2016, Mercury Marine. All Rights Reserved. 90-8M0107213Document94 pagesService Manual: © MARCH 2016, Mercury Marine. All Rights Reserved. 90-8M0107213fabianoNo ratings yet

- G240 (16 Speeds) CEI MERCEDES-4-307-231-242Document12 pagesG240 (16 Speeds) CEI MERCEDES-4-307-231-242عبدالغني القباطي100% (3)

- g240 16a11a7 0a69 PDFDocument9 pagesg240 16a11a7 0a69 PDFlenin100% (1)

- Previous Screen: Generator Set C4.4 Generator Set S1M C4.4 Marine Gen Set S1M00001-UPDocument3 pagesPrevious Screen: Generator Set C4.4 Generator Set S1M C4.4 Marine Gen Set S1M00001-UPPaulvi MankouNo ratings yet

- JV3-160SP Mechanical Drawing V1.01 PDFDocument56 pagesJV3-160SP Mechanical Drawing V1.01 PDFErnestoNo ratings yet

- Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogDocument15 pagesAllison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogZafiro Feliz GalanNo ratings yet

- The Fusion Marketing Bible: Fuse Traditional Media, Social Media, & Digital Media to Maximize MarketingFrom EverandThe Fusion Marketing Bible: Fuse Traditional Media, Social Media, & Digital Media to Maximize MarketingRating: 5 out of 5 stars5/5 (2)

- BPT Targha Instalation ManualDocument12 pagesBPT Targha Instalation ManualFernando Manon100% (1)

- Overview of Functions and Operations BSPDocument2 pagesOverview of Functions and Operations BSPKarla GalvezNo ratings yet

- Service Parts List: 54-38-2600 J49A 2648-20 M18™ Random Orbit Sander See Page 2Document2 pagesService Parts List: 54-38-2600 J49A 2648-20 M18™ Random Orbit Sander See Page 2Daniel SierraNo ratings yet

- Service Parts List: Bulletin NoDocument2 pagesService Parts List: Bulletin NoRao ANo ratings yet

- Service Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillDocument2 pagesService Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillAmjad AlQasrawiNo ratings yet

- Service Parts List M12 Fuel 3" Compact Cut Off ToolDocument1 pageService Parts List M12 Fuel 3" Compact Cut Off TooljmzclrsNo ratings yet

- Service Parts List: M18™ Switch Tank™Document2 pagesService Parts List: M18™ Switch Tank™Ori umNo ratings yet

- Service Parts List: Bulletin NoDocument1 pageService Parts List: Bulletin NoEmmanuel Polledo TrujilloNo ratings yet

- Blue Star 145dx 185dx Part ManualDocument12 pagesBlue Star 145dx 185dx Part ManualGhislain ClicheNo ratings yet

- 6148-30 TYPE B71B MilwaukeeDocument3 pages6148-30 TYPE B71B MilwaukeeanibaltinoNo ratings yet

- MilwaukeeDocument2 pagesMilwaukeeLeoSolanoNo ratings yet

- Williams F98 Pump Parts ListDocument1 pageWilliams F98 Pump Parts Listbadawai sallamNo ratings yet

- Milwaukee PartsDocument1 pageMilwaukee PartsAmiet ChatterpalNo ratings yet

- SR-60 Kelly Bar FrictionDocument5 pagesSR-60 Kelly Bar Frictionاياد القباطيNo ratings yet

- Paramount Parts List Weed Eater Parts List Poulan Parts List Parts ListDocument2 pagesParamount Parts List Weed Eater Parts List Poulan Parts List Parts ListUNIMATE UNIMATENo ratings yet

- Parts Sheet: Electric Rod-Style ActuatorDocument18 pagesParts Sheet: Electric Rod-Style ActuatorSakahi SharmaNo ratings yet

- 1107-2740 hd4 1463084984Document12 pages1107-2740 hd4 1463084984ravenhotrods64No ratings yet

- Parts List ABYA30GATHDocument6 pagesParts List ABYA30GATHDino wowowNo ratings yet

- To Parts Spares Poulan p3500Document2 pagesTo Parts Spares Poulan p3500hdellarteNo ratings yet

- IntelliFloXF Variable Speed Pump After August 2015Document1 pageIntelliFloXF Variable Speed Pump After August 2015marlenetapiaarmentaNo ratings yet

- Vue Eclatee Mac GBV 325Document4 pagesVue Eclatee Mac GBV 325GegeNo ratings yet

- Service Parts List: M12™ HackzallDocument3 pagesService Parts List: M12™ Hackzallashtaroths1005sNo ratings yet

- Type 1: Paramount Parts List Weed Eater Parts List Poulan Parts List R Parts ListDocument5 pagesType 1: Paramount Parts List Weed Eater Parts List Poulan Parts List R Parts ListchiliwillyNo ratings yet

- Service Parts List: Cordless M12™ 3/8" Driver-DrillDocument3 pagesService Parts List: Cordless M12™ 3/8" Driver-DrillSergio BernalNo ratings yet

- Service Parts List: Cordless M12™ 3/8" Driver-DrillDocument3 pagesService Parts List: Cordless M12™ 3/8" Driver-DrillAmjad AlQasrawiNo ratings yet

- A Part 58Document1 pageA Part 58betabet GeorgeNo ratings yet

- Kassia Brochure Unit Floor PlansDocument19 pagesKassia Brochure Unit Floor PlansRonnie TanNo ratings yet

- Poluan 4218 Parts DiagDocument2 pagesPoluan 4218 Parts DiagJeffrey FarrowNo ratings yet

- LLAVE INALAMBRICA DE 3-4 MILWAUKEElgyc KyxcdluytflufvDocument2 pagesLLAVE INALAMBRICA DE 3-4 MILWAUKEElgyc Kyxcdluytflufvalejandro.morenoNo ratings yet

- 2606 20 (F24A) Milwaukee PBDocument3 pages2606 20 (F24A) Milwaukee PBhiramfgarciaNo ratings yet

- BAYLX - ULP Parts Manual NADocument24 pagesBAYLX - ULP Parts Manual NAJonah RagleNo ratings yet

- Skidding Winch Parts Manual fx90Document12 pagesSkidding Winch Parts Manual fx90iQuABoBNo ratings yet

- Mercedes: Actros Mp2 Actros Mp3 Actros Mp4 G330 - 16 SpeedsDocument73 pagesMercedes: Actros Mp2 Actros Mp3 Actros Mp4 G330 - 16 SpeedsJonathan TDS ZFNo ratings yet

- Olb Page20 20101002Document1 pageOlb Page20 20101002OutlookMagazineNo ratings yet

- Options: CatalogueDocument4 pagesOptions: CataloguessinokrotNo ratings yet

- 34 PartsDocument24 pages34 Partskirk sutherlandNo ratings yet

- P278215D - Miller Big Blue 400 PartsbookDocument19 pagesP278215D - Miller Big Blue 400 Partsbookalif.radinaNo ratings yet

- Char-Lynn 10000 Series Repair ManualDocument12 pagesChar-Lynn 10000 Series Repair Manualmillers roblesNo ratings yet

- Ecr Change Description 1229 Updated Title Block, Sheet Size Was B, Drawing Number Was Uldc-011, at A2 Add Dimension 320Document1 pageEcr Change Description 1229 Updated Title Block, Sheet Size Was B, Drawing Number Was Uldc-011, at A2 Add Dimension 320JBladonegNo ratings yet

- Allison at 500, at 1500 Series Parts CatalogDocument7 pagesAllison at 500, at 1500 Series Parts Catalogamin chaabenNo ratings yet

- Miller BIG BLUE 400 PRO Part ManualDocument19 pagesMiller BIG BLUE 400 PRO Part ManualWahyu Sriharja100% (2)

- Illustrated Parts Manual: Transmatic Lawn Tractor - Models 760-779Document28 pagesIllustrated Parts Manual: Transmatic Lawn Tractor - Models 760-779joeladamsNo ratings yet

- Poulan p4018wt Parts Manual 718469Document3 pagesPoulan p4018wt Parts Manual 718469Armando Lopez GonzalezNo ratings yet

- 54-24-3310 Milwaukee Service ManualDocument2 pages54-24-3310 Milwaukee Service ManualCarlos Salcedo100% (1)

- Des-J-1360-001-01-0 (Mto - Sketch - Form)Document1 pageDes-J-1360-001-01-0 (Mto - Sketch - Form)Yawar AliNo ratings yet

- Instructions For Parts Books: Note About Country CodesDocument12 pagesInstructions For Parts Books: Note About Country Codes12345ace12345No ratings yet

- Service Manual: ECM-MS907Document8 pagesService Manual: ECM-MS907imoon63No ratings yet

- Spare Parts List Ersatzteilliste Liste de Pièces Détachées Lista de Piezas de RepuestoDocument16 pagesSpare Parts List Ersatzteilliste Liste de Pièces Détachées Lista de Piezas de RepuestoDani.ZNo ratings yet

- Poulan Pro 4218Document3 pagesPoulan Pro 4218AlexNo ratings yet

- Dorsu MapDocument2 pagesDorsu Mapoffhegoes2No ratings yet

- ES5162 - RSPL - Rev - 5 PDFDocument63 pagesES5162 - RSPL - Rev - 5 PDFOkidata Impresoras0% (1)

- UT08017L Thru UT080119Document12 pagesUT08017L Thru UT080119Andreas ChristakosNo ratings yet

- Service Parts List: 54-00-2723 M18 FUEL Compact Router K91A Bulletin NoDocument5 pagesService Parts List: 54-00-2723 M18 FUEL Compact Router K91A Bulletin NoAmjad AlQasrawiNo ratings yet

- VIS30Document4 pagesVIS30Chali AndresNo ratings yet

- The Power of Scarcity: Leveraging Urgency and Demand to Influence Customer DecisionsFrom EverandThe Power of Scarcity: Leveraging Urgency and Demand to Influence Customer DecisionsNo ratings yet

- M.H. Saboo Siddik College of Engineering: CertificateDocument55 pagesM.H. Saboo Siddik College of Engineering: Certificatebhanu jammu100% (1)

- Dispersion PollutantsDocument18 pagesDispersion PollutantsAmira GogoantaNo ratings yet

- Hypersep: Centrifugal Water SeparationDocument4 pagesHypersep: Centrifugal Water SeparationClaudio TurlherNo ratings yet

- Carrier Air Cooled Liquid Chillers 30GH GZ Series DatasheetDocument16 pagesCarrier Air Cooled Liquid Chillers 30GH GZ Series DatasheetQazertNo ratings yet

- Earthquake Resistance BuildingDocument62 pagesEarthquake Resistance BuildingTGODA_13No ratings yet

- Vector XIIDocument2 pagesVector XIIShreeNo ratings yet

- PE PipesDocument28 pagesPE Pipesmanar rafikNo ratings yet

- Bio Kertas 2 - SkemaDocument11 pagesBio Kertas 2 - SkemaHaslinda SheikhNo ratings yet

- Acids and BasesDocument26 pagesAcids and BasesGaayathiriNo ratings yet

- Belt Reeler BrochureDocument4 pagesBelt Reeler BrochureRestuNo ratings yet

- Flatland Lets Think About ItDocument6 pagesFlatland Lets Think About Itpj_lastkissNo ratings yet

- Beverage Purchasing ControlDocument51 pagesBeverage Purchasing ControlMoses Mwah Muraya100% (2)

- DIM100D283490 (1) - 7.5MVA - CommentsDocument1 pageDIM100D283490 (1) - 7.5MVA - CommentsnisarbashaNo ratings yet

- BW010En Plastic Mould SteelsDocument20 pagesBW010En Plastic Mould SteelsFarid Impact TubesNo ratings yet

- Achasta Bear Paw RidgeDocument1 pageAchasta Bear Paw RidgeC Bombin'No ratings yet

- TZL1D L96 6000LM FST Mvolt 50K 80cri WHDocument6 pagesTZL1D L96 6000LM FST Mvolt 50K 80cri WHSolidNo ratings yet

- Assessment: Facial ShavingDocument2 pagesAssessment: Facial ShavingA CNo ratings yet

- Shop Manual: 97F21409 Backhoe Loader WB97R-2Document570 pagesShop Manual: 97F21409 Backhoe Loader WB97R-2Teknik Makina100% (1)

- 3D Geoscience Modeling, Computer Techniques For Geological Characterization (Simon W. Houlding, 1994) - (Geo Pedia) PDFDocument309 pages3D Geoscience Modeling, Computer Techniques For Geological Characterization (Simon W. Houlding, 1994) - (Geo Pedia) PDFbeku_ggs_beku100% (1)

- Bajaj Electricals Limited: Head of R & D AB Square Navi Mumbai Executive DirectorDocument2 pagesBajaj Electricals Limited: Head of R & D AB Square Navi Mumbai Executive DirectorabhijitNo ratings yet

- Ise Human Genetics Concepts and Applications 13Th Edition Ricki Lewis Full ChapterDocument65 pagesIse Human Genetics Concepts and Applications 13Th Edition Ricki Lewis Full Chapterkatelyn.willis396100% (4)

- Optimizing HPLC Methods 1684601740Document46 pagesOptimizing HPLC Methods 1684601740AlexandreLuizdeSouzaNo ratings yet

- General Pre Stress and ElasticDocument28 pagesGeneral Pre Stress and ElasticJorge Nickolai NavalesNo ratings yet