Professional Documents

Culture Documents

Jet Flusher Pre Start Checklist

Jet Flusher Pre Start Checklist

Uploaded by

asan0 ratings0% found this document useful (0 votes)

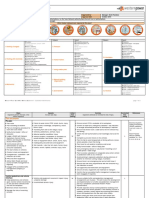

38 views1 pageThe document is a high pressure water jetting pre-start checklist that contains safety requirements and checks to complete before starting a high pressure water jetting job. It includes checking that the crew is trained, exclusion zones are set up, equipment is rated for the pressure and task, personal protective equipment is worn, hoses and connections are inspected and in good condition, emergency communications are available, and attachments are correct for the job. Crew members must sign off agreeing to follow the requirements.

Original Description:

jet of water

Original Title

Jet-Flusher-Pre-Start-Checklist

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a high pressure water jetting pre-start checklist that contains safety requirements and checks to complete before starting a high pressure water jetting job. It includes checking that the crew is trained, exclusion zones are set up, equipment is rated for the pressure and task, personal protective equipment is worn, hoses and connections are inspected and in good condition, emergency communications are available, and attachments are correct for the job. Crew members must sign off agreeing to follow the requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

38 views1 pageJet Flusher Pre Start Checklist

Jet Flusher Pre Start Checklist

Uploaded by

asanThe document is a high pressure water jetting pre-start checklist that contains safety requirements and checks to complete before starting a high pressure water jetting job. It includes checking that the crew is trained, exclusion zones are set up, equipment is rated for the pressure and task, personal protective equipment is worn, hoses and connections are inspected and in good condition, emergency communications are available, and attachments are correct for the job. Crew members must sign off agreeing to follow the requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

High Pressure Water Jetting Pre-Start Checklist

Job/Task: Date:

Job Number: Plant Number:

Training Requirements Yes No N/A

Are all crew members adequately trained to complete the specified task

Site Requirements to be Completed: Yes No N/A

Crew members communicated with any effected parties in the vicinity

Exclusion zones/barricading and signage is in place

Pre-start Requirements (Please ensure the following are correct and complete :) Yes No N/A

Is the unit being used correct for the task

Flusher truck pre-start checks have been completed

All components are of the correct pressure rating and in good condition

Have all primary shut off devices (Gun/foot pedal/E-Stop) been tested and are

operating correctly

Gun barrel must be at least 1.2m long

For manual handgun operation, reaction force is not exceeding 250N (25.5kg)

Anti-withdrawal devices shall be used for manual tube/pipe cleaning

A starter bar is used where the nozzle can turn around inside the pipe

Exclusion zones/barricading and signage in place at exit points

Safety Requirements (Please ensure the following are correct and complete :) Yes No N/A

Operators and persons within the exclusion zones have required PPE on

Hose restrains have been fitted to all high pressure hose connections and are in

good condition

All high pressure hoses/flex lances have been inspection in test date and in good

condition

The safety observer shall have a clear line of sigh of the nozzle operator

The safety observer shall have direct / immediate access to the emergency shut

off device

The RCP is understood by all team members and they have signed on to the RCP

Are emergency communications (Radio/Mobile phone) readily available

All team members are aware of access ways

Is the pump/truck parked in a safe location? (ie safe distance from flying debris

and no obstructions of the exhaust outlets)

Is the pump free of oil/water leaks

Are the attachments correct for the task

Have all components been inspected and are free from signs of wear and tear,

rust, foreign material inside the barrel and threads checked for damage

All hoses laid out free from rub points and sharp edges

Have all hose O-rings, hose connections and fittings been checked for wear and

tear and cross threading

Pressure shall be increased slowly to identify leaks or faulty components

If you answer No to any of the checks, STOP and seek guidance from your team leader

Hose Number Expiry Date Pressure Rating Condition Comments

You might also like

- Inspection ChecklistDocument1 pageInspection ChecklistAli Asim Iftikhar80% (5)

- Hydrotesting ChecklistDocument1 pageHydrotesting ChecklistDwi Iin Novianti80% (5)

- Bolt Tightening Procedure and Method StatementDocument9 pagesBolt Tightening Procedure and Method Statementmanoj thakkar100% (1)

- AGROINDUSTRIALA BREDAL K35-K165 - ENG - Until - 2018Document66 pagesAGROINDUSTRIALA BREDAL K35-K165 - ENG - Until - 2018PopSorinNo ratings yet

- Welder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamFrom EverandWelder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamNo ratings yet

- Certificate Aboveground PipingDocument5 pagesCertificate Aboveground Pipingsajeed76740No ratings yet

- Pressure Switch Function TestDocument5 pagesPressure Switch Function Testnjenns100% (1)

- Stringing Check ListDocument2 pagesStringing Check ListPraveen100% (6)

- Job Safety Analysis FormDocument4 pagesJob Safety Analysis FormMohammed NayeemuddinNo ratings yet

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- HH:MM Dd/Mm/Yyy Y HH:MM Dd/Mm/Yyy Y Name / Surname Name / SurnameDocument3 pagesHH:MM Dd/Mm/Yyy Y HH:MM Dd/Mm/Yyy Y Name / Surname Name / Surnamesubhanmusadiq100% (2)

- Tug and Barge Survey ReportDocument14 pagesTug and Barge Survey Reportchepurthi100% (1)

- Jsa For Static Equipment ErectionDocument15 pagesJsa For Static Equipment ErectionKhuda Buksh100% (1)

- Port State ControlDocument26 pagesPort State ControlReuben Ephraim33% (3)

- Aluma Beam Product SheetDocument2 pagesAluma Beam Product SheetRubén Alejandro Arenas PizarroNo ratings yet

- Drilling Rig Checklist Rev1Document29 pagesDrilling Rig Checklist Rev1Abdulsani3357No ratings yet

- ContractorsAbovegroundPiping PDFDocument2 pagesContractorsAbovegroundPiping PDFIvan SFNo ratings yet

- JSA23 Hydro Static Pressure Testing Various Pipe AuxiliariesDocument5 pagesJSA23 Hydro Static Pressure Testing Various Pipe AuxiliariesslmLSU100% (3)

- TS PRC 8222C Layer 2 QuestionnaireDocument3 pagesTS PRC 8222C Layer 2 QuestionnaireJOECOOL67No ratings yet

- Safety Inspection Check ListDocument24 pagesSafety Inspection Check ListSarah MclaughlinNo ratings yet

- PSC Checklist For Tokyo Mou AreaDocument8 pagesPSC Checklist For Tokyo Mou AreaDimosNo ratings yet

- Aerial Lift Inspection FormsDocument15 pagesAerial Lift Inspection FormsianNo ratings yet

- PSC Checklist For Tokyo Mou AreaDocument8 pagesPSC Checklist For Tokyo Mou AreaPKNo ratings yet

- Chemical Operations Safety AuditDocument4 pagesChemical Operations Safety AuditDinda Naiya AzhariNo ratings yet

- Risk Awareness PollutionDocument32 pagesRisk Awareness PollutionReda HmrNo ratings yet

- Pre Start Check List For Works Inside Shaft & CoresDocument1 pagePre Start Check List For Works Inside Shaft & CoresELANCHELIYANNo ratings yet

- Template Process Optimization Check ListDocument1 pageTemplate Process Optimization Check ListNithiyakumar.PNo ratings yet

- Attachment - I: Pre Start-Up Safety Review Checklist - 1Document15 pagesAttachment - I: Pre Start-Up Safety Review Checklist - 1HamzaNoumanNo ratings yet

- Pressure Testing - Take 5 Rev C FinalDocument2 pagesPressure Testing - Take 5 Rev C FinalVicky JiNo ratings yet

- 10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)Document1 page10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)caovanthien10121992No ratings yet

- CardDocument4 pagesCardsiva kumarNo ratings yet

- Method of Procedure CPE Installation / Removal / ModificationDocument4 pagesMethod of Procedure CPE Installation / Removal / ModificationAnthony BarringtonNo ratings yet

- 05.JHA-Site Survey For TR-9702A Transformer Marshalling Box Wiring Verification at Substation EDocument5 pages05.JHA-Site Survey For TR-9702A Transformer Marshalling Box Wiring Verification at Substation EFrancis Enriquez TanNo ratings yet

- Safety ChecklistDocument2 pagesSafety ChecklistAnonymous nF3tseUAGeNo ratings yet

- Distribution Swms Substation MaintenanceDocument5 pagesDistribution Swms Substation MaintenanceAnonymous mNQq7ojNo ratings yet

- SHE 68 - 9589 - Elevator Work PermitDocument2 pagesSHE 68 - 9589 - Elevator Work PermitciupcicNo ratings yet

- Audit Check List For Catalyst Loading & Unloading: Arabian Consolidated Industrial Cleaning Services - TandheefDocument2 pagesAudit Check List For Catalyst Loading & Unloading: Arabian Consolidated Industrial Cleaning Services - TandheefIvanna Bijo100% (1)

- FINAL Shivani Confined Space PermitDocument1 pageFINAL Shivani Confined Space PermitVimal SinghNo ratings yet

- Method of Statement For Bus Bar HV Test: Owner/Client Owner'S Engineer ContractorDocument6 pagesMethod of Statement For Bus Bar HV Test: Owner/Client Owner'S Engineer ContractorPandrayar MaruthuNo ratings yet

- Guide For Vetting InspectionsDocument6 pagesGuide For Vetting InspectionsAnonymous b68EQR100% (1)

- Job Plan: Lead Craft Condition For Work Crafts Department Craft QTYDocument3 pagesJob Plan: Lead Craft Condition For Work Crafts Department Craft QTYMohsin YasinNo ratings yet

- Automatic Sprinkler Systems ITMDocument4 pagesAutomatic Sprinkler Systems ITMamsyong loeNo ratings yet

- PTW Part - B: 16-4055 Jul 28, 2016 11:00 AM Vamsinath Vepery 9652225152Document2 pagesPTW Part - B: 16-4055 Jul 28, 2016 11:00 AM Vamsinath Vepery 9652225152subhashkpn86No ratings yet

- HVAC PumpDocument1 pageHVAC PumpmonpetitchatshopNo ratings yet

- 02 2011 Viðheft - Kekklisti - Fyrireiking Til Port State ControlDocument2 pages02 2011 Viðheft - Kekklisti - Fyrireiking Til Port State ControlRUBEN FERNANDESNo ratings yet

- Supervisors - HSE ChecklistDocument2 pagesSupervisors - HSE Checklistchikkam50% (4)

- Skai Air Pressure Testing PermitDocument4 pagesSkai Air Pressure Testing Permitasmita22744742No ratings yet

- OCP - 10 Wave TrapDocument5 pagesOCP - 10 Wave TrapNaveedNo ratings yet

- LIMA-Z-PLA-1026 - Rev1 Personnel Transfer With Barge CraneDocument20 pagesLIMA-Z-PLA-1026 - Rev1 Personnel Transfer With Barge CraneCahya Adi YeftaNo ratings yet

- Ajith Antony Rajan Mechanial MaintenanceDocument3 pagesAjith Antony Rajan Mechanial Maintenancenadal.shahidNo ratings yet

- OCP - 06 LT Panel (SWGR)Document10 pagesOCP - 06 LT Panel (SWGR)NaveedNo ratings yet

- Check List For CraneDocument30 pagesCheck List For CraneMukesh Katarnavare100% (1)

- GCL 14 Working OversideDocument1 pageGCL 14 Working OversideSailorNo ratings yet

- Aht Attendance ReportDocument42 pagesAht Attendance Reportiskalkos100% (1)

- Toaz - Info Cat Compact Start Up and Commissioning Checklist PRDocument19 pagesToaz - Info Cat Compact Start Up and Commissioning Checklist PRKhaled Naseem Abu-SabhaNo ratings yet

- ETS Hazard Identification - Slickline-Shorish1Document9 pagesETS Hazard Identification - Slickline-Shorish1Rahil QamerNo ratings yet

- Book 1Document6 pagesBook 1Jaime WalkerNo ratings yet

- Breaking Containment - Take 5 Revision Rev D FinalDocument2 pagesBreaking Containment - Take 5 Revision Rev D FinalVicky JiNo ratings yet

- Generic Leak Test Procedure PDFDocument7 pagesGeneric Leak Test Procedure PDFMohd Shafuaaz Kassim100% (3)

- Confined Space Work PermitDocument2 pagesConfined Space Work PermitHariharan MuthukrishananNo ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Aviation Mechanic Oral & Practical Exam Guide: Comprehensive preparation for the FAA Aviation Mechanic General, Airframe, and Powerplant Oral & Practical ExamsFrom EverandAviation Mechanic Oral & Practical Exam Guide: Comprehensive preparation for the FAA Aviation Mechanic General, Airframe, and Powerplant Oral & Practical ExamsNo ratings yet

- Inter Q AnsDocument9 pagesInter Q AnsasanNo ratings yet

- 2 - Hazards Indentification PlanDocument27 pages2 - Hazards Indentification PlanasanNo ratings yet

- 2 - Hazards Indentification Plan CheckedDocument28 pages2 - Hazards Indentification Plan Checkedasan100% (1)

- 4b PPE ChecklistDocument3 pages4b PPE Checklistasan100% (1)

- 364 Pre Job Check List High Pressure Hydro Jetting Rev 000Document2 pages364 Pre Job Check List High Pressure Hydro Jetting Rev 000asan100% (1)

- Job DescriptionDocument13 pagesJob DescriptionasanNo ratings yet

- What Is Memo and How SamplesDocument46 pagesWhat Is Memo and How SamplesasanNo ratings yet

- NFPA DiamondDocument7 pagesNFPA DiamondasanNo ratings yet

- Pre Shutdown ChecklistDocument12 pagesPre Shutdown ChecklistasanNo ratings yet

- Confined Space Entry PermitDocument1 pageConfined Space Entry PermitasanNo ratings yet

- Procedure/Method Statement: Risk AssessmentDocument29 pagesProcedure/Method Statement: Risk AssessmentasanNo ratings yet

- Typesof HazardsDocument37 pagesTypesof HazardsasanNo ratings yet

- Cap 1484 Mar17Document58 pagesCap 1484 Mar17asanNo ratings yet

- Hand Tools HIRADocument4 pagesHand Tools HIRAasanNo ratings yet

- GD 2008Document8 pagesGD 2008asanNo ratings yet

- Carelink Evacplan ChecklistDocument5 pagesCarelink Evacplan ChecklistasanNo ratings yet

- Toolbox Talk RegisterDocument2 pagesToolbox Talk RegisterasanNo ratings yet

- AccidentDocument5 pagesAccidentasanNo ratings yet

- 2006 Turki Andijani Siddiqui ERP Trends in Saudi ArabiaDocument11 pages2006 Turki Andijani Siddiqui ERP Trends in Saudi ArabiaasanNo ratings yet

- Ilo Glossary of Terms ChemicalDocument56 pagesIlo Glossary of Terms ChemicalasanNo ratings yet

- COSHH Risk Assessment FormDocument6 pagesCOSHH Risk Assessment FormasanNo ratings yet

- Notes IGC-I PortraitDocument38 pagesNotes IGC-I PortraitasanNo ratings yet

- Accident RateDocument6 pagesAccident RateasanNo ratings yet

- Deluge System General PDFDocument2 pagesDeluge System General PDFkaiju85100% (3)

- Cone BrochureDocument6 pagesCone BrochureJaime I. de la RosaNo ratings yet

- HydraulicDocument1 pageHydrauliclezgogoooNo ratings yet

- Owen Scalloped Gun SystemDocument2 pagesOwen Scalloped Gun SystemMiguel Angel PedrazaNo ratings yet

- Document DetailsDocument28 pagesDocument DetailsSubash ChandraboseNo ratings yet

- Model 496 Service Regulator: Technical DataDocument2 pagesModel 496 Service Regulator: Technical DatavirgolostNo ratings yet

- Steam Turbine 2022Document18 pagesSteam Turbine 2022Proshenjit BaruaNo ratings yet

- L Charts FloorDocument1 pageL Charts Floorczavadil81_820502911No ratings yet

- Second Semester Examination 2012-2013Document2 pagesSecond Semester Examination 2012-2013Ahmed AlmayaliNo ratings yet

- Redneck Golf PlanDocument7 pagesRedneck Golf PlanAndré SilvaNo ratings yet

- Centrifugal Pump Vs Reciprocating Pump 1619353778Document1 pageCentrifugal Pump Vs Reciprocating Pump 16193537784A28Sparsh JainNo ratings yet

- Delta Valves Tech Tips PDFDocument20 pagesDelta Valves Tech Tips PDFBrendon CorreaNo ratings yet

- HL 1500Document16 pagesHL 1500Stgo TurcoNo ratings yet

- Handling Tools: Drill Pipe ElevatorsDocument1 pageHandling Tools: Drill Pipe ElevatorsRICHARDNo ratings yet

- ACE Vacuum Cleaner - FAQDocument1 pageACE Vacuum Cleaner - FAQRahul KumarNo ratings yet

- ATPL POF - Principles of Flight Questions BankDocument32 pagesATPL POF - Principles of Flight Questions Bankpilotmo100% (2)

- Solution To Problem 130 Bearing Stress - Strength of Materials ReviewDocument4 pagesSolution To Problem 130 Bearing Stress - Strength of Materials ReviewRen AlvNo ratings yet

- Bone CrusherDocument18 pagesBone CrusherMark Angelo UyNo ratings yet

- S-03710 P42118-Rev. 3-P18-Steam DrumDocument1 pageS-03710 P42118-Rev. 3-P18-Steam Drumwylie01No ratings yet

- Bond Development LengthDocument8 pagesBond Development LengthAbhinav Sethi100% (1)

- Sti Myanmar University: Page 1 of 3Document3 pagesSti Myanmar University: Page 1 of 3htet waiNo ratings yet

- Stresses in KN/M 2Document3 pagesStresses in KN/M 2Basava SrikanthNo ratings yet

- 2024 NZDE (Civil) Study Block Timetable v2Document1 page2024 NZDE (Civil) Study Block Timetable v2lmiitobnykhpvdwuzyNo ratings yet

- PN16 Flange TablesDocument3 pagesPN16 Flange TablesMichael VillaluzNo ratings yet

- Pilot Operated Safety Valves Type 95 Anderson Greenwood (Tyco) PDFDocument16 pagesPilot Operated Safety Valves Type 95 Anderson Greenwood (Tyco) PDFdhaneshbhorNo ratings yet

- Milroyal D Disc Diaphragm PDFDocument28 pagesMilroyal D Disc Diaphragm PDFvikramchowdaryNo ratings yet

- Aramco Pre-Spud ChecklistDocument3 pagesAramco Pre-Spud ChecklistCISHAC FPNo ratings yet