Professional Documents

Culture Documents

WSC2019 TP10 Ass Iso-E

WSC2019 TP10 Ass Iso-E

Uploaded by

Zenaida AlbanioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WSC2019 TP10 Ass Iso-E

WSC2019 TP10 Ass Iso-E

Uploaded by

Zenaida AlbanioCopyright:

Available Formats

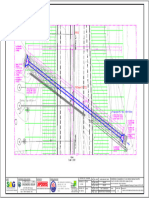

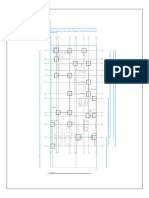

1 2 3 4 5 6

200

100 131.21

E

E L 39.29

20

M

A

39.29

60

A D

D D

60

120

110

C

C "A" Det.

J 60.5

I

H

135

B G

60

B B

110

20 110 E

20 160 20 B

D C

J

I

"A" Detail

110

F F

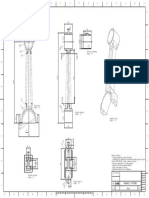

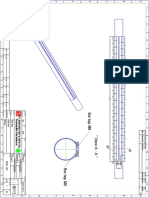

M 1 OD 60X25X3.0, AA 5154 ALUMINIUM PIPE

L 1 200X120X3.0, AA 5154 ALUMINIUM SHEET

A K 1 160X105.56X3.0, AA 5154 ALUMINIUM SHEET

J 1 160X48.76X3.0, AA 5154 ALUMINIUM SHEET

I 1 160X56.26X3.0, AA 5154 ALUMINIUM SHEET

C H 1 160X45.56X3.0, AA 5154 ALUMINIUM SHEET C

G 1 160X60X3.0, AA 5154 ALUMINIUM SHEET

F 2 140X80X3.0, AA 5154 ALUMINIUM SHEET

K E 2 100X50X3.0, AA 5154 ALUMINIUM SHEET

D 2 131.21X110X60.5X3.0, AA 5154 ALUMINIUM SHEET, AS PER SKETCH

C 2 110X110X3.0 AA 5154 ALUMINIUM SHEET, TRIANGLE, AS PER SKETCH

20 20 B 2 110X60X3.0 AA 5154 ALUMINIUM SHEET

A 1 200X130X3.0, AA 5154 ALUMINIUM SHEET

Item. Q'ty Descriptions

Test Project for the 45th WorldSkills

INSTRUCTIONS TO COMPETITORS Competition in Kazan, Russia 2019.

1. WELDING PROCESS:ISO 4063-141 (AWS A3.0 GTAW) Copyright © 2019 WorldSkills International.

2. WELDING POSITIONS: ALL EXCEPT VERTICAL DOWN. All Rights Reserved.

3. NO GAPS ARE ALLOWED ON THE BUTT & CORNER WELD JOINTS.

D

D 4. ALL BUTT & CORNER WELDS SHALL HAVE FULL PENETRATIONS. Skill: 10. Сварочные технологии, Welding, Schweissen, Soudage

5. ALL THE WELDING TO BE CARRIED OUT WITH BASE PLATE "A" IN THE FLAT POSITION. OR

Scale: N. T. S Date: 15. May. 2019 Paper: A3

6. ALL LEG SIZES OF FILLET WELDS: 4.0 mm WITH TOLERANCE (+2.0 mm/-0.0 mm).

7. OUTSIDE CORNER WELD RADII TO BE JUDGEMENT ASSESSED WITH GRADE (0,1,2,3). Drawn/Designed by: Chih-Peng Chen TW/ Kamyar Sadeghi IR Drawing No:WSC2019_TP10_IR_AL_ASSEMBLY_ISO E

8. ALL WELDS SHALL BE COMPLETED IN ONLY ONE PASS WITH FILLER ROD ADDED. Description: Aluminium-Assembly Rev: 3 Page:

9. NO PENETRATION AND REINFORCEMENT OF WELD TO BE MEASURED BETWEEN ITEM I&J.

NOTE: ALL DIMENSTIONS IN MILLIMETRE Appd: Sign:

1 2 3 4 5 6

You might also like

- C - MU üSICA - ARRANJAMENTS - Let Me Out Particellas - 01 Clarinets ClarinetesDocument1 pageC - MU üSICA - ARRANJAMENTS - Let Me Out Particellas - 01 Clarinets ClarinetesWiteyElCaballeroOscuroNo ratings yet

- SRTT-B 50 NM - 36 01 PDFDocument1 pageSRTT-B 50 NM - 36 01 PDFONURNo ratings yet

- Cazan Ignitubular Compact-Sigma Ab500: Popa Mihai A2 3 - Rampa AburDocument1 pageCazan Ignitubular Compact-Sigma Ab500: Popa Mihai A2 3 - Rampa AburTiti PavelNo ratings yet

- Merry Go Round of Life: Violin 1Document2 pagesMerry Go Round of Life: Violin 1İnci SökmenNo ratings yet

- CNC 3018 Upgrade Linear Rails T8 Lead Screw: Dept. Technical Reference Created by Approved byDocument1 pageCNC 3018 Upgrade Linear Rails T8 Lead Screw: Dept. Technical Reference Created by Approved byyosef melkaNo ratings yet

- MARINES CORPS CORPORAL Homenagem Aos Cabos Da Banda Marcial Do CFN-FLAUTIMDocument2 pagesMARINES CORPS CORPORAL Homenagem Aos Cabos Da Banda Marcial Do CFN-FLAUTIMRosinaldo Araújo LimaNo ratings yet

- Disassembly of Screw Jack53Document1 pageDisassembly of Screw Jack53Chetan HoleNo ratings yet

- EjercicioDocument1 pageEjercicioESTEFANY FLORES CORTESNo ratings yet

- 15 PRIMAVERAS - Violín IIDocument1 page15 PRIMAVERAS - Violín IIRonald FonsecaNo ratings yet

- Sing A Song of Song-Saxophone - BarytonDocument1 pageSing A Song of Song-Saxophone - Barytonsimon.meliandeNo ratings yet

- Sag 011 5267 DSN PW CD PK24.476 Ol SG2 100 02Document1 pageSag 011 5267 DSN PW CD PK24.476 Ol SG2 100 02Sanjay SwamiNo ratings yet

- Swan Lake Op. 20 Act 2 No.10 Scene Moderato-Bb ClarinetDocument1 pageSwan Lake Op. 20 Act 2 No.10 Scene Moderato-Bb ClarinetFleuryNo ratings yet

- Plano Ejemplo3 DesagueDocument1 pagePlano Ejemplo3 Desagueeva acuña diazNo ratings yet

- Part 7Document1 pagePart 7mamad mamadNo ratings yet

- 02 Goza Plinio Sierra - Trompeta BB 2Document2 pages02 Goza Plinio Sierra - Trompeta BB 2Gonzalo ArdilaNo ratings yet

- Bracket DrawingDocument1 pageBracket DrawingdhareeshNo ratings yet

- A C D E F G A': Gspublisherversion 0.5.100.100Document1 pageA C D E F G A': Gspublisherversion 0.5.100.100Moisil EmanuilNo ratings yet

- Part 2Document1 pagePart 2mamad mamadNo ratings yet

- Victor SantillanDocument1 pageVictor Santillanjuan pablo zarateNo ratings yet

- Plan Terasament PDFDocument1 pagePlan Terasament PDFGavrilescu AlexandruNo ratings yet

- David Cgomas-ModelDocument1 pageDavid Cgomas-ModelWilliam Andersen Martinez SantosNo ratings yet

- SafeLink 2 GA DWG - Generic - AF+AFLRDocument9 pagesSafeLink 2 GA DWG - Generic - AF+AFLRSimonNo ratings yet

- 000-OkDocument2 pages000-OkSonNguyenNo ratings yet

- Plano Municipal PixartDocument1 pagePlano Municipal PixartVasitec Trading AcademyNo ratings yet

- Caribeños - Mix DinamitaDocument7 pagesCaribeños - Mix DinamitaMario Silva HerediaNo ratings yet

- Casa 31Document1 pageCasa 31Ramon LinoNo ratings yet

- Rueda NDFDocument1 pageRueda NDFEddy Braython Perez BustamanteNo ratings yet

- 1588 006 SWDocument1 page1588 006 SWSam ZhangNo ratings yet

- 1:1 1/1 A1 Dassault Systemes: BielaDocument1 page1:1 1/1 A1 Dassault Systemes: BielaCristianNo ratings yet

- EstudoDocument1 pageEstudoRobson NerioNo ratings yet

- Uhle Box PPM-4Document1 pageUhle Box PPM-4Wawan SaputraNo ratings yet

- A B C D E F: Edificio ComercialDocument1 pageA B C D E F: Edificio ComercialGustavoLazaroNo ratings yet

- Razvan 2 ParterDocument1 pageRazvan 2 ParterMaria MateiNo ratings yet

- Donhutn N. C. San 29 DEC 2023 IssuedDocument1 pageDonhutn N. C. San 29 DEC 2023 Issuedrajitkumar.3005No ratings yet

- The Avangers Theme-ViolonDocument1 pageThe Avangers Theme-ViolonHenrique Augusto Dos AnjosNo ratings yet

- Drawing CARCASADocument1 pageDrawing CARCASAtawfik14sendiNo ratings yet

- Evaluación de Asentamientos Y Diseño Estructural de La CimentaciónDocument7 pagesEvaluación de Asentamientos Y Diseño Estructural de La CimentaciónJULIO QUENTANo ratings yet

- ENG-DWG-001 - Site Plan 01Document1 pageENG-DWG-001 - Site Plan 01Koro WisnuNo ratings yet

- 08 - Cielito Lindo - Tenor SaxDocument1 page08 - Cielito Lindo - Tenor Saxnataliastracqualursi31No ratings yet

- Tristar Tripod 1Document1 pageTristar Tripod 1Wawan SaputraNo ratings yet

- MotorholderfrontDocument1 pageMotorholderfrontnavahnavahnavahNo ratings yet

- Plano-Model 1pdfDocument1 pagePlano-Model 1pdfBris HuertaNo ratings yet

- Nas Regias Mansoes V3 Ok - TP3Document1 pageNas Regias Mansoes V3 Ok - TP3Marcelo Oliveira OliveiraNo ratings yet

- Plan Parter 50X70Document1 pagePlan Parter 50X70Alina DogeanuNo ratings yet

- TrumpetDocument2 pagesTrumpetPaulo CorreaNo ratings yet

- 0473 Motor DG 168A2 AssemblyDocument1 page0473 Motor DG 168A2 AssemblyAli JalilaraziNo ratings yet

- AualDocument1 pageAualRobson NerioNo ratings yet

- Cupid - Fifty Fifty-Alto - SaxophoneDocument1 pageCupid - Fifty Fifty-Alto - SaxophoneSherwin TorresNo ratings yet

- PDF 601-2-08835 A1Document3 pagesPDF 601-2-08835 A1mohammad.shahrukh1No ratings yet

- A B C D A B C D: de Enero Dist. de J.L.B y RiveroDocument1 pageA B C D A B C D: de Enero Dist. de J.L.B y RiveroFernando CruzNo ratings yet

- 22bme0399 VL2023240101741 Ast02Document9 pages22bme0399 VL2023240101741 Ast02towibo1372No ratings yet

- PMS - Detail Drawing Man Hole For BA SiloDocument3 pagesPMS - Detail Drawing Man Hole For BA Siloup_freeyantoNo ratings yet

- Ultraman Returns Theme-Bb Trumpet-1Document1 pageUltraman Returns Theme-Bb Trumpet-1Flávio LacerdaNo ratings yet

- Jig KHDocument1 pageJig KHbuicocle90No ratings yet

- Levantamiento Velasco PlantasDocument1 pageLevantamiento Velasco Plantasvictor capchaNo ratings yet

- Colombia Tierra Querida - TubaDocument1 pageColombia Tierra Querida - TubaJaironman 56No ratings yet

- 845a35-Datasheet - VANESSA 20131231 - jp-534793 PDFDocument2 pages845a35-Datasheet - VANESSA 20131231 - jp-534793 PDFAle NqnNo ratings yet

- Datasheet - VANESSA - : Drawing Title Part NumberDocument2 pagesDatasheet - VANESSA - : Drawing Title Part NumberAle NqnNo ratings yet