Professional Documents

Culture Documents

10 1002@slct 202003890

10 1002@slct 202003890

Uploaded by

Nguyễn Thị Huyền TrânOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 1002@slct 202003890

10 1002@slct 202003890

Uploaded by

Nguyễn Thị Huyền TrânCopyright:

Available Formats

Full Papers

ChemistrySelect doi.org/10.1002/slct.202003890

z Catalysis

Fe(III)/Bentonite as a Heterogeneous Catalyst for the

Synthesis of 3,4-dihydropyrimidin-2-(1H)-ones

Lakha V Chopda[a] and Pragnesh N. Dave*[a, b]

Fe(III) immobilized over natural bentonite (bent) using the product towards the synthesis of a variety of dihydropyrimi-

impregnation method. Prepared catalysts were well character- dones (DHPMs). The high yield of dihydropyrimidone (DHPM)

ized by XRD, FT-IR and FeSEM. The catalytic activity of three was obtained in model reaction in ethanol, acetonitrile, DMF

catalysts 10, 20 and 30 % Fe(III)/bent evaluated for the synthesis and solvent - free condition. The reusability test indicated that

of 3,4-dihydropyrimidin-2(1H)-ones known as Biginelli reaction. 6 % of yield of product decreased after 5th cycle.

The catalyst 30 % Fe(III)/bent exhibited a high yield of the

Highlights (OTf)3, RuCl3, SbCl3, SnCl22H2O, Sr(OTf)2, TiCl4, Yb(OTf)3, ZnCl2,

ZrCl4 and ZrCl4 or ZrOCl28H2O[8–27] subsequently were devel-

* 10, 20 and 30 % Fe(III) were supported over bentonite clay. oped to enhance the yield of product. All mentioned catalysts

The catalysts are well characterized by (XRD), FT-IR, FeSEM improved the yield of product but most of them are expensive;

and EDS. All charactization method showed that Fe difficult to remove from solution consequently metal traces can

supported over bentonite. be remained in the final product and reusability are the key

* The used catalysts were screened for Biginelli reaction for issues. To address these problems, heterogeneous catalysts are

synthesis dihydropyrimidones. extensively employed for this reaction which displayed good

* 30 % Fe(III)/bent exhibited high yield of product towards activity and reusability and facilitated easy separation of

model Biginelli reaction between benzaldehyde, ethylacetoa- product.[28–30] Various Lewis acids are supported over different

cetate and urea in ethanol. kind of solid support for this reaction. These are

* 30 % Fe(III)/bent exhibited high yield of product in CH3CN, FeCl3@nanopore silica, Lewis acids (ZnCl2,AlCl3,GaCl3,InCl3 and

DMF and solvent free- condition. FeCl3) @MCM-41 & montmorrionolite K 10 clay, ZnCl2 over silica,

* The catalyst 30 % Fe(III)/bent applied for synthesis of variety Cu@PMO-IL, MoO3@Al2O3, HBF4-SiO2, SbCl3@Al2O3, LaCl3-graph-

of dihydropyrimodone in good yield in CH3CN. ite, Mo/γ-Al2O3, CuCl2-SiO2, SnCl4 & TiCl4@SiO2, FeCl3@Al-MCM-

* Reusability studies show that no great decline in activity 41, FeCl3@PANI, Nafion-Ga, Yttria-Zirconia, ZrO2-pillared clay,

after 5th cycle. Ce@MCM-41, Ps-AlCl3, metalsalts@NaY, SnCl2@nanoSiO2, Mg/Fe

hydrotalcite, ZnCl2, CuCl2, NiCl2, and CoCl2 doped hydroxyapa-

tite, ZnCl2, CuCl2 and NiCl2 doped fluorapatite, SOCl2@ silica gel

Introduction

and recently work on HClO4-Al2O3 were devised for Biginelli

Biginelli reaction is a three component reaction of aldehydes, 1, reaction.[31–55] These reported catalyst exhibited very good yield

3-dicarbonyl compounds and urea/thiourea accessible to 3, 4- towards DHPMS/DHPMTHs with good reusability. Bentonite

dihydropyrimidin-2(1H)-ones/thiones (DHPMS/DHPMTHs) in the belongs to the family of smecitie which contains one octahe-

presence of acidic catalyst. This reaction first developed by dral sheet and two silica sheets (2 : 1 or tetrahedral-octahedral-

Pietro Biginelli in the presence of catalytic amount of HCl in tetrahedra (TOT) mineral) that form layer through van der waals

ethanol that provided 3, 4-dihydropyrimidin-2(1H)-ones/thiones force and has the general formula as Rx(H2O)4{(Al2-

in low to moderate yield (20–60 %).[1–4] Dihydropyrimidin-2(1H)- x,Mgx)2[(Si,Al)4O10](OH)2}, R is the exchangeable cations of alkali

ones/thiones displayed variety of biological activity.[5–7] Hence, and alkaline earth metals between layers.[56–61] Apart from this,

several homogeneous catalysts especially Lewis acids such as it possesses both Lewis and Bronsted acidity,[56,62,63] thus it was

BiCl3, Bi(OTf)3, Bi(NO3)3, CeCl37H2O, Cu(OTf)2, CuCl22H2O/ explored as a heterogeneous catalyst in organic synthesis.[62]

CuSO45H2O, Fe(NO3)39H2O, Fe(OTs)36H2O, GaCl3, Hf(OTf)4, In The other unique properties made it a favorable support for

immobilization of metals nanoparticles,[57,59,64] metal oxides,[65,66]

[a] L. V Chopda, Prof. Dr. P. N. Dave metal salts[56,60,63,67] and other modification of bentonite for

Department of Chemistry, KSKV Kachchh University, Bhuj, India various application.[68–76] Bentonite is widely distributed in the

[b] Prof. Dr. P. N. Dave Kachchh region of India and mainly sodium and calcium

Department Of Chemistry, Sardar Patel University, Vallabh Vidyanagar,

bentonite are found in this area. In the field of synthetic

India

E-mail: pragnesh7@yahoo.com organic chemistry, bentonite based material explored as

Supporting information for this article is available on the WWW under catalyst. FeCl3/bentonite for the synthesis of (E)-1-(2,4-dimeth-

https://doi.org/10.1002/slct.202003890 ylthiazol-5-yl)-3-phenylprop-2-en-1-ones under solvent-free

ChemistrySelect 2020, 5, 14161 – 14167 14161 © 2020 Wiley-VCH GmbH

Full Papers

ChemistrySelect doi.org/10.1002/slct.202003890

conditions, Cu-bentonite for the synthesis of benzimidazoles, reflect that bentonite contains ample amount of quartz and no

benzoxazoles and benzothiazoles, vanadium-chromium-ben- peak has seen at 31.30° represent for cristobalite.[103] It shows

tonite used as catalyst for epoxidation of cyclohexene, H2SO4 that bentonite does not bear cristobalite. The low intensity

activated bentonite, bentonite functionalized by propyl sulfonic peak at 61.7° reveals about octahedral sheet in bentonite[105]

acid and ionic liquid 8B@bentonite for esterification reaction, which remains intact in all three samples. It indicates that no

montmorillonite KSF for pyrano and furanoquinolines and distraction occurred in octahedral sheet after supporting of Fe

CTMAB-bentonite for synthesis of 3,4-dihydropyrano[c]chro- (III) while in our reported work, this peak almost disappeared as

mene derivatives.[77–84] In the literature, a very few examples percentage TSA & TPA increased in bentonite which could led

available on bentonite based catalyst for Biginelli reaction to some distraction in octahedral sheet.[93,94] A new peaks

which include montmorillonite KSF catalyst, bentonite clay, 30.81°, 38.67°, 44.54°, 67.07°, 67.47° and 80.53 can be assigned

montmorillonite KSF assisted by microwave, activated mont- to Fe(III) over bentonite and some peaks such as 38.67°, 67.07°,

morrilonite, bentonite-PS-SO3H, Fe(III)-montmorillonite K10, 67.47° and 80.53° are not detected at higher loading (20 & 30 %

TiO2-pillared montmorillonite, Co@imine-Na + -MMT, ionic Fe(III)/bent). This could be indicated that as loading increased

liquid@bentonite and including our reported work on Fe(III) homogeneously deposited over bentonite.

H4[W12SiO40]/bent & H3[PW12SiO40]/bent.[85–95] In this work, we

developed Fe(III)/bent as a heterogeneous catalyst for synthesis

FT-IR analysis

of 3,4-dihydropyrimidin-2-(1H)-ones.

FT-IR spectra of raw bentonite and 10, 20 and 30 % Fe(III)/bent

are shown in Figure 2. In the raw bentonite, a strong band at

Result and Discussion 1006.84 cm 1 corresponds to Si O stretching vibrations and

bending vibration of Al Al OH appears at 921 cm 1.[100,101,107]

XRD analysis

Bands of Si O Al and Si O Si attribute between 521–

The XRD patterns of raw bentonite and impregnation of 800 cm 1.[108,109] The bands at 876 and 793 cm 1 could be

different loading of Fe(III) to bentonite are shown in Figure 1. associated with Si-O Al and Si O Si bending vibrations

The characteristic peak (basal spacing) of d001 refection of respectively. The bands at 671 cm 1 can be assigned to

bentonite appears at 2θ = 7.09°.[88,96–99] After loading of Fe(III), combine Al O and Si O out of plane vibrations.[107] The peaks

this main diffraction peak shifted to lower angle as percentage observe at 3623 cm 1 and 3508 cm 1 ascertain to stretching

of Fe(III) increased from 10 to 20 to 30 % (4.96°, 4.70° and 4.56°). vibration of a surface hydroxyl group attached to bentonite

The corresponding d-spacing is shown in Table no.1. The and stretching vibration of H O H of adsorbed water

increased in d-spacing signifies that Fe(III) incorporated into respectively.[96,99] The band at 1640 cm 1 relates to bending

interlayer space of bentonite[100,101] by replacing of interlayer vibration of O H (surface of bentonite) and H O H of

cations Na and Ca. The intense peak at 2θ = 20.91° in raw adsorbed water.[110] The FT-IR spectra of 10, 20 and 30 % Fe(III)/

bentonite attributes to its SiO2 crystalline nature.[102] The bent have a similar pattern that of raw bentonite. The only

intensity of this peak decreased in all three samples and almost difference is that the intensity of Si O stretching vibrations

vanished in 30 % Fe(III)/bent. It showed that crystallinity of SiO2 decreased after loading of Fe(III) and shifted to higher wave

turned to amorphous nature[88,96,102] as similar observation made number. It is in good agreement to XRD results in which

by us in our previous work.[93,94] Other diffraction peaks of intensity of d001 reflection peak decreased after loading of Fe

bentonite observe at 2θ = 19.9°, 26.6°, 28.58°, 36.0°, 42.5° and (III). This could be provided evidence of presence of Fe(III) over

61.7°.[103–106] The peaks at 2θ = 20.91°, 26.6°, 36.0° and 42.5° bentonite. No characteristic bands of Fe(III) observe in all three

Figure 1. XRD pattern of 10, 20 and 30 % Fe(III)/bent. Figure 2. FT-IR of 10, 20 and 30 % Fe(III)/bent.

ChemistrySelect 2020, 5, 14161 – 14167 14162 © 2020 Wiley-VCH GmbH

Full Papers

ChemistrySelect doi.org/10.1002/slct.202003890

samples which signify that Fe(III) homogeneously distributed bent catalysts is quite differing from that of raw bentonite. Fe-

over bentonite. SEM images of Fe(III)/bent (Figure 3b to 3d), where no hexagon

shape of raw bentonite is shown. It shows that Fe(III) is

homogeneous distributed over surface of bentonite. EDS

FeSEM-EDS analysis

analysis of three samples confirms presence of Fe in bentonite

Fe-SEM images of raw bentonite and 10, 20 and 30 % of Fe(III)/ (Figure S1 (b–d). Detailed analysis of the EDS of four catalysts is

bent are shown in Figure 3a–3d respectively. Fe-SEM image of shown in Table S1 (b–d) respectively.

raw bentonite exhibit hexagon shape with an average particle

size around 200 nm. The surface morphology of 10–30 % Fe(III)/

Catalytic activity

The model reaction was chosen between benzaldehyde, ethyl-

acetoacetate and urea in 2 : 2 : 2.4 mmol ratio of reactants

respectively using, 10, 20 and 30 % of Fe(III)/bent. The reaction

performed in the presence of 0.09 g amount of catalysts in

ethanol at 80 °C. The yield of corresponding DHPM achieved in

Scheme 1. Model Biginelli reaction in the presence of Fe(III)/bent.

54, 68 and 84 % by 10, 20 and 30 % Fe(III)/bent respectively for

7 h of reaction time as shown in Table 2 (entry 1 to 3). The % of

Fe(III) was increased in catalyst led to enhance the yield of

product (Table S1 (b–d)). In addition, effect of amount of

catalyst of 30 % Fe(III)/bent was carried out to find optimum

amount of catalyst required for the reaction. The yield of

desired product was achieved in 89 and 94 % at 0.1 and 0.15 g

of catalyst as shown in Table 2 (entry 4 & 5). 0.2 g of catalyst

showed 94 % yield of product. It showed that higher amount

(0.2 g) did not enhance the yield of product (Table 2, entry 6).

Hence 0.15 g of catalyst found to be sufficient amount of

catalyst to catalyze the reaction. Further, using 0.15 g of

catalyst, reaction was performed in acetonitrile (80 °C), DMF

(90 °C), methanol (60 °C) and solvent-free conditions (80 °C). The

yield of product was 95, 88, 60 and 90 % in acetonitrile, DMF,

methanol and solvent-free conditions respectively as repre-

sented in Table 2 (entry 7–10). Catalyst 30 % Fe(III)/bent

required to high loading (0.15 g) than our reported work on

Figure 3. FeSEM images of bent, 10, 20 & 30 % Fe(III)/bent. 30 %TSA/bent and 30 %TPA/bent (0.09 g) catalysts.[93,94] Various

DHPMs are prepared using 0.15 g of catalyst in acetonitrile for

7 h of reaction time as shown in Table 3.The DHPMs are

Table 1. D-spacing of 10, 20 and 30 % Fe(III)/bent. obtained in good to high yield of products.

Sr No d-spacing (nm) Reusability test of 30 % Fe(III)/bent has been conduct in

order to check its efficiency. Catalyst displayed 95, 92, 91, 91

Bentonite 1.245

10 % Fe(III) /bent 1.782

and 89 % yield of product after 1st, 2nd, 3rd, 4th and 5th cycles

20 % Fe(III) /bent 1.878 respectively. The 6 % of yield of product decreased after 5th

30 % Fe(III) /bent 1.939 round. Leaching test was performed using hot filtration

Table 2. Model Biginelli reaction in the presence of 10, 20 & 30 % Fe(III)/bent.

No. Catalyst Solvent Temperature (°C) Amount of catalyst (g) Yield

1 10 % Fe(III)/bent Ethanol 80° 0.09 54 %

2 20 % Fe(III)/bent Ethanol 80° 0.09 68 %

3 30 % Fe(III)/bent Ethanol 80° 0.09 84 %

4 30 % Fe(III)/bent Ethanol 80° 0.1 89 %

5 30 % Fe(III)/bent Ethanol 80° 0.15 94 %

6 30 % Fe(III)/bent Ethanol 80° 0.2 94 %

7 30 % Fe(III)/bent Acetonitrile 80° 0.15 95 %

8 30 % Fe(III)/bent DMF 90° 0.15 88 %

9 30 % Fe(III)/bent Methanol 60° 0.15 60 %

10 30 % Fe(III)/bent Solvent- free 80° 0.09 90 %

Reaction conditions: Benzaldehyde (2 mmol), ethylacetoacetate (2 mmol), urea (2.4 mmol), solvent (25 ml), temperature 80 °C and reaction time 7 h.

M.P. of compound : 204–206 (205-206).[109]

ChemistrySelect 2020, 5, 14161 – 14167 14163 © 2020 Wiley-VCH GmbH

Full Papers

ChemistrySelect doi.org/10.1002/slct.202003890

Table 3. Synthesis of DHPMs using 30 % Fe(III)/bent. bentonite is usually neutral or weakly basic in nature which is

attributed to presence of intercations Na and Ca in the form of

oxide.[116,117] After immobilization of Fe(III), these cations (Na

and Ca) interchanged with Fe(III) as evident by XRD by

increasing d-spacing. The pH of Fe(III)/bent could be decreased

that of raw bentonite. The nature of Fe(III)/bent is acidic. Belaidi

et al measured the acidity of AAC (acid-activated clay-

bentonite), Cr-AAC and 5 V/Cr-AAC materials by pyridine

adsorption method.[79] Bronsted and Lewis/Bronsted acids sites

of Cr-AAC and 5 V/Cr-AAC increased than AAC and prakash et

al also studied the effect of acidity of Al3 + Mont(100), Al3 +

Mont(200) and Al3 + Mont(400) as prepared different condi-

tions for esterification reaction between propionic acid and p-

cresol.[118] Catalysts Al3 + -Mont(100), Al3 + -Mont(200) and Al3 +

-Mont(400) exhibited 88 %, 56 % and negligible activity. It

revealed that increased temperature led to decrease the

Bronsted acidity concentration due to loss of water from

montmorillonite clay. These both reported work support our

assumption about acidic nature of Fe(III)/bent as preparation

and reaction temperature around 100 °C. In the proposed

Reaction conditions: Benzaldehyde (2 mmol), ethylacetoacetate (2 mmol), reaction mechanism, carbonyl group first activated by Fe(III)/

urea (2.4 mmol), acetonitrile (25 ml), temperature 80 °C and reaction time bent same in the case of acid catalyze reaction[119] produces

7 h.

electrophilic centre at carbonyl carbon. Nucleophilic attacks by

M.P. of compounds: 1: 230–232 (233–235)[111] 2: 214–216 (215–216)[110] 3:

214–217 (215–216)[112] 4: 200–203 (200–201)[112] 5: 176–180 (177–179)[111] 6: urea or ethylacetoacetate led to form iminium I or Knoevenagel

256–260(255–256)[113] 7: 208–211 (210)[112] 8: 226–230 (227–228)[112] 9: 210– II intermediates. These intermediates could be rate-determining

214 (213–214)[112] 10: 183–185 (184–186)[114] 11: 206–209 (206–208)[114] 12: step in this reaction. Iminium I or Knoevenagel II intermediates

202–204(204–205)[115] 13: 203–206 (205–206)[112] 14: 210–212 (210–211).[112]

react with ethylacetoacetate and urea respectively. Imine

intermediate I reacts with ethyacetoacetate furnished inter-

mediate III and Knoevenagel intermediate reacts to urea

method in order to confirm whether Fe leached out or not. The produces intermediate IV. Both intermediates undergo cycliza-

model reaction performed under optimized conditions and tion to form intermediate V which finally generates dihydropyr-

after half & hour catalyst removed by filtration reaming reaction imidone. In a comparison of intermediates I & II, intermediate I

mixture was kept for 24 h. After 24 h, concerning product was prefers over II because of high nucleophilicity of urea than

obtained in 25 %. It confirmed that Fe was not leached out. ethylacetoacetate, hence proposed reaction mechanism of

30 % Fe(III)/bent is line with proposed by Kappe, Johnson and

Hu means iminium pathway.[4] The third possible reaction

Plausible reaction mechanism and comparison of catalyst

mechanism was proposed in the literature for this reaction. It is

The possible reaction mechanism of 30 % Fe(III)/bent catalyst occurring through enamine. It happens by nucleophilic attack

can be envisaged and displayed in Figure 5. Generally, of urea to ethylacetoacetate but possibility of this pathway is

Table 4. Comparison of catalyst.

Entry Catalyst Conditions Amount catalyst Time Yield (%) Ref

(min)

[31]

1 FeCl3/nanopore silica (1 : 1 : 1.2) 400 W 180 °C(solvent-free) 0.05 g 15 75

5 FeCl3/MCM-41 (1 : 1 : 1.2) 400 W 180 °C(solvent -free) 0.05 g 15 78

6 FeCl3/SBA-15 (1 : 1 : 1.2) 400 W 180 °C(solvent free) 0.05 g 15 82

7 FeCl3/VSB-15 (1 : 1 : 1.2) 400 W & 180 °C(solvent- free) 0.05 g 15 92

[32]

8 FeCl3/MCM-41 (1 : 1 : 1.3) 700 W(solvent-free) 0.03 g 3 89

9 FeCl3/montmorillonite 700 W(solvent-free) 0.03 g 3 70

K 10(1 : 1 : 1.3)[a]

[42]

10 Fe(III)/Al-MCM-41(2 : 2 : 3) Reflux(acetonitrile) 0.03 g 240 85

[43]

11 FeCl3/PANI(1.8 : 1.8 : 2.3) Reflux(acetonitrile) 0.2 g 1440 83

[90]

12 Fe(III)/montmorrillonite K10(1 : 1 : 1) Grinding(pulverizing) 0.1 g 10 92

13 Present work 80 °C(acetonitrile) 0.09 g 420 95 –

(2 : 2 : 2.4)

Reactants (Benzaldehyde: Ethylacetoacetate: Urea) ratio in mmol

[a] indicated used 4-methoxy benzaldehyde instead of benzaldehyde.

ChemistrySelect 2020, 5, 14161 – 14167 14164 © 2020 Wiley-VCH GmbH

Full Papers

ChemistrySelect doi.org/10.1002/slct.202003890

Acknowledgements

We acknowledge Panjab University and VGEC Chandkheda for

utilizing their characterization facility.

Conflict of Interest

The authors declare no conflict of interest.

Keywords: Support catalyst · Bentonite · Heterogeneous

catalysis · Lewis acid · Dihydropyrimidones

[1] C. O. Kappe, Tetrahedron 1993, 49,6937–6963.

[2] C. O. Kappe, Acc. Chem. Res. 2000, 33, 879–888.

[3] E. H. Hu, D. R. Sidler, U.-H. Dolling, J. Org. Chem. 1998, 63, 3454–3457.

Figure 4. Reusability test of 30 % Fe(III)/bent. [4] J. Lu, H. Ma, Synlett 2000, 2000, 63–64.

[5] Suresh, J. S. Sandhu, Arkivoc 2011, 2012, 66.

[6] Â. De Fátima, T. C. Braga, L. da S. Neto, B. S. Terra, B. G. F. Oliveira, D. L.

da Silva, L. V. Modolo, J. Adv. Res. 2015, 6, 363–373.

[7] H. Nagarajaiah, A. Mukhopadhyay, J. N. Moorthy, Tetrahedron Lett.

2016, 57, 5135–5149.

[8] K. Ramalinga, P. Vijayalakshmi, T. N. B. Kaimal, Synlett 2001, 2001, 0863–

0865.

[9] Ra. Varala, M. M. Alam, S. R. Adapa, Synlett 2003, 2003, 67–70.

[10] H. Slimi, Y. Moussaoui, R. ben Salem, Arab. J. Chem. 2016, 9, S510–S514.

[11] D. S. Bose, L. Fatima, H. B. Mereyala, J. Org. Chem. 2003, 68, 587–590.

[12] A. S. Paraskar, G. K. Dewkar, A. Sudalai, Tetrahedron Lett. 2003, 44,

3305–3308.

[13] M. Gohain, D. Prajapati, J. S. Sandhu, Synlett 2004, 0235–0238.

[14] M. Phukan, M. K. Kalita, R. Borah, Green Chem. Lett. Rev. 2010, 3, 329–

334.

[15] J. T. Starcevich, T. J. Laughlin, R. S. Mohan, Tetrahedron Lett. 2013, 54,

983–985.

[16] H. Yuan, K. Zhang, J. Xia, X. Hu, S. Yuan, Cogent Chem. 2017, 3,

1318692, DOI 10.1080/23312009.2017.1318692.

Figure 5. Proposed reaction of 30 % Fe(III)/bent. [17] R. Kong, S.-B. Han, J.-Y. Wei, X.-C. Peng, Z.-B. Xie, S.-S. Gong, Q. Sun,

Molecules 2019, 24, 364.

[18] R. Ghosh, S. Maiti, A. Chakraborty, J. Mol. Catal. Chem. 2004, 217, 47–

50.

discarded due to the acidic nature of catalyst. Comparison of [19] Ss.-F. De, R. A. Gibbs, Synthesis 2005, 2005, 1748–1750.

this catalyst is shown in Table 4. [20] I. Cepanec, M. Litvić, M. Filipan-Litvić, I. Grüngold, Tetrahedron 2007,

63, 11822–11827.

[21] D. Russowsky, F. A. Lopes, V. S. S. da Silva, K. F. S. Canto, M. G. M. D’Oca,

Conclusions M. N. Godoi, J. Braz. Chem. Soc. 2004, 15, 165–169.

[22] W. Su, J. Li, Z. Zheng, Y. Shen, Tetrahedron Lett. 2005, 46, 6037–6040.

In this work, Fe(III) supported over bentonite. The catalytic [23] R. R. Nagawade, S. A. Kotharkar, D. B. Shinde, Mendeleev Commun.

activity of prepared three catalysts was evaluated between 2005, 15, 150–151.

[24] Y. Ma, C. Qian, L. Wang, M. Yang, J. Org. Chem. 2000, 65, 3864–3868.

benzaldehyde, ethylacetoacetate and urea as a model reaction

[25] Y. Wang, Z. Ge, T. Cheng, R. Li, Synthesis 2004, 2004,1047–1051.

in a different solvent. The corresponding Biginelli product was [26] Ch. V. Reddy, M. Mahesh, P. V. K. Raju, T. R. Babu, V. V. N. Reddy,

obtained in 94, 95, 88 and 90 % in ethanol, acetonitrile, DMF Tetrahedron Lett. 2002, 43, 2657–2659.

and solvent-free condition. The different DHPMs were synthe- [27] J. C. Rodríguez-Domínguez, D. Bernardi, G. Kirsch, Tetrahedron Lett.

2007, 48, 5777–5780.

sized in good yield in acetonitrile at 80 °C. The reusability study

[28] M. José Climent, A. Corma, S. Iborra, RSC Adv. 2012, 2, 16–58.

signified that catalyst showed 89 % yield of the product after [29] B. Mohammadi, F. K. Behbahani, Mol. Diversity 2018, 22, 405–446.

the 5th cycle. [30] R. V. Patil, J. U. Chavan, D. S. Dalal, V. S. Shinde, A. G. Beldar, ACS Comb.

Sci. 2019, 21, 105–148.

[31] B. J. Ahn, M. S. Gang, K. Chae, Y. Oh, J. Shin, W. Chang, J. Ind. Eng.

Supporting Information summary Chem. 2008, 14, 401–405.

[32] V. Choudhary, Catal. Commun. 2003, 4, 449–453.

It contains experiment section including materials, synthesis [33] R. Gupta, M. Gupta, S. Paul, R. Gupta, Can. J. Chem. 2007, 85, 197–201.

procedure of catalyst,characterization techniques and proce- [34] D. Elhamifar, F. Hosseinpoor, B. Karimi, S. Hajati, Microporous

Mesoporous Mater. 2015, 204, 269–275.

dure for reaction. Spectral data (1H &13C) are also included.

[35] S. L. Jain, V. V. D. N. Prasad, B. Sain, Catal. Commun. 2008, 9, 499–503.

[36] V. T. Kamble, D. B. Muley, S. T. Atkore, S. D. Dakore, Chin. J. Chem. 2010,

28, 388–392.

ChemistrySelect 2020, 5, 14161 – 14167 14165 © 2020 Wiley-VCH GmbH

Full Papers

ChemistrySelect doi.org/10.1002/slct.202003890

[37] K. K. Kapoor, B. A. Ganai, S. Kumar, C. S. Andotra, Can. J. Chem. 2006, [76] G.-T. Wei, C.-Y. Fan, L.-Y. Zhang, R.-C. Ye, T.-Y. Wei, Z.-F. Tong, Catal.

84, 433–437. Commun. 2012, 17, 184–188.

[38] H. Khabazzadeh, K. Saidi, H. Sheibani, Bioorg. Med. Chem. Lett. 2008, 18, [77] S. Balaji, V. Manikandan, M. Rajarajan, V. Usha, S. Rajalakshmi, P.

278–280. Venkatachalam, I. Muthuvel, G. Thirunarayanan, Mater. Today Proc.

[39] K. Kouachi, G. Lafaye, S. Pronier, L. Bennini, S. Menad, J. Mol. Catal. 2020, 22, 931–936.

Chem. 2014, 395, 210–216. [78] A. Mestari, A. Ejjoummany, Y. Rakhila, A. Elmchaouri, A. Elhakmaoui, M.

[40] G. Kour, M. Gupta, S. Paul, Rajnikant, V. K. Gupta, J. Mol. Catal. Chem. Safi, M. Akssira, J. Mater. Environ. Sci. 2017, 8, 4816–4823.

2014, 392, 260–269. [79] N. Belaidi, S. Bedrane, A. Choukchou-Braham, R. Bachir, Appl. Clay Sci.

[41] K. Niknam, A. Hasaninejad, M. Arman, Chin. Chem. Lett. 2010, 21, 399– 2015, 107, 14–20.

402. [80] B. Vijayakumar, G. Nagendrappa, B. S. Jai Prakash, Catal. Lett. 2009, 128,

[42] H. A. Oskooie, M. M. Heravi, N. Karimi, M. H. Monjezy, Synth. Commun. 183–189.

2011, 41, 826–831. [81] D. S. Moraes, R. S. Angélica, C. E. F. Costa, G. N. Rocha Filho, J. R.

[43] H. A. Patel, A. M. Sawant, V. J. Rao, A. L. Patel, A. V. Bedekar, Catal. Lett. Zamian, Appl. Clay Sci. 2011, 51, 209–213.

2017, 147, 2306–2312. [82] B. Aghabarari, N. Dorostkar, J. Inst. Chem. 2014, 45, 1468–1473.

[44] G. K. S. Prakash, H. Lau, C. Panja, I. Bychinskaya, S. K. Ganesh, B. Zaro, T. [83] J. S. Yadav, B. V. S. Reddy, K. Sadasiv, P. S. R. Reddy, Tetrahedron Lett.

Mathew, G. A. Olah, Catal. Lett. 2014, 144, 2012–2020. 2002, 43, 3853–3856.

[45] S. Ramalingam, P. Kumar, Synth. Commun. 2009, 39, 1299–1309. [84] M. E. Sedaghat, M. Rajabpour Booshehri, M. R. Nazarifar, F. Farhadi,

[46] V. Singh, V. Sapehiyia, V. Srivastava, S. Kaur, Catal. Commun. 2006, 7, Appl. Clay Sci. 2014, 95, 55–59.

571–578. [85] F. Bigi, S. Carloni, B. Frullanti, R. Maggi, G. Sartori, Tetrahedron Lett.

[47] P. Vadivel, R. Ramesh, A. Lalitha, J. Catal. 2013, 2013, 1–8. 1999, 40, 3465–3468.

[48] L. Wang, C. Cai, J. Heterocycl. Chem. 2008, 45, 1771–1774. [86] M. Salmón, R. Osnaya, L. Gómez, G. Arroyo, F. Delgado, R. Miranda,

[49] M. Zendehdel, A. Mobinikhaledi, A. Asgari, J. Inclusion Phenom. Macro- Revista de la Sociedad Química de México 2001, 45, 206–207.

cyclic Chem. 2008, 60, 353–357. [87] A. K. Mitra, K. Banerjee, Synlett 2003, 2003, 1509–1511.

[50] J. Safaei Ghomi, R. Teymuri, A. Ziarati, Monatsh. Chem. 2013, 144, 1865– [88] A. Phukan, S. J. Borah, P. Bordoloi, K. Sharma, B. J. Borah, P. P. Sarmah,

1870. D. K. Dutta, Adv. Powder Technol. 2017, 28, 1585–1592.

[51] V. V. Dabholkar, K. S. Badhe, S. K. Kurade, Curr. Chem. Lett. 2017, 6, 77– [89] R. J. Kalbasi, A. R. Massah, B. Daneshvarnejad, Appl. Clay Sci. 2012, 55,

90. 1–9.

[52] H. El Badaoui, F. Bazi, S. Sokori, S. Boulaajaj, H. Lazrek, S. Sebti, Lett. Org. [90] L. Z. Fekri, M. Nikpassand, M. Movaghari, Bull. Chem. Soc. Ethiop. 2017,

Chem. 2005, 2, 561–565. 31, 313–321.

[53] H. El Badaoui, F. Bazi, R. Tahir, H. B. Lazrek, S. Sebti, Catal. Commun. [91] D. A. Darehkordi, M. M. S. Hosseini, Iran. J. Mater. Sci. Eng. 2012, 9, 1–9.

2005, 6, 455–458. [92] A. Khorshidi, K. Tabatabaeian, H. Azizi, M. Aghaei-Hashjin, E. Abbas-

[54] H. Karade, M. Sathe, M. Kaushik, Molecules 2007, 12, 1341–1351. pour-Gilandeh, RSC Adv. 2017, 7, 17732–17740.

[55] L. L. Zanin, A. L. M. Porto, ChemistrySelect 2020, 5, 8604–8608. [93] L. V. Chopda, P. N. Dave, ChemistrySelect 2020, 5, 2395–2400.

[56] J. Amaya, L. Bobadilla, L. Azancot, M. Centeno, S. Moreno, R. Molina, [94] L. V. Chopda, P. N. Dave, Arab. J. Chem. 2020, 13, 5911–5921.

Mater. Res. Bull. 2020, 123, 110728. [95] S. Sadjadi, F. Koohestani, J. Mol. Liq. 2020, 319, 114393.

[57] W. Wang, H. Liu, T. Wu, P. Zhang, G. Ding, S. Liang, T. Jiang, B. Han, J. [96] B. J. Borah, D. Dutta, D. K. Dutta, Appl. Clay Sci. 2010, 49, 317–323.

Mol. Catal. Chem. 2012, 355, 174–179. [97] H. Faghihian, M. H. Mohammadi, Appl. Surf. Sci. 2013, 264, 492–499.

[58] T. K. Sen, D. Gomez, Desalination 2011, 267, 286–294. [98] P. P. Sarmah, D. K. Dutta, Green Chem. 2012, 14, 1086–1093.

[59] T. Bao, M. M. Damtie, A. Hosseinzadeh, W. Wei, J. Jin, H. N. Phong Vo, [99] D. Liu, P. Yuan, H. Liu, J. Cai, D. Tan, H. He, J. Zhu, T. Chen, Appl. Clay

J. S. Ye, Y. Liu, X. F. Wang, Z. M. Yu, Z. J. Chen, K. Wu, R. L. Frost, B.-J. Ni, Sci. 2013, 80–81, 407–412.

J. Environ. Manage. 2020, 260, 110105. [100] A. Komlósi, E. Kuzmann, N. M. Nagy, Z. Homonnay, S. Kubuki, J. Kónya,

[60] B. Bananezhad, M. R. Islami, E. Ghonchepour, H. Mostafavi, A. M. Tikdari, Clays Clay Miner. 2007, 55, 89–95.

H. R. Rafiei, Polyhedron 2019, 162, 192–200. [101] I. Muthuvel, S. Dineshkumar, K. Thirumurthy, S. Rajasri, G. Thirunar-

[61] A. Kaya, A. H. Ören, J. Hazard. Mater. 2005, 125, 183–189. ayanan, Indian J. Chem. 2016, 55B, 252–260.

[62] V. A. Cardozo, R. Sánchez-Obregón, H. Salgado-Zamora, R. Jiménez- [102] L. Wang, A. Lu, C. Wang, X. Zheng, D. Zhao, R. Liu, J. Colloid Interface

Juárez, Monatsh. Chem. 2015, 146, 1335–1337. Sci. 2006, 295, 436–439.

[63] N. Liu, X. Pu, X. Wang, L. Shi, J. Ind. Eng. Chem. 2014, 20, 2848–2857. [103] G. A. Ikhtiyarova, A. S. Özcan, Ö. Gök, A. Özcan, Clay Miner. 2012, 47,

[64] M. Nasrollahzadeh, S. M. Sajadi, M. Maham, I. Kohsari, Microporous 31–44.

Mesoporous Mater. 2018, 271, 128–137. [104] T. J. Gilberto, L. Marçal, J. M. Silva, L. A. Rocha, K. J. Ciuffi, E. H. Faria, E. J.

[65] K. Selvakumar, A. Raja, M. Arunpandian, K. Stalindurai, P. Rajasekaran, Nassar, J. Braz. Chem. Soc. 2016, 27,933–940.

P. Sami, E. R. Nagarajan, M. Swaminathan, Appl. Surf. Sci. 2019, 481, [105] S. Yang, X. Ren, G. Zhao, W. Shi, G. Montavon, B. Grambow, X. Wang,

1109–1119. Geochim. Cosmochim. Acta 2015, 166, 129–145.

[66] E. Hass Caetano Lacerda, F. C. Monteiro, J. R. Kloss, S. T. Fujiwara, J. [106] D. P. C. Batista, I. N. de Oliveira, A. R. B. Ribeiro, E. J. S. Fonseca, N. S.

Photochem. Photobiol. Chem. 2020, 388, 112084. Santos-Magalhães, J. G. de Sena-Filho, A. V. Teodoro, L. A. M. Grillo, R. S.

[67] X. Tang, X. Meng, L. Shi, Ind. Eng. Chem. Res. 2011, 50, 7527–7533. de Almeida, C. B. Dornelas, RSC Adv. 2017, 7, 26468–26477.

[68] F. O. Nwosu, O. J. Ajala, R. M. Owoyemi, B. G. Raheem, Appl. Water Sci. [107] H. Zaitan, D. Bianchi, O. Achak, T. Chafik, J. Hazard. Mater. 2008, 153,

2018, 8, 195. 852–859.

[69] M. Naswir, S. Arita, P. Jumaida, Desfaournatalia, M. Lince, Tasmin, J. [108] L. Rožić, B. Grbić, N. Radić, S. Petrović, T. Novaković, Z. Vuković, Z.

Phys. Conf. Ser. 2018, 1116, 042026. Nedić, Appl. Clay Sci. 2011, 53, 151–156.

[70] K. Al-Essa, J. Chem. 2018, 2018, 1–10. [109] L. Rožić, B. Grbić, S. Petrović, N. Radić, L. Damjanović, Z. Vuković, Mater.

[71] S. Yaghoobi-Rahni, B. Rezaei, N. Mirghaffari, J. Water Reuse Desalin. Chem. Phys. 2015, 167, 42–48.

2017, 7, 175–186. [110] L. Zhirong, Md. Azhar Uddin, S. Zhanxue, Spectrochim. Acta. A. Mol.

[72] S. Kakaei, E. S. Khameneh, F. Rezazadeh, M. H. Hosseini, J. Mol. Struct. Biomol. Spectrosc. 2011, 79, 1013–1016.

2020, 1199, 126989. [111] E. Kolvari, N. Koukabi, M. M. Hosseini, M. Vahidian, E. Ghobadi, RSC Adv.

[73] C. V. Diniz, J. V. Nascimento, I. Binatti, P. E. Freitas, R. V. Mambrini, Catal. 2016, 6, 7419–7425.

Today 2020, 344, 75–83. [112] J. Javidi, M. Esmaeilpour, F. N. Dodeji, RSC Adv. 2015, 5, 308–315.

[74] S. Ramola, T. Belwal, C. J. Li, Y. Y. Wang, H. H. Lu, S. M. Yang, C. H. Zhou, [113] P. Wu, L. Feng, Y. Liang, X. Zhang, B. Mahmoudi, M. Kazemnejadi, Appl.

Sci. Total Environ. 2020, 709, 136171. Catal. Gen. 2020, 590, 117301.

[75] F. E. Soetaredjo, A. Ayucitra, S. Ismadji, A. L. Maukar, Appl. Clay Sci. [114] K. L. Dhumaskar, S. N. Meena, S. C. Ghadi, S. G. Tilve, Bioorg. Med. Chem.

2011, 53, 341–346. Lett. 2014, 24, 2897–2899.

ChemistrySelect 2020, 5, 14161 – 14167 14166 © 2020 Wiley-VCH GmbH

Full Papers

ChemistrySelect doi.org/10.1002/slct.202003890

[115] A. Debache, B. Boumoud, M. Amimour, A. Belfaitah, S. Rhouati, B. [118] C. R. Reddy, Y. S. Bhat, G. Nagendrappa, B. S. Jai Prakash, Catal. Today

Carboni, Tetrahedron Lett. 2006, 47, 5697–5699. 2009, 141, 157–160.

[116] M. Benna, N. Kbir-Ariguib, A. Magnin, F. Bergaya, J. Colloid Interface Sci. [119] C. O. Kappe, J. Org. Chem. 1997, 62, 7201–7204.

1999, 218, 442–455.

[117] S. Kaufhold, R. Dohrmann, D. Koch, G. Houben, Clays Clay Miner. 2008,

Submitted: October 9, 2020

56, 338–343.

Accepted: November 16, 2020

ChemistrySelect 2020, 5, 14161 – 14167 14167 © 2020 Wiley-VCH GmbH

You might also like

- Refractory Engineering German BookDocument445 pagesRefractory Engineering German BookSURULIAPPAN PREMKMAR100% (8)

- IJE - Volume 34 - Issue 1 - Pages 177-183 PDFDocument7 pagesIJE - Volume 34 - Issue 1 - Pages 177-183 PDFshivani sumanNo ratings yet

- Synthesis and Properties of Poly (Butylene Succinate) :efficiency of Different Transesterification CatalystsDocument12 pagesSynthesis and Properties of Poly (Butylene Succinate) :efficiency of Different Transesterification Catalystsfarideh100% (1)

- 2-Mercaptobenzoxazole Pentacyanoferrate (II/III) Complexes Kinetics of Formation, Substitution and The Thermodynamic CycleDocument6 pages2-Mercaptobenzoxazole Pentacyanoferrate (II/III) Complexes Kinetics of Formation, Substitution and The Thermodynamic CycleMiguel Alberto CasabNo ratings yet

- Anie 201004263Document4 pagesAnie 201004263ATUL CHAUDHARYNo ratings yet

- The Effect of Methanol Atmosphere and or H ZSM 5 Catalyst On The The - 2023 - FuDocument11 pagesThe Effect of Methanol Atmosphere and or H ZSM 5 Catalyst On The The - 2023 - FuDana MateiNo ratings yet

- Ijbpr: International Journal of Biological & Pharmaceutical ResearchDocument5 pagesIjbpr: International Journal of Biological & Pharmaceutical ResearchPharmaIntelligenceNo ratings yet

- Heterogeneous Photo-Fenton Degradation of Phenolic Aqueous Solutions Over Iron-Containing SBA-15 CatalystDocument10 pagesHeterogeneous Photo-Fenton Degradation of Phenolic Aqueous Solutions Over Iron-Containing SBA-15 CatalystSaba GheniNo ratings yet

- Research Article Tio /Diazonium/Graphene Oxide Composites: Synthesis and Visible-Light-Driven Photocatalytic Degradation of Methylene BlueDocument16 pagesResearch Article Tio /Diazonium/Graphene Oxide Composites: Synthesis and Visible-Light-Driven Photocatalytic Degradation of Methylene BlueVõ Thắng NguyênNo ratings yet

- Kaur2017 Article CoinageMetalAgCuDecoratedBiFeODocument8 pagesKaur2017 Article CoinageMetalAgCuDecoratedBiFeOTania ChatterjeeNo ratings yet

- 8100 10718 1 PBAdsorption StudyDocument14 pages8100 10718 1 PBAdsorption StudyTaghreed H AlnoorNo ratings yet

- Controlled Reduction of Red Mud Waste ToDocument5 pagesControlled Reduction of Red Mud Waste Totrunghieucni75No ratings yet

- Catalysts and Process For The ProductionDocument6 pagesCatalysts and Process For The ProductionJosé Guadalupe García EstradaNo ratings yet

- Heterogeneous Fenton Catalyst Supports Screening For Mono Azo Dye Degradation in Contaminated WastewatersDocument8 pagesHeterogeneous Fenton Catalyst Supports Screening For Mono Azo Dye Degradation in Contaminated Wastewatersatina niesaNo ratings yet

- Formation Pathways of Magnetite Nanoparticles by CoprecipitationDocument8 pagesFormation Pathways of Magnetite Nanoparticles by CoprecipitationShweta KaurNo ratings yet

- IR Ni LanthanaDocument6 pagesIR Ni LanthanaNelly RojasNo ratings yet

- Poly (Ethylene Terephthalate) Synthesis With Catalysts Derived From Chrysotile AsbestosDocument6 pagesPoly (Ethylene Terephthalate) Synthesis With Catalysts Derived From Chrysotile AsbestosXO XONo ratings yet

- Synthesis A Novel Multilamellar Mesoporous TiO2-ZSM-5 For Photo-Catalyticdegradation of Methyl Orange Dye in Aqueous MediaDocument10 pagesSynthesis A Novel Multilamellar Mesoporous TiO2-ZSM-5 For Photo-Catalyticdegradation of Methyl Orange Dye in Aqueous MediaDevi LestariNo ratings yet

- Study of Structural and Optical Properties of Fe (Iii) - Doped Tio Prepared by Sol-Gel MethodDocument7 pagesStudy of Structural and Optical Properties of Fe (Iii) - Doped Tio Prepared by Sol-Gel MethodLinda J KusumawardaniNo ratings yet

- 2020, Heterogeneous Catalyst of FeCo2O4-g-C3N4Document9 pages2020, Heterogeneous Catalyst of FeCo2O4-g-C3N4TRINH HUỲNH NGỌC DIỄMNo ratings yet

- A Comparative Study of Ni Catalysts Supported On Al2O - 2022 - International JouDocument17 pagesA Comparative Study of Ni Catalysts Supported On Al2O - 2022 - International JouSaepulloh Rahmat SolehudinNo ratings yet

- Fe304 Tio2Document9 pagesFe304 Tio2Aulia Rizki ramadhantiNo ratings yet

- Alkylation and Acylation of Phenol With Methyl AcetateDocument7 pagesAlkylation and Acylation of Phenol With Methyl AcetateSaravanamurugan ShumugavelNo ratings yet

- Preparation and Characterization Heteroagglomeration of Fe O /tio Composites byDocument23 pagesPreparation and Characterization Heteroagglomeration of Fe O /tio Composites byRiriNo ratings yet

- A Novel WO3 - MoS2 Photocatalyst Applied To The Decolorization of The Textile Dye Reactive Blue 198 - Suellen - 2018Document10 pagesA Novel WO3 - MoS2 Photocatalyst Applied To The Decolorization of The Textile Dye Reactive Blue 198 - Suellen - 2018leonardoNo ratings yet

- Preferential Hexacoordination of Cobalt (II) Complexes With Heteroaroyl-HydrazonesDocument5 pagesPreferential Hexacoordination of Cobalt (II) Complexes With Heteroaroyl-HydrazonesMailinkoNo ratings yet

- Microporous and Mesoporous Materials: Haiyan Song, Gang Li, Xiangsheng WangDocument5 pagesMicroporous and Mesoporous Materials: Haiyan Song, Gang Li, Xiangsheng WangLuis TNNo ratings yet

- Nanomaterials 10 02300Document26 pagesNanomaterials 10 02300Venkata KishoreNo ratings yet

- Diurnal Photodegradation of Fluorinated Diketones (FDKS) by OH RadicalsDocument9 pagesDiurnal Photodegradation of Fluorinated Diketones (FDKS) by OH RadicalsÁlvaro Gómez DelgadoNo ratings yet

- 10 1016@j Jphotochem 2019 01 012Document9 pages10 1016@j Jphotochem 2019 01 012mauricioespitiaNo ratings yet

- RSC Advances: PaperDocument8 pagesRSC Advances: PaperJhonathan SouzaNo ratings yet

- JCPDS 2Document8 pagesJCPDS 2hajingukNo ratings yet

- Li 2017Document7 pagesLi 2017IscienceNo ratings yet

- Applied Surface Science 347 (2015) 40-47Document8 pagesApplied Surface Science 347 (2015) 40-47Hugo DuarteNo ratings yet

- Chen 2016Document8 pagesChen 2016Stiven Loaiza CastroNo ratings yet

- Accepted Manuscript: Materials LettersDocument11 pagesAccepted Manuscript: Materials LettersSaurav PaulNo ratings yet

- Efficient Route For The Synthesis of 1,3-Dioxolanes Catalyzed by Sulfated Mixed Oxides of Yttria-ZirconiaDocument5 pagesEfficient Route For The Synthesis of 1,3-Dioxolanes Catalyzed by Sulfated Mixed Oxides of Yttria-ZirconiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 1 s2.0 S000862150000046X MainDocument9 pages1 s2.0 S000862150000046X MainIsa Guerrero TroyanoNo ratings yet

- Kinetics and Mechanism of The mercuryII Assisted Hydrolysis of Methyl Iodide - 2005 - Inorganic ChemistryDocument7 pagesKinetics and Mechanism of The mercuryII Assisted Hydrolysis of Methyl Iodide - 2005 - Inorganic ChemistryTriết LêNo ratings yet

- ART - Tartaric-acid-enhanced-CuFe2O4-catalyzed-heterogeneo - 2019 - Materials-ScienceDocument10 pagesART - Tartaric-acid-enhanced-CuFe2O4-catalyzed-heterogeneo - 2019 - Materials-ScienceAntonio romero de avilaNo ratings yet

- VRUBEL, HASEGAWA, OLIVEIRA, NUNES. A New Facile High Yield Preparative Route For Mixed-Trinuclear Acetate Clusters.Document4 pagesVRUBEL, HASEGAWA, OLIVEIRA, NUNES. A New Facile High Yield Preparative Route For Mixed-Trinuclear Acetate Clusters.Caroline RochaNo ratings yet

- 10 Cap 04Document9 pages10 Cap 04nataliaNo ratings yet

- 1 s2.0 S001623612032202X MainDocument8 pages1 s2.0 S001623612032202X MainUmair Afzal ChNo ratings yet

- Bahan Metilen BlueDocument5 pagesBahan Metilen Blue4uvq5j3lNo ratings yet

- EstrcturaDocument8 pagesEstrcturaGuiexhoba MedranoNo ratings yet

- LithiumtiDocument7 pagesLithiumtijeremy parkerNo ratings yet

- Belhadjltaief 2016Document9 pagesBelhadjltaief 2016Blessing HarvestNo ratings yet

- Artículo 06 PDFDocument7 pagesArtículo 06 PDFJ Mora GañanNo ratings yet

- Fabrication of Ag Po /tio Composite and Its Photodegradation of Formaldehyde Under Solar RadiationDocument9 pagesFabrication of Ag Po /tio Composite and Its Photodegradation of Formaldehyde Under Solar Radiationcesafilho.idtNo ratings yet

- Formation Pathways of Magnetite Nanoparticles by Coprecipitation MethodDocument8 pagesFormation Pathways of Magnetite Nanoparticles by Coprecipitation Method122866No ratings yet

- Journal of Colloid and Interface Science: Mitra Mousavi, Aziz Habibi-YangjehDocument10 pagesJournal of Colloid and Interface Science: Mitra Mousavi, Aziz Habibi-YangjehJorge Eduardo JuarezNo ratings yet

- 1 s2.0 S0926860X23003058 MainDocument12 pages1 s2.0 S0926860X23003058 Mainhenry martinez quiñonezNo ratings yet

- A Study of The Deactivation of Low Loading Ni:Al2O3 Steam Reforming Catalyst by TetrahydrothiopheneDocument7 pagesA Study of The Deactivation of Low Loading Ni:Al2O3 Steam Reforming Catalyst by TetrahydrothiopheneVương Duy NghiêmNo ratings yet

- 1 s2.0 S092633731300057X MainDocument5 pages1 s2.0 S092633731300057X MainGerson Martinez ZuñigaNo ratings yet

- Synthesis, Characterization and Photocatalytic Activity of MnO2 Al2O3 Fe2O3 Nanocomposite For Degradation of Malachite GreenDocument12 pagesSynthesis, Characterization and Photocatalytic Activity of MnO2 Al2O3 Fe2O3 Nanocomposite For Degradation of Malachite Greenaidah amirNo ratings yet

- Aqueous Oxidation of Dimethyl Phthalate in A Fe (Vi) - Tio - Uv Reaction SystemDocument28 pagesAqueous Oxidation of Dimethyl Phthalate in A Fe (Vi) - Tio - Uv Reaction SystemArpit Kumar MishraNo ratings yet

- Byrne Et Al - 2011 - IOP Nanotechnology - Control of Particle SizeDocument9 pagesByrne Et Al - 2011 - IOP Nanotechnology - Control of Particle SizeSami UllahNo ratings yet

- 19 Fe2O3 - CNTDocument9 pages19 Fe2O3 - CNTraj mallickNo ratings yet

- Synthesis and Characterization of Fe-Doped Tio2 Photocatalyst by The Sol-Gel MethodDocument6 pagesSynthesis and Characterization of Fe-Doped Tio2 Photocatalyst by The Sol-Gel MethodsatishNo ratings yet

- Impact of Sorbitol Addition On The Structure and Performance of Silica-SupportedDocument6 pagesImpact of Sorbitol Addition On The Structure and Performance of Silica-SupportedRamakanta SahuNo ratings yet

- Graphene Oxide: Fundamentals and ApplicationsFrom EverandGraphene Oxide: Fundamentals and ApplicationsAyrat M. DimievNo ratings yet

- (Dogster) 23 UK Pet Industry Statistics To Know in 2024 Trends Market Size & FAQDocument20 pages(Dogster) 23 UK Pet Industry Statistics To Know in 2024 Trends Market Size & FAQNguyễn Thị Huyền TrânNo ratings yet

- (IntraFish) UKs Largest Seafood Processors Jump On Snacking Trend To Boost Consumption SalesDocument2 pages(IntraFish) UKs Largest Seafood Processors Jump On Snacking Trend To Boost Consumption SalesNguyễn Thị Huyền TrânNo ratings yet

- (Petfood Industry) Cat Food Treat Innovation Rises in 2024 With Health FocusDocument5 pages(Petfood Industry) Cat Food Treat Innovation Rises in 2024 With Health FocusNguyễn Thị Huyền TrânNo ratings yet

- Molecules 27 03040 v2Document22 pagesMolecules 27 03040 v2Nguyễn Thị Huyền TrânNo ratings yet

- Bilia 2006Document7 pagesBilia 2006Nguyễn Thị Huyền TrânNo ratings yet

- Tao 2013Document9 pagesTao 2013Nguyễn Thị Huyền TrânNo ratings yet

- Nowak 2021Document9 pagesNowak 2021Nguyễn Thị Huyền TrânNo ratings yet

- Coordination Compound-1Document38 pagesCoordination Compound-1Sambhav SinghalNo ratings yet

- Materials Science and Engineering C: Dan Kai, Sing Shy Liow, Xian Jun LohDocument12 pagesMaterials Science and Engineering C: Dan Kai, Sing Shy Liow, Xian Jun Lohjohn munezNo ratings yet

- SELINA Solutions For Class 9 Chemistry Chapter 1Document53 pagesSELINA Solutions For Class 9 Chemistry Chapter 1thakurrmcplNo ratings yet

- 2021 NSMQ Regional Qualifiers Bono Contest 2Document8 pages2021 NSMQ Regional Qualifiers Bono Contest 2ariakiara88No ratings yet

- Electrodeposition and AnodizationDocument3 pagesElectrodeposition and AnodizationMahabub Alam MoonNo ratings yet

- 148 16SCCCH8 2020062412102615Document25 pages148 16SCCCH8 2020062412102615Jawad MughalNo ratings yet

- IUPAC Nomenclaute, Structural Isomerism & Practical Organic ChemistryDocument35 pagesIUPAC Nomenclaute, Structural Isomerism & Practical Organic ChemistryAmit Tiwari100% (1)

- Board QB - ObjectivesDocument30 pagesBoard QB - Objectivessawant yashNo ratings yet

- Experiment # 1 PH Measurement and Buffer Preparation I. ObjectivesDocument5 pagesExperiment # 1 PH Measurement and Buffer Preparation I. ObjectiveschynnaNo ratings yet

- Marking Scheme - Chemistry (Subject Code - 043) (Paper Code - 56/1/1,2,3)Document17 pagesMarking Scheme - Chemistry (Subject Code - 043) (Paper Code - 56/1/1,2,3)Rupa SharmaNo ratings yet

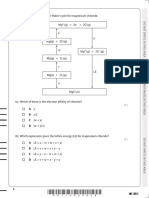

- 7 The Diagram Shows The Born-Haber Cycle For Magnesium ChlorideDocument6 pages7 The Diagram Shows The Born-Haber Cycle For Magnesium ChlorideAathifa ThowfeekNo ratings yet

- Master Thesis: Moving Biofiles in Sequential Discharge Reactor (SBR)Document88 pagesMaster Thesis: Moving Biofiles in Sequential Discharge Reactor (SBR)DianerNo ratings yet

- Anisotropic Conductive FilmDocument2 pagesAnisotropic Conductive FilmDaniel Martinez CollazoNo ratings yet

- Harrison Sinclairhairstylingl-2003-Journal of Cosmetic DermatologyDocument7 pagesHarrison Sinclairhairstylingl-2003-Journal of Cosmetic Dermatologyلمياء لعلاج وفرد الشعرNo ratings yet

- Critical Review On Types of Bricks Type 3: Aac Block: Manish Kumar Sahu, Lokesh SinghDocument5 pagesCritical Review On Types of Bricks Type 3: Aac Block: Manish Kumar Sahu, Lokesh Singhekantus ekantusNo ratings yet

- Enzyme: Ayesha Shafi Pharm-D, (P.U.), M. Phil. Pharmaceutical Chemistry (P.U.)Document34 pagesEnzyme: Ayesha Shafi Pharm-D, (P.U.), M. Phil. Pharmaceutical Chemistry (P.U.)Shafaqat Ghani Shafaqat Ghani100% (2)

- Process Aids Booklet ENG Print A4 AB VickersDocument8 pagesProcess Aids Booklet ENG Print A4 AB VickersFabioNo ratings yet

- Chemical Mediators of InflammationDocument46 pagesChemical Mediators of Inflammationroohi khanNo ratings yet

- PPT, Indicator and Acid StrengthDocument20 pagesPPT, Indicator and Acid StrengthZUNINo ratings yet

- DPP-01 Chemical KineticsDocument1 pageDPP-01 Chemical Kineticsprathmfed100% (1)

- Word To Text 3-01 (17 Files Merged)Document39 pagesWord To Text 3-01 (17 Files Merged)Nor Shailanie NalamNo ratings yet

- Kettle Process Industrial ChemistryDocument7 pagesKettle Process Industrial ChemistryKcirtap ZkethNo ratings yet

- Biochemistry of Cheese Ripening PDFDocument12 pagesBiochemistry of Cheese Ripening PDFLocoharold AZNo ratings yet

- Science7 - SLM - Q1 - M2 - V1.0 - CO Released 08032020Document36 pagesScience7 - SLM - Q1 - M2 - V1.0 - CO Released 08032020anne abadiezNo ratings yet

- CKRD-MS-03 (2020)Document51 pagesCKRD-MS-03 (2020)Shakoor MalikNo ratings yet

- Citric AcidDocument23 pagesCitric AcidLali SalcedoNo ratings yet

- Effect of Salt Solution and Plasticity Index On Undrain Shear Strength of ClaysDocument5 pagesEffect of Salt Solution and Plasticity Index On Undrain Shear Strength of ClaysHafiz Zulkarami RayendraNo ratings yet

- Offer Letter: Price ListDocument11 pagesOffer Letter: Price ListJose CastroNo ratings yet

- Ps-2 Grade XII ChemistryDocument1 pagePs-2 Grade XII Chemistrynishchala knNo ratings yet