Professional Documents

Culture Documents

Pharmaceutical Industry Hazards and Safety

Pharmaceutical Industry Hazards and Safety

Uploaded by

fadli0 ratings0% found this document useful (0 votes)

110 views23 pagesThis document discusses industrial safety hazards in pharmaceutical industries. It identifies major hazards as toxic chemicals, fires, explosions, and falls. It emphasizes the importance of identifying hazards and implementing protective measures to control risks and protect workers. Various industrial hazards are described such as chemical, electrical, mechanical, fire, and pharmaceutical hazards. Exposure routes and acute vs chronic poisoning are also covered. The document recommends safety practices like proper equipment maintenance, training, and use of protective gear to prevent hazards in pharmaceutical facilities.

Original Description:

Original Title

Pharmaceutical Industry Hazards and safety

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses industrial safety hazards in pharmaceutical industries. It identifies major hazards as toxic chemicals, fires, explosions, and falls. It emphasizes the importance of identifying hazards and implementing protective measures to control risks and protect workers. Various industrial hazards are described such as chemical, electrical, mechanical, fire, and pharmaceutical hazards. Exposure routes and acute vs chronic poisoning are also covered. The document recommends safety practices like proper equipment maintenance, training, and use of protective gear to prevent hazards in pharmaceutical facilities.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

110 views23 pagesPharmaceutical Industry Hazards and Safety

Pharmaceutical Industry Hazards and Safety

Uploaded by

fadliThis document discusses industrial safety hazards in pharmaceutical industries. It identifies major hazards as toxic chemicals, fires, explosions, and falls. It emphasizes the importance of identifying hazards and implementing protective measures to control risks and protect workers. Various industrial hazards are described such as chemical, electrical, mechanical, fire, and pharmaceutical hazards. Exposure routes and acute vs chronic poisoning are also covered. The document recommends safety practices like proper equipment maintenance, training, and use of protective gear to prevent hazards in pharmaceutical facilities.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 23

Prepared By: Rizwan Naqvi

Industrial Safety refers to reduce the risk of

injury or loss and danger to persons, property

from the industrial hazards.

Toxic corrosive chemicals, fire explosions and

personnel falling into accident are major health

and safety hazards encountered in the

operations of pharmaceutical industries.

Identification of hazards and employing

protective measures to control the hazards are

important to protect the people from their

consequences.

Understand the harmful effects of industrial

hazards.

Define the relationship between hazard and risk

Explore the routes of exposure to industrial

hazards

Shed lights on type of toxicity by industrial

hazards

Know the most toxic environmental hazardous

substances.

Hazard is the potential of a substance

to cause damage.

Toxicity is the hazard of a substance which

can cause poisoning

Risk is a measure of the probability that harm

will occur under defined conditions of

exposure to a chemical.

Large exposures to chemicals can effect

human health directly or indirectly

The release of chemicals into environment

can have global impacts

All the changes that occur in

the environment affect people.

There are 03 main routes by

which hazardous chemicals enter

the body;

1) Absorption through the respiratory tract

through inhalation.

2) Absorption or injection through the skin or

eyes.

3) Absorption through digestive tract. This may

occur with contaminated hands or in

contaminated works in areas.

Acute Poisoning is characterized by rapid

absorption of the substance and the exposure

is sudden & severe. e.g. carbon monoxide

Chronic Poisoning is characterized by

prolonged or repeated exposures of a

duration measured in days, months or years.

e.g. lead or mercury poisoning & pesticide

exposure.

Fire Hazards

Chemical Hazards

Electrical Hazards

Mechanical hazards

Pharmaceutical Hazards

The self-sustaining process of rapid oxidation

of fuel which produces heat and light.

Three essential for combustion of fire are;

Fuel (any combustible materials)

Oxygen

Temperature

Well planned design and layout

Proper ventilated system

Chemical data sheet

Proper training of personnel

Fire fighting equipments

Sprinkler systems

Many chemicals can cause severe burns. If

these coming to contact with living tissues or

other routes like inhalation.

Living tissues may be destroyed by chemical

reactions such as dehydration, digestion,

oxidation etc.

Some common organic solvents like

chloroform & benzene.

Application of barrier creams before

commenting the work

Using the high vapor pressure solvents,

safety goggles, gloves and helmet.

Electrical hazards occurs when a person come in

contact with the conductor carrying current and

simultaneously contacts with the ground,

usually known to be work hazards.

Sources

Short circuits

Electrostatic hazard

Arcs & Sparks hazard

Improper wiring

Insulation failure

Proper maintenance of wiring and equipment

High voltage equipment should be properly

enclosed

Good house keeping

Worker should avoid working in electrical

circuits or equipments in

wet clothing or shoes.

These are associated with power-driven

machine, whether automated or manually

operated by steam, hydraulic and/or electric

power introduced new hazards into work

place.

Its can be reduced by application of

appropriate safeguards such as;

Prevent contact

Protect against falling objects

Do not create interference

Allow safe maintenance

Use types of safeguards i.e. fixed guards,

interlocked guards & adjustable guards.

Hazards drugs that pose a potential health

risk to health care workers who may be

exposed during drug manufacturing.

Dugs that meet one or more of the following

criteria should be hazardous

Carcinogenicity

Teratogenicity

Reproductive toxicity

Organ toxicity at lower doses.

Use personnel protective equipments for

hazardous drug handling

Proper treatment and disposal method for

effluents

Awareness program

Disposable gowns

Powder free gloves

Face & eye protection

Approved respirator

Gas release should be vented outside building

Exhaust should be provided

Prepare Drug Disaster Management plan

Disease due to biological hazards are;

Bruccellosis (dairy industry)

Byssinosis (textile industry)

Bagassosis (sugar-cane)

Loco motor disorder

Proper treatment and disposal method for

Biological hazards

Periodic health checkup

Personnel protection

First Aid Facilities

Facility vaccination

Routine sanitization programme

Initial examination

Proper treatment and disposal method for effluents

Standard operating procedures

Handling of Hazardous materials

Water supply and drainage

Emergency Exists

Back up plan if anything goes

wrong

Health polices & insurance

Safety Audits

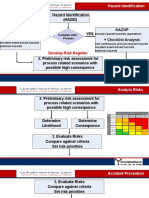

Risk Analysis

Regular Monitoring of workplace

Awareness and training Program

Written documentations

In short safety aspects

must be considered by the

pharmaceutical industry not

only in the interest of the

property but also in terms of employee.

The source of possible hazards, risk analysis,

control procedures preventive measures and

contingency plan are the main five essentials for

ensuring a completed safe work atmosphere in

the industry.

You might also like

- Sika Seal-410 PG (Curing Agent) - SDS - AE - 180719Document13 pagesSika Seal-410 PG (Curing Agent) - SDS - AE - 180719usman khalid100% (1)

- Benzene: 1. Purpose 2. ScopeDocument8 pagesBenzene: 1. Purpose 2. ScopeKandhasamy888No ratings yet

- CRSP Examination Blueprint Reference Texts: Title & Auxiliary InformationDocument2 pagesCRSP Examination Blueprint Reference Texts: Title & Auxiliary Informationrob mclellanNo ratings yet

- Occupational Health Saftey Management Plan (OHMSP) - NZDocument29 pagesOccupational Health Saftey Management Plan (OHMSP) - NZRam P0% (1)

- Occupational healthWHO 2018Document173 pagesOccupational healthWHO 2018jackleenNo ratings yet

- Hazard and Risk For Nurse in HospitalDocument4 pagesHazard and Risk For Nurse in HospitalFaraahNo ratings yet

- 2 Industrial HygieneDocument6 pages2 Industrial HygieneSayed DarwishNo ratings yet

- Topic 3 Health Hazard and Their ControlsDocument15 pagesTopic 3 Health Hazard and Their Controlschristopher mendozaNo ratings yet

- Sharps Injury Surveillance Manual MOHDocument53 pagesSharps Injury Surveillance Manual MOHpaanarNo ratings yet

- Sop Occupational Safety and Health Complaints Mechanism UnitDocument12 pagesSop Occupational Safety and Health Complaints Mechanism UnitEmdad YusufNo ratings yet

- BiohazardDocument14 pagesBiohazardsujan maharjanNo ratings yet

- Safety in Hospitals: A Computer - Based Learning Program For StudentsDocument15 pagesSafety in Hospitals: A Computer - Based Learning Program For Studentsmonir61No ratings yet

- Vinay K Khanna - Occupational Health (Rajendra)Document34 pagesVinay K Khanna - Occupational Health (Rajendra)Nora FahsyaNo ratings yet

- 11.2 Baseline Medical Surveillance ProcedureDocument18 pages11.2 Baseline Medical Surveillance ProcedureaceNo ratings yet

- OccuPational SafetyDocument7 pagesOccuPational SafetyElaida CM ThriftshopNo ratings yet

- Accident Prevention: Training Module Prepared By:Safety Dept - GCL LoteDocument30 pagesAccident Prevention: Training Module Prepared By:Safety Dept - GCL LotednkishoreNo ratings yet

- Workplace SafetyDocument14 pagesWorkplace SafetyCarol Lee Yiew ChaiNo ratings yet

- First Aid LeafletDocument11 pagesFirst Aid LeafletshahnawazNo ratings yet

- Cooking Example Risk Assessment March 2023Document3 pagesCooking Example Risk Assessment March 2023Craig ParkinsonNo ratings yet

- Practice Occupational Health and Safety ProceduresDocument8 pagesPractice Occupational Health and Safety ProceduresCelNo ratings yet

- Vertigo TestDocument6 pagesVertigo Testalam saroorNo ratings yet

- Hygine PracticeDocument12 pagesHygine Practicejaykotak12345No ratings yet

- Identifying and Controlling Hazards: We Lco MeDocument45 pagesIdentifying and Controlling Hazards: We Lco MeAijaz Ahmed Shaikh100% (1)

- Basic First Aid - AEDDocument49 pagesBasic First Aid - AEDSalvacion JaroNo ratings yet

- Procedure: (Optional Heading Here. Change Font Size To Suit)Document4 pagesProcedure: (Optional Heading Here. Change Font Size To Suit)Ian Kristian BelgicaNo ratings yet

- University of Mindanao: College of Engineering EducationDocument6 pagesUniversity of Mindanao: College of Engineering EducationZerlyn JoebeNo ratings yet

- SOP For Preparation of Commonly Used Disinfectants and Fumigants Against Coronavirus (SARS-CoV-2)Document27 pagesSOP For Preparation of Commonly Used Disinfectants and Fumigants Against Coronavirus (SARS-CoV-2)andualemNo ratings yet

- Occupational Health Hazards and Workers' Health: Marissa G. Lomuntad - San Jose, MD, MOHDocument86 pagesOccupational Health Hazards and Workers' Health: Marissa G. Lomuntad - San Jose, MD, MOHAviects Avie JaroNo ratings yet

- Personal Protective Equipment (PPE) at Work: A Brief GuideDocument6 pagesPersonal Protective Equipment (PPE) at Work: A Brief GuideMohamed Omar100% (1)

- PPE GuideDocument4 pagesPPE Guidenadar nagarNo ratings yet

- Hazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisDocument7 pagesHazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisZeroRecoNo ratings yet

- DR Azrul Rozaiman Dato HJ Abdullah - An-Nur Specialist HospitalDocument22 pagesDR Azrul Rozaiman Dato HJ Abdullah - An-Nur Specialist Hospitalakubestlah100% (1)

- Behavior Based Safety Approach To Advance Injury Free CultureDocument7 pagesBehavior Based Safety Approach To Advance Injury Free CultureRibka FridayNo ratings yet

- Personal Protective EquipmentDocument22 pagesPersonal Protective EquipmentAdam H100% (1)

- Toolbox Talks Personal Protective Equipment English PDFDocument1 pageToolbox Talks Personal Protective Equipment English PDFHosamMohamedNo ratings yet

- SDS Ar-Afff 3-3C6Document5 pagesSDS Ar-Afff 3-3C6A K KarmakarNo ratings yet

- LITE Manual Handling Risk AssessmentDocument2 pagesLITE Manual Handling Risk AssessmentTina fu Gee100% (1)

- Day 2-5 Personal Protective EquipmentDocument28 pagesDay 2-5 Personal Protective EquipmentMegaNo ratings yet

- HAZARD - Definition: Hazard at Workplace Categorized: Physical, Chemical, Biological & PhyscosocialDocument9 pagesHAZARD - Definition: Hazard at Workplace Categorized: Physical, Chemical, Biological & PhyscosocialDevvrat ChowdharyNo ratings yet

- Protocol For Needle Stick Injur1Document1 pageProtocol For Needle Stick Injur1Prem KumarNo ratings yet

- Basics of Equipment Guarding: Mining and Petroleum Training ServiceDocument51 pagesBasics of Equipment Guarding: Mining and Petroleum Training ServiceKim Lien TrinhNo ratings yet

- Occupational Safety and Health Risk Assessment of Workers in The Manufacturing IndustryDocument15 pagesOccupational Safety and Health Risk Assessment of Workers in The Manufacturing IndustryCj SesnorioNo ratings yet

- IGC1 Element 4 End of Element Questions and Answers Health and Safety Management Systems 3 - PlanningDocument5 pagesIGC1 Element 4 End of Element Questions and Answers Health and Safety Management Systems 3 - PlanningDrmusharraf AnsariNo ratings yet

- (Facility Name) : Emergency Operations PlanDocument26 pages(Facility Name) : Emergency Operations PlanIbsen CampoverdeNo ratings yet

- Lec11 Hazrd CommDocument51 pagesLec11 Hazrd Commjune1911No ratings yet

- Chapter 1-Introduction To OshaDocument32 pagesChapter 1-Introduction To OshafettaneNo ratings yet

- The Science of ErgonomicsDocument54 pagesThe Science of Ergonomicsscherrercute100% (1)

- Basic PPT For First Aid TrainingDocument10 pagesBasic PPT For First Aid TrainingMohan RadiyaNo ratings yet

- 3M Fit Test KitDocument16 pages3M Fit Test Kitgeorge_rusuNo ratings yet

- Basic Safety PDFDocument69 pagesBasic Safety PDFMichael M. SolivaNo ratings yet

- First Aid and Factories ActDocument2 pagesFirst Aid and Factories ActChaitra PrasannaNo ratings yet

- FiveSteps PDFDocument1 pageFiveSteps PDFMohamed FouadNo ratings yet

- 1 Introduction To Safety EngineeringDocument5 pages1 Introduction To Safety EngineeringMANNNo ratings yet

- BOILER - Act 139Document24 pagesBOILER - Act 139Uzair Jais100% (1)

- Gilair 3 and 5 Manual - 0Document40 pagesGilair 3 and 5 Manual - 0ramosibarranestorNo ratings yet

- Accident Prevention Toolbox TalkDocument1 pageAccident Prevention Toolbox TalkPhanankosi DubeNo ratings yet

- Hazardous SubstancesDocument9 pagesHazardous SubstancesMdhafis SamsualdinNo ratings yet

- Toluene:: Standard Operating ProcedureDocument7 pagesToluene:: Standard Operating ProcedureRicardo VilchezNo ratings yet

- Fire Risk Assessment and Emergency Route Decision Analysis Based On Big Data Platform-Example of HuizhouDocument12 pagesFire Risk Assessment and Emergency Route Decision Analysis Based On Big Data Platform-Example of HuizhouPriyanka KilaniyaNo ratings yet

- Method Validation and VerificationDocument54 pagesMethod Validation and VerificationfadliNo ratings yet

- Rouging - When Stainless Steel Corrodes - Operation ADocument6 pagesRouging - When Stainless Steel Corrodes - Operation AfadliNo ratings yet

- OOSDocument26 pagesOOSfadliNo ratings yet

- Regulatory Affairs Strategies For C M CDocument5 pagesRegulatory Affairs Strategies For C M CfadliNo ratings yet

- CTD Dossier Preparation: K. Srikantha Reddy K. Srikantha ReddyDocument46 pagesCTD Dossier Preparation: K. Srikantha Reddy K. Srikantha Reddyfadli100% (1)

- Named ReactionsDocument15 pagesNamed Reactionsabhiramiajith0203No ratings yet

- Unit Conversion Factors - RakeshRRDocument4 pagesUnit Conversion Factors - RakeshRRRakesh Roshan RanaNo ratings yet

- Project Specification PaintingDocument13 pagesProject Specification PaintingBudi Indra100% (1)

- Iso 16967 2015Document11 pagesIso 16967 2015Fer NandoNo ratings yet

- Kinetic Theory of Gases CH13Document17 pagesKinetic Theory of Gases CH13Rishab SharmaNo ratings yet

- Paper - 2 (Question Paper) - 6Document16 pagesPaper - 2 (Question Paper) - 6Saumya MundraNo ratings yet

- Seminar Report On Solar Cooling: Under The Guidence: Submitted byDocument43 pagesSeminar Report On Solar Cooling: Under The Guidence: Submitted byAbhay SinghNo ratings yet

- F HG I KJ: NEET (UG) 2020 Exam PaperDocument23 pagesF HG I KJ: NEET (UG) 2020 Exam PaperN KNo ratings yet

- MSDS Protectol PEDocument14 pagesMSDS Protectol PEElisabeth YunitaNo ratings yet

- Thermo Lab 3 BG Vilakazi - 220001965Document6 pagesThermo Lab 3 BG Vilakazi - 220001965Bonginkosi VilakaziNo ratings yet

- Safety Data Sheet: 1 Identification of The Substance and of The CompanyDocument7 pagesSafety Data Sheet: 1 Identification of The Substance and of The CompanyGianpieroNo ratings yet

- Research Paper in PHYSICSDocument8 pagesResearch Paper in PHYSICSAngelica Rico100% (1)

- The World of Two-Dimensional Carbides and Nitrides (MXenes)Document16 pagesThe World of Two-Dimensional Carbides and Nitrides (MXenes)Arkan AzaniNo ratings yet

- Structural Steel en 10025-10027Document2 pagesStructural Steel en 10025-10027apply19842371No ratings yet

- Gas Engines PortfolioDocument41 pagesGas Engines PortfolioAnonymous alQXB11EgQ100% (1)

- Act7 MelicadoDocument5 pagesAct7 MelicadochristinamelicadoNo ratings yet

- The Dyeing of Woollen Fabrics by Beech, FranklinDocument198 pagesThe Dyeing of Woollen Fabrics by Beech, FranklinGutenberg.orgNo ratings yet

- Development of Chicken Meat Patties Incorporating Natural AntioxidantsDocument14 pagesDevelopment of Chicken Meat Patties Incorporating Natural AntioxidantsTJPRC PublicationsNo ratings yet

- Is Carbon Black Pigment Organic or InorganicDocument3 pagesIs Carbon Black Pigment Organic or Inorganicwiwat dussadinNo ratings yet

- Tension Test On Hot Rolled Plain Steel Bar (ASTM-A615/615-M)Document19 pagesTension Test On Hot Rolled Plain Steel Bar (ASTM-A615/615-M)Adil Javed Chaudhary67% (3)

- Heidarpour, (2010) - FSJDocument10 pagesHeidarpour, (2010) - FSJluisalvesqueirozNo ratings yet

- Generon Membrane 4100 CPDocument2 pagesGeneron Membrane 4100 CPJavier Garcia MarquezNo ratings yet

- ME104 2 B Chua Kim Lian 25062012Document51 pagesME104 2 B Chua Kim Lian 25062012kkkNo ratings yet

- Vortex Tube - Yunpeng XueDocument121 pagesVortex Tube - Yunpeng XueVladan MilojevićNo ratings yet

- Design Techniques To AbsorptionDocument54 pagesDesign Techniques To AbsorptionFASIH AFZAL KHANNo ratings yet

- TSB 120Document7 pagesTSB 120patelpiyushbNo ratings yet

- THE EFFECT OF VANADIUM AND GRAIN REFINER ADDITIONS ON THE NUCLEATION OF SECONDARY PHASES IN 1XXX Al ALLOYSDocument17 pagesTHE EFFECT OF VANADIUM AND GRAIN REFINER ADDITIONS ON THE NUCLEATION OF SECONDARY PHASES IN 1XXX Al ALLOYSdrika100% (1)

- Botrytis Cinerea, Penicillium Expansum, and Rhizopus Stolonifer) Were Examined Using A 96-Well MicrotiterDocument10 pagesBotrytis Cinerea, Penicillium Expansum, and Rhizopus Stolonifer) Were Examined Using A 96-Well MicrotiterAli SulaimanNo ratings yet

- Week 1a Course DetailsDocument19 pagesWeek 1a Course DetailsAraasu EgambaramNo ratings yet

- AqudDocument5 pagesAqudch0k3 iiiNo ratings yet