Professional Documents

Culture Documents

Anixter Thermocouple and RTD Wire Wire Wisdom en

Anixter Thermocouple and RTD Wire Wire Wisdom en

Uploaded by

Felipe GustavoCopyright:

Available Formats

You might also like

- Obtaining Spectrometric Data For Object-Color EvaluationDocument9 pagesObtaining Spectrometric Data For Object-Color Evaluationavik6294846100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- Holland Shielding Catalog-2018 PDFDocument145 pagesHolland Shielding Catalog-2018 PDFdilnair99No ratings yet

- Thermocouple and RTD Wire: Reference JunctionsDocument2 pagesThermocouple and RTD Wire: Reference JunctionsFelipe GustavoNo ratings yet

- Various Temperature MeasurementsDocument3 pagesVarious Temperature MeasurementsPrincess PurnimaNo ratings yet

- Temperature SenesorDocument16 pagesTemperature SenesordskjajkdsaNo ratings yet

- What Is A ThermocoupleDocument13 pagesWhat Is A ThermocoupleMuhammad Wasiq TanveerNo ratings yet

- WP 003 Endress TemperatureDocument17 pagesWP 003 Endress Temperaturevenkatesh425No ratings yet

- Thermocouple Questions and AnswersDocument12 pagesThermocouple Questions and AnswersJêmš Navik0% (1)

- What Is A Thermocouple?Document9 pagesWhat Is A Thermocouple?Bisma khanNo ratings yet

- What Is A ThermocoupleDocument5 pagesWhat Is A ThermocoupleGalih A. KurniawanNo ratings yet

- What Is A ThermocoupleDocument10 pagesWhat Is A ThermocoupleKannan RamarajNo ratings yet

- RTD Theory: Platinum Thin Film RTDDocument5 pagesRTD Theory: Platinum Thin Film RTDMurali Krishna GbNo ratings yet

- CLB21103 Process Instrumentation Experiment 5: Thermocouple RTD MeasurementDocument9 pagesCLB21103 Process Instrumentation Experiment 5: Thermocouple RTD MeasurementSiti Hajar MohamedNo ratings yet

- RTD Standards: AccuracyDocument11 pagesRTD Standards: AccuracyAhmad Adel El TantawyNo ratings yet

- Types of Thermocouples:: What Is A Thermocouple?Document13 pagesTypes of Thermocouples:: What Is A Thermocouple?Mark Peter PalayanNo ratings yet

- Thermocouple PDFDocument6 pagesThermocouple PDFibrahim2129047No ratings yet

- RTDDocument4 pagesRTDCss GaneshNo ratings yet

- Resistance Temperature Detectors: Element Material Temperature Range Benefits (%/ C)Document4 pagesResistance Temperature Detectors: Element Material Temperature Range Benefits (%/ C)Harish SundarNo ratings yet

- Thermocouples: Advantages DisadvantagesDocument5 pagesThermocouples: Advantages DisadvantagesAffa YogiswaraNo ratings yet

- Metrology 150902141622 Lva1 App6892Document31 pagesMetrology 150902141622 Lva1 App6892Eng-anwer kadhimNo ratings yet

- Thermocouple PiDocument8 pagesThermocouple PiKamal JoshiNo ratings yet

- RTD Theory: So What Exactly Is An RTD?Document6 pagesRTD Theory: So What Exactly Is An RTD?ouhamidNo ratings yet

- Difference Between RTD, Thermocouple and ThermistorDocument3 pagesDifference Between RTD, Thermocouple and ThermistorVenkata Suresh MandavaNo ratings yet

- Thermocouple and RTDDocument13 pagesThermocouple and RTDrana 13022001No ratings yet

- Temperature MeasurementDocument18 pagesTemperature MeasurementKaja YusufNo ratings yet

- Comparison of Thermocouples, RTDS, and ThermistorsDocument2 pagesComparison of Thermocouples, RTDS, and ThermistorsAlwyzz Happie RaamzzNo ratings yet

- Ipc Quiz AssignDocument12 pagesIpc Quiz AssignHayyaAliNo ratings yet

- Thermocouple Wire ReportDocument16 pagesThermocouple Wire ReportshadiNo ratings yet

- Types of Thermocouples With Temperature Ranges & Color Codes - Blaze ProbesDocument1 pageTypes of Thermocouples With Temperature Ranges & Color Codes - Blaze ProbesFrank AtkinsNo ratings yet

- RTD - Theory Temperature PDFDocument6 pagesRTD - Theory Temperature PDFpandit1010No ratings yet

- Thermocouple NotesDocument5 pagesThermocouple NotesJane Marek100% (1)

- RTDvs TCDocument2 pagesRTDvs TCNarain RamNo ratings yet

- Measurement Lab.: Dr. Ahmad Al-SalaymehDocument12 pagesMeasurement Lab.: Dr. Ahmad Al-SalaymehqusayNo ratings yet

- Overview of Temperature MeasurementDocument54 pagesOverview of Temperature MeasurementGurtej SinghNo ratings yet

- ThermocouplesDocument7 pagesThermocouplesMustafa HidayetNo ratings yet

- Capgo - RTDsDocument4 pagesCapgo - RTDsdark*nightNo ratings yet

- 6Document52 pages6Virendra Kumar PareekNo ratings yet

- Instrumentation SensorsDocument145 pagesInstrumentation SensorsGulfam ShahzadNo ratings yet

- Thermocouple CalibirationDocument18 pagesThermocouple CalibirationAnonymous w6v7JWfr5100% (2)

- Thermocouple: From Wikipedia, The Free EncyclopediaDocument9 pagesThermocouple: From Wikipedia, The Free EncyclopediaKiệt Huỳnh AnhNo ratings yet

- Rtds - or Resistance Temperature Detectors - Are Temperature Sensors That Contain A Resistor ThatDocument6 pagesRtds - or Resistance Temperature Detectors - Are Temperature Sensors That Contain A Resistor Thatmuhammad aliNo ratings yet

- TermocuplasDocument10 pagesTermocuplasAnonymous i0SMnrONo ratings yet

- This Work Is Prepared By:: Jasim Mohammed MehdiDocument12 pagesThis Work Is Prepared By:: Jasim Mohammed MehdiJasim Al-rubayieNo ratings yet

- Temperature Measurement in Liquid MetalDocument16 pagesTemperature Measurement in Liquid MetalkpbaijuNo ratings yet

- W RTD: Ire WoundDocument11 pagesW RTD: Ire WoundEng-anwer kadhimNo ratings yet

- Thermocouple OverviewDocument22 pagesThermocouple OverviewAhmed RamadanNo ratings yet

- Temperature MeasurementDocument35 pagesTemperature MeasurementAlaa Shahwan88% (8)

- Resistance Thermometer: Resistance Thermometers, Also Called Resistance Temperature Detectors ('RTD'S), AreDocument10 pagesResistance Thermometer: Resistance Thermometers, Also Called Resistance Temperature Detectors ('RTD'S), AreMac Jayson DiazNo ratings yet

- What Is A Thermocouple Sensor?: View A Complete Reference TableDocument7 pagesWhat Is A Thermocouple Sensor?: View A Complete Reference Tablesankarsuper83No ratings yet

- Thermocouples Definition PDFDocument4 pagesThermocouples Definition PDFmouNo ratings yet

- R Vs T Relationship of Various Metals: SensorsDocument6 pagesR Vs T Relationship of Various Metals: SensorsAnbu AyyappanNo ratings yet

- 6.thermo CoupleDocument30 pages6.thermo CoupleEZHIL NNo ratings yet

- SensorsDocument55 pagesSensorsellyNo ratings yet

- RTD, Thermocouple, Thermistors, Manometer, Bourdon TubeDocument36 pagesRTD, Thermocouple, Thermistors, Manometer, Bourdon TubeDINESH KUMAR DRAVIDAMANI100% (1)

- Kelompok 5 - RTD & ThermocoupleDocument8 pagesKelompok 5 - RTD & Thermocoupleryan manggasaNo ratings yet

- Electroplating for Amateurs: Classic Reference for Small WorkshopsFrom EverandElectroplating for Amateurs: Classic Reference for Small WorkshopsNo ratings yet

- Soldering Electronic Components 2nd EditionFrom EverandSoldering Electronic Components 2nd EditionRating: 3 out of 5 stars3/5 (2)

- Anixter Csa Flame Tests Wire Wisdom enDocument2 pagesAnixter Csa Flame Tests Wire Wisdom enFelipe GustavoNo ratings yet

- Anixter Wire Wisdom Category Cable Industry StandardsDocument2 pagesAnixter Wire Wisdom Category Cable Industry StandardsFelipe GustavoNo ratings yet

- Tech 27Document2 pagesTech 27Felipe GustavoNo ratings yet

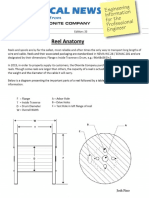

- Technical News: Reel AnatomyDocument3 pagesTechnical News: Reel AnatomyFelipe GustavoNo ratings yet

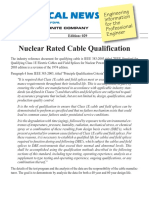

- Technical News: Nuclear Rated Cable QualificationDocument2 pagesTechnical News: Nuclear Rated Cable QualificationFelipe GustavoNo ratings yet

- Technical News: Cable Seals For Type TC/Type TC-ER CablesDocument2 pagesTechnical News: Cable Seals For Type TC/Type TC-ER CablesFelipe GustavoNo ratings yet

- Technical News: Epr Semicons A PerspectiveDocument2 pagesTechnical News: Epr Semicons A PerspectiveFelipe GustavoNo ratings yet

- Technical News: Cables Used in Intrinsically Safe CircuitsDocument1 pageTechnical News: Cables Used in Intrinsically Safe CircuitsFelipe GustavoNo ratings yet

- Technical News: Engineering Information For The Professional EngineerDocument2 pagesTechnical News: Engineering Information For The Professional EngineerFelipe GustavoNo ratings yet

- Technical News: Cables Qualified For Use in Nuclear PlantsDocument1 pageTechnical News: Cables Qualified For Use in Nuclear PlantsFelipe GustavoNo ratings yet

- Technical News: NEC 2005 Changes To Medium Voltage Nonshielded CableDocument2 pagesTechnical News: NEC 2005 Changes To Medium Voltage Nonshielded CableFelipe GustavoNo ratings yet

- Technical News: Dupont Exits Global Hypalon BusinessDocument2 pagesTechnical News: Dupont Exits Global Hypalon BusinessFelipe GustavoNo ratings yet

- Technical News: Low Smoke JacketsDocument3 pagesTechnical News: Low Smoke JacketsFelipe GustavoNo ratings yet

- Magnetic Field Theory - The Uniform Plane Wave - Notes PDFDocument57 pagesMagnetic Field Theory - The Uniform Plane Wave - Notes PDFMohammed AliNo ratings yet

- Data Sheet For Three-Phase Motors: 1LA8317-4PB90-Z MLFB-Ordering DataDocument1 pageData Sheet For Three-Phase Motors: 1LA8317-4PB90-Z MLFB-Ordering Dataatlas tajhizNo ratings yet

- Bright Solitons From Defocusing Nonlinearities in Optical and Matter-Wave MediaDocument52 pagesBright Solitons From Defocusing Nonlinearities in Optical and Matter-Wave MediaVidula PalekarNo ratings yet

- 1SDC001007D0202-sn1250sace AbbDocument128 pages1SDC001007D0202-sn1250sace AbbUmberPenza100% (1)

- Black Body Radiation (Wein Displacement)Document17 pagesBlack Body Radiation (Wein Displacement)Khushi YadavNo ratings yet

- Team P1 Design and Manufacture of A Solenoid Powered V8 EngineDocument1 pageTeam P1 Design and Manufacture of A Solenoid Powered V8 EngineYuvaraj SamuvelNo ratings yet

- COSIMAT N Plus EDocument40 pagesCOSIMAT N Plus EDmitry Selyugin0% (1)

- Airpax Stepper MotorDocument8 pagesAirpax Stepper MotorTiago GalloNo ratings yet

- Al 38/66kV: HV Cables With Longitudinal Water-Blocking SystemDocument4 pagesAl 38/66kV: HV Cables With Longitudinal Water-Blocking SystemCarlos PlaceresNo ratings yet

- Paper 2 With Solution PhysicsDocument17 pagesPaper 2 With Solution Physicsattackerasp1234No ratings yet

- Ideal and Resistive MHD: Magnetohydrodynamics (MHD) (Magnetofluiddynamics or Hydromagnetics) Is TheDocument9 pagesIdeal and Resistive MHD: Magnetohydrodynamics (MHD) (Magnetofluiddynamics or Hydromagnetics) Is ThePraveen RajkumarNo ratings yet

- Answers To Selected ProblemsDocument7 pagesAnswers To Selected ProblemsEduard BurlacuNo ratings yet

- Unit Iv Optical Detectors and ReceiversDocument27 pagesUnit Iv Optical Detectors and ReceiversPavani MandapatiNo ratings yet

- Wideband Dipoles - Fan Dipoles: Microstrip AntennasDocument13 pagesWideband Dipoles - Fan Dipoles: Microstrip AntennasclanonNo ratings yet

- Calculation of IlluminationDocument8 pagesCalculation of IlluminationEasier Said Than DoneNo ratings yet

- A Guide To High Impedance Ref CalculationsDocument13 pagesA Guide To High Impedance Ref Calculationsafm100% (1)

- Tarun Jain Physics Investigatory ProjectDocument23 pagesTarun Jain Physics Investigatory ProjectTarun JainNo ratings yet

- Lambda Export: Omnidirectional Colinear Base Station Antenna With Heavy-Duty-Fiberglass Radome For The 144-174 MHZ BandDocument1 pageLambda Export: Omnidirectional Colinear Base Station Antenna With Heavy-Duty-Fiberglass Radome For The 144-174 MHZ Bandmnolasco2010No ratings yet

- Switchgear Type SIMOPRIME A4 Up To 24 KV, Air-Insulated Tested According To IEC 62271-200Document11 pagesSwitchgear Type SIMOPRIME A4 Up To 24 KV, Air-Insulated Tested According To IEC 62271-200Yulian Dea ZollaNo ratings yet

- Phys 1011-Chapter 6Document139 pagesPhys 1011-Chapter 6YordanosNo ratings yet

- Awp Study MaterialDocument151 pagesAwp Study MaterialjeevaNo ratings yet

- Chapter 2.2 ElectrostaticsDocument15 pagesChapter 2.2 ElectrostaticsNivil MathewNo ratings yet

- Over Current ProtectionDocument22 pagesOver Current Protectionnihkinwejkb100% (1)

- Medium Voltage Submarine Cable: LS Cable & System Lights Up The World Through The SeaDocument16 pagesMedium Voltage Submarine Cable: LS Cable & System Lights Up The World Through The SeaThai AnhNo ratings yet

- Voltage Drop CalculationsDocument5 pagesVoltage Drop CalculationsAnd WebNo ratings yet

- Week 2 - Element 4: Electrical Hazards and ControlDocument33 pagesWeek 2 - Element 4: Electrical Hazards and Controlananthu.u100% (2)

- Infrared and Terahertz Detectors Rogalski Antoni Online Ebook Texxtbook Full Chapter PDFDocument69 pagesInfrared and Terahertz Detectors Rogalski Antoni Online Ebook Texxtbook Full Chapter PDFdeborah.pariente972100% (10)

- Pi734a 1250kva StamfordDocument9 pagesPi734a 1250kva Stamfordaleenmalek2024No ratings yet

Anixter Thermocouple and RTD Wire Wire Wisdom en

Anixter Thermocouple and RTD Wire Wire Wisdom en

Uploaded by

Felipe GustavoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anixter Thermocouple and RTD Wire Wire Wisdom en

Anixter Thermocouple and RTD Wire Wire Wisdom en

Uploaded by

Felipe GustavoCopyright:

Available Formats

THERMOCOUPLE AND RTD WIRE

A thermocouple is composed of two wires made from dissimilar metals. REFERENCE JUNCTIONS

These two wires are joined to form a temperature measurement junction. As noted earlier, a reference (cold) junction is also required in a

Each wire is made of a specific metal or metal alloy. For example, the thermocouple circuit. Because the voltage read by the instrumentation

positive (+) conductor of a type K thermocouple is made of a chromium/ is actually proportional to the difference in temperature between the

nickel alloy called chromel and the negative (-) conductor is made of an measuring junction and the reference junction, it is necessary to know

aluminum/nickel alloy called alumel. Wire used to make a thermocouple the temperature of the reference junction to determine the temperature

junction is called thermocouple wire. at the measuring junction. In practice, the reference junction is frequently

built into the temperature recording or process control instrumentation.

THERMOELECTRICITY As a result, the reference junction is often “invisible” to the user. The

As shown below, when the measuring (hot) junction is at a different thermocouple is connected to the extension wire and the extension

temperature than the reference (cold) junction, a voltage is produced wire is connected to the process control instrumentation.

in a thermocouple circuit due to the so-called Seebeck, or thermoelectric

effect. This effect can be thought of as a small battery whose output

voltage is proportional to the temperature of the measuring junction.

The voltage produced is in the millivolt (mV) range and is different

for each thermocouple type. This voltage is measured by electronic

equipment that converts it to a temperature reading.

MEASURING JUNCTIONS THERMOCOUPLE TYPES

There are three main types of measuring junctions. An exposed junction

Industry specifications recognize different types of thermocouples

has no protective sheath. A grounded junction has a protective metallic

and thermocouple wires with a letter designating each type. Some

sheath such as stainless steel, which encloses the conductors and

common types are K, J, T and E. Different thermocouple types have

insulation. This junction type is more physically durable and more

different temperature ranges over which they can be used successfully.

resistant to corrosion than an exposed junction. An ungrounded junction

The chemical make-up of each thermocouple alloy, the temperature

is similar to a grounded junction except the thermocouple wires do not

error limits allowed, and the color codes for each thermocouple type

connect electrically to the metallic sheath. This junction type is better

are specified in ISA/ANSI standard MC96.1. The important thing to

protected from electromagnetic interference.

remember from an application standpoint is that the thermocouple

wire type must match the thermocouple type.

THERMOCOUPLE AND RTD WIRE

EXTENSION WIRE

Thermocouple extension wire types such as KX, JX, TX and EX are used to connect the measuring junction to the temperature recording or

process control instrumentation. This can be hundreds or even thousands of feet away. Extension wire is normally exposed to temperatures

and other environmental conditions that are less extreme than those encountered by the measuring junction. As a result, “extension” grade

wire is not calibrated above 400° F (204° C) and is typically insulated and jacketed with materials with lower temperature ratings. Since

low voltage instrumentation signals are being carried thermocouple extension wire is often shielded.

RTDS

There are other temperature measurement technologies than the thermocouple such as RTDs (resistance temperature detector). In applications

with temperatures above 1,200° F (650° C) thermocouple is used. At lower temperatures RTDs are used for their simpler operation and greater

sensitivity and stability. Thermocouples have a better response time. RTDs are special resistors whose resistance value changes with temperature

in a known way. RTDs are connected to the temperature recording or process control instrumentation using ordinary copper instrumentation

cable. Thermocouple wire is not required to connect an RTD.

Typical RTD cable is standard instrumentation cable in two, three, or four conductors or possibly groups of pairs/triads/quads depending on the

type of RTD being used and number of devices being monitored. Individual or overall shielding is often used for noise immunity.

Thermocouple Extension Conductor Colors Alloys

Grade Grade

ANSI Code Jacket Color Jacket Color Positive Negative Positive Negative Temperature Range

J Brown Black White Red Iron Constantan -210° to 1,200° C / -346° to 2,193° F

Copper-Nickel

K Brown Yellow Yellow Red Nickel- Nickel-Aluminum –270° to 1,372°C / –454° to 2,501°F

Chromium

T Brown Blue Blue Red Copper Constantan –270° to 400° C / –454° to 752° F

Copper-Nickel

E Brown Purple Purple Red Nickel- Constantan –270° to 1,000° C / –454° to 1,832° F

Chromium Copper-Nickel

Table 1: Thermocouple Wire and Thermocouple Extension Wire Types

WIREwisdom

About Anixter: anixter.com/aboutus Anixter Inc. World Headquarters TM

Legal Statement: anixter.com/legalstatement 2301 Patriot Boulevard

Glenview, Illinois 60026

15F4612GL © 2015 Anixter Inc. • 03/15 224.521.8000

1.800.ANIXTER | anixter.com

Products. Technology. Services. Delivered Globally.

You might also like

- Obtaining Spectrometric Data For Object-Color EvaluationDocument9 pagesObtaining Spectrometric Data For Object-Color Evaluationavik6294846100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- Holland Shielding Catalog-2018 PDFDocument145 pagesHolland Shielding Catalog-2018 PDFdilnair99No ratings yet

- Thermocouple and RTD Wire: Reference JunctionsDocument2 pagesThermocouple and RTD Wire: Reference JunctionsFelipe GustavoNo ratings yet

- Various Temperature MeasurementsDocument3 pagesVarious Temperature MeasurementsPrincess PurnimaNo ratings yet

- Temperature SenesorDocument16 pagesTemperature SenesordskjajkdsaNo ratings yet

- What Is A ThermocoupleDocument13 pagesWhat Is A ThermocoupleMuhammad Wasiq TanveerNo ratings yet

- WP 003 Endress TemperatureDocument17 pagesWP 003 Endress Temperaturevenkatesh425No ratings yet

- Thermocouple Questions and AnswersDocument12 pagesThermocouple Questions and AnswersJêmš Navik0% (1)

- What Is A Thermocouple?Document9 pagesWhat Is A Thermocouple?Bisma khanNo ratings yet

- What Is A ThermocoupleDocument5 pagesWhat Is A ThermocoupleGalih A. KurniawanNo ratings yet

- What Is A ThermocoupleDocument10 pagesWhat Is A ThermocoupleKannan RamarajNo ratings yet

- RTD Theory: Platinum Thin Film RTDDocument5 pagesRTD Theory: Platinum Thin Film RTDMurali Krishna GbNo ratings yet

- CLB21103 Process Instrumentation Experiment 5: Thermocouple RTD MeasurementDocument9 pagesCLB21103 Process Instrumentation Experiment 5: Thermocouple RTD MeasurementSiti Hajar MohamedNo ratings yet

- RTD Standards: AccuracyDocument11 pagesRTD Standards: AccuracyAhmad Adel El TantawyNo ratings yet

- Types of Thermocouples:: What Is A Thermocouple?Document13 pagesTypes of Thermocouples:: What Is A Thermocouple?Mark Peter PalayanNo ratings yet

- Thermocouple PDFDocument6 pagesThermocouple PDFibrahim2129047No ratings yet

- RTDDocument4 pagesRTDCss GaneshNo ratings yet

- Resistance Temperature Detectors: Element Material Temperature Range Benefits (%/ C)Document4 pagesResistance Temperature Detectors: Element Material Temperature Range Benefits (%/ C)Harish SundarNo ratings yet

- Thermocouples: Advantages DisadvantagesDocument5 pagesThermocouples: Advantages DisadvantagesAffa YogiswaraNo ratings yet

- Metrology 150902141622 Lva1 App6892Document31 pagesMetrology 150902141622 Lva1 App6892Eng-anwer kadhimNo ratings yet

- Thermocouple PiDocument8 pagesThermocouple PiKamal JoshiNo ratings yet

- RTD Theory: So What Exactly Is An RTD?Document6 pagesRTD Theory: So What Exactly Is An RTD?ouhamidNo ratings yet

- Difference Between RTD, Thermocouple and ThermistorDocument3 pagesDifference Between RTD, Thermocouple and ThermistorVenkata Suresh MandavaNo ratings yet

- Thermocouple and RTDDocument13 pagesThermocouple and RTDrana 13022001No ratings yet

- Temperature MeasurementDocument18 pagesTemperature MeasurementKaja YusufNo ratings yet

- Comparison of Thermocouples, RTDS, and ThermistorsDocument2 pagesComparison of Thermocouples, RTDS, and ThermistorsAlwyzz Happie RaamzzNo ratings yet

- Ipc Quiz AssignDocument12 pagesIpc Quiz AssignHayyaAliNo ratings yet

- Thermocouple Wire ReportDocument16 pagesThermocouple Wire ReportshadiNo ratings yet

- Types of Thermocouples With Temperature Ranges & Color Codes - Blaze ProbesDocument1 pageTypes of Thermocouples With Temperature Ranges & Color Codes - Blaze ProbesFrank AtkinsNo ratings yet

- RTD - Theory Temperature PDFDocument6 pagesRTD - Theory Temperature PDFpandit1010No ratings yet

- Thermocouple NotesDocument5 pagesThermocouple NotesJane Marek100% (1)

- RTDvs TCDocument2 pagesRTDvs TCNarain RamNo ratings yet

- Measurement Lab.: Dr. Ahmad Al-SalaymehDocument12 pagesMeasurement Lab.: Dr. Ahmad Al-SalaymehqusayNo ratings yet

- Overview of Temperature MeasurementDocument54 pagesOverview of Temperature MeasurementGurtej SinghNo ratings yet

- ThermocouplesDocument7 pagesThermocouplesMustafa HidayetNo ratings yet

- Capgo - RTDsDocument4 pagesCapgo - RTDsdark*nightNo ratings yet

- 6Document52 pages6Virendra Kumar PareekNo ratings yet

- Instrumentation SensorsDocument145 pagesInstrumentation SensorsGulfam ShahzadNo ratings yet

- Thermocouple CalibirationDocument18 pagesThermocouple CalibirationAnonymous w6v7JWfr5100% (2)

- Thermocouple: From Wikipedia, The Free EncyclopediaDocument9 pagesThermocouple: From Wikipedia, The Free EncyclopediaKiệt Huỳnh AnhNo ratings yet

- Rtds - or Resistance Temperature Detectors - Are Temperature Sensors That Contain A Resistor ThatDocument6 pagesRtds - or Resistance Temperature Detectors - Are Temperature Sensors That Contain A Resistor Thatmuhammad aliNo ratings yet

- TermocuplasDocument10 pagesTermocuplasAnonymous i0SMnrONo ratings yet

- This Work Is Prepared By:: Jasim Mohammed MehdiDocument12 pagesThis Work Is Prepared By:: Jasim Mohammed MehdiJasim Al-rubayieNo ratings yet

- Temperature Measurement in Liquid MetalDocument16 pagesTemperature Measurement in Liquid MetalkpbaijuNo ratings yet

- W RTD: Ire WoundDocument11 pagesW RTD: Ire WoundEng-anwer kadhimNo ratings yet

- Thermocouple OverviewDocument22 pagesThermocouple OverviewAhmed RamadanNo ratings yet

- Temperature MeasurementDocument35 pagesTemperature MeasurementAlaa Shahwan88% (8)

- Resistance Thermometer: Resistance Thermometers, Also Called Resistance Temperature Detectors ('RTD'S), AreDocument10 pagesResistance Thermometer: Resistance Thermometers, Also Called Resistance Temperature Detectors ('RTD'S), AreMac Jayson DiazNo ratings yet

- What Is A Thermocouple Sensor?: View A Complete Reference TableDocument7 pagesWhat Is A Thermocouple Sensor?: View A Complete Reference Tablesankarsuper83No ratings yet

- Thermocouples Definition PDFDocument4 pagesThermocouples Definition PDFmouNo ratings yet

- R Vs T Relationship of Various Metals: SensorsDocument6 pagesR Vs T Relationship of Various Metals: SensorsAnbu AyyappanNo ratings yet

- 6.thermo CoupleDocument30 pages6.thermo CoupleEZHIL NNo ratings yet

- SensorsDocument55 pagesSensorsellyNo ratings yet

- RTD, Thermocouple, Thermistors, Manometer, Bourdon TubeDocument36 pagesRTD, Thermocouple, Thermistors, Manometer, Bourdon TubeDINESH KUMAR DRAVIDAMANI100% (1)

- Kelompok 5 - RTD & ThermocoupleDocument8 pagesKelompok 5 - RTD & Thermocoupleryan manggasaNo ratings yet

- Electroplating for Amateurs: Classic Reference for Small WorkshopsFrom EverandElectroplating for Amateurs: Classic Reference for Small WorkshopsNo ratings yet

- Soldering Electronic Components 2nd EditionFrom EverandSoldering Electronic Components 2nd EditionRating: 3 out of 5 stars3/5 (2)

- Anixter Csa Flame Tests Wire Wisdom enDocument2 pagesAnixter Csa Flame Tests Wire Wisdom enFelipe GustavoNo ratings yet

- Anixter Wire Wisdom Category Cable Industry StandardsDocument2 pagesAnixter Wire Wisdom Category Cable Industry StandardsFelipe GustavoNo ratings yet

- Tech 27Document2 pagesTech 27Felipe GustavoNo ratings yet

- Technical News: Reel AnatomyDocument3 pagesTechnical News: Reel AnatomyFelipe GustavoNo ratings yet

- Technical News: Nuclear Rated Cable QualificationDocument2 pagesTechnical News: Nuclear Rated Cable QualificationFelipe GustavoNo ratings yet

- Technical News: Cable Seals For Type TC/Type TC-ER CablesDocument2 pagesTechnical News: Cable Seals For Type TC/Type TC-ER CablesFelipe GustavoNo ratings yet

- Technical News: Epr Semicons A PerspectiveDocument2 pagesTechnical News: Epr Semicons A PerspectiveFelipe GustavoNo ratings yet

- Technical News: Cables Used in Intrinsically Safe CircuitsDocument1 pageTechnical News: Cables Used in Intrinsically Safe CircuitsFelipe GustavoNo ratings yet

- Technical News: Engineering Information For The Professional EngineerDocument2 pagesTechnical News: Engineering Information For The Professional EngineerFelipe GustavoNo ratings yet

- Technical News: Cables Qualified For Use in Nuclear PlantsDocument1 pageTechnical News: Cables Qualified For Use in Nuclear PlantsFelipe GustavoNo ratings yet

- Technical News: NEC 2005 Changes To Medium Voltage Nonshielded CableDocument2 pagesTechnical News: NEC 2005 Changes To Medium Voltage Nonshielded CableFelipe GustavoNo ratings yet

- Technical News: Dupont Exits Global Hypalon BusinessDocument2 pagesTechnical News: Dupont Exits Global Hypalon BusinessFelipe GustavoNo ratings yet

- Technical News: Low Smoke JacketsDocument3 pagesTechnical News: Low Smoke JacketsFelipe GustavoNo ratings yet

- Magnetic Field Theory - The Uniform Plane Wave - Notes PDFDocument57 pagesMagnetic Field Theory - The Uniform Plane Wave - Notes PDFMohammed AliNo ratings yet

- Data Sheet For Three-Phase Motors: 1LA8317-4PB90-Z MLFB-Ordering DataDocument1 pageData Sheet For Three-Phase Motors: 1LA8317-4PB90-Z MLFB-Ordering Dataatlas tajhizNo ratings yet

- Bright Solitons From Defocusing Nonlinearities in Optical and Matter-Wave MediaDocument52 pagesBright Solitons From Defocusing Nonlinearities in Optical and Matter-Wave MediaVidula PalekarNo ratings yet

- 1SDC001007D0202-sn1250sace AbbDocument128 pages1SDC001007D0202-sn1250sace AbbUmberPenza100% (1)

- Black Body Radiation (Wein Displacement)Document17 pagesBlack Body Radiation (Wein Displacement)Khushi YadavNo ratings yet

- Team P1 Design and Manufacture of A Solenoid Powered V8 EngineDocument1 pageTeam P1 Design and Manufacture of A Solenoid Powered V8 EngineYuvaraj SamuvelNo ratings yet

- COSIMAT N Plus EDocument40 pagesCOSIMAT N Plus EDmitry Selyugin0% (1)

- Airpax Stepper MotorDocument8 pagesAirpax Stepper MotorTiago GalloNo ratings yet

- Al 38/66kV: HV Cables With Longitudinal Water-Blocking SystemDocument4 pagesAl 38/66kV: HV Cables With Longitudinal Water-Blocking SystemCarlos PlaceresNo ratings yet

- Paper 2 With Solution PhysicsDocument17 pagesPaper 2 With Solution Physicsattackerasp1234No ratings yet

- Ideal and Resistive MHD: Magnetohydrodynamics (MHD) (Magnetofluiddynamics or Hydromagnetics) Is TheDocument9 pagesIdeal and Resistive MHD: Magnetohydrodynamics (MHD) (Magnetofluiddynamics or Hydromagnetics) Is ThePraveen RajkumarNo ratings yet

- Answers To Selected ProblemsDocument7 pagesAnswers To Selected ProblemsEduard BurlacuNo ratings yet

- Unit Iv Optical Detectors and ReceiversDocument27 pagesUnit Iv Optical Detectors and ReceiversPavani MandapatiNo ratings yet

- Wideband Dipoles - Fan Dipoles: Microstrip AntennasDocument13 pagesWideband Dipoles - Fan Dipoles: Microstrip AntennasclanonNo ratings yet

- Calculation of IlluminationDocument8 pagesCalculation of IlluminationEasier Said Than DoneNo ratings yet

- A Guide To High Impedance Ref CalculationsDocument13 pagesA Guide To High Impedance Ref Calculationsafm100% (1)

- Tarun Jain Physics Investigatory ProjectDocument23 pagesTarun Jain Physics Investigatory ProjectTarun JainNo ratings yet

- Lambda Export: Omnidirectional Colinear Base Station Antenna With Heavy-Duty-Fiberglass Radome For The 144-174 MHZ BandDocument1 pageLambda Export: Omnidirectional Colinear Base Station Antenna With Heavy-Duty-Fiberglass Radome For The 144-174 MHZ Bandmnolasco2010No ratings yet

- Switchgear Type SIMOPRIME A4 Up To 24 KV, Air-Insulated Tested According To IEC 62271-200Document11 pagesSwitchgear Type SIMOPRIME A4 Up To 24 KV, Air-Insulated Tested According To IEC 62271-200Yulian Dea ZollaNo ratings yet

- Phys 1011-Chapter 6Document139 pagesPhys 1011-Chapter 6YordanosNo ratings yet

- Awp Study MaterialDocument151 pagesAwp Study MaterialjeevaNo ratings yet

- Chapter 2.2 ElectrostaticsDocument15 pagesChapter 2.2 ElectrostaticsNivil MathewNo ratings yet

- Over Current ProtectionDocument22 pagesOver Current Protectionnihkinwejkb100% (1)

- Medium Voltage Submarine Cable: LS Cable & System Lights Up The World Through The SeaDocument16 pagesMedium Voltage Submarine Cable: LS Cable & System Lights Up The World Through The SeaThai AnhNo ratings yet

- Voltage Drop CalculationsDocument5 pagesVoltage Drop CalculationsAnd WebNo ratings yet

- Week 2 - Element 4: Electrical Hazards and ControlDocument33 pagesWeek 2 - Element 4: Electrical Hazards and Controlananthu.u100% (2)

- Infrared and Terahertz Detectors Rogalski Antoni Online Ebook Texxtbook Full Chapter PDFDocument69 pagesInfrared and Terahertz Detectors Rogalski Antoni Online Ebook Texxtbook Full Chapter PDFdeborah.pariente972100% (10)

- Pi734a 1250kva StamfordDocument9 pagesPi734a 1250kva Stamfordaleenmalek2024No ratings yet