Professional Documents

Culture Documents

Why Is Granulation Necessary

Why Is Granulation Necessary

Uploaded by

RainMan75Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Why Is Granulation Necessary

Why Is Granulation Necessary

Uploaded by

RainMan75Copyright:

Available Formats

Why is Granulation Necessary?

The granulation process allows particles to stick together more firmly. It

increases the particle size of the constituents used, which are mostly very

fine powders. The greater the particle size of a constituent, greater will be its

compressive or binding ability.

Granulation process for tablet manufacturing process is mainly of two types:

1. Wet Granulation

2. Dry Granulation

1. Wet Granulation

In wet granulation technique, the following steps are involved:

Sifting: Active Pharmaceutical Ingredient (API) and excipients are sifted,

usually through a 40 mass or 60 mass sieve. When API and excipients are

sifted they mix together.

Mixing: In order to mix them up more thoroughly, the dry mixing process is

utilized. Once the mixing is complete, granulating fluid is added to rapid

mixture granulator or RMG.

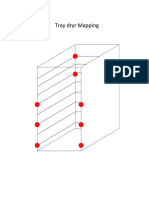

Drying: The materials are then dried in a dryer, usually a fluid bed dryer or

a tray dryer. When the constituents have dried, they are then milled using 16

mass or 20 mass sieves.

Lubrication: The final step is lubrication in order to make the particles

adhere firmly together. This is done with the addition of a lubricating agent.

The use of lubricating agents is particular to the types of API and excipients

used. The most commonly used lubricating agent is magnesium stearate. The

material formed is thus ready for further compression and manufacturing.

2. Dry Granulation

Dry granulation does not involve the use of a liquid lubricating agent. This is

because constituents utilized might chemically react with the agent used, thus dry

granulation equipment technique is used.

Dispensing: The first step in dry granulation is dispensing of the API and

excipients used, in specified amounts.

Dry Mixing or Blending: Once both the constituents are dispensed, API and

intragranular excipients are mixed together through dry mixing.

Compaction: After dry mixing of the materials, they are passed through roller

powder compactors for compaction. This results in the formation of slugs. Slugs

are the rough form of tablets, usually quite large in size.

You might also like

- SOP For Airflow Velocity and Uniformity TestDocument3 pagesSOP For Airflow Velocity and Uniformity TestRainMan75100% (2)

- SOP For Room Particle Count TestDocument3 pagesSOP For Room Particle Count TestRainMan75100% (1)

- Sop of Cleaning and Operation of Dispensing BoothDocument3 pagesSop of Cleaning and Operation of Dispensing BoothRainMan7575% (4)

- Granulation إyu 2017Document31 pagesGranulation إyu 2017Alaa AlzoubiNo ratings yet

- GranulationDocument32 pagesGranulationSantosh Payghan100% (1)

- AssignmentDocument12 pagesAssignmentAbdul Wahid OrakzaiNo ratings yet

- GranulationDocument6 pagesGranulationMansoor KhanNo ratings yet

- Tablet Manufacture 1Document23 pagesTablet Manufacture 1Afzal AslamNo ratings yet

- Tablet Manufacturing: Industrial Pharmacy 5 Class 1 SemesterDocument23 pagesTablet Manufacturing: Industrial Pharmacy 5 Class 1 SemesterShirzad HasanNo ratings yet

- GranulationDocument47 pagesGranulationMuhtashim RifatNo ratings yet

- Industrial AssignmentDocument5 pagesIndustrial AssignmentM NoumanNo ratings yet

- Tablet Manufacturing, Storage DefectsDocument52 pagesTablet Manufacturing, Storage Defectsphd0780No ratings yet

- Industrial Training Report PDFDocument63 pagesIndustrial Training Report PDFVandana SinghNo ratings yet

- Acfrogbzaohyqwh2pmqy Xc5r2bryynto10vnidopagron0 Bg0vhtsd Ks-Bvwwfj3oqwq6wdeencuabhgun4in7kf2qbtmebsvxuazxwt5ohrr1cjvownd1ru5ssmhtvkj28qwf475dcyp4joDocument96 pagesAcfrogbzaohyqwh2pmqy Xc5r2bryynto10vnidopagron0 Bg0vhtsd Ks-Bvwwfj3oqwq6wdeencuabhgun4in7kf2qbtmebsvxuazxwt5ohrr1cjvownd1ru5ssmhtvkj28qwf475dcyp4joatik bappiNo ratings yet

- Lecture 5 GRANULATION PT 506Document45 pagesLecture 5 GRANULATION PT 506ahmed sharafNo ratings yet

- Granulation For HerbalDocument35 pagesGranulation For Herbal0921pyNo ratings yet

- Granules AssignmentDocument15 pagesGranules AssignmentKarnati PraveenaNo ratings yet

- Dosage Form PPT 6 Tablet MFGTRNGDocument24 pagesDosage Form PPT 6 Tablet MFGTRNGShumaila QadirNo ratings yet

- The Art and Science of Granulation PresentationDocument39 pagesThe Art and Science of Granulation PresentationumarNo ratings yet

- TABLET Manufacturing MethodsDocument13 pagesTABLET Manufacturing MethodsDarshan Singh Budwal75% (4)

- Wet Granulation Process: Solvent (E.g. Ethanol, Isopropanol)Document4 pagesWet Granulation Process: Solvent (E.g. Ethanol, Isopropanol)armstrongvinodrajNo ratings yet

- Industrial Training ReportDocument43 pagesIndustrial Training ReportApurba Sarker Apu80% (10)

- Compressionand Compaction - TabletsDocument23 pagesCompressionand Compaction - TabletsEmmaNo ratings yet

- Method of Preparation of Tabletdry GranulationDocument11 pagesMethod of Preparation of Tabletdry GranulationChristopher LunaNo ratings yet

- SurbhiDocument21 pagesSurbhiKashish MahajanNo ratings yet

- GranulationDocument37 pagesGranulationMuhammad Ali RizviNo ratings yet

- Granulation: Ideal Characteristics of GranulesDocument8 pagesGranulation: Ideal Characteristics of GranulesDr_Asma86100% (1)

- What Is TABLETDocument39 pagesWhat Is TABLETmuizmahmoodNo ratings yet

- Tabletting HandoutsDocument117 pagesTabletting Handoutsrazansayyahin03No ratings yet

- Granulation ProcessDocument17 pagesGranulation ProcessSyed Waqas HaiderNo ratings yet

- My Presentation at Incepta Pharmaceuticals in Bangladesh 1655409400Document54 pagesMy Presentation at Incepta Pharmaceuticals in Bangladesh 1655409400Roberto AlmodovarNo ratings yet

- Tablet and Capsule ManufacturingDocument28 pagesTablet and Capsule ManufacturingShibaprasad DandapatNo ratings yet

- Tablet Technology StepsDocument9 pagesTablet Technology StepsVikas JhawatNo ratings yet

- Bi 5 55 PDFDocument9 pagesBi 5 55 PDFKarine Jéssica SantanaNo ratings yet

- Acknowledgement: Industrial Training FileDocument24 pagesAcknowledgement: Industrial Training FileGaurav Prabhakar100% (1)

- Novel Granulation Techniques ERUMDocument7 pagesNovel Granulation Techniques ERUMErum JanNo ratings yet

- Granulation in Tablet Manufacturing 1657552942Document43 pagesGranulation in Tablet Manufacturing 1657552942Roberto AlmodovarNo ratings yet

- Particle Size EnlargementDocument8 pagesParticle Size EnlargementZaid Bin GhaziNo ratings yet

- Granulation Techniques 70100219Document6 pagesGranulation Techniques 70100219Taffazzul ShaukatNo ratings yet

- Recent Advances in Granulation Techniques: January 2014Document11 pagesRecent Advances in Granulation Techniques: January 2014Hà Thanh TúNo ratings yet

- EXP9Document4 pagesEXP9supss2411No ratings yet

- Ranulation I: Rahul Singour Formulation & DevelopmentDocument33 pagesRanulation I: Rahul Singour Formulation & DevelopmentBayu Maulida NaryoNo ratings yet

- MCQs Pharmaceutics 2-2Document2 pagesMCQs Pharmaceutics 2-2www.muhammad181No ratings yet

- GranulationDocument16 pagesGranulationalishba aliNo ratings yet

- Granulation 1Document16 pagesGranulation 1kelvin ambazaNo ratings yet

- Activity 7 GranulationDocument18 pagesActivity 7 GranulationIvy Rose OrozcoNo ratings yet

- Tablet ManufacturingDocument88 pagesTablet ManufacturingStikes SambasNo ratings yet

- ManufacturingDocument45 pagesManufacturingMasum ParvesNo ratings yet

- Unit Operations in Secondary ManufacturingDocument11 pagesUnit Operations in Secondary ManufacturingJoyce Marian BelonguelNo ratings yet

- Unit Operations in Tablet Manufacturing MainDocument13 pagesUnit Operations in Tablet Manufacturing MainMd. Neyamat UllahNo ratings yet

- Manufacturing of Tablets-PART-IIDocument12 pagesManufacturing of Tablets-PART-IIbalamuruganNo ratings yet

- Spheronizer and Marumerisiers and Other Special Is Ed Granulation andDocument56 pagesSpheronizer and Marumerisiers and Other Special Is Ed Granulation andNitu JhaNo ratings yet

- Dry Granulation: - Powder Is Squeezed Between Two Rollers To Produce Sheet of MaterialDocument5 pagesDry Granulation: - Powder Is Squeezed Between Two Rollers To Produce Sheet of MaterialLuong AnhNo ratings yet

- Granulation Process Basic UnderstandingDocument3 pagesGranulation Process Basic UnderstandingRainMan75No ratings yet

- Web Site You Tube What App Telegram Face Book E-Mail Page - 1Document27 pagesWeb Site You Tube What App Telegram Face Book E-Mail Page - 1Divyank GhadageNo ratings yet

- Dry GranulationDocument17 pagesDry GranulationMd.Motaleb HossenNo ratings yet

- Granulation TechniqueDocument6 pagesGranulation TechniqueSrijonNo ratings yet

- Department of Pharmacy: Pharma-Technology AssignmentDocument12 pagesDepartment of Pharmacy: Pharma-Technology AssignmentMian Waqar MunawarNo ratings yet

- Kekurangan GranulDocument10 pagesKekurangan GranulFADHIL AGUNG NUGRAHANo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- SOP On Transferring Finished Products To Finished Goods StoresDocument3 pagesSOP On Transferring Finished Products To Finished Goods StoresRainMan7567% (3)

- Try DryerDocument2 pagesTry DryerRainMan75No ratings yet

- SOP On Operating Procedure For Conveyor BeltDocument2 pagesSOP On Operating Procedure For Conveyor BeltRainMan75No ratings yet

- SOP For Disintegration Test ApparatusDocument4 pagesSOP For Disintegration Test ApparatusRainMan75No ratings yet

- PW Specification USPDocument2 pagesPW Specification USPRainMan75No ratings yet

- Types of Lubricants Used For Phrmaceutical MachinesDocument2 pagesTypes of Lubricants Used For Phrmaceutical MachinesRainMan75No ratings yet

- Sampling Procedure by ISO KineticDocument2 pagesSampling Procedure by ISO KineticRainMan75No ratings yet

- Line Clearance Procedure at Pharma ManufacturingDocument3 pagesLine Clearance Procedure at Pharma ManufacturingRainMan75No ratings yet

- Laminar Air Flow SpecificationDocument2 pagesLaminar Air Flow SpecificationRainMan75No ratings yet

- SOP For Installed Filter Leakage TestDocument2 pagesSOP For Installed Filter Leakage TestRainMan75100% (1)

- Aseptic and Sterile in PharmaceuticalDocument2 pagesAseptic and Sterile in PharmaceuticalRainMan75No ratings yet

- Sop of Operating Procedure For Operation and Cleaning of Insect Killer EquipmentDocument2 pagesSop of Operating Procedure For Operation and Cleaning of Insect Killer EquipmentRainMan75100% (1)

- Sop of Operation & Cleaning of Distillation AssemblyDocument2 pagesSop of Operation & Cleaning of Distillation AssemblyRainMan75No ratings yet

- Training SOP Part - 3Document4 pagesTraining SOP Part - 3RainMan75No ratings yet

- SOP OF Operating and Cleaning Procedure For Vacuum CleanerDocument2 pagesSOP OF Operating and Cleaning Procedure For Vacuum CleanerRainMan75No ratings yet

- Sop of Operation and Cleaning of Mechanical StirrerDocument3 pagesSop of Operation and Cleaning of Mechanical StirrerRainMan75100% (1)

- Training SOP Part - 2Document3 pagesTraining SOP Part - 2RainMan75No ratings yet

- Procedure For Planned Internal Quality Audits in PharmaDocument5 pagesProcedure For Planned Internal Quality Audits in PharmaRainMan75No ratings yet

- Training SOP Part - 1Document4 pagesTraining SOP Part - 1RainMan75No ratings yet

- SOP On Storage and Labeling of Raw and Packing MaterialsDocument2 pagesSOP On Storage and Labeling of Raw and Packing MaterialsRainMan75No ratings yet

- Entry Exit Procedure SOPDocument4 pagesEntry Exit Procedure SOPRainMan75100% (1)

- CAPA Corrective and Preventive Action in PharmaceuticalDocument5 pagesCAPA Corrective and Preventive Action in PharmaceuticalRainMan75No ratings yet

- Good Weighing in Pharma - 3Document4 pagesGood Weighing in Pharma - 3RainMan75No ratings yet

- Good Weighing in Pharma - 5Document4 pagesGood Weighing in Pharma - 5RainMan75No ratings yet

- Good Weighing in Pharma - 4Document6 pagesGood Weighing in Pharma - 4RainMan75No ratings yet

- Good Weighing in Pharma - 2Document3 pagesGood Weighing in Pharma - 2RainMan75No ratings yet

- SOP For Hot Air Oven Cleaning, Operation & Calibration of Hot Air OvenDocument3 pagesSOP For Hot Air Oven Cleaning, Operation & Calibration of Hot Air OvenRainMan75100% (1)