Professional Documents

Culture Documents

Effects of Growth Interruption of ZnO Buffer Layers On The Structural and

Effects of Growth Interruption of ZnO Buffer Layers On The Structural and

Uploaded by

Sara MAROUFOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effects of Growth Interruption of ZnO Buffer Layers On The Structural and

Effects of Growth Interruption of ZnO Buffer Layers On The Structural and

Uploaded by

Sara MAROUFCopyright:

Available Formats

Journal of the Korean Physical Society, Vol. 56, No. 6, June 2010, pp.

1833∼1837

Effects of Growth Interruption of ZnO Buffer Layers on the Structural and

the Optical Properties of ZnO Thin Films Grown by Using PA-MBE

Min Young Cho, Min Su Kim, Hyun Young Choi, Su Min Jeon,

Ghun Sik Kim, Do Yeob Kim, Kwang Gug Yim and Jae-Young Leem∗

Department of Nano Systems Engineering, Center for Nano Manufacturing, Inje University, Gimhae 621-749

Dong-Yul Lee

Epi-manufacturing Technology, Samsung LED Co., Ltd., Suwon 443-373

Jin Soo Kim

Division of Advanced Materials Engineering, Chonbuk National University, Jeonju 561-756

Jong Su Kim

Department of Physics, Yeungnam University, Gyeongsan 712-749

Joo In Lee

Advanced Instrument Technology Center, Korea Research Institute of Standards and Science, Daejeon 305-340

(Received 31 March 2010, in final form 27 April 2010)

ZnO thin films with ZnO buffer layers were grown on Si substrates by using plasma-assisted

molecular beam epitaxy (PA-MBE). The ZnO buffer layers were grown with the growth interrup-

tion technique. The structural and the optical properties of the ZnO thin films were investigated by

using X-ray diffraction (XRD), field-emission scanning electron microscopy (FE-SEM), and photo-

luminescence (PL). The surface morphology of the ZnO thin films was changed from an island to a

net-like shape. An evident net-like shape was observed, and the optical properties were enhanced

with increasing number of growth interruptions.

PACS numbers: 73.61.Ga, 81.15.Hi, 68.55.Jk

Keywords: Zinc oxide, Molecular beam epitaxy, Interruption, X-ray diffraction, Field-emission scanning

electron microscopy, Photoluminescence

DOI: 10.3938/jkps.56.1833

I. INTRODUCTION It is also well-known that an interruption in the MBE

growth can significantly modify the surface or interface

of the heterostructure [12]. Further, in quantum dots

ZnO is an n-type semiconductor with a hexagonal (QDs), the size and optical properties of the QDs are af-

wurtzite structure and a large exciton binding energy fected by growth interruption [13]. The ability to control

of 60 meV, which is 2.4 times that of GaN [1]. ZnO has the surface morphology of nanocrystals is an important

been studied extensively for its potential use in various objective in their growth as size and shape can influence

applications, such as gas sensors [2], solar cells [3], pho- various properties [14].

todetectors [4], and light emitting diodes [5]. ZnO lay- Nanometer-scale semiconductors have attracted atten-

ers can be prepared by using various techniques such as tion because they exhibit curious structures and vari-

sputtering [6], pulsed laser deposition (PLD) [7], metal- ous remarkable physical, chemical, and electrical prop-

organic chemical vapor deposition (MOCVD) [8], the sol- erties distinctive from those of conventional bulk mate-

gel method [9], and molecular beam epitaxy (MBE) [10]. rials [15,16]. ZnO can be formed into specific nanostruc-

Among the above-mentioned methods, MBE has the ad- tures such as nanowires [17], nanorods [18], nanoparti-

vantage of being able to facilitate atomic layer control cles [19], nanobelts [20], and nanotetrapods [21]. There

during film growth under ultra-high vacuum (UHV) [11]. have been reports of ZnO morphology control of hun-

dreds of nanometer to micron-sized particles [22], and

∗ E-mail: jyleem@inje.ac.kr; Fax: +82-55-320-3631

researchers have reported the elongation of particles into

-1833-

-1834- Journal of the Korean Physical Society, Vol. 56, No. 6, June 2010

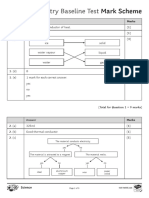

Fig. 2. X-ray diffraction patterns of the ZnO films as a

function of the number of growth interruptions.

Fig. 1. Zn cell shutter ON/OFF interruption cycle for all

the samples. layers were grown with a conventional growth technique,

which resulted in an uninterrupted growth for 14 min

(sample A). In the second step, a growth interruption

rods at high precursor concentrations [23]. However, a technique was used. The growth interruption technique

simple, generic, synthetic method that is morphologically was a combination of conventional MBE and migration

tunable at the tens of nanometer scale has not been de- enhanced epitaxy. It consists of a sequence of ON/OFF

veloped yet [24-26]. cycles of the Zn beams while the O2 plasma is kept con-

In this study, the ZnO thin films were grown on ZnO stant during the buffer layer growth. The Zn cell shutter

buffer layers by using plasma-assisted molecular beam ON/OFF interruption cycle is shown in Fig. 1. The Zn

epitaxy (PA-MBE). The buffer layers were grown on Si beam ON time of 18 s (sample B), 12 s (sample C), or

substrates using a two-step process with growth inter- 9 s (sample D) was followed by a Zn beam OFF time of

ruption technique in an oxygen plasma. The effects of 10 s. The cycle was repeated 20 (sample B), 30 (sample

growth interruption on the surface morphology and the C), or 40 times (sample D), respectively. The ZnO thin

optical properties of the ZnO thin films were investigated films were grown at a substrate temperature of 600 ◦ C.

by using X-ray diffraction (XRD), field-emission scan-

ning electron microscopy (FE-SEM), and photolumines-

cence (PL) measurements.

III. RESULTS AND DISCUSSION

Figure 2 shows the θ - 2θ XRD spectra of samples A, B,

II. EXPERIMENTAL PROCEDURE

C, and D. The diffraction peaks of ZnO (002) and ZnO

(004) are seen in all the samples. This indicates that

ZnO thin films with ZnO buffer layers were grown on all the ZnO thin films were crystallized with a wurtzite

p-type Si (100) substrates by using a growth interrup- structure; the preferred orientation axis was the c-axis.

tion technique with a PA-MBE system equipped with The c-axis orientation is common in ZnO thin films be-

a Zn effusion cell and an O2 plasma cell. Elemental cause the (001) basal plane of ZnO has the lowest surface

zinc with 99.9999% purity was used as the precursor. energy [27,28]. Consistent with this theory, all samples

Oxygen radicals were produced from ultra-high-purity in our experiments exhibited the preferred orientation of

O2 gas by using a radio frequency (RF). The Si sub- (001), inferred from the observed (002) reflections in the

strates were cleaned in a piranha solution (H2 SO4 :H2 O2 XRD spectra. The full width at half maximum (FWHM)

= 8:1) at 110 ◦ C for 15 min and then hydrofluoric acid of ZnO (002) decreased from 0.24◦ to 0.21◦ , indicating

(HF 50%:H2 O = 1:9) for 5 min. The Si substrates were enhancement in the crystal quality of the ZnO thin films

thermally cleaned at a substrate temperature of 300 ◦ C with increasing number of growth interruptions .

for 10 min in a load-lock chamber. Then, the substrates Figure 3(a) shows the (002) peak positions of samples

were inserted into an UHV working chamber and an- A, B, C, and D as a function of the number of growth

nealed at 850 ◦ C for 60 min. The initial Zn layers with interruptions. Since the peak position of the ZnO pow-

a thickness of 120 Å were grown at a temperature of 350 der with a (002) orientation was at 2θ = 34.43◦ [29], the

◦

C to prevent the oxidation of the Si substrates by the shifts of the (002) peaks of the samples indicate the exis-

O2 plasma source. The ZnO buffer layers were grown us- tence of residual stress [30]. The c-axis strain (εzz ) values

ing a two-step process. In the first step, the ZnO buffer were calculated using the following equation:

Effects of Growth Interruption of ZnO Buffer Layers on the Structural and the Optical · · · – Min Young Cho et al. -1835-

Fig. 4. FE-SEM images of samples A, B, C, and D.

growth temperature, the gas pressure, the RF power, and

Fig. 3. (a) Peak position and (b) stress of the ZnO thin the gas mixtures, can contribute to the intrinsic stress.

films as functions of the number of growth interruptions. In the normal growth of ZnO film, the intrinsic stress

of the as-grown ZnO films has been shown to be com-

pressive [36–38]. During the growth process, the magni-

tude of the compressive stress component is larger than

that of the thermal (tensile) stress component; there-

c − c0

εzz (%) = × 100. (1) fore, the as-grown ZnO films exhibits an overall com-

c0 pressive residual stress. In the case of ZnO films grown

The lattice constant c was calculated using Bragg’s on interrupted buffer layers, the stress of the ZnO thin

law on the basis of the XRD results: 2dsinθ = λ; co films changed from compressive to tensile as shown in

(5.2066 Å) was the unstrained lattice parameter of ZnO Fig. 3(b) because the lattice constant of the samples de-

[31]. The strain of samples A, B, C, and D were 0.206, creased. Compared to the unstrained lattice parameter

-0.319, -0.318, and -0.279, respectively. The biaxial films of ZnO (5.2066 Å), the larger value of the lattice con-

stress σ is related to the measured c-axis strain as follows stant in sample A (5.2173 Å) indicated that the unit cell

[32]: was elongated along the c-axis and that the compressive

forces were acting in the plane of the films [39,40]. How-

ever, in samples B to D, the lattice constant decreased

2c213 − c33 (c11 + c12 ) c − c0 to around 5.19 Å.

σ= × , (2) Figure 4 shows FE-SEM images of the ZnO thin films.

2c13 c0

The surface morphology of sample A was island shaped,

where cij are the elastic stiffness constants for single- and samples B, C, and D had a net-like shape. In par-

crystal ZnO (C11 = 208.8 GPa, C33 = 213.8 GPa, C12 ticular, an evident net-like shape was observed at the

= 119.7 GPa, and C13 = 104.2 GPa) [33]. The stresses surfaces of samples C and D, which indicates that the

of samples A, B, C, and D were -0.479, 0.743, 0.740, and net-like shape becomes clearer with increasing number

0.649 GPa, respectively. The stress in the ZnO films con- of growth interruptions. The net-like shape was first

tains a thermal component and an intrinsic component. observed by Wei et al. under nanorods grown on AlN

If the stress is positive, the biaxial stress is tensile; if buffer layers by using MOCVD [41]. They reported that

the stress is negative, the biaxial stress is compressive the ZnO net-like films under the nanorods had tensile

[34]. The thermal stresses are a result of the differences in-plane strains because the AlN film were oxidated by

in the thermal expansion coefficients between the ZnO the O2 at the interface due to the bond of Al-O being

films and the Si substrates. The thermal expansion co- stronger than that of Al-N [42]. The buffer layers grown

efficient of ZnO (4.75 × 10−6 K−1 ) [35] is larger than with the interruption had abundant oxygen on the sur-

that of silicon (2.6 × 10−6 K−1 ) [35], resulting in a ten- face because the growth interruption was performed in

sile lateral stress in the ZnO film due to the cooling af- the oxygen plasma. The ZnO net-like films were grown

ter the growth. On the other hand, the intrinsic stress on abundant oxygen surfaces because ZnO could eas-

has its origin in the imperfections of the crystallites dur- ily grow on an O surface, but not on a N surface [42].

ing the growth. Several growth parameters, such as the Although the formation mechanism of the ZnO net-like

-1836- Journal of the Korean Physical Society, Vol. 56, No. 6, June 2010

IV. CONCLUSIONS

ZnO thin films were prepared with ZnO buffer layers

on Si substrates by using PA-MBE. The ZnO buffer lay-

ers were grown by using a two-step growth process with

a variation of 20 - 40 times in the number of growth in-

terruptions. A change in the surface morphology of the

ZnO thin films from an island shape to a net-like shape

was observed with increasing number of growth inter-

ruptions. The FWHM of the ZnO (002) diffraction peak

decreased and the intensity of the NBE emission of the

PL spectra increased with increasing number of growth

interruptions. Control of the surface morphology, as well

as an enhancement of the luminescence properties, was

achieved using the growth interruption technique in PA-

MBE.

Fig. 5. PL spectra of the ZnO thin films as a function of

the number of growth interruptions.

ACKNOWLEDGMENTS

This research was supported by Basic Science Research

Program Through the National Research Foundation of

films is still not known, it is obvious that ZnO net-like Korea (NRF) funded by the Ministry of Education, Sci-

films are related to the oxidation or oxygen states of the ence and Technology (No. 2010-0016147)

buffer layers. A net-like shape could be useful for ZnO

applications such as gas sensors because the increase in

the effective surface area could be attributed to an in- REFERENCES

crease in gas-adsorption quantities [43].

In order to investigate the optical properties of the

[1] Y. Zhang, G. Du, X. Yang, B. Zhao, Y. Ma, T. Yang,

ZnO thin films, we carried out PL measurement at room

H. C. Ong, D. Liu and S. Yang, Semicond. Sci. Technol.

temperature by using a He-Cd laser with an excitation 19, 755 (2004).

power of 30 mW and a 1-m single-grating monochroma- [2] A. M. Gaskov and M. N. Rumyantseva, Russ. J. Appl.

tor with a photomultiplier tube. The PL spectra of the Chem. 74, 440 (2001).

ZnO thin films are shown in Fig. 5. The PL spectra [3] U. Rau and M. Schmidt, Thin Solid Films 387, 141

showed sharp near band edge (NBE) emissions, which (2001).

were generated by the free-exciton recombination at 380 [4] J. P. Kar, S. N. Das, J. H. Choi, Y. A. Lee, T. Y. Lee

nm, and the intensity of NBE emissions increased with and J. M. Myoung, J. Cryst. Growth 311, 3305 (2009).

increasing number of growth interruptions. The broad [5] T. Soki, Y. Hatanaka and D. C. Look, Appl. Phys. Lett.

deep level emission (DLE), which was caused by impu- 76, 3257 (2000).

rities and structural defects, was blue-shifted from 646 [6] Y. Zhang, G. Du, D. Liu, X. Wang, Y. Ma, J. Wang,

J. Yin, X. Yang, X. Hou and S. Yang, J. Cryst. Growth

(orange emission) to 568 nm (green emission) with in-

243, 439 (2002).

creasing number of growth interruptions. In general, the [7] J. L. Zhao, X. M. Li, J. M. Bian, W. D. Yu and X. D.

origin of the DLE is considered to be caused by an oxygen Gao, J. Cryst. Growth 276, 507 (2005).

vacancy (VO ), a zinc vacancy (VZn ), an oxygen atom at [8] Y. Zhang, G. Du, B. Zhang, Y. Cui, H. Zhu and Y.

the zinc position in the crystal lattice (OZn ), a zinc atom Chang, Semicond. Sci. Technol. 20, 1132 (2005).

at the oxygen position in the crystal lattice (ZnO ), an in- [9] S. Mandal, M. L. N. Goswami, K. Das, A. Dhar and S.

terstitial oxygen (Oi ), and an interstitial zinc (Zni ). The K. Ray, Thin Solid Films 516, 8702 (2008).

orange emission is due to Zni , and the green emission is [10] M. S. Kim et al., J. Cryst. Growth 311, 3568 (2009).

associated with OZn [44]. Zni is easily formed in ZnO [11] M. S. Kim et al., J. Korean Phys. Soc. 56, 827 (2010).

grown by using conventional growth techniques because [12] X. D. Luo, Z. Y. Xu, Y. Q. Wang, W. X. Wang, J. N.

the radius of the zinc atom is much smaller than that Wang and W. K. Ge, J. Cryst. Growth 247, 99 (2003).

[13] J. S Kim, C. J. Yang, U. Sim, J. Y. Lee, E. J. Yoon and

of oxygen [45]. An increased number of oxygen atoms Y. S. Lee, Thin Solid Films 517, 3963 (2009).

were absorbed into the ZnO buffer layers because of the [14] C. Lieber, Solid State Commun. 107, 607 (1998).

growth interruption in the oxygen plasma. This suggests [15] A. P. Alivisatos, Science 271, 933 (1996).

that the green emission is closely related to the abundant [16] R. C. Ashoori, Nature 379, 413 (1996).

oxygen in the buffer layer. The details of the mechanism [17] S. C. Lyu, Y. Zhang, C. J. Lee, H. Ruh and H. J. Lee,

for green emission are still a subject of controversy. Chem. Mater. 15, 3294 (2003).

Effects of Growth Interruption of ZnO Buffer Layers on the Structural and the Optical · · · – Min Young Cho et al. -1837-

[18] M. Yin, Y. Gu, I. Kuskovsky, T. Andelman, Y. Zhu, G. [32] R. Hong, J. Huang, H. He, Z. Fan and J. Shao, Appl.

F. Neumark and S. J. O’Brien, J. Am. Chem. Soc. 126, Surf. Sci. 242, 346 (2005).

6206 (2004). [33] C. Wang, P. Zhang, J. Yue, Y. Zhang and L. Zheng,

[19] P. Cozzoli, M. Curri, A. Agostiano, G. Leo and M. Lo- Physica B 403, 2235 (2008).

mascolo, J. Phys. Chem. B 107, 4756 (2003). [34] C. Li, X. C. Li, P. X. Yan, E. M. Chong, Y. Liu, G. H.

[20] Z. Pan, Z. R. Dai and Z. L. Wang, Science 291, 1947 Yue and X. Y. Fan, Appl. Surf. Sci. 253, 4000 (2007).

(2001). [35] L. Wang, Y. Pu, Y. F. Chen, C. L. Mo, W. Q. Fang, C.

[21] Z. Chen, Z. Shan, M. Cao, L. Lu and S. Mao, Nanotech- B. Xiong, J. N. Dai and F. Y. Jiang, J. Cryst. Growth

nology 15, 365 (2004). 284, 459 (2005).

[22] J. Zhang, L. Sun, J. Yin, H. Su, C. Liao and C. Yan, [36] Z. B. Fang, Z. J. Yan, Y. S. Tan, X. Q. Liu and Y. Y.

Chem. Mater. 14, 4172 (2002). Wang, Appl. Surf. Sci. 241, 303 (2005).

[23] L. Guo, S. Yang, C. Yang, P. Yu, J. Wang, W. Ge and [37] M. Wang, J. Wang, W. Chen, Y. Cui and L. Wang,

G. Wong, Chem. Mater. 12, 2268 (2000). Mater. Chem. Phys. 97, 219 (2006).

[24] J. Zhang, L. Sun, X. Jiang, C. Liao and C. Yan, Cryst. [38] A. Cimpoiasu, N. M. van der Pers, Th. H. de Keyser, A.

Growth Des. 4, 309 (2004). Venema and M. J. Vellekoop, Smart Mater. Struct. 5,

[25] L. Wang and M. Muhammed, J. Mater. Chem. 9, 2871 744 (1996).

(1999). [39] M. K. Puchert, P. Y. Timbrell and R. N. Lamb, J. Vac.

[26] H. Yan, R. He, J. Pham and P. Yang, Adv. Mater. 15, Sci. Technol. A 14, 2220 (1996).

402 (2003). [40] V. Gupta and A. Mansingh, J. Appl. Phys. 80, 1063

[27] V. Vaithianathan, S. Hishita, J. Y. Park and S. S. Kim, (1996).

J. Appl. Phys. 102, 086107 (2007). [41] H. Y. Wei et al, J. Cryst. Growth 306, 12 (2007).

[28] S. P. Changa, S. J. Changa, Y. Z. Chioub, C. Y. Lua, T. [42] X. Q. Wang, Y. Tomita, O.-H. Roh, M. Ohsugi, S-B.

K. Lina, C. F. Kuoa, H. M. Changa and U. H. Liawc, J. Che, Y. Ishitani and A. Yoshikawa, Appl. Phys. Lett.

Cryst. Growth 310, 290 (2008). 86, 011921 (2005).

[29] A. Miyake, H. Kominami, H. Tatsuoka, H. Kuwabara, [43] L. Bie, X. Yan, J. Yin, Y. Duan and Z. Yuan, Sens.

Y. Nakanishi and Y. Hatanaka, J. Cryst. Growth 214, Actuators B 126, 604 (2007).

294 (2000). [44] W. Zhaoyang and H. Lizhong, Vacuum 83, 906 (2009).

[30] Z. B. Fang, Z. J. Yan, Y. S. Tan, X. Q. Liu and Y. Y. [45] X. Pengshou, S. Yuming, S. Chaoshu, X. Faqiang and P.

Wang, Appl. Surf. Sci. 241, 303 (2005). Haibin, Sci. China, Ser. A Math. 44, 1174 (2001).

[31] H. C. Ong, A. X. E. Zhu and G. T. Du, Appl. Phys. Lett.

80, 941 (2002).

You might also like

- Maximum Levels of Nitrogen Trichloride in Liquid ChlorineDocument35 pagesMaximum Levels of Nitrogen Trichloride in Liquid ChlorineKimberly Conley100% (1)

- Gold Standard MCAT General Chemistry Review: StoichiometryDocument12 pagesGold Standard MCAT General Chemistry Review: StoichiometryMaxine Taeyeon100% (2)

- Growth ZnODocument3 pagesGrowth ZnOdanaaaa007No ratings yet

- Study of Structural and Optical Properties of Zinc Oxide Rods Grown On Glasses by Chemical Spray PyrolysisDocument8 pagesStudy of Structural and Optical Properties of Zinc Oxide Rods Grown On Glasses by Chemical Spray PyrolysismanisjcNo ratings yet

- Yusof2020 Merged OrganizedDocument9 pagesYusof2020 Merged Organized069 Sharathkumar V G EENo ratings yet

- Structural and Optical Characterization of Cu DopeDocument5 pagesStructural and Optical Characterization of Cu DopeSyahrul MuchlisNo ratings yet

- Macromolecular SympposiaDocument4 pagesMacromolecular Sympposiasunny1288No ratings yet

- Chemosensors 09 00005 v2Document13 pagesChemosensors 09 00005 v2Tanvir KaurNo ratings yet

- Superlattices and MicrostructuresDocument11 pagesSuperlattices and MicrostructuresBenzarti NejiNo ratings yet

- Zno NanorodsDocument5 pagesZno NanorodsmirelamanteamirelaNo ratings yet

- Meziane - Et - Al - ApplPhysA2017 - Li Concentration Dependence of Structural Properties and Optical PDFDocument6 pagesMeziane - Et - Al - ApplPhysA2017 - Li Concentration Dependence of Structural Properties and Optical PDFNektaria LouiseNo ratings yet

- A Review of The Impact of Zinc Oxide NanostructureDocument19 pagesA Review of The Impact of Zinc Oxide NanostructurekhouloudNo ratings yet

- Selective Mocvd Growth of Zno NanotipsDocument5 pagesSelective Mocvd Growth of Zno NanotipsShri44222No ratings yet

- Sol Gel Spin Coated Zno Thin Films For Biosensing ApplicationsDocument3 pagesSol Gel Spin Coated Zno Thin Films For Biosensing ApplicationserpublicationNo ratings yet

- Highly Oriented 1-D Zno Nanorod Arrays On Zinc Foil: Direct Growth From Substrate, Optical Properties and Photocatalytic ActivitiesDocument5 pagesHighly Oriented 1-D Zno Nanorod Arrays On Zinc Foil: Direct Growth From Substrate, Optical Properties and Photocatalytic ActivitiesAleandra Rasyid AzuraNo ratings yet

- 2005 LinDocument4 pages2005 LinRodolfo Angulo OlaisNo ratings yet

- Synthesis and Characterization of Znonano-Rods at Different TemperatureDocument6 pagesSynthesis and Characterization of Znonano-Rods at Different TemperatureInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Zno Thin Films Prepared by A Single Step Sol - Gel Process: Shane O'Brien, L.H.K. Koh, Gabriel M. CreanDocument5 pagesZno Thin Films Prepared by A Single Step Sol - Gel Process: Shane O'Brien, L.H.K. Koh, Gabriel M. Creanumut bayNo ratings yet

- Metals 10 00437Document10 pagesMetals 10 00437069 Sharathkumar V G EENo ratings yet

- Synthesis, Structure, Vapour Pressure and Deposition of ZnO Thin FilmDocument9 pagesSynthesis, Structure, Vapour Pressure and Deposition of ZnO Thin Filmkadhim1985No ratings yet

- Vertical Growth of Zno Nanowires On C-Al O Substrate by Controlling Ramping Rate in A Vapor-Phase Epitaxy MethodDocument5 pagesVertical Growth of Zno Nanowires On C-Al O Substrate by Controlling Ramping Rate in A Vapor-Phase Epitaxy MethodRaj PrakashNo ratings yet

- Thesis Zinc Oxide Thin FilmsDocument8 pagesThesis Zinc Oxide Thin FilmsKatie Robinson100% (2)

- Heliyon: Md. Irfan Khan, Tasratur Reaj Neha, Md. Muktadir BillahDocument8 pagesHeliyon: Md. Irfan Khan, Tasratur Reaj Neha, Md. Muktadir BillahMurtaza SieamNo ratings yet

- Spectral Investigations of Chemical Bath Deposited Zinc Oxide Thin Films - Ammonia Gas SensorDocument9 pagesSpectral Investigations of Chemical Bath Deposited Zinc Oxide Thin Films - Ammonia Gas SensorAditya GannamarajuNo ratings yet

- IOSR JournalsDocument6 pagesIOSR JournalsInternational Organization of Scientific Research (IOSR)No ratings yet

- Arif Wahya Handoko - The Crystalline Structure, Conductivity and Optical Properties of Co-Doped ZnO Thin FilmsDocument5 pagesArif Wahya Handoko - The Crystalline Structure, Conductivity and Optical Properties of Co-Doped ZnO Thin FilmsGutama Ade WardanaNo ratings yet

- 5 - Photo-Response of Functionalized Self-Assembled Graphene Oxide On Znic Oxide Hetrostructure To UV IlluminationDocument8 pages5 - Photo-Response of Functionalized Self-Assembled Graphene Oxide On Znic Oxide Hetrostructure To UV IlluminationEid ElsayedNo ratings yet

- Henni 2015Document6 pagesHenni 2015Abdelmalek TAYEBINo ratings yet

- Effect of ZnO2 NanowireDocument4 pagesEffect of ZnO2 NanowireSalsabila NurjihanNo ratings yet

- Synthesis of Zinc Oxide Nanoparticles VIDocument10 pagesSynthesis of Zinc Oxide Nanoparticles VIHarden PatilNo ratings yet

- Optical Materials: S. Anandan, S. MuthukumaranDocument9 pagesOptical Materials: S. Anandan, S. MuthukumaranUstym MostovyjNo ratings yet

- 10 1016@j Ceramint 2019 05 060 PDFDocument25 pages10 1016@j Ceramint 2019 05 060 PDFAshis MannaNo ratings yet

- Visible Emission From Zno Nanorods Synthesized by A Simple Wet Chemical MethodDocument10 pagesVisible Emission From Zno Nanorods Synthesized by A Simple Wet Chemical MethodKenn SenadosNo ratings yet

- 1-D ZnO Nano Structures and Application To ETA-Solar CellsDocument4 pages1-D ZnO Nano Structures and Application To ETA-Solar CellsTôn Vương NguyễnNo ratings yet

- Microwave Assisted Synthesis of Zno Nano-Sheets and Their Application in Uv-DetectorDocument4 pagesMicrowave Assisted Synthesis of Zno Nano-Sheets and Their Application in Uv-DetectorqeqwrwersrdfsdfNo ratings yet

- Solvothermal Synthesis and Photocatalytic Properties of ZnO Micro/nanostructures2019Document19 pagesSolvothermal Synthesis and Photocatalytic Properties of ZnO Micro/nanostructures2019karina CruzNo ratings yet

- Structural, Morphological, Photo-Properties of Hetrojunction Zno Nanostructure Films Deposited On N-Si (100) by PLDDocument12 pagesStructural, Morphological, Photo-Properties of Hetrojunction Zno Nanostructure Films Deposited On N-Si (100) by PLDInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- ZnMgO by Sol-Gel Thin Films PDFDocument9 pagesZnMgO by Sol-Gel Thin Films PDFMorari VadimNo ratings yet

- Thesis On Doped ZnoDocument6 pagesThesis On Doped Znoameliarichardsonsouthbend100% (1)

- Microwave-Assisted Hydrothermal Synthesis of ZnO Rod-Assembled Microspheres and Their Photocatalytic PerformancesDocument5 pagesMicrowave-Assisted Hydrothermal Synthesis of ZnO Rod-Assembled Microspheres and Their Photocatalytic Performanceskarina CruzNo ratings yet

- Hong 2009Document7 pagesHong 2009Saniaputri WulandariNo ratings yet

- ZnO NanoparticlesDocument36 pagesZnO Nanoparticlesadharsh27100% (1)

- Zno-Mg Nanoparticles Produced by Pulsed Laser Ablation in Liquid (Plal) TechniqueDocument9 pagesZno-Mg Nanoparticles Produced by Pulsed Laser Ablation in Liquid (Plal) TechniqueAleandra Rasyid AzuraNo ratings yet

- Effect of ZN Concentration On Structural and Optical Proprieties of Zno Thin Films Deposited by Spray PyrolysisDocument14 pagesEffect of ZN Concentration On Structural and Optical Proprieties of Zno Thin Films Deposited by Spray Pyrolysisjournalaeij100% (1)

- M K Gupta Integrated Ferro (2010)Document7 pagesM K Gupta Integrated Ferro (2010)Tarun YadavNo ratings yet

- Synthesis, Optical and Electrochemical Properties of Zno Nanowires/Graphene Oxide HeterostructuresDocument6 pagesSynthesis, Optical and Electrochemical Properties of Zno Nanowires/Graphene Oxide HeterostructuresAbdul Karim KhanNo ratings yet

- Properties of Thin Films: TeammatesDocument8 pagesProperties of Thin Films: TeammatesSuhil IrshadNo ratings yet

- Phsv01i02p0115 PDFDocument6 pagesPhsv01i02p0115 PDFphysicsjournalNo ratings yet

- Hierarchically Structured Zno Film For Dye-Sensitized Solar Cells With Enhanced Energy Conversion EfficiencyDocument5 pagesHierarchically Structured Zno Film For Dye-Sensitized Solar Cells With Enhanced Energy Conversion EfficiencyVivian AnggraeniNo ratings yet

- Sonochemical and Microwave-Assisted Synthesis of Linked Single-Crystalline Zno RodsDocument6 pagesSonochemical and Microwave-Assisted Synthesis of Linked Single-Crystalline Zno RodssecateNo ratings yet

- Determination of Optical Constants and Thickness of Nanostructured Zno Film by Spin Coating TechniqueDocument8 pagesDetermination of Optical Constants and Thickness of Nanostructured Zno Film by Spin Coating TechniqueDeym GómezNo ratings yet

- Applied Surface Science: K.M. Wu, Y. Pan, C. LiuDocument5 pagesApplied Surface Science: K.M. Wu, Y. Pan, C. LiuBillieNo ratings yet

- Synthesis of ZnO Nanospheres With Uniform Nanopores by A Hydrothermal ProcessDocument6 pagesSynthesis of ZnO Nanospheres With Uniform Nanopores by A Hydrothermal ProcessSekhar BabuNo ratings yet

- Buffer1 s2.0 S0272884213003519 Main PDFDocument7 pagesBuffer1 s2.0 S0272884213003519 Main PDFeid elsayedNo ratings yet

- High-Performance Hole-Extraction Layer of Sol-Gel-Processed NiO Nanocrystals For Inverted Planar Perovskite Solar CellsDocument5 pagesHigh-Performance Hole-Extraction Layer of Sol-Gel-Processed NiO Nanocrystals For Inverted Planar Perovskite Solar CellsHuckkey HuNo ratings yet

- Synthesis and Characterization of Co Doped ZnO Thin Film by Sol-Gel Dip Coating MethodDocument10 pagesSynthesis and Characterization of Co Doped ZnO Thin Film by Sol-Gel Dip Coating MethodIJRASETPublicationsNo ratings yet

- The Electrical and Physical Characteristics of MGDocument12 pagesThe Electrical and Physical Characteristics of MGpraveen.hNo ratings yet

- Thesis On Zno NanostructuresDocument8 pagesThesis On Zno Nanostructuresxgkeiiygg100% (2)

- Growth of Zno Nanorods On Gan Using Aqueous Solution MethodDocument4 pagesGrowth of Zno Nanorods On Gan Using Aqueous Solution MethoddancercelNo ratings yet

- Optik: Azeddine Chelouche, Tahar Touam, Djamel Djouadi, Ali AksasDocument4 pagesOptik: Azeddine Chelouche, Tahar Touam, Djamel Djouadi, Ali AksasyuyunworoNo ratings yet

- Surface Plasmon Enhanced, Coupled and Controlled FluorescenceFrom EverandSurface Plasmon Enhanced, Coupled and Controlled FluorescenceNo ratings yet

- Influence of Drying Conditions On The Optical and Structural Properties of Sol-Gel-Derived ZnO Nanocrystalline FilmsDocument11 pagesInfluence of Drying Conditions On The Optical and Structural Properties of Sol-Gel-Derived ZnO Nanocrystalline FilmsSara MAROUFNo ratings yet

- Zno SarsourDocument4 pagesZno SarsourSara MAROUFNo ratings yet

- Growth of Zinc Oxide NanostructuresDocument6 pagesGrowth of Zinc Oxide NanostructuresSara MAROUFNo ratings yet

- A Study of Annealing Time Effects On The Properties ofDocument5 pagesA Study of Annealing Time Effects On The Properties ofSara MAROUFNo ratings yet

- A Novel Approach To Use ZnO Thin Film As A SwitchingDocument4 pagesA Novel Approach To Use ZnO Thin Film As A SwitchingSara MAROUFNo ratings yet

- Amorphous and Nanocrystalline SrTiO, Thin FilmsDocument5 pagesAmorphous and Nanocrystalline SrTiO, Thin FilmsSara MAROUFNo ratings yet

- P&ID LAP 5 Rev 4Document2 pagesP&ID LAP 5 Rev 4Muhammad Taufiq Ikram 1807124818No ratings yet

- CSEC Chemistry - Structure and BondingDocument10 pagesCSEC Chemistry - Structure and BondingCornflakes ToastedNo ratings yet

- MolproDocument591 pagesMolproKalakkan KollamNo ratings yet

- 8 Absorber DesignDocument16 pages8 Absorber DesignilhamriswandaaNo ratings yet

- Structure of Chemical Compounds. Methods of Analysis and Process ControlDocument5 pagesStructure of Chemical Compounds. Methods of Analysis and Process Controlronahaniifah11No ratings yet

- KS3 Chemistry Baseline Test - Mark SchemeDocument5 pagesKS3 Chemistry Baseline Test - Mark Schemefadua barakatNo ratings yet

- ORIENT ProductsDocument1 pageORIENT ProductsSindhi DigiLitNo ratings yet

- How To Properly Size A Steam TrapDocument4 pagesHow To Properly Size A Steam TrapJessicalba Lou100% (2)

- SuspensionsDocument31 pagesSuspensionsAyu MooriNo ratings yet

- Adnan Aljarallah 1988 Kinetic of MTBE Over AmberlystDocument6 pagesAdnan Aljarallah 1988 Kinetic of MTBE Over AmberlystJason NunezNo ratings yet

- UV-Vis Application - Quantitative Analysis Using Second-Order Derivative Spectrum No A349Document2 pagesUV-Vis Application - Quantitative Analysis Using Second-Order Derivative Spectrum No A349Ramon Trinidad De la ONo ratings yet

- Ch1 IntroductionDocument39 pagesCh1 IntroductionRishintiran GovindarajanNo ratings yet

- Thermodynamic Representation of Phase Equilibria of Mixed-Solvent Electrolyte SystemsDocument10 pagesThermodynamic Representation of Phase Equilibria of Mixed-Solvent Electrolyte SystemsAlejandro Duvan Lopez RojasNo ratings yet

- HMT Question Bank-1Document10 pagesHMT Question Bank-1parasuramanNo ratings yet

- 95 Sigma Profile Database 2006Document27 pages95 Sigma Profile Database 2006NafferNo ratings yet

- SAS Science Class 10Document111 pagesSAS Science Class 10Shivam MauryaNo ratings yet

- Properties of EVM Compounds in Relation To The Vinyl Acetate Content of The PolymerDocument10 pagesProperties of EVM Compounds in Relation To The Vinyl Acetate Content of The PolymerabiliovieiraNo ratings yet

- 3 - Electron Microscope Specimen Prepearation Tehcnique in Materials Science - K C Thompson Russell - J W EdingtonDocument122 pages3 - Electron Microscope Specimen Prepearation Tehcnique in Materials Science - K C Thompson Russell - J W EdingtonAdil ShaikNo ratings yet

- 1 PCCC3 3C NielsenDocument17 pages1 PCCC3 3C NielsenchemengNo ratings yet

- Coal AnalysisDocument7 pagesCoal AnalysisManigandan ChinnasamyNo ratings yet

- 8 Types of Chemical Reactions and Balancing EquationsDocument2 pages8 Types of Chemical Reactions and Balancing Equationssummer07No ratings yet

- Water Conveyance With Syphons: September, 2000 (Rev 2009)Document19 pagesWater Conveyance With Syphons: September, 2000 (Rev 2009)Sameer ShrivastavaNo ratings yet

- Sulfur Trioxide and OleumDocument21 pagesSulfur Trioxide and OleumEduardo Magallon100% (1)

- CS095 Membrane ElectrolyzerDocument13 pagesCS095 Membrane ElectrolyzerJuan Diego Arbelaez AlzateNo ratings yet

- Selecting The Right Insulation Material PDFDocument6 pagesSelecting The Right Insulation Material PDFShahab Z AhmedNo ratings yet

- Reviewing The Operation of Gold ElectrowDocument35 pagesReviewing The Operation of Gold ElectrowAnonymous FfIxH2o9100% (1)

- DiffusionDocument2 pagesDiffusionKrishna Kumar MishraNo ratings yet

- Salt Analysis 1Document2 pagesSalt Analysis 1sowndharya.abigailNo ratings yet