Professional Documents

Culture Documents

Soy Milk Yoghurt

Soy Milk Yoghurt

Uploaded by

SruthyCopyright:

Available Formats

You might also like

- Production of YoghurtDocument63 pagesProduction of YoghurtIbe Collins100% (4)

- Intensive Kitchen Training Manual (IKTM): INTENSIVE KITCHEN TRAINING MANUALFrom EverandIntensive Kitchen Training Manual (IKTM): INTENSIVE KITCHEN TRAINING MANUALRating: 5 out of 5 stars5/5 (1)

- For Hino: Tics Pump Electrical Part Resistance Value ListDocument35 pagesFor Hino: Tics Pump Electrical Part Resistance Value Listfersky90% (10)

- Soy Milk Yoghurt: Biotechnol. & Biotechnol. Eq. 19/2005/1Document3 pagesSoy Milk Yoghurt: Biotechnol. & Biotechnol. Eq. 19/2005/1Jen SapinNo ratings yet

- SJPM 1242 49Document8 pagesSJPM 1242 49Richard ObinnaNo ratings yet

- Yogurt 3Document3 pagesYogurt 3th laNo ratings yet

- Production of Soy-Yoghurt by Fermentation of Soymilk With Lactobacillus Isolated From NunuDocument5 pagesProduction of Soy-Yoghurt by Fermentation of Soymilk With Lactobacillus Isolated From NunuInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Physical Properties of YogurtDocument7 pagesPhysical Properties of YogurtDrMandeep Singh SibianNo ratings yet

- Pakistan J. Agric. Res., Vol. 3, No. 2, 1982Document4 pagesPakistan J. Agric. Res., Vol. 3, No. 2, 1982sharenNo ratings yet

- Hilal Cla 2016Document5 pagesHilal Cla 2016Anonymous zIj5DCCANo ratings yet

- Preparation of Ice Cream Type Frozen YogurtDocument7 pagesPreparation of Ice Cream Type Frozen YogurtIceBearNo ratings yet

- Production and Quality Evaluation of Imitation Yoghurt From Blends of Cow Milk and Cashewnut Milk Anacadium OcidentaleDocument7 pagesProduction and Quality Evaluation of Imitation Yoghurt From Blends of Cow Milk and Cashewnut Milk Anacadium OcidentaleIJARP PublicationsNo ratings yet

- Starter Cultures For Production of Yoghurt From Sheep'S Milk With Extended Shelf LifeDocument3 pagesStarter Cultures For Production of Yoghurt From Sheep'S Milk With Extended Shelf LifeM Zenal AbidinNo ratings yet

- Chemistry ProjectDocument9 pagesChemistry Projectmaakashdeep90% (10)

- Production and Quality Evaluation of Soy Milk Yoghurt.: October 2019Document8 pagesProduction and Quality Evaluation of Soy Milk Yoghurt.: October 2019giangNo ratings yet

- Promotion of Coconut in The Production of Yoghurt: Short CommunicationDocument3 pagesPromotion of Coconut in The Production of Yoghurt: Short CommunicationNayeli MelendrezNo ratings yet

- Yoghurt Production From Powdered Milk Using Mixed Lactic Acid Bacteria Starter CulturesDocument9 pagesYoghurt Production From Powdered Milk Using Mixed Lactic Acid Bacteria Starter CulturesSHEILLA DATORNo ratings yet

- PDFDocument3 pagesPDFStefania DavidNo ratings yet

- Production of Yoghurts From Cow and Soy Composite Milk Using Starter Cultures From Different SourcesDocument7 pagesProduction of Yoghurts From Cow and Soy Composite Milk Using Starter Cultures From Different Sourcesdaisialaba722No ratings yet

- Production of Hard Tofu From Calcium Fortifi Ed Soybean Milk and Its Chemical and Sensory PropertiesDocument9 pagesProduction of Hard Tofu From Calcium Fortifi Ed Soybean Milk and Its Chemical and Sensory PropertiesusbauraNo ratings yet

- Characteristics of Soy Corn YogurtDocument4 pagesCharacteristics of Soy Corn YogurtJhon CastañoNo ratings yet

- Evaluation of The Rheological, Textural, Microstructural andDocument11 pagesEvaluation of The Rheological, Textural, Microstructural andJorge RamirezNo ratings yet

- Chemistry Project Preparation of SoyabeaDocument6 pagesChemistry Project Preparation of SoyabeaCherish BinnyNo ratings yet

- Chemistry Project: Preparation of Soyabean Milk & Its Comparison With Natural MilkDocument6 pagesChemistry Project: Preparation of Soyabean Milk & Its Comparison With Natural MilkKrishna SahuNo ratings yet

- Chemistry Project Preparation of SoyabeaDocument6 pagesChemistry Project Preparation of SoyabeaPrietesh PatilNo ratings yet

- Đặc Điểm Và Thời Hạn Sử Dụng Của Sữa Chua Sữa NgôDocument18 pagesĐặc Điểm Và Thời Hạn Sử Dụng Của Sữa Chua Sữa NgôĐoanNo ratings yet

- Does Lactic Fermentation Influence Soy Yogurt Protein Digestibility A Comperative Study Between Soymilk and Soy Yoghurt at Different PHDocument33 pagesDoes Lactic Fermentation Influence Soy Yogurt Protein Digestibility A Comperative Study Between Soymilk and Soy Yoghurt at Different PHNabilaNo ratings yet

- Dairy Tech TestDocument13 pagesDairy Tech TestMitchelle ChikakaNo ratings yet

- Ayib, AdugnaDocument22 pagesAyib, AdugnaAmbi Bekele ZewdieNo ratings yet

- Chemistry ProjectDocument10 pagesChemistry ProjectAbhey Gupta100% (3)

- Characteristics and Shelf-Life of Corn Milk YogurtDocument18 pagesCharacteristics and Shelf-Life of Corn Milk YogurtegavirganaNo ratings yet

- Effect of Micro Fluid Ization of Heat-Treated Milk On Rheology and Sensory Properties of Reduced Fat YoghurtDocument7 pagesEffect of Micro Fluid Ization of Heat-Treated Milk On Rheology and Sensory Properties of Reduced Fat YoghurtCostaEdvaldoNo ratings yet

- Chemistry ProjectDocument12 pagesChemistry ProjectAmit Kumar50% (2)

- Standardization Parameters For Production of Tofu Using WSD-Y-1 MachineDocument6 pagesStandardization Parameters For Production of Tofu Using WSD-Y-1 MachineAdjengIkaWulandariNo ratings yet

- 7 FreezDrying PDFDocument5 pages7 FreezDrying PDFIJEAB JournalNo ratings yet

- Be Hare 2016Document7 pagesBe Hare 2016RheinNo ratings yet

- Probiotic Cheese Production Using Lactobacillus Casei Cells Immobilized On Fruit PiecesDocument13 pagesProbiotic Cheese Production Using Lactobacillus Casei Cells Immobilized On Fruit PiecesĐức TrầnNo ratings yet

- Foods: Storage Stability of Texture and Sensory Properties of Yogurt With The Addition of Polymerized Whey ProteinsDocument9 pagesFoods: Storage Stability of Texture and Sensory Properties of Yogurt With The Addition of Polymerized Whey ProteinsLiz Pilar Saravia HuaringaNo ratings yet

- Jurnal BiotekDocument6 pagesJurnal BiotekAdry ShevchenkoNo ratings yet

- Making Soy Cheese With Combination StarterDocument3 pagesMaking Soy Cheese With Combination StarterFery HaidirNo ratings yet

- Evaluasi Perbedaan Varietas Kacang Kedelai Terhadap Mutu Produk Susu KedelaiDocument7 pagesEvaluasi Perbedaan Varietas Kacang Kedelai Terhadap Mutu Produk Susu KedelaiHilda NurfitrianaNo ratings yet

- Chemistry ProjectDocument12 pagesChemistry ProjectprakyathNo ratings yet

- Utilization of Labneh Whey Lactose Hydrolyzed Syrup in Baking and ConfectioneryDocument8 pagesUtilization of Labneh Whey Lactose Hydrolyzed Syrup in Baking and ConfectioneryDollyNo ratings yet

- TAPI 08 MilkpowderandyoghurtDocument5 pagesTAPI 08 MilkpowderandyoghurtNguyen Minh TrongNo ratings yet

- Preparation of Soymilk Using Different Methods: Journal of Food and Nutrition SciencesDocument7 pagesPreparation of Soymilk Using Different Methods: Journal of Food and Nutrition SciencesTaha RahmanNo ratings yet

- Soy Milk: Nutrition and Health InformationDocument8 pagesSoy Milk: Nutrition and Health InformationRahul JadhavNo ratings yet

- 2010 Set Type Yoghurt Production by Exopolysaccharide Producing TurkishDocument6 pages2010 Set Type Yoghurt Production by Exopolysaccharide Producing TurkishТаро и Астрология с Anatoly KartNo ratings yet

- Kle International 6Document8 pagesKle International 6yashubohra38No ratings yet

- 5107 Production of Soy Cheese From Vegetable Protein Using Different CoagulantsDocument5 pages5107 Production of Soy Cheese From Vegetable Protein Using Different Coagulantsmizanabaynew19No ratings yet

- Assessment of The Nutritional Profile of Variable Graded Levels of Julie Mango Fruit Juice Flavoured Yoghurt and Plain YoghurtDocument7 pagesAssessment of The Nutritional Profile of Variable Graded Levels of Julie Mango Fruit Juice Flavoured Yoghurt and Plain YoghurtInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Zhihong Qiao 2010Document16 pagesZhihong Qiao 2010nlddoan Nguyễn Thị Lâm ĐoànNo ratings yet

- Makalah InternasionalDocument1 pageMakalah InternasionalIwa SutiswaNo ratings yet

- Chemistry and Biochemistry of FermentedDocument19 pagesChemistry and Biochemistry of Fermentedgaroasenti44No ratings yet

- CHEMISTRYDocument21 pagesCHEMISTRYzoyaNo ratings yet

- Elaboración de Yogurt Con Probiótico (Bifidobacterium Spp. y Lactobacillus Acidophilus) e InulinaDocument5 pagesElaboración de Yogurt Con Probiótico (Bifidobacterium Spp. y Lactobacillus Acidophilus) e InulinaJhairo TafhurNo ratings yet

- Satanic ProceedingsDocument4 pagesSatanic ProceedingseddNo ratings yet

- Physics ProjectDocument12 pagesPhysics ProjectNisha HussainNo ratings yet

- ChemistryDocument17 pagesChemistryVishal KamalakannanNo ratings yet

- Handbook of Food Science and Technology 3: Food Biochemistry and TechnologyFrom EverandHandbook of Food Science and Technology 3: Food Biochemistry and TechnologyNo ratings yet

- Hizon, Czarina May CVDocument3 pagesHizon, Czarina May CVnotapernota101No ratings yet

- User Flow DiagramDocument1 pageUser Flow DiagramjimNo ratings yet

- Assessment of Critical Success FactorsDocument34 pagesAssessment of Critical Success FactorsTMC officeNo ratings yet

- Rotational Motion 8.0Document11 pagesRotational Motion 8.0adnan khanNo ratings yet

- Effects of Handling On Animals Welfare During TranDocument54 pagesEffects of Handling On Animals Welfare During TranNikhilesh WaniNo ratings yet

- AP 5902 Liability Supporting NotesDocument6 pagesAP 5902 Liability Supporting NotesMeojh Imissu100% (1)

- IMMI Grant NotificationDocument4 pagesIMMI Grant NotificationAngeline GarciaNo ratings yet

- DokDocument5 pagesDokNur IdahNo ratings yet

- A VFP-SQL Server Application From The BeginingDocument38 pagesA VFP-SQL Server Application From The Beginingmohsin.computers3076No ratings yet

- Pond Based Tilapia Hatchery ManagementDocument50 pagesPond Based Tilapia Hatchery ManagementAlvin Javier PeranteNo ratings yet

- Virtual CrashDocument57 pagesVirtual Crashjruiz2No ratings yet

- 2021 Nqesh Mock Test Set BDocument36 pages2021 Nqesh Mock Test Set Brandolf traigo100% (3)

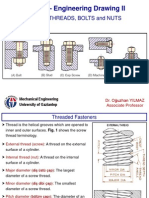

- SCREW THREADS, BOLTS and NUTS PDFDocument10 pagesSCREW THREADS, BOLTS and NUTS PDFhrhgk50% (2)

- Pre Issue ManagementDocument19 pagesPre Issue Managementbs_sharathNo ratings yet

- Query ManualDocument37 pagesQuery ManualstraNo ratings yet

- Upper Gastrointestinal BleedingDocument4 pagesUpper Gastrointestinal BleedingRazi HaiderNo ratings yet

- Ground Floor Sewage/Sewer Layout Second Floor Sewage/Sewer LayoutDocument1 pageGround Floor Sewage/Sewer Layout Second Floor Sewage/Sewer LayoutJanine LeiNo ratings yet

- M50-2014 V6Document334 pagesM50-2014 V6Dragan MilosevicNo ratings yet

- Duxbury Clipper 2011 - 02 - 02Document44 pagesDuxbury Clipper 2011 - 02 - 02Duxbury ClipperNo ratings yet

- JES Command OverviewDocument74 pagesJES Command Overviewdb manishNo ratings yet

- BK Ambari InstallationDocument72 pagesBK Ambari InstallationFernovy GesnerNo ratings yet

- Conviction in Cheque Bounce CaseDocument24 pagesConviction in Cheque Bounce CaseArvind PatilNo ratings yet

- LinkBelt 108H5Document20 pagesLinkBelt 108H5amirNo ratings yet

- GregormendelandhispeasreadingandquestionsDocument2 pagesGregormendelandhispeasreadingandquestionsapi-248015505No ratings yet

- TOT Water For Pharmaceutical Use - Part 1Document132 pagesTOT Water For Pharmaceutical Use - Part 1Delly AnakAfternoonyesterdays0% (1)

- Rex International Holding Limited Preliminary Offer DocumentDocument723 pagesRex International Holding Limited Preliminary Offer DocumentInvest StockNo ratings yet

- Oxygen Scavenger Boiler Water TreatmentDocument6 pagesOxygen Scavenger Boiler Water TreatmentDarius DsouzaNo ratings yet

- pBrain-HexEngine Configuration Guide v1.2Document35 pagespBrain-HexEngine Configuration Guide v1.2lazer155No ratings yet

- Typical Details of Switchyard RequirementDocument364 pagesTypical Details of Switchyard RequirementEspro100% (1)

Soy Milk Yoghurt

Soy Milk Yoghurt

Uploaded by

SruthyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Soy Milk Yoghurt

Soy Milk Yoghurt

Uploaded by

SruthyCopyright:

Available Formats

Biotechnology & Biotechnological Equipment

ISSN: 1310-2818 (Print) 1314-3530 (Online) Journal homepage: https://www.tandfonline.com/loi/tbeq20

Soy Milk Yoghurt

Z.R. Denkova & I.D. Murgov

To cite this article: Z.R. Denkova & I.D. Murgov (2005) Soy Milk Yoghurt, Biotechnology &

Biotechnological Equipment, 19:1, 193-195, DOI: 10.1080/13102818.2005.10817180

To link to this article: https://doi.org/10.1080/13102818.2005.10817180

© 2005 Taylor and Francis Group, LLC

Published online: 15 Apr 2014.

Submit your article to this journal

Article views: 379

View related articles

Citing articles: 1 View citing articles

Full Terms & Conditions of access and use can be found at

https://www.tandfonline.com/action/journalInformation?journalCode=tbeq20

SOY MILK YOGHURT

Z.R.Denkova, I.D.Murgov

University of Food Technologies, Plovdiv, Bulgaria

ABSTRACT

The influence of the initial dry substance of reconstituted soymilk and two types of starter

cultures (single-strain and symbiotic) of Lactobacillus delbrueckii ssp. bulgaricus and

Streptococcus thermophilus on the fermentation process duration and the fermented milk

quality was investigated. Witht 10% initial dry substance of the soymilk and 1% of the

starter cultures for Bulgarian yoghurt the fermentation continued for2.5 h. The soy milk

yoghurt had a titratable acidity of 65-75ºT and the cell titre reached 1010 cfu/cm3. The soy

milk yoghurt retained its organoleptic qualities when stored for up to 3 days at tempera-

tures of 25-30ºC and for 15 days at 4-6º.

Introduction purposes of this study. Their composition

Soy and soy products occupy a traditional included selected strains of Lactobacillus

position in the diet of Far East nations. delbrueckii ssp. bulgaricus and Streptococ-

They are very well received in the rest of cus thermophilus.

the world as well. Soymilk yoghurt has The fresh soymilk was prepared by dis-

been studied extensively (6, 8). Fermented solving dried soymilk in water. After ste-

soy milk products may be beneficial from rilization, it was poured into jars and ino-

an economic and nutritional point of view culated with 1% of the indicated starter

since they can be prepared with higher cultures for sour milk. It was thermostated

protein levels at a comparable or lower cost at a temperature of 42ºC until coagulation

than regular fermented milk products (2). of the soymilk.

Soy proteins have a favourable amino acid The titre of the viable cells was deter-

balance meeting the essential amino acid mined by inoculation of the cultures in a

requirements except for methionine (7). medium of LAPTg10 (g/dm3): peptone –

The research of a number of authors (1, 3, 15, tripton – 10, yeast extract – 10, glucose

4) has indicated a lot of advantages of soy – 10, Tween 80 – 1, distilled water up to 1

milk products for the nutrition of children dm3, agar-agar – 15, pH 6.6.

and adults suffering from allergies, diabe- The titratable acidity was determined ti-

tes, cancer, heart and renal diseases. trimetrically by a 0.1 n NaOH with phenol-

Soymilk products and soymilk yoghurt can phthalein as an indicator and it represented

successfully replace the fermented milk the used up millilitres of a 0.1 n NaOH for

products from cow’s milk (3, 4, 9). neutralization of the acid in 100 cm3 of the

The present study has aimed at investi- product expressed in Toerner’s degree (ºT).

gating the possibilities of obtaining

soymilk yoghurt (sour soymilk) and deter- Results and Discussion

mining some characteristic properties of It is necessary that the organoleptic indices

the final product. of sour soymilk be close to those of Bul-

garian yoghurt. Therefore the relationship

Materials and Methods between the dried soymilk and the water

Two types of starter cultures for Bulgarian used for the preparation of the fresh

yoghurt (Y-I and Y-A) were used for the soymilk, which was inoculated with the

193 Biotechnol. & Biotechnol. Eq. 19/2005/1

TABLE 1

Characteristics of soymilk yoghurt depending on the dry substance of reconstituted soymilk

Starter culture Dry sub- Taste Flavour Consistency

for sour milk stance, %

9 of fermented milk with slightly of sour milk loose

expressed soy off-taste

10 of fermented milk with slightly of sour milk thick coagulum of sour

Y-I expressed soy off-taste milk

11 of fermented milk with clearly of sour milk very thick coagulum

expressed soy off-taste

9 of fermented milk with slightly of sour milk loose

expressed soy off-taste

Y-A 10 of fermented milk with slightly of sour milk thick coagulum of sour

expressed soy off-taste milk

11 of fermented milk with clearly of sour milk very thick coagulum

expressed soy off-taste

TABLE 2

Physicochemical indices of soymilk yoghurt

Yoghurt Titre of viable cells, cfu/g Titratable acidity, ºT Coagulation time, h

Y-1 1.2.1010 65 2.5

Y-A 2.5.1010 66 2.5

symbiotic lactic acid bacterial cultures, was yoghurt preparation from cow’s milk

investigated. The taste, flavour and consis- (Table 2).

tency of the final soymilk yoghurt were The soymilk coagulation time and the ti-

determined. The results of the experimental tratable acidity at the end of the process

studies are given in Table 1. were similar to those observed during Bul-

The data in the table show that the garian yoghurt preparation (2.5 hours and

soymilk yoghurt obtained was similar to titratable acidity of about 65-79 ºT).

Bulgarian yoghurt when soymilk with 10% The yoghurt durability during storage

of dry substance was used, with both types was determined at room temperature (25-

of starter cultures. The yoghurt resembled 30 ºC) and in refrigeration conditions (4-

Bulgarian yoghurt in taste and flavour and 6 ºC) (Table 3).

at the same time possessed the dietetic The soymilk yoghurt prepared with the

properties of soy products. Y-I starter culture could be stored for 3

Sour soymilks were prepared from fresh days at 25 – 30 ºC and for 15 days in re-

soymilk with the starter cultures Y-I and Y- frigeration conditions (4 – 6 ºC), whereas

A for Bulgarian yoghurt as shown in Table the product prepared with the Y-A starter

1. The coagulation time of the milk, the culture rapidly increased its acidity at 25-

titre of viable cells and the titratable acidity 30 ºC and retained its organoleptic indices

of the final soymilk yoghurt were deter- for 15 days at 4 – 6 ºC.

mined. On the bases of the experimental work

The soymilk prepared with both types of done, the following conclusions can be

starter cultures had a high content of living drawn:

cells (1010 cfu/g) and the fermentation It was established that soymilk yoghurt

process did not differ from the one during with good physicochemical and organoleptic

Biotechnol. & Biotechnol. Eq. 19/2005/1 194

TABLE 3

Change in the titratable acidity of soymilk yoghurt during its storage

Storage at temperatures of 25 – 30 ºC Storage at temperatures of 4 – 6 ºC

Yoghurt Titratable acidity, ºT Titratable acidity, ºT

1 day 2 days 3 days 6 days 7 days 7 days 15 days

Y-1 65 100 113 145 145 75 75

Y-A 66 110 137 165 170 80 80

qualities was obtained from reconstituted 4. Nsofor L., Nsofor O.N., Udegbe C., Nwoke E.C.

soymilk with 10% dry substance. (1996) J. Food Research International. 29(5-6), 549-

Soymilk yoghurt is prepared with a high 553.

content of viable cells (1010 cfu/g) and it 5. Shirai K., Pedrasa G., Duran M.G., Marshall

can be stored for 3 days at 25 – 30 ºC and V.M.E., Moiseev S.R., Gaibay M.G. (1992a) Sci.

for more than 2 weeks in refrigeration con- Food Agric. 59, 199-204.

ditions. 6. Shirai K., Pedrasa G., Duran M.G., Marshall

V.M.E., Moiseev S.R., Gaibay M.G. (1992) Sci.

REFERENCES Food Agric. 59, 205-210.

1. Chang C.-Y., Stone M.B. (1990) J. of Food Sci- 7. Snyder H.E., Kwon T.W. (1998) Soybean utili-

ence 55(6), 1643-1646. zation. AVI Publication, New York.

2. Karlekind K., Laye I., Halpin E., Morr C.V. 8. Yadav V.B., Jha Y.K., Garg S.K., Mital B.K.

(1991) J. Food Sci., 56, 999-1001. (1994) The Australian J. Dairy Technol., 49, 34-38.

3. Kyung-Hee Kim, Yong-Tae Ko (1987) Korean J. 9. Cheng Y.I., Thompson L.D., Brittin N.C. (1990)

Food Sci.Technol., 19(2), 151-155. J. Food Science, 55(4), 1178-1179.

195 Biotechnol. & Biotechnol. Eq. 19/2005/1

You might also like

- Production of YoghurtDocument63 pagesProduction of YoghurtIbe Collins100% (4)

- Intensive Kitchen Training Manual (IKTM): INTENSIVE KITCHEN TRAINING MANUALFrom EverandIntensive Kitchen Training Manual (IKTM): INTENSIVE KITCHEN TRAINING MANUALRating: 5 out of 5 stars5/5 (1)

- For Hino: Tics Pump Electrical Part Resistance Value ListDocument35 pagesFor Hino: Tics Pump Electrical Part Resistance Value Listfersky90% (10)

- Soy Milk Yoghurt: Biotechnol. & Biotechnol. Eq. 19/2005/1Document3 pagesSoy Milk Yoghurt: Biotechnol. & Biotechnol. Eq. 19/2005/1Jen SapinNo ratings yet

- SJPM 1242 49Document8 pagesSJPM 1242 49Richard ObinnaNo ratings yet

- Yogurt 3Document3 pagesYogurt 3th laNo ratings yet

- Production of Soy-Yoghurt by Fermentation of Soymilk With Lactobacillus Isolated From NunuDocument5 pagesProduction of Soy-Yoghurt by Fermentation of Soymilk With Lactobacillus Isolated From NunuInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Physical Properties of YogurtDocument7 pagesPhysical Properties of YogurtDrMandeep Singh SibianNo ratings yet

- Pakistan J. Agric. Res., Vol. 3, No. 2, 1982Document4 pagesPakistan J. Agric. Res., Vol. 3, No. 2, 1982sharenNo ratings yet

- Hilal Cla 2016Document5 pagesHilal Cla 2016Anonymous zIj5DCCANo ratings yet

- Preparation of Ice Cream Type Frozen YogurtDocument7 pagesPreparation of Ice Cream Type Frozen YogurtIceBearNo ratings yet

- Production and Quality Evaluation of Imitation Yoghurt From Blends of Cow Milk and Cashewnut Milk Anacadium OcidentaleDocument7 pagesProduction and Quality Evaluation of Imitation Yoghurt From Blends of Cow Milk and Cashewnut Milk Anacadium OcidentaleIJARP PublicationsNo ratings yet

- Starter Cultures For Production of Yoghurt From Sheep'S Milk With Extended Shelf LifeDocument3 pagesStarter Cultures For Production of Yoghurt From Sheep'S Milk With Extended Shelf LifeM Zenal AbidinNo ratings yet

- Chemistry ProjectDocument9 pagesChemistry Projectmaakashdeep90% (10)

- Production and Quality Evaluation of Soy Milk Yoghurt.: October 2019Document8 pagesProduction and Quality Evaluation of Soy Milk Yoghurt.: October 2019giangNo ratings yet

- Promotion of Coconut in The Production of Yoghurt: Short CommunicationDocument3 pagesPromotion of Coconut in The Production of Yoghurt: Short CommunicationNayeli MelendrezNo ratings yet

- Yoghurt Production From Powdered Milk Using Mixed Lactic Acid Bacteria Starter CulturesDocument9 pagesYoghurt Production From Powdered Milk Using Mixed Lactic Acid Bacteria Starter CulturesSHEILLA DATORNo ratings yet

- PDFDocument3 pagesPDFStefania DavidNo ratings yet

- Production of Yoghurts From Cow and Soy Composite Milk Using Starter Cultures From Different SourcesDocument7 pagesProduction of Yoghurts From Cow and Soy Composite Milk Using Starter Cultures From Different Sourcesdaisialaba722No ratings yet

- Production of Hard Tofu From Calcium Fortifi Ed Soybean Milk and Its Chemical and Sensory PropertiesDocument9 pagesProduction of Hard Tofu From Calcium Fortifi Ed Soybean Milk and Its Chemical and Sensory PropertiesusbauraNo ratings yet

- Characteristics of Soy Corn YogurtDocument4 pagesCharacteristics of Soy Corn YogurtJhon CastañoNo ratings yet

- Evaluation of The Rheological, Textural, Microstructural andDocument11 pagesEvaluation of The Rheological, Textural, Microstructural andJorge RamirezNo ratings yet

- Chemistry Project Preparation of SoyabeaDocument6 pagesChemistry Project Preparation of SoyabeaCherish BinnyNo ratings yet

- Chemistry Project: Preparation of Soyabean Milk & Its Comparison With Natural MilkDocument6 pagesChemistry Project: Preparation of Soyabean Milk & Its Comparison With Natural MilkKrishna SahuNo ratings yet

- Chemistry Project Preparation of SoyabeaDocument6 pagesChemistry Project Preparation of SoyabeaPrietesh PatilNo ratings yet

- Đặc Điểm Và Thời Hạn Sử Dụng Của Sữa Chua Sữa NgôDocument18 pagesĐặc Điểm Và Thời Hạn Sử Dụng Của Sữa Chua Sữa NgôĐoanNo ratings yet

- Does Lactic Fermentation Influence Soy Yogurt Protein Digestibility A Comperative Study Between Soymilk and Soy Yoghurt at Different PHDocument33 pagesDoes Lactic Fermentation Influence Soy Yogurt Protein Digestibility A Comperative Study Between Soymilk and Soy Yoghurt at Different PHNabilaNo ratings yet

- Dairy Tech TestDocument13 pagesDairy Tech TestMitchelle ChikakaNo ratings yet

- Ayib, AdugnaDocument22 pagesAyib, AdugnaAmbi Bekele ZewdieNo ratings yet

- Chemistry ProjectDocument10 pagesChemistry ProjectAbhey Gupta100% (3)

- Characteristics and Shelf-Life of Corn Milk YogurtDocument18 pagesCharacteristics and Shelf-Life of Corn Milk YogurtegavirganaNo ratings yet

- Effect of Micro Fluid Ization of Heat-Treated Milk On Rheology and Sensory Properties of Reduced Fat YoghurtDocument7 pagesEffect of Micro Fluid Ization of Heat-Treated Milk On Rheology and Sensory Properties of Reduced Fat YoghurtCostaEdvaldoNo ratings yet

- Chemistry ProjectDocument12 pagesChemistry ProjectAmit Kumar50% (2)

- Standardization Parameters For Production of Tofu Using WSD-Y-1 MachineDocument6 pagesStandardization Parameters For Production of Tofu Using WSD-Y-1 MachineAdjengIkaWulandariNo ratings yet

- 7 FreezDrying PDFDocument5 pages7 FreezDrying PDFIJEAB JournalNo ratings yet

- Be Hare 2016Document7 pagesBe Hare 2016RheinNo ratings yet

- Probiotic Cheese Production Using Lactobacillus Casei Cells Immobilized On Fruit PiecesDocument13 pagesProbiotic Cheese Production Using Lactobacillus Casei Cells Immobilized On Fruit PiecesĐức TrầnNo ratings yet

- Foods: Storage Stability of Texture and Sensory Properties of Yogurt With The Addition of Polymerized Whey ProteinsDocument9 pagesFoods: Storage Stability of Texture and Sensory Properties of Yogurt With The Addition of Polymerized Whey ProteinsLiz Pilar Saravia HuaringaNo ratings yet

- Jurnal BiotekDocument6 pagesJurnal BiotekAdry ShevchenkoNo ratings yet

- Making Soy Cheese With Combination StarterDocument3 pagesMaking Soy Cheese With Combination StarterFery HaidirNo ratings yet

- Evaluasi Perbedaan Varietas Kacang Kedelai Terhadap Mutu Produk Susu KedelaiDocument7 pagesEvaluasi Perbedaan Varietas Kacang Kedelai Terhadap Mutu Produk Susu KedelaiHilda NurfitrianaNo ratings yet

- Chemistry ProjectDocument12 pagesChemistry ProjectprakyathNo ratings yet

- Utilization of Labneh Whey Lactose Hydrolyzed Syrup in Baking and ConfectioneryDocument8 pagesUtilization of Labneh Whey Lactose Hydrolyzed Syrup in Baking and ConfectioneryDollyNo ratings yet

- TAPI 08 MilkpowderandyoghurtDocument5 pagesTAPI 08 MilkpowderandyoghurtNguyen Minh TrongNo ratings yet

- Preparation of Soymilk Using Different Methods: Journal of Food and Nutrition SciencesDocument7 pagesPreparation of Soymilk Using Different Methods: Journal of Food and Nutrition SciencesTaha RahmanNo ratings yet

- Soy Milk: Nutrition and Health InformationDocument8 pagesSoy Milk: Nutrition and Health InformationRahul JadhavNo ratings yet

- 2010 Set Type Yoghurt Production by Exopolysaccharide Producing TurkishDocument6 pages2010 Set Type Yoghurt Production by Exopolysaccharide Producing TurkishТаро и Астрология с Anatoly KartNo ratings yet

- Kle International 6Document8 pagesKle International 6yashubohra38No ratings yet

- 5107 Production of Soy Cheese From Vegetable Protein Using Different CoagulantsDocument5 pages5107 Production of Soy Cheese From Vegetable Protein Using Different Coagulantsmizanabaynew19No ratings yet

- Assessment of The Nutritional Profile of Variable Graded Levels of Julie Mango Fruit Juice Flavoured Yoghurt and Plain YoghurtDocument7 pagesAssessment of The Nutritional Profile of Variable Graded Levels of Julie Mango Fruit Juice Flavoured Yoghurt and Plain YoghurtInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Zhihong Qiao 2010Document16 pagesZhihong Qiao 2010nlddoan Nguyễn Thị Lâm ĐoànNo ratings yet

- Makalah InternasionalDocument1 pageMakalah InternasionalIwa SutiswaNo ratings yet

- Chemistry and Biochemistry of FermentedDocument19 pagesChemistry and Biochemistry of Fermentedgaroasenti44No ratings yet

- CHEMISTRYDocument21 pagesCHEMISTRYzoyaNo ratings yet

- Elaboración de Yogurt Con Probiótico (Bifidobacterium Spp. y Lactobacillus Acidophilus) e InulinaDocument5 pagesElaboración de Yogurt Con Probiótico (Bifidobacterium Spp. y Lactobacillus Acidophilus) e InulinaJhairo TafhurNo ratings yet

- Satanic ProceedingsDocument4 pagesSatanic ProceedingseddNo ratings yet

- Physics ProjectDocument12 pagesPhysics ProjectNisha HussainNo ratings yet

- ChemistryDocument17 pagesChemistryVishal KamalakannanNo ratings yet

- Handbook of Food Science and Technology 3: Food Biochemistry and TechnologyFrom EverandHandbook of Food Science and Technology 3: Food Biochemistry and TechnologyNo ratings yet

- Hizon, Czarina May CVDocument3 pagesHizon, Czarina May CVnotapernota101No ratings yet

- User Flow DiagramDocument1 pageUser Flow DiagramjimNo ratings yet

- Assessment of Critical Success FactorsDocument34 pagesAssessment of Critical Success FactorsTMC officeNo ratings yet

- Rotational Motion 8.0Document11 pagesRotational Motion 8.0adnan khanNo ratings yet

- Effects of Handling On Animals Welfare During TranDocument54 pagesEffects of Handling On Animals Welfare During TranNikhilesh WaniNo ratings yet

- AP 5902 Liability Supporting NotesDocument6 pagesAP 5902 Liability Supporting NotesMeojh Imissu100% (1)

- IMMI Grant NotificationDocument4 pagesIMMI Grant NotificationAngeline GarciaNo ratings yet

- DokDocument5 pagesDokNur IdahNo ratings yet

- A VFP-SQL Server Application From The BeginingDocument38 pagesA VFP-SQL Server Application From The Beginingmohsin.computers3076No ratings yet

- Pond Based Tilapia Hatchery ManagementDocument50 pagesPond Based Tilapia Hatchery ManagementAlvin Javier PeranteNo ratings yet

- Virtual CrashDocument57 pagesVirtual Crashjruiz2No ratings yet

- 2021 Nqesh Mock Test Set BDocument36 pages2021 Nqesh Mock Test Set Brandolf traigo100% (3)

- SCREW THREADS, BOLTS and NUTS PDFDocument10 pagesSCREW THREADS, BOLTS and NUTS PDFhrhgk50% (2)

- Pre Issue ManagementDocument19 pagesPre Issue Managementbs_sharathNo ratings yet

- Query ManualDocument37 pagesQuery ManualstraNo ratings yet

- Upper Gastrointestinal BleedingDocument4 pagesUpper Gastrointestinal BleedingRazi HaiderNo ratings yet

- Ground Floor Sewage/Sewer Layout Second Floor Sewage/Sewer LayoutDocument1 pageGround Floor Sewage/Sewer Layout Second Floor Sewage/Sewer LayoutJanine LeiNo ratings yet

- M50-2014 V6Document334 pagesM50-2014 V6Dragan MilosevicNo ratings yet

- Duxbury Clipper 2011 - 02 - 02Document44 pagesDuxbury Clipper 2011 - 02 - 02Duxbury ClipperNo ratings yet

- JES Command OverviewDocument74 pagesJES Command Overviewdb manishNo ratings yet

- BK Ambari InstallationDocument72 pagesBK Ambari InstallationFernovy GesnerNo ratings yet

- Conviction in Cheque Bounce CaseDocument24 pagesConviction in Cheque Bounce CaseArvind PatilNo ratings yet

- LinkBelt 108H5Document20 pagesLinkBelt 108H5amirNo ratings yet

- GregormendelandhispeasreadingandquestionsDocument2 pagesGregormendelandhispeasreadingandquestionsapi-248015505No ratings yet

- TOT Water For Pharmaceutical Use - Part 1Document132 pagesTOT Water For Pharmaceutical Use - Part 1Delly AnakAfternoonyesterdays0% (1)

- Rex International Holding Limited Preliminary Offer DocumentDocument723 pagesRex International Holding Limited Preliminary Offer DocumentInvest StockNo ratings yet

- Oxygen Scavenger Boiler Water TreatmentDocument6 pagesOxygen Scavenger Boiler Water TreatmentDarius DsouzaNo ratings yet

- pBrain-HexEngine Configuration Guide v1.2Document35 pagespBrain-HexEngine Configuration Guide v1.2lazer155No ratings yet

- Typical Details of Switchyard RequirementDocument364 pagesTypical Details of Switchyard RequirementEspro100% (1)