Professional Documents

Culture Documents

Photovoltaic Sizing and Battery

Photovoltaic Sizing and Battery

Uploaded by

Salaudeen Kola IsmailCopyright:

Available Formats

You might also like

- Project Report On Solar Module Manufacturing Unit (250-300 Mw/annum)Document12 pagesProject Report On Solar Module Manufacturing Unit (250-300 Mw/annum)EIRI Board of Consultants and Publishers50% (2)

- Human Anatomy Physiology 10th Edition Marieb Hoehn Test BankDocument36 pagesHuman Anatomy Physiology 10th Edition Marieb Hoehn Test Bankdorislanhpr028No ratings yet

- C9e Answers Active Reading 04Document4 pagesC9e Answers Active Reading 04Jordan Camina75% (8)

- Case Study-Solar EnergyDocument24 pagesCase Study-Solar Energyadam0611No ratings yet

- Calculation of Electrical Energy With SolarDocument4 pagesCalculation of Electrical Energy With Solarmohamed parvez100% (1)

- Smart Task 1 Solar PVDocument7 pagesSmart Task 1 Solar PVShubham AroraNo ratings yet

- Chapter 2 Solar PowerDocument112 pagesChapter 2 Solar PowerBewnet GetachewNo ratings yet

- Solar Panel: Jump To Navigation Jump To SearchDocument18 pagesSolar Panel: Jump To Navigation Jump To SearchEr Dinesh TambeNo ratings yet

- MainDocument25 pagesMainDurgaprasadNo ratings yet

- Design and Construction of A Solar Powered Streetlight SystemDocument7 pagesDesign and Construction of A Solar Powered Streetlight Systemsamuel mechNo ratings yet

- Solar Power Plant Report 1Document28 pagesSolar Power Plant Report 1Alankar MishraNo ratings yet

- Chapter Three DesignDocument20 pagesChapter Three DesignADEFRIS BELACHEWNo ratings yet

- Solar Power Plant: Government Engineering College BharatpurDocument29 pagesSolar Power Plant: Government Engineering College BharatpurHinduja KumarasamyNo ratings yet

- Solar Cells & Their ApplicationDocument11 pagesSolar Cells & Their ApplicationpiyushNo ratings yet

- Chapter-1 IntroductionDocument24 pagesChapter-1 IntroductionNaveenNo ratings yet

- SDPV31306Document65 pagesSDPV31306bdsisira100% (1)

- Group3-SECT W.answersDocument44 pagesGroup3-SECT W.answersJustino BalaneNo ratings yet

- Projectreport REDocument15 pagesProjectreport REUnzillahNo ratings yet

- SolarDocument57 pagesSolarRaghavendra Raghav100% (1)

- CHAPTER 3 TECHNICAL ASPECT Solar Powered GeneratorDocument47 pagesCHAPTER 3 TECHNICAL ASPECT Solar Powered GeneratorRed SecretarioNo ratings yet

- Design of A Photovoltaic System For A Rural House: M.Aminy, N.Barhemmati, A.Hadadian, F.ValiDocument5 pagesDesign of A Photovoltaic System For A Rural House: M.Aminy, N.Barhemmati, A.Hadadian, F.ValiHypnotic KnightNo ratings yet

- Solar Mobile Charging Station Final ProjectDocument23 pagesSolar Mobile Charging Station Final Projectyash Jadhao100% (1)

- Rev. in PhotovoltaicDocument2 pagesRev. in PhotovoltaicChristopher AsuncionNo ratings yet

- Sun (Up)Document17 pagesSun (Up)Rakibul HassanNo ratings yet

- 22661-RET Notes-UNIT 02Document25 pages22661-RET Notes-UNIT 02jayeshdeore398No ratings yet

- What Is Solar Systems and How To Design ItDocument5 pagesWhat Is Solar Systems and How To Design Itabuzar12533No ratings yet

- Solar Mobile Charger PDFDocument29 pagesSolar Mobile Charger PDFAayush guptaNo ratings yet

- Solar PV Individual ReportDocument7 pagesSolar PV Individual ReportshathishNo ratings yet

- Shathish Solar PVDocument7 pagesShathish Solar PVshathishNo ratings yet

- Effect of Shading On Photovoltaic Cell: Ekpenyong, E.E and Anyasi, F.IDocument6 pagesEffect of Shading On Photovoltaic Cell: Ekpenyong, E.E and Anyasi, F.IM VetriselviNo ratings yet

- Chapter:-1: 1.1 Introduction To Solar EnergyDocument15 pagesChapter:-1: 1.1 Introduction To Solar EnergySwaroopNo ratings yet

- Renewable Energy-Design Concepts & Implementation: Engr. Nwafor Chukwubuikem MichaelDocument20 pagesRenewable Energy-Design Concepts & Implementation: Engr. Nwafor Chukwubuikem MichaelSixtus OkoroNo ratings yet

- IJNRD1704035Document6 pagesIJNRD1704035Eslam MetwalyNo ratings yet

- Unit II - RETDocument59 pagesUnit II - RETsagarpatil03012No ratings yet

- Solar Panel: Solar PV Modules Mounted On A RooftopDocument17 pagesSolar Panel: Solar PV Modules Mounted On A RooftopMaria Sweetlin DNo ratings yet

- Project Report On Maximum Power Point Tracking of PV Arrays in SimulinkDocument7 pagesProject Report On Maximum Power Point Tracking of PV Arrays in SimulinkPriyanshu SinghNo ratings yet

- Solar IeeeDocument7 pagesSolar IeeeDinesh Venkata RamaGopal MorlaNo ratings yet

- PhtoDocument18 pagesPhtoshaurya sharmaNo ratings yet

- SolarDocument57 pagesSolarNag Y50% (2)

- Design and Implementation of A Solar Charge Controller With Variable OutputDocument12 pagesDesign and Implementation of A Solar Charge Controller With Variable OutputEmmanuel SundayNo ratings yet

- History of Solar PowerDocument3 pagesHistory of Solar PowersmshivaNo ratings yet

- Report 3 D Solar Cell...Document15 pagesReport 3 D Solar Cell...Pankaj DeshmukhNo ratings yet

- Project Topic:Solar Panel: Worked By:lavdimir Ferraj& Briken Shehaj Accepted From Prof - Sonila DaiuDocument16 pagesProject Topic:Solar Panel: Worked By:lavdimir Ferraj& Briken Shehaj Accepted From Prof - Sonila DaiuBriken ShehajNo ratings yet

- REPORTDocument57 pagesREPORTSonu YadavNo ratings yet

- Chapter OneDocument36 pagesChapter OneStanleyNo ratings yet

- Solar Cell System Design-2Document12 pagesSolar Cell System Design-2spotifyladderNo ratings yet

- Enerji InggDocument7 pagesEnerji InggFATMA GİZEM ŞAHİNNo ratings yet

- A10020115 KTI AJER InternasionalDocument15 pagesA10020115 KTI AJER Internasionalarief ndartoNo ratings yet

- Efficient Use of Solar Power Energy: Ruby Vij, Research Scholar D.A.V Institute of Tech. JalandharDocument3 pagesEfficient Use of Solar Power Energy: Ruby Vij, Research Scholar D.A.V Institute of Tech. JalandharPramod KumarNo ratings yet

- How A PV System Works - pdf-20200211100803465Document9 pagesHow A PV System Works - pdf-20200211100803465ahmed abusnoubarNo ratings yet

- Report On Visit To Solar Power PlantDocument16 pagesReport On Visit To Solar Power Plantsm4513848No ratings yet

- Introduction To PV SystemDocument18 pagesIntroduction To PV SystemOmotoye EmmanuelNo ratings yet

- Design of A 50 KW Solar PV Rooftop SystemDocument9 pagesDesign of A 50 KW Solar PV Rooftop SystemvmramakrishnanNo ratings yet

- Basic Components Needed For SolarDocument6 pagesBasic Components Needed For Solarhmha83No ratings yet

- Implementation of Solar Energy Tracking System: AbstractDocument3 pagesImplementation of Solar Energy Tracking System: AbstractZohaib HassanNo ratings yet

- CHAPTER II Solar-Powered Automatic Lighting SystemDocument32 pagesCHAPTER II Solar-Powered Automatic Lighting SystemJo Sofia Delos SantosNo ratings yet

- Solar Photovoltaic SystemsDocument15 pagesSolar Photovoltaic SystemsJunnel NegadNo ratings yet

- Final Minor ProjectDocument20 pagesFinal Minor ProjectVishal SinghNo ratings yet

- Peres Unit 3Document86 pagesPeres Unit 3ulaganathanNo ratings yet

- Photovoltaic System: Camilo Peñaranda Rincon 1092156401Document3 pagesPhotovoltaic System: Camilo Peñaranda Rincon 1092156401Camilo PeñarandaNo ratings yet

- Solar Electricity Generation System with a DIY Sun-Tracking PropositionFrom EverandSolar Electricity Generation System with a DIY Sun-Tracking PropositionNo ratings yet

- Photovoltaics | 101: The hands-on beginner's guide for designing an on-grid or off-grid PV systemFrom EverandPhotovoltaics | 101: The hands-on beginner's guide for designing an on-grid or off-grid PV systemNo ratings yet

- Covalent Bonding WorksheetDocument4 pagesCovalent Bonding WorksheetVKEXODIUSNo ratings yet

- 1.1 Atomic Theory and StructureDocument30 pages1.1 Atomic Theory and StructureYan WangNo ratings yet

- Atomic Structure & The Periodic Table 3 QPDocument9 pagesAtomic Structure & The Periodic Table 3 QPMagd OsamaNo ratings yet

- Chemistry Project ON: Growing CrystalsDocument17 pagesChemistry Project ON: Growing CrystalsPranjalNo ratings yet

- Pharmaceutical Chemistry IDocument179 pagesPharmaceutical Chemistry IEdson Garamendez Castillo100% (1)

- Chemistry ACPDocument6 pagesChemistry ACPdhruvin.prasanth12No ratings yet

- PPSC Syllabus For Chemistry Lecturer 2021 Sample Test PatternDocument5 pagesPPSC Syllabus For Chemistry Lecturer 2021 Sample Test PatternMirza Rehman417No ratings yet

- 9185 s13 QP 13 PDFDocument16 pages9185 s13 QP 13 PDFsarahNo ratings yet

- Alphonsa School, Kalamjote - Preboard - ChemistryDocument4 pagesAlphonsa School, Kalamjote - Preboard - Chemistryakshayashivakumar96No ratings yet

- Kathmandu University Dhulikhel, Kavre: Course: Genomics & Proteomics (BIOT 414) Assignment: 02Document7 pagesKathmandu University Dhulikhel, Kavre: Course: Genomics & Proteomics (BIOT 414) Assignment: 02Reeha NeupaneNo ratings yet

- Theory and Importance of Oxygen Bridge BondingDocument23 pagesTheory and Importance of Oxygen Bridge BondingHarryNo ratings yet

- Gwenn Zyrene Toldoya Worksheet 1 - Q3Document9 pagesGwenn Zyrene Toldoya Worksheet 1 - Q3Mary Bernadeth S. PeligresNo ratings yet

- BondingDocument55 pagesBondingJoshua lopezNo ratings yet

- UT Dallas Syllabus For Chem1311.004.07f Taught by Sandhya Gavva (Sgavva)Document6 pagesUT Dallas Syllabus For Chem1311.004.07f Taught by Sandhya Gavva (Sgavva)UT Dallas Provost's Technology GroupNo ratings yet

- CHEM PP2 KCSE 2024 PREDICTION TRIALS With AnswersDocument132 pagesCHEM PP2 KCSE 2024 PREDICTION TRIALS With AnswersMusa LeiyaguNo ratings yet

- MVN Student Entrance Test Syllabus Class Xi-2024 2025Document4 pagesMVN Student Entrance Test Syllabus Class Xi-2024 2025purple11102007No ratings yet

- JKDocument2 pagesJKIftikhar AhmedNo ratings yet

- CH5 Reacting Masses, and Chemical EquationsDocument2 pagesCH5 Reacting Masses, and Chemical EquationsHazim AlJabrNo ratings yet

- '.Chemistry IX Federal Chapter 1 Short Q/ADocument9 pages'.Chemistry IX Federal Chapter 1 Short Q/AAbdul HaseebNo ratings yet

- Element & Compound Poster WorksheetDocument3 pagesElement & Compound Poster WorksheetClaudia PinnaNo ratings yet

- Water?Document20 pagesWater?Lei Yamin ChitNo ratings yet

- Review Unique Selective Detectors For Gas Chromatography: Nitrogen and Sulfur Chemiluminescence DetectorsDocument15 pagesReview Unique Selective Detectors For Gas Chromatography: Nitrogen and Sulfur Chemiluminescence DetectorsnmmMJKJNo ratings yet

- Latihan Empirical FormulaDocument11 pagesLatihan Empirical FormulaRusdi Chodeng100% (1)

- Set ADocument12 pagesSet AgoodNo ratings yet

- Chem 101 2008-Q and AnswersDocument13 pagesChem 101 2008-Q and AnswersAmroKashtNo ratings yet

- Cambridge IGCSE™: Combined Science 0653/42 March 2020Document10 pagesCambridge IGCSE™: Combined Science 0653/42 March 2020Hin Wa LeungNo ratings yet

- Chem 12123123Document4 pagesChem 12123123ZombieSlayer1730No ratings yet

- Pages From Glencoe - Chemistry - Matter and Change (Mcgraw 2008) ch8Document40 pagesPages From Glencoe - Chemistry - Matter and Change (Mcgraw 2008) ch8api-261034721No ratings yet

Photovoltaic Sizing and Battery

Photovoltaic Sizing and Battery

Uploaded by

Salaudeen Kola IsmailOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Photovoltaic Sizing and Battery

Photovoltaic Sizing and Battery

Uploaded by

Salaudeen Kola IsmailCopyright:

Available Formats

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

CHAPTER ONE

INTRODUCTION

1.1 Background of Study

Photovoltaic system comprises of photovoltaic cells that converts light energy

directly into electricity. Because the source of light is usually the sun, they are

often called solar cells (Michael Mooney, 1997). The word photovoltaic comes

from “photo” meaning light and “voltaic” refers to producing electricity.

Therefore, the photovoltaic process is “producing electricity directly from

sunlight”. Photovoltaic are often referred to as PV. (Michael Mooney, 1997).

Photovoltaic (PV) cells converts sunlight directly into electricity without creating

any air or water pollution and after consumers the ability to generate electricity

in a clean, quiet and reliable way, (Michael Money, 1997).

Solar battery capacity determination (otherwise known as solar battery bank

sizing) is one of the most important considerations when choosing the specific

solar electric system. A battery bank stores electricity produced by a solar

electric system. If the house is not connected to the utility grid or if long power

outages is anticipated from the grid, a battery bank will be needed, (National

Rewable Energy Laboratory 2002). Solar energy is radiant light and heat from

the sun harnessed using a range of ever-evolving technologies such as

photovoltaic and solar thermal energy.

Photovoltaic Application: photovoltaic has been routinely used for roadside

emergency phones and many temporary construction signs, where the cost

and trouble of bringing in utility power outweighs the higher initial expenses

of photovoltaic and where mobile generator sets present more fueling and

maintenance trouble (solar Direct, 2016).

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

1

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Thermal Application: photovoltaic cells, which make electricity from light are

not the only way of making solar power. Many homes use solar-thermal

panels to make hot water instead of electricity. These work in a completely

different way that does not involve electricity at all. Although they look

similar to photovoltaic panels, often sitting on the roof of a building in the

same way, solar thermal panels use a large sheet of black glass to soak up

the sun’s heat. Water trickles through the panels, warming up as it goes

before flowing through the homes water tank. That warms up the water in

the tank, which then flows out through people’s faucets (taps). The water

from the solar panel then returns to the roof to pick up more heat (Chris

Woodford, 2014).

1.2 Statement of Problem

The major problem of solar electricity system is a problem (Olaboni et al.,

2016). Determining the sizing of photovoltaic cells and battery capacity has

gone in a wrong way due to the fact that the right load capacity of solar

electricity system is not put into consideration. Therefore, this present research

is aimed to determine the load of photovoltaic sizing battery capacity.

1.3 Aims and Objectives

The aim of this project work is to determine the size of photovoltaic panels

required for a particular battery capacity in solar electricity system.

The Objectives are:

Establishing the size of photovoltaic system and ratings of major

components needed to meet a certain performance.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

2

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Sizing of photovoltaic system base on any number of factors, depending

on the type system and its functional requirements (Jim Dunlop Solar

2012).

By getting a battery bank that can handle the load coming from the

photovoltaic (PV) panel array.

For the battery to provide enough stored power for the needs without

having to regularly discharge to an unhealthy point.

By wiring multiple batteries together in different wiring arrangements, a

battery bank that is right for the solar power system can be designed and

thus correctly perform solar battery sizing (Alternate Energy Solution,

2016).

1.4 Significance of Study

This project work is significantly important to estimate and recommend solar

cell or panel sizing for a particular battery capacity for better performance and

provision of solar electricity systems.

1.5 Definition of Terms

Cell (Solar): This is the basic unit of a photovoltaic solar panel. A

12volt solar panel typically has 36 individual cells; a 24volt solar

panels use 72 cells.

Module (solar): A number of individual solar cells connected together

in an environmentally protected housing producing a standard output

voltage and power. Multiple modules or panels can be assembled into

an array for increased power or voltage.

Photon: A particle of light that act as an individual unit of energy.

Array (Solar): Any number of photovoltaic modules or panels

connected together to provide a single electrical output.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

3

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Back-up energy system: A back-up electric power system using

batteries and inverter, an AC generator, or both.

Battery: A device containing electrolytic cells to store electrical energy

in chemical form.

Cell (Battery): The basic unit of an electrochemical battery. A lead acid

cell produces about 2.12volts and a 12volts battery uses 6 of this cells

and fully charged measures about 12.72volts.

Solar Energy: Electromagnetic energy transmitted from the sun (solar

radiation). The amount that reaches the earth is equal one billionth of

total solar energy generated or be equivalent of about 420 trillion

kilowatt-hours

Sizing: The process of designing a solar electric system to meet the

required operating loads based on the total wattage of all appliances

in the system.

Series: A wiring technique where multiple devices are wired together

to increase voltage but current remains the same.

Parallel: A wiring technique where multiple devices are wired together

to increase but voltage remains the same.

Panel (solar): A solar photovoltaic device composed of groups of

individual solar cells connected in series, in parallel, or in series-

parallel combination to produce a standard output.

Load: The devices and appliances that draw power from an electrical

supply system.

Grid: A common term referring to an electricity transmission and

distribution system run by large utility companies.

Electrical grid: A large integrated system of electricity distribution

from centralized locations to individual homes and business.

D.O.D (Depth of Discharge): the percentage that a battery is

discharged from a fully charged condition.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

4

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

NOCT (Nominal Operating cell Temperature): This is the cell

temperature reached by open circuited cells in a module under

certain condition of irradiance on cell surface, air temperature, wind

velocity and mounting or open back side.

Tamb (Ambient Temperature): This is the air temperature of an

environment or surrounding.

Tamb (Cell temperature): This is the temperature of the solar cell itself,

not the temperature of the surrounding.

STC (Standard Test Condition): This is the industry standard for the

condition under which solar panels are tested. By using a fixed set of

conditions, all solar panels can be more accurately compared and

rated against each other.

Peak Watt (WP): The maximum nominal output of a PV (Solar) device,

in watt (WP) under standardized test condition (usually the most

favourable) (free sun power, 2015).

Autonomy: This is the number of days that is needed for the system to

operate when there is no power produced by the PV panel.

Autonomous System: This is a stand-alone power system that has no

utility connection. Most systems are designed for 3-5 of power from

batteries without recharging from a solar source of standby generator.

Blocking DIODE: a semiconductor device used to stop the flow of

current from one direction, but allows it from opposite direct.

Bypass DIODE: A diode connected across a solar cell in a photovoltaic

module such that the diode will conduct if the cell becomes reverse

bias due to shading or failure of other cells.

TILT Angle (of a Solar Array): This is the angle at which a solar array

is set to face the sun relative to horizontal position and it is usually

adjusted seasonal due to the changing declination of the sun.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

5

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Peak Sun Hours (PSH): This is the equivalent numbers of hours per

day when solar radiation averages 1 kilo watt per square meter. For

example, 5 peak sun hours’ means that the energy received during

total day light hours equals the energy that would have been received

add the solar radiation for 5 hours being 1 kilo watt per square meter.

Inverter (AC): An electronic device that converts 12, 24,48 or higher

volts DC power from batteries or solar panels from 120 or 240 volts

AC to operate normal appliances.

Solar Irradiance, G: 1000w per square meter (WLM 2). This number

refers the to the amount of light energy falling on a given area at a

given time.

Ambient Temperature (Temperature of the cell): This is the

temperature of the solar cell itself (usually 25 0c to 350c), not the

temperature of the surrounding.

Maximum Power Point (MPP): This is the point on the current-voltage

(I-V) curve of a solar panel, where the product of current time’s

voltage equals maximum wattage.

Maximum Power Point Tracking (MPPT): This is a charge controller

technique that attempts to supply maximum power to the batteries by

tracking the maximum power point (MPP) at all times achieving a 15%

to 35% increase over other types of charging techniques.

Charge Controller: This is an electronic device that regulates the

voltage from the solar panel array to ensure maximum transfer of

energy and prevent overcharging the battery bank.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

6

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

CHAPTER TWO

LITERATURE REVIEW

2.1 Historical Development

The story of Photovoltaic cell began in 1839 and it takes through some facts,

persons and events which have marked the history of Photovoltaic’s.

Discovery of basic phenomena and properties of PV materials 1839-1899:

A physical phenomena allowing light-electric conversion-the photovoltaic

effects, was discovered in 1839 by the French physicist, Alexandra Edmond

Becquerel. Experimenting with mental electrode and electrolyte, he discovered

that conductance rises with illumination. Willougby Smith discovered the

photovoltaic effects in selenium in 1973. In 1876, with his students Richard E.

Day, William G. Adams discovered that illuminating a junction between

selenium and platinum also has a photovoltaic effect. These two discoveries

formed a foundation for the first selenium solar cell construction, which was

built in 1877. Charles Frits first described them in detail in 1883. In 1887,

Henrich Hertz discovered that ultra-videt light changes the voltage at which

sparks between two metals electrode would initiated.

Theoretical explanation of the photovoltaic effects and first solar cells,

1900 – 1949: The author of the most comprehensive work about the

photovoltaic effect was Albert Eistein, who described the phenomina in 1904.

For his theoretical explanation, he was awarded a Nobel Prize in 1921.

Einstein’s theoretical explanation was proven in practiced by Robert Millikan’s

experiment in 1916. In 1918, a Polish scientist Jan Czochralski discovered a

method for mono-crystalline silicon production, which enables mono-

crystalline solar cell production. The first silicon mono-crystalline solar cell was

constructed in 1941. In 1932, the photovoltaic effect in cadmium-selenide was

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

7

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

observed. Nowadays, cadmium-selenide, cds is among the important materials

for solar cell production (Denis Lenardic, 2015).

2.2 Solar Cells

Photovoltaic are best as a method for generating electric power by using solar

cells to convert energy from sun into a flow of electrons. The photovoltaic effect

refers to photons of light exciting electrons into a higher state of energy,

allowing them to act as charge carriers for an electric current. The photovoltaic

effect was first observed by Alexander-Edmond Becquerel in 1839. The term

photovoltaic denotes the unbiased operating mode of a photo diode in which

current through the device is entirely due to the transduced light energy.

Virtually all photovoltaic devices and some type of photo diode.

Solar cells produced direct current electricity from sunlight which can be used

to power equipment or to recharge a battery. The first practical application was

to power orbiting satellite and other space craft, but today the majority of

photovoltaic modules are used for grid connected power generation. In this

case, an inverter is required to convert the DC to AC.

Photovoltaic power generation employs solar panels composed of a number of

solar cells containing a photovoltaic material. Materials presently used for

photovoltaic include mono-crystalline silicon, poly-crystalline silicon,

amorphous silicon, cadmium telluride, and copper indium, gallium selenide or

sulfide.

Cells require protection from the environment and are usually packaged tightly

behind a glass sheet. When more power is required than a single cell can

deliver, cells are electrically connected together to form photovoltaic modules,

or solar panels. A single module is enough to power an emergency telephone,

but for a house or a power plant, the modules must be arranged in multiples

as arrays.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

8

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Photovoltaic power capacity is measured as maximum power output under

standardized test condition (STC) in “WP” (Watts Peak). The actual power

output at particular point in time may be less than or greater than this

standardized, ‘rated’, value, depending on geographical location, time of day,

weather conditions and other factors. Solar photovoltaic array capacity factor

are typically under 25%, which is lower than many other industrial sources of

electricity (Wikipedia, 2016).

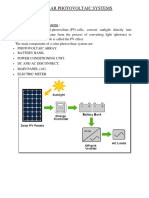

2.3 Solar Electricity System Components

Solar photovoltaic system include different component that should be selected

according to system type, site locations and application. The major components

for solar PV system are photovoltaic modules, photovoltaic arrays and wiring

panels (Leonics, 2013). The components of solar electricity include;

i. Photovoltaic cell (solar panel)

ii. Battery

iii. Control unit

iv. Inverter

v. AC and DC loads

vi. Cables

PV Solar

Module Charge Inverter Battery

Controller

DC AC

Load Load

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

9

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Fig. 2.1: Block diagram of a solar electricity system.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

10

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

2.4 Photovoltaic Modules

A photovoltaic module consists of PV cells circuits sealed in an environmentally

protective laminate and are the fundamental building block of PV systems. The

various PV cells are wired in parallel to increase current and in series to

produce a higher voltage. 36 cells modules are the industry standard for a

large power production.

The module is encapsulated with tempered glass (or some other transparent

materials) on the front surface, and with a protective and waterproof material

on the back surface. The edges are sealed for waterproofing and there is often

an aluminum frame holding everything together a mountable unit. In the back

of the module, there is a junction box or wire leads providing electrical

connections.

2.5. Photovoltaic Array

A PV array is the complete power-generating unit consists of any number of PV

modules and panels that have been wired together in a series or parallel to

deliver the voltage and amperage a particular system requires, (Solar Direct

1986-2016).

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

11

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

2.6. Wiring Panels

Panels can be wired either in series or parallel. For example, if the panels are

24 volts and the controller and batteries are 24volts, then one will need to wire

the panels in parallel, this is done by connecting all the positives connections

together and separately connect all the negatives together

(www.solarfacts.com).

24V to charge + + + +

24V Panel 24V Panel 24V Panel 24V Panel

Controller _ _ _ _

Fig. 2.2: Diagram of panels connected in parallel.

In order to connect pairs of solar panels in series, the positive terminal of one

panel is connected to the negative of the next; this is done so as to increase the

voltage. This is shown in the figure below:

+ +

24V Panel 24V Panel

_ _

+ +

24V Panel 24V Panel

_ _

Fig. 2.3: Diagram of panels connected in series.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

12

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

13

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

2.7. Types of Solar Panel

There are four (4) main types of solar panel, namely;

i. Mono-crystalline Silicon Cells: This is made using cells saw-cut from

single cylindrical of silicon; this is the most efficient of the PV

technologies. The principal advantages of mono-crystalline cells is

their high efficiency, typically around 15% although the

manufacturing process required to produced mono-crystalline silicon

is complicated resulting in slightly higher costs than other

technologies.

ii. Multi-Crystalline Silicon cells: This is made from cells cut from an in-

got of melted and re-crystalline silicon. In the manufacturing process,

molten silicon cast into in-got of poly-crystalline silicon, there in-got

are then saw-cut into very thin wafers and assembled into complete

cells. They are less efficient with average efficient efficiencies of

around 12% creating a granular texture.

iii. Thick-film Silicon cells: This is another multi-crystalline technology

where the silicon is deposited in a continuous process onto a base

material giving a fine grained, sparkling appearance. This is

encapsulated in a transparent insulating polymer with a tempered

glass cover and usually bound into a strong aluminum frame.

iv. Amorphous Silicon Cells (thin-film): These are composed of silicon

atoms in a thin homogenous layer than crystalline silicon, so the cells

can be thinner. Amorphous cells are less efficient than crystalline

based cells, with typical efficiencies of around 6% easier and

therefore, cheap to produced. Their low cost make them ideally suited

for many applications where high efficiency is not required and low

cost is important.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

14

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Fig. 2.4: Solar Panels

2.8 History of Battery

In the modern era, electrical energy is normally converted from mechanical

energy, solarenergy and chemical energy etc. a battery is a device that converts

chemical energy to electrical energy. The first battery was developed by

Alessandro Volta in the year of 1800. In the year 1836, John Frederic Daniell, a

British chemist developed the Daniell cell as an improved version of the voltaic

cell. From that time until today, the battery has been the most popular source

of electricity in many daily life applications. In our daily life, we generally use

two types of batteries; one of them is which can be used once before it gets

totally discharged. Another type of battery is rechargeable which means it can

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

15

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

be used multiple times by recharging it externally. The former is called primary

battery and the later is called primary battery and the later is called secondary.

Battery can be found in different sizes. A battery may be as small as a shirt

button or may be so big in size that a whole room will be required to install a

battery bank. With this variation of sizes, the battery is used anywhere from

small wrist watches to a large ship.

Fig. 2.5a Battery-Symbol

We often see this symbol in many diagrams of electrical and electronics

network. This is the most popularly used symbol for battery. The bigger lines

represent positive terminal of the cells and smaller lines represent negative

terminal of the cells connected in the battery. We are often confused about the

terms battery cells and battery. We generally refer to a battery as single

electrochemical cell. But literally, battery does not mean that. Battery means a

number of electrochemical cells connected together to meet a certain voltage

and current level. Although, there may be a single cell battery, literally, battery

and cell are different (Electrical 4u, 2016).

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

16

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Fig. 2.5b: Parthian Battery

In the year 1936 during the middle of summer, an ancient tomb was

discovered during construction of a new railway line near Bagdad city in Iraq.

The relics found in that tomb were about 2000 years old. Among these relics,

there were clay jars of vessels which were seals at the top with pitch. An iron

rod surrounded by a cylindrical tube made of wrapped copper sheet was

projected out from this sealed top.

When theses pots were filled with an acidic liquid, they produce a potential

difference of around 2volts between the iron and copper. These clay jars are

suspected to be 2000 years old battery cells.

Fig. 2.5c: Luigi Galvani Experiment

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

17

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

In 1786, Luigi Galvani, an Italian anatomist and physiologist was surprised

that when he touched a dead frog’s leg with two different metals, the muscles

of the legs contracted. He could not understand the actual reason why,

otherwise, he would have been know as the first inventor of the battery cell. He

thought the reaction might be due to a property of the tissue.

Fig. 2.5d: voltaic-pile

After that, Alessandro volta realized that some phenomena could be created by

using cardboard soaked in salt water instead of using frog’s leg. He sandwiched

a copper disc with a piece of cardboard soaked in salt water in between them

and found a potential difference between the copper and zinc.

After that, in 1800, He developed the first voltaic pile (battery) constructed of

alternating copper and zinc discs with pieces of cardboard soaked in brine

between them. This system could produce measurable current. Alessandro

Volta’s voltaic pile was considered the first “wet battery cell”. Thus, the history

of battery began.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

18

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Fig 2.5e Daniell-cell

The main problem with the Voltaic pile was that, it could not deliver current for

a long time. This problem was solved by a British inventor John F Daniel in

1836. He invented a more developed version of the battery cell which is known

as the Daniell cell. Here in this cell, one zinc sulfate in one container and one

copper rod is immersed in copper (11) sulfate in another container. The

solutions of these two containers are bridged by a U shaped salt bridge. A

Daniell cell could produce 1.1 volt and this type of battery lasted much longer

than the Voltaic pile.

In 1839, the fuel cell was designed by Sir William Robert Grove, a discoverer

and man of science. He mixed hydrogen and oxygen within an electrolyte

solution, and created electricity and water. The fuel cell did not deliver enough

electricity, but it is helpful.

Bunsen (1842) and Grove (1839) created enhancements to battery that used

liquid electrodes to supply electricity.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

19

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Fig 2.5f Lead Acid Battery

In the year of 1859, Gaston Plante; first developed the lead acid battery cell.

This was the first form of rechargeable secondary battery. The lead acid battery

is still in use for many industrial purposes. It is still the most popular to be

used as car battery.

In 1866, the battery was again developed by a French engineer, Georges

Leclanche. It was a carbon-zinc wet cell battery known as the Leclanchecell.

Crushed manganese dioxide mixed with a bit of carbon forms the positive

electrode and a zinc rod is used as the negative electrode. Ammonium chloride

solution is used as a liquid electrolyte. After some years, Georges Leclanche

himself improved his own design by replacing liquid ammonium chloride

solution with ammonium chloride. This was the invention of the first dry cell.

In 1901, Thomas Alva Edison discovered the alkaline accumulator. Thomas

Edison’s basic cell had iron as the anode material (-ve) and nickel oxide as the

cathode material (+ve), this is just one portion of an endless history of battery,

(electrical4u.com, 2016).

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

20

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Table 2.1 Step by step development in history of batteries. (Electrical

4u.com 2016)

Developer / Inventor Country Year Invention

Luigi Galvani Italy 1786 Animal electricity

Alessandro Volta Italy 1800 Voltaic Pile

John F. Daniell Britain 1836 Daniell cell

Sir William Robert Britain 1839 Fuel cell Grove

Robert Bunsen German 1842 used liquid electrodes

to supply electricity

Gaston Plante France 1859 Lead Acid cell

Thomas Alva Edison United 1901 Alkaine Accumulator

states

2.8.1 Battery Bank

Since the photovoltaic panels produced electricity whenever the sun shines on

them, if the system off grid, a battery bank will be needed to store energy so as

to have electricity at night and on a cloudy day. Battery bank for, off-grid is

designed to keep household electricity running for on one to three cloudy day.

Grid intertied system can also include battery banks t provide emergency

backup power during blackouts-perfect for keeping critical electric loads

operate until the power is restored.

There are many types of batteries available and each type is designed for

specific applications. Lead-acid batteries have been used for residential solar

electric systems for many years and are still the best choice for this application

because of their low maintenance requirements.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

21

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

The best kinds of batteries to use in a residential power system are deep-

discharge lead-acid batteries specially designed for stationary solar electric

systems. Car and marine batteries are not recommended for solar electric

system use because they are designed to give a large burst of energy when

starting a vehicle and are not made for deep discharges. Although they are

sometimes used in situations in which deep discharge batteries are not

available, car and, marine batteries will quickly fail if used in a solar electric

application.

The basic building block of a lead-acid battery is a 2volt cell. A battery bank is

a collection of connected 2-, 6-, or 12-volt batteries that supply power to the

household in case of outage or low production from renewable energy sources.

The batteries are wired together in series to produce 12-, 24-, or 48-volt

strings. These strings are then connected in parallel to make up the entire

battery bank. The battery bank supplies DC power to an inverter, which

produces AC power that can be used to run appliances. The decision to select a

12-, 24-, or 48 volt battery bank will be determined by the inverter’s input, the

type of battery selected and the amount of energy storage required (National

Renewable Energy Laboratory, 2002).

Fig. 2.6: The Battery

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

22

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

2.8.2 Deep Cycle Battery

They are constructed to be discharged down as much as 80% after the time

and have much thicker plates. A deep cycle battery is designed to be regularly

deeply discharge using most of its capacity. In contrast, starter batteries (e.g.

most automobile batteries) are designed to deliver short, high-current bursts

for cracking the engine, thus frequently discharge of only a very small part of

their capacity.

2.8.3 Deep Cycle Battery Rating

There are two ways to rate a battery; volts and Amp hours (Ah) are rated

capacity available in chemical energy inside a battery is converted into

electrical energy. It also refers to the amount of energy that the battery can

store or conversely, it can be defined as the discharge rate which measures the

time it takes to discharge a battery before it need charging. The Amp hour (Ah)

capacity will be reduced by about 50% and so will be the amount of cycles over

a number of hours. For example, many small batteries are rated at the C 20rate;

this means that they will deliver their Amp hour capacity if discharged over

20hours.

2.9 Principle of Operation of Photovoltaic Solar Panels

The photovoltaic phenomenon was started to be used to turn direct sunlight

into energy since 1954. The principle is that when a photo reaches a

semiconductor, then the negative transitional surface of the polarity ejects the

electron thus two conductors are created: the free electron and the electron

hole.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

23

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

The released electrons flow to the upper layer. In the bottom layer the electrons

are deflected from one atom to the other in a way that they fill the empty

places. The free electrons are conducted from the upper layer into the electric

field where the solar cell is located. This is how electricity is created in this area

as long as sunlight reaches the solar panel.

The photovoltaic equipment operates automatically and without maintenance.

Solar panels produce direct electrical current, which is converted to 230Volt AC

by means of an inverter (power conversion equipment). The solar power system

is running in parallel, with the electric provider’s network (Fotowoltaika, 2016).

2.10 Principle of Operation of Battery

To understand the basic principle of battery properly, first, we have some basic

concept of electrolytes and electrons affinity. Actually, when two dissimilar

metals or metallic compounds are immersed in an electrolyte, there will be a

potential difference produced between these metals or metallic compounds. It

is found that, when some specific compounds are added to water, they get

dissolved and produce negative and positive ions. This type of compound is

called an electrolyte. The popular examples of electrolytes are almost all kinds

of salts, acids and bases etc.

The energy released during accepting an electron by a neutral atom is known

as electron affinity. As the atomic structure for different materials are different,

the electron affinity of different materials will differ. If two different kinds of

metals or metallic compounds are immersed in the same electrolyte solution,

one of them will gain electrons and the other will release electrons. Which

metal (or metallic compound) will gain electrons and which will lose them

depend upon the electron affinities of these metals or metallic compounds. The

metal with low electron affinity will gain electrons from the negative ions of the

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

24

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

electrolyte solution. On the other hand, the metal with high electron affinity

will release electrons and these electrons come out into the electrolyte solution

and are added to the positive ions of the solution. In this way, one of these

metals or compounds gains electrons and another one losses electrons. As a

result, there will be a different in electron concentration between these two

metals. This difference of electron concentration causes an electrical potential

difference to develop between the metals. This electrical potential difference or

e.m.f can be utilized as a source of voltage in any electronic or electrical circuit.

This is a general and basic principal of battery (electrical4u.com, 2016).

2.11 Charge Controller

The term “charge control or control unit” may refer to either a stand-alone

device, or to control circulatory integrated with a battery pack, battery-power

device, battery recharger. A charge controller is basically a voltage and or

current regulator to keep batteries from over charging. It regulates the voltage

and current coming from the solar panels going to the battery.

A charge controller or battery regulator limits the rate at which electric current

is added to a drawn from electric batteries. It prevents over-charging and may

prevent against over-voltage, which can reduce battery performance or lifespan,

and may pose a safety risk. It may also prevent completely drain (deep

discharging) a battery, or perform controlled discharge, depending on the

battery technology to protect battery life.

Solar lighting controller is controlled by micro-CPU and has the SOC (state of

charge) a battery system control function. It can intelligently sense the outside

light. It turns on light at dark and turns off light at dawn or the fixed time. This

controller also monitors battery charging and discharging. It will protect

batteries by turning off light by pulse-width-modulation (PWM) automatically

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

25

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

as the batteries approach full charge. The controller also has a protection

circuit to prevent accidental damage.

Fig. 2.7: Charge controller (Regulator)

2.12 Inverter

This is an electrical or electronic device used to convert DC produced by the

solar panels and DC stored in battery into AC electricity.

Fig. 2.8: The Inverter

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

26

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

27

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

2.12.1 Different Types of Inverter

The following are basic types of inverter:

i. Modified Sine Wave Inverter: this type of inverter obtains power

from a battery of 12volts and must be recharged using a generator or

a solar panel. Appliances like microwaves, oven. Light bulbs etc can

run using this type of inverter.

ii. True Sine Wave: This type of inverter provides better power compared

to the modified sine wave inverter. They are also run using a battery

of a large capacity.

iii. Solar Inverter: Solar inverters are energy efficient as they do not

require a separate source for generating power. The solar energy is

collected during the day time and used as time of need after being

converted into electricity energy. There are three types of solar

inverter;

(a) Stand-Alone Inverter: these are used in isolated systems such as

cabins, cottages, water heaters, pumps and monitoring stations.

They are used for mobile energy such boats. The stand-alone

inverter draws the DC energy taken from solar rays, from batteries

and other sources such as wind turbines, hydro-turbines and

engine generators. The stand alone inverters do not usually work

with utility grids and are not required to have anti-islanding

protection.

(b) Grid-Tie Inverter:A grid tie inverter is an electrical device that

allows users to complement their grid power with solar energy. The

grid-tie inverter regulates the amount of voltage and the current

that is received from the DC solar panel and then converts it into

an AC. Grid-tie inverter makes sure that the power will be in phase

with the grid-power. Grid-tie inverters do not provide power in the

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

28

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

event of a power shortage. On the AC side, grid-tie inverters supply

electricity in sinusoidal form.

(c) Battery Backup Inverter:This is a special inverter that draws

energy from a battery, as well as manages the battery charge via

an on-board charge, and also transfer is required to have anti-

islanding protection.

2.12.2. Intelligent Charge Inverter

Intelligent charge inverter is an uninterruptible power supply for load home

appliances. AC output switches automatically between wire and inverter. It

adopts switch power supply with high efficiency. Under the same load, its

service life can be 1/2 to 1/3 longer than conventional inverter battery; a

certain safety load shall be reserved for induction load (because actuation

current of induction load is 5-10 times of running current). This equipment can

be used in electrical refrigerators, computers, televisions, electric drills,

electrical hammers, fluorescent tubes and other homes appliances.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

29

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

CHAPTER THREE

METHODOLOGY

3.1 Sizing of Photovoltaic (PV) and Determination of Battery Capacity

The materials required and used to determine photovoltaic sizing battery

capacity are as follows:

i. Mono-Crystalline Photovoltaic Panels (80W): It is used in charging the

battery to determine its size (in power) that will charge or supply

current to a particular battery capacity in it full strength in Current-

Hour (Amp-Hour).

ii. Battery (100A-h lead-acid): It was been charged by the current

supplied by the photovoltaic panels to determine its Current-Hour

(Amp-Hour) capacity and its performances per time for solar

electricity system.

iii. Charge Controller: it was been connected to the PV panels to regulate

the voltage and current coming from the solar panels going to charge

the battery through an inverter.

iv. Inverter: This an electrical device connected to a charge controller

(regulator) used to store DC produced by the solar panels into the

battery and converting it into AC electricity.

v. Multi-Meter: It was used to determine the current and voltage

supplied by a photovoltaic panel.

vi. Connecting Wires: It was used in connecting the panels to the

regulators, the regulator to the inverter, and the inverter to the

battery.

vii. Pliers: It was used in joining two connecting wires together.

viii. Screw driver: It was used to tie and untie the nut and screw on a

panel and battery.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

30

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

3.2 Basics of Sizing

The most important thing that one needs to know before sizing a PV system is

the energy requirements of a set-up. (Along with all the electrical values of the

appliances), a few things that can help are:

i. Wattages and counts of all the appliances that needs to be run on

solar PV.

ii. If there is no wattages, then the current requirement (in Amperes) of

the appliances can be used for calculating the wattage with the simple

formula:

Watt = Ampere x voltage (240)

iii. Electricity bills of the set up. Used to check the monthly electricity

units used in a set up. Daily units can be obtained by dividing month

units by 28, 29, 30, or 31 (depending on the number of days in the

month for which the bill is generated).

iv. Daily usage of each appliance in hours. This is required if there is no

sample electricity bill. This helps in calculating the number of units of

electricity used in a day using the formula below:

Units = (Watts x Hours)

100

Two things are absolutely essential which are:

a. Total wattage of appliances (which denotes the instantaneous

electricity requirement of a set up).

b. Total units (which denotes the total electricity used in a day).

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

31

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

3.3 Sizing a PV Panel

To size a PV panel, the most essential thing to know is the total units

consumed in a day by the appliances in a set up (unless it is direct connected

system or a grid connected system. The size of PV system was not less than the

one that can generate total units consumed in a day. Every PV panel has a

peak watt (Wp) mentioned on them. A 1KWp (or peak kilowatt) system would

generate 5 – 7units in a day. Thus, the right size of PV system (in KWp) should

be estimated by dividing maximum daily usage unit by 5.

A bigger system can be used if going for a grid connected system where extra

electricity produced will be sold back to the electricity power. In such cases,

the size of PV system can be optimized based on the space that is available for

installing PV panels (BijliBachao, 2016).

3.4 Sizing Batteries for PV System

If there is no grid connected system or a direct connected system, batteries are

needed to store the energy generated using PV panels. Along with sizing of the

PV panel, it is important to size the batteries as well. Because, if more batteries

are purchased then they will not get fully charged. If fewer batteries are

bought, maximum benefits may not be able to be gotten out of the solar panels.

Most big PV system use deep cycle (or deep discharge) batteries that are

designed to discharge to low energy levels and also to recharge rapidly. These

are typically lead-acid batteries that may or may not require maintenance.

Batteries have energy storage ratings measured in Amp-Hour (Ah) or mili-Amp-

Hour (mAh). They also have a nominal voltage that they generate (typically

deep discharge batteries are 12V batteries, cell phones batteries are 5V

batteries etc).To calculate the total energy a battery can store, the following

formula can be used:

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

32

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Units = (volt x Ah)÷1000 or (Volt x mAh)÷1000000.

The total units required in a day has been discussed and also the sizing of the

PV system. The batteries were sized in such a way that the units of energy

generated by the PV system were equal to the number that was calculated.

So, assuming we have a 1KWp system and we assume that on an average it

generates 6 units a day, and if we have to buy 12V battery for it, the Ah (or

storage) or battery required will be:

(6 x 1000)÷12 = 500Ah.

3.5 Sizing Inverter for a Solar PV System

Sizing of inverter depends on the wattage of appliances connected to it. The

input rating of inverter should never be lower than the total wattages of the

appliances. Also, it should have the same nominal input voltage as that of the

battery set-up. It is always better to have inverter wattage about 20-25% moa

than that of the appliances connected. This is specifically essential if the

appliances connected have compressors or motors (like AC, refrigerator, pump

etc), which draw high starting current.

Most inverters available in market are rated on KVA/VA or KiloVolts

Ampere/Volts Ampere. In ideal situation (power factor of 1) 1VA = 1Watt. But

in real power factor varies from 0.85-0.99. So one can assume 1.18VA = 1watt.

So if there is a setup where the total wattage of the system is 1000Watt, it

means the inverter size required is more than 1180VA or 1.18KVA (add some

extra to be on a safer side).

The higher the VA of an inverter more is the number of appliances it can

support, but more costly it would be. Also for a grid-tied system, as there are

no batteries connected, the size or VA of the inverter should match the wattage

of PV panel for efficient and safe operation (BijliBachao, 2016).

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

33

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

In determining the solar power requirements and size of component for an

electric system using solar power (PV), the first two (2) factors that were

considered werethe sunlight levels (isolation values) from the area and the daily

power consumption of the electrical loads.

The thesis of this project work is sizing of photovoltaic (PV)and by determining

the capacity of the battery for a four (4) bedroom flat that will power the

following appliances; DC fan, Radio, TV, Compact Fluorescent Light (CFL), tube

light, refrigerator, microwave, washing machine, DVD Player, pumping

machine.

The total Ampere hours per day used by all the AC and DC loads in the

building were determined to sizing the photovoltaic (PV) and the battery

capacity required. The watt was multiplied by hours per day to get Watt-Hour

(Wh/day) for each load (wattage of appliance is from the owner’s manual). For

an item rated in ampere, it was multiplied by operating to find the watts.

Alternatively, AC loads can be accurately calculated by the use of a power

meter. All the watts-hours per day were added to determine total watts-hours

per day.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

34

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

3.6 Table 3.1: Loads Required for the Estimation

Energy Requirement: Sample list for DC and AC loads.

Description Power Quantity Total Duration Efficiency Energy

(w) (W) (H) (Wh)

DC fan 45 2 90 8 0.9 800

CF Light 11 8 88 6 0.85 621

Radio 20 1 20 12 0.9 267

Microwave 500 1 500 1 0.85 588

Washing 100 1 100 2 0.85 235

machine

Total DC 2,511

Tube Light 45 4 180 6 0.9 1200

TV 100 2 200 4 0.8 1000

Refrigerato 200 1 200 8 0.9 1778

r

DVD 40 1 40 4 0.8 200

Player

Total AC 4,178

Extra Load 25 17 425 2 0.85 1000

Total Load 1843 7,689

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

35

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

3.7 Results

Energy (Wh) = total power (W) x usage (h)

Efficiency (decimal)

∑Energy (Wh) = 7689Wh

Therefore, total energy =7689Wh

Established based on the total energy requirement in the system voltage.

i. System voltage chooses as a multiple of 12 volts (subject to system

size).

Maximum current (A) = Total power (W)

System Voltage

= 1843W

12V

= 153.58A

Charge Required (Ah) = Energy required (Wh)

System voltage (V)

= 7,689 Wh

12V

= 640.75Ah

ii. Select Battery:

Ideal C20 12Volts (Available voltages are 2, 6, 12, Vdc)

C20 battery 100Ah 100Ah/20h = 5A for 20 hours

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

36

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Battery capacity required (Ah) = Charge required (Ah) x autonomy (d)

Maximum debt of discharge (decimal) DOD

= 640.75Ah x 3

0.80

= 2402.81Ah

Number of batteries (series) = PV system Voltage (V)

Nominal battery voltage

= 12v

12v

= 1

Number of batteries (parallel) = Battery Capacity Required (Ah)

Selected Battery Capacity (Ah)

= 2402.81

100

= 24.03 ≈25

Battery Bank Capacity (Ah) = 25 (parallel) x 100 (Ah)

= 2500Ah

iii. PV Array Sizing

PV Array Output Needed (Ah)= Battery Capacity Required (Ah)

Battery charging Efficiency (decimal)

= 2402.81

0.9

= 2669.79Ah

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

37

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Nominal Capacity cell Temperature, NOCT = 45oc

Solar power Irradiance, G = 920Whm -2

Ambient Temperature , Tamb. = 35oc

Peak Solar Hours, Psh = 3.5hours

PV Panel Data = 80Wp

Current at maximum power point, Imp = 4.54A

Temperature Coefficient Crystalline = 0.5%/oC

Temperature Coefficient Amorphous = 0.25%/oC

Tcell = Tamb + (NOCT – 20) x G

0.8

= 35 + (45 – 20) x 0.92KWhm-2

0.8

= 35 + (31.25) (0.92)

Tcell = 35 + 28.75

= 63.750C

Temperature at Standard Test Condition, TSTC= 250C

Pderated (Wp) = Ftemp. x PSTC(Wp)

= [1-(γVmp x (Tcell - TSTC)] x PSTC(Wp)

= [1 – (0.5 x (63.75 – 25)] x 80Wp

100

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

38

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

= 0.806 x 80Wp = 64.5Wpderated

Vderated = Pderated (Wp)

Imp

= 64.5Wp

4.54A

= 14.21V

Number of Modules in Series = PV System Voltage

Vderated

= 12V

14.21

= 0.844≈1

PV Module Daily Output (Ah) = Imp x Psh

= 4.54A x 3.5h

= 15.89Ah

Number of Module in Parallel = PV Output Required

PV Daily Output

= 2669.79Ah

15.89

= 168.02 ≈ 169

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

39

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Total Number of Modules Required =

Number of module in series x number of module in parallel

= 1 x 169

= 169 modules

Parray STC (Wp)= Pmod STC (Wp) x Total number of modules required

Parray STC (Wp) = 80(Wp) x 169

= 13,520 Wp.

3.8 Summary

PV Modules: 1 in series x 169 in parallel = 169 modules

PV Capacity at STC/Location: 13,520 Wp

Batteries: 1 in series x 25 in parallel = 25 batteries

Battery Bank Peak Capacity: 2500Ah.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

40

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic sizing and battery capacity

determination in solar elctricity system

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

3.9 General Installation of Solar Electricity Generator with PV Array in

both Series and Parallel Connections

Fig. 3.1: The Block Diagram of a Solar Electricity Generator

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

41

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

CHAPTER FOUR

CONCLUSION AND RECOMMENDATION

4.1 Conclusion

The number of the Photovoltaic cells and batteries depend on the purpose

(loads) in which it is designed for determining its performance characteristics.

The photovoltaic cells size and battery capacity was found adequate to power

all the appliances available in the four (4) bedroom flat as shown in table 3.1.

The total number of the photovoltaic modules and batteries are 169 and 25

respectively which are all connected in parallel to increase the current output

and keep the voltage output within the charging and system voltage rating.

Hence, the result of this work will be a good prototype for photovoltaic cells

sizing and batteries capacity determinant.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

42

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

4.2 Recommendation

From the discovery, the initial cost of setting up of a solar system is high when

compared with other forms of electricity generator such as fuel type, but on the

long run, it is cost effective and environmental friendly, it has lesser

maintenance service, and not difficult to operate. Moreover, the durability of

solar electricity system is greater than other forms of electricity generator if

proper and standard sizing techniques are accurately put in place.

A larger sized system may cost more whereas a smaller sized system may not

fulfill one’s requirements and thus, sizing a solar PV system before purchasing

is very important and should be considered. Sizing depends on the load

requirements in the set up.

Therefore, with the result of this project, for better and efficient solar energy

system, a bigger sized solar system is required.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

43

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

REFERENCES

Al-Mohamad, Ali, (2004): Efficiency Improvements of photo-voltaic panels

using a sun-tracking system. Applied Energy, 79 (3): 345-354. doi:

10.1016/j.apenergy. 2003.12.004.

Amanda Cain (2014): What is a photovoltaic diesel hybrid system? Renewable

energy world.com.

Andrews, Rob W, (2013): The effects of snow fall on solar photovoltaic

performance. Solar energy. 92 (8497): 84-97. doi:

10.1016/j.solener.2013.02.014.

BijliBachao, (2016): Sizing Batteries and Inverters for a solar PV system.

Accessed on April 22, 2016.

Branka, J. M. (2011): A review of solar photovoltaic levelized costs of

electricity. Renewable and sustainable energy review. 15 (9): 4470-4482.

Doi: 10.1016/j.rser.2011.07.104 hdl: 1974/6879.

Brennan, M. P., (2014): Effects of spectra albeldo on solar photovoltaic

devices.

Chris Woodford, (2014): Solar thermal energy which covers humankind’s

efforts to harness energy. How do solar cells work? – Available at:

explainthatstuff.com. Accessed on 2nd May, 2016.

Clarke, Chris (2011): Efficiency Record for PV. Available at Optics.org.

Accessed on 10th May, 2016.

Edoff, Marika (2012): Thin film Solar cells. Research in an industry

perspective. ISSN 0044-7447. PMC 335764. PMID 22434436.

Free Sun Power,(2015): Solar energy systems terms and definitions,

freesunpower.com/solar-term php.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

44

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

Photovoltaic Sizing and Battery Capacity Determination in Solar Electricity System

Gevorkian, Peter (2007): Sustainable energy system enginerring; the complete

green building design resource. McGraw Hill Professional. ISBN 978-0-

07-147359-0

Jone, Geoffery (2012): Power from sunshine. A Business History of Solar

Energy. Harvard Business School.

Kim, D. S (2003): String ribbon silicon solar cells with 17.8% efficiency.

Proceedings of 3rd World Conference on Photovoltaic energy conversion,

2013. ISBN 4-9901816-0-3

Leonics Co, (2013): Solar photovoltaic system, how to design solar PV system.

Guide for sizing your solar photovoltaic system.

Lunt, R. R. (2012): Theoretical limit for visibly transparent photovoltaic.

Applied Physics Letters 101(4):043902. doi: 10.1063/1.4738896

Michael Mooney, (1997): A self study guidebook on the exciting world of solar

electricity with detailed examples to power both large and small

dwellings.ARC Press of Cane Hill, 1997

Morgan, Baziliana (2012): Reconsidering the economics of PV power. United

Nations-Energy (Report).

Solar Direct, (2016): Aims and objectives of PV cell sizing, photovoltaic benefits

in solar PV system. Available at: www.solarfacts.com. Accessed on 8th

April, 2016.

Tsokos, K. A. (2010): Physics for diploma full colour. Cambridge University

Press. ISBN 978-0-521-13821-5

Williams, Neville (2005): Chasing the sun. Solar adventures around the

world. New society Publishers. ISBN 9781550923124.

OYEDEMI MAYOWA RICHARD [LT/ND/P12/1703]

45

AND ONYEMECHA HENRY OKWUDIRI [LT/ND/P12/1699]

You might also like

- Project Report On Solar Module Manufacturing Unit (250-300 Mw/annum)Document12 pagesProject Report On Solar Module Manufacturing Unit (250-300 Mw/annum)EIRI Board of Consultants and Publishers50% (2)

- Human Anatomy Physiology 10th Edition Marieb Hoehn Test BankDocument36 pagesHuman Anatomy Physiology 10th Edition Marieb Hoehn Test Bankdorislanhpr028No ratings yet

- C9e Answers Active Reading 04Document4 pagesC9e Answers Active Reading 04Jordan Camina75% (8)

- Case Study-Solar EnergyDocument24 pagesCase Study-Solar Energyadam0611No ratings yet

- Calculation of Electrical Energy With SolarDocument4 pagesCalculation of Electrical Energy With Solarmohamed parvez100% (1)

- Smart Task 1 Solar PVDocument7 pagesSmart Task 1 Solar PVShubham AroraNo ratings yet

- Chapter 2 Solar PowerDocument112 pagesChapter 2 Solar PowerBewnet GetachewNo ratings yet

- Solar Panel: Jump To Navigation Jump To SearchDocument18 pagesSolar Panel: Jump To Navigation Jump To SearchEr Dinesh TambeNo ratings yet

- MainDocument25 pagesMainDurgaprasadNo ratings yet

- Design and Construction of A Solar Powered Streetlight SystemDocument7 pagesDesign and Construction of A Solar Powered Streetlight Systemsamuel mechNo ratings yet

- Solar Power Plant Report 1Document28 pagesSolar Power Plant Report 1Alankar MishraNo ratings yet

- Chapter Three DesignDocument20 pagesChapter Three DesignADEFRIS BELACHEWNo ratings yet

- Solar Power Plant: Government Engineering College BharatpurDocument29 pagesSolar Power Plant: Government Engineering College BharatpurHinduja KumarasamyNo ratings yet

- Solar Cells & Their ApplicationDocument11 pagesSolar Cells & Their ApplicationpiyushNo ratings yet

- Chapter-1 IntroductionDocument24 pagesChapter-1 IntroductionNaveenNo ratings yet

- SDPV31306Document65 pagesSDPV31306bdsisira100% (1)

- Group3-SECT W.answersDocument44 pagesGroup3-SECT W.answersJustino BalaneNo ratings yet

- Projectreport REDocument15 pagesProjectreport REUnzillahNo ratings yet

- SolarDocument57 pagesSolarRaghavendra Raghav100% (1)

- CHAPTER 3 TECHNICAL ASPECT Solar Powered GeneratorDocument47 pagesCHAPTER 3 TECHNICAL ASPECT Solar Powered GeneratorRed SecretarioNo ratings yet

- Design of A Photovoltaic System For A Rural House: M.Aminy, N.Barhemmati, A.Hadadian, F.ValiDocument5 pagesDesign of A Photovoltaic System For A Rural House: M.Aminy, N.Barhemmati, A.Hadadian, F.ValiHypnotic KnightNo ratings yet

- Solar Mobile Charging Station Final ProjectDocument23 pagesSolar Mobile Charging Station Final Projectyash Jadhao100% (1)

- Rev. in PhotovoltaicDocument2 pagesRev. in PhotovoltaicChristopher AsuncionNo ratings yet

- Sun (Up)Document17 pagesSun (Up)Rakibul HassanNo ratings yet

- 22661-RET Notes-UNIT 02Document25 pages22661-RET Notes-UNIT 02jayeshdeore398No ratings yet

- What Is Solar Systems and How To Design ItDocument5 pagesWhat Is Solar Systems and How To Design Itabuzar12533No ratings yet

- Solar Mobile Charger PDFDocument29 pagesSolar Mobile Charger PDFAayush guptaNo ratings yet

- Solar PV Individual ReportDocument7 pagesSolar PV Individual ReportshathishNo ratings yet

- Shathish Solar PVDocument7 pagesShathish Solar PVshathishNo ratings yet

- Effect of Shading On Photovoltaic Cell: Ekpenyong, E.E and Anyasi, F.IDocument6 pagesEffect of Shading On Photovoltaic Cell: Ekpenyong, E.E and Anyasi, F.IM VetriselviNo ratings yet

- Chapter:-1: 1.1 Introduction To Solar EnergyDocument15 pagesChapter:-1: 1.1 Introduction To Solar EnergySwaroopNo ratings yet

- Renewable Energy-Design Concepts & Implementation: Engr. Nwafor Chukwubuikem MichaelDocument20 pagesRenewable Energy-Design Concepts & Implementation: Engr. Nwafor Chukwubuikem MichaelSixtus OkoroNo ratings yet

- IJNRD1704035Document6 pagesIJNRD1704035Eslam MetwalyNo ratings yet

- Unit II - RETDocument59 pagesUnit II - RETsagarpatil03012No ratings yet

- Solar Panel: Solar PV Modules Mounted On A RooftopDocument17 pagesSolar Panel: Solar PV Modules Mounted On A RooftopMaria Sweetlin DNo ratings yet

- Project Report On Maximum Power Point Tracking of PV Arrays in SimulinkDocument7 pagesProject Report On Maximum Power Point Tracking of PV Arrays in SimulinkPriyanshu SinghNo ratings yet

- Solar IeeeDocument7 pagesSolar IeeeDinesh Venkata RamaGopal MorlaNo ratings yet

- PhtoDocument18 pagesPhtoshaurya sharmaNo ratings yet

- SolarDocument57 pagesSolarNag Y50% (2)

- Design and Implementation of A Solar Charge Controller With Variable OutputDocument12 pagesDesign and Implementation of A Solar Charge Controller With Variable OutputEmmanuel SundayNo ratings yet

- History of Solar PowerDocument3 pagesHistory of Solar PowersmshivaNo ratings yet

- Report 3 D Solar Cell...Document15 pagesReport 3 D Solar Cell...Pankaj DeshmukhNo ratings yet