Professional Documents

Culture Documents

Toulouse, France 14-17 October 2008: International Conference On Space Optics-ICSO 2008

Toulouse, France 14-17 October 2008: International Conference On Space Optics-ICSO 2008

Uploaded by

jaber resalatiCopyright:

Available Formats

You might also like

- BP Approved Connection ListDocument10 pagesBP Approved Connection ListEDWIN M.PNo ratings yet

- Selection Criteria For EnginesDocument13 pagesSelection Criteria For EnginesVeda Prasad. RNo ratings yet

- MT6763 Android ScatterDocument12 pagesMT6763 Android ScatterJenny TubaranNo ratings yet

- Proceedings of Spie: Development, Calibration and Characterization of Silicon Photonics Based Optical Phased ArraysDocument9 pagesProceedings of Spie: Development, Calibration and Characterization of Silicon Photonics Based Optical Phased ArraysramyradyNo ratings yet

- Hollow Core Fiber Optic Ring Resonator For Rotation Sensing: ME6 PDFDocument4 pagesHollow Core Fiber Optic Ring Resonator For Rotation Sensing: ME6 PDFSebastian Soto PerdomoNo ratings yet

- Probe Signal, and A Continuous Power Wavelength, A2, Called The PumpDocument13 pagesProbe Signal, and A Continuous Power Wavelength, A2, Called The PumpYenny Isabel BetancourtNo ratings yet

- Range-Gated Active Imaging System For Search and Rescue, and Surveillance OperationsDocument12 pagesRange-Gated Active Imaging System For Search and Rescue, and Surveillance OperationsR_o_M_a_N_c_ENo ratings yet

- A 1-D Photonic Band Gap Tunable Optical Filter in (110) SiliconDocument7 pagesA 1-D Photonic Band Gap Tunable Optical Filter in (110) SiliconYasser SabryNo ratings yet

- Lange 2006Document9 pagesLange 2006isaanisaanNo ratings yet

- Comparative Assessment On Ramp and Bias Voltage Variations of Closed Loop Interferometric Fiber Optic GyroscopeDocument11 pagesComparative Assessment On Ramp and Bias Voltage Variations of Closed Loop Interferometric Fiber Optic Gyroscopejaber resalatiNo ratings yet

- Fiber Optic Sensors and Their Applications: Conference PaperDocument7 pagesFiber Optic Sensors and Their Applications: Conference Paperpaolo.baraldiNo ratings yet

- Chalcogenide Glass Optical Wave Guides For Infrared Bio SensingDocument14 pagesChalcogenide Glass Optical Wave Guides For Infrared Bio SensingHoward NgNo ratings yet

- Sensor 2024Document7 pagesSensor 2024k6bqph7hxbNo ratings yet

- Evaluation of Signal Degradation Due To birefringence-TOMI-2022Document13 pagesEvaluation of Signal Degradation Due To birefringence-TOMI-2022Amelia DemianowiczNo ratings yet

- Exfo - Wpaper113 Spectral Testing Active Systems in Lab and Manufacturing Environments - enDocument7 pagesExfo - Wpaper113 Spectral Testing Active Systems in Lab and Manufacturing Environments - enAbdalmoedAlaiashyNo ratings yet

- Octans Highly CompactDocument8 pagesOctans Highly CompactgeenjunkmailNo ratings yet

- Installation and Commissioning of FLAMES, The VLT Multifibre FacilityDocument52 pagesInstallation and Commissioning of FLAMES, The VLT Multifibre FacilityEuropean Southern ObservatoryNo ratings yet

- Free Space OpticsDocument7 pagesFree Space OpticsDeepäk KümàwätNo ratings yet

- Development of Fiber Optic Radiation Monitor Using Plastic Scintillation FibersDocument9 pagesDevelopment of Fiber Optic Radiation Monitor Using Plastic Scintillation FibersdeellNo ratings yet

- Integrated Frequency-Modulated Optical Parametric OscillatorDocument27 pagesIntegrated Frequency-Modulated Optical Parametric Oscillatorazzaali0909No ratings yet

- Wireless CommunicationDocument8 pagesWireless CommunicationranandmavenNo ratings yet

- FREE SPACEOPTICS (Wireless Communication)Document6 pagesFREE SPACEOPTICS (Wireless Communication)Raja SekharNo ratings yet

- Fiber Optic Components For Fiber Optic Gyroscope ApplicationsDocument2 pagesFiber Optic Components For Fiber Optic Gyroscope ApplicationsDK Photonics100% (1)

- Optical Fibre: Physics Investigatory ProjectDocument22 pagesOptical Fibre: Physics Investigatory ProjectSurendar MVNo ratings yet

- Fiber Optic Monitoring in Openhole Gravel Pack CompletionsDocument14 pagesFiber Optic Monitoring in Openhole Gravel Pack CompletionsKen NgNo ratings yet

- Ring LasersDocument7 pagesRing LasersMansoor KhanNo ratings yet

- History and Vision of Optical Fiber Fusion Splicing TechnologyDocument4 pagesHistory and Vision of Optical Fiber Fusion Splicing TechnologyCHARLES ROBERTNo ratings yet

- 08572252Document4 pages08572252angelikjoliehNo ratings yet

- Highly Sensitive Fiber-Optic Fabry-Perot Geophone With Graphene-Coated PMMA MembraneDocument4 pagesHighly Sensitive Fiber-Optic Fabry-Perot Geophone With Graphene-Coated PMMA MembranebackupzalfaaNo ratings yet

- Aerospace Optical Sensors Handout WEB v2Document2 pagesAerospace Optical Sensors Handout WEB v2ggggggbNo ratings yet

- An Introduction To Fibre Optic Systems - Part IDocument6 pagesAn Introduction To Fibre Optic Systems - Part I5606438No ratings yet

- Presentation ShamimDocument14 pagesPresentation ShamimBINOY KRISHNA GHOSHNo ratings yet

- CONSTRUCTION OF A 700 MHZ PROTOTYPICAL CRYOMODULEDocument6 pagesCONSTRUCTION OF A 700 MHZ PROTOTYPICAL CRYOMODULEvladimirNo ratings yet

- Design Performance Evaluation of A Dipole Antenna Using Various Lengths of Antenna MaterialDocument7 pagesDesign Performance Evaluation of A Dipole Antenna Using Various Lengths of Antenna Materialronak kishorNo ratings yet

- W-Band Optoelectronic OscillatorDocument4 pagesW-Band Optoelectronic OscillatorHari EnthiranNo ratings yet

- Module 3 and 4 PDFDocument30 pagesModule 3 and 4 PDFAyushi SharmaNo ratings yet

- Development of Highly Sensitive Fiber Optic Acosutic Sensor and Its Preliminary Application For Sound LocalizationDocument10 pagesDevelopment of Highly Sensitive Fiber Optic Acosutic Sensor and Its Preliminary Application For Sound LocalizationJoseph ThomasNo ratings yet

- Applications: Optical Fiber Attenuation InterferenceDocument6 pagesApplications: Optical Fiber Attenuation InterferenceezohaibNo ratings yet

- Nphoton 2012 15Document1 pageNphoton 2012 15arkoprobho235No ratings yet

- Fiber GyroDocument5 pagesFiber GyroDanny DeWittNo ratings yet

- Mode Coupling and Equilibrium Mode Distribution Conditions in Plastic Optical FibersDocument3 pagesMode Coupling and Equilibrium Mode Distribution Conditions in Plastic Optical Fibersjianing sunNo ratings yet

- 10.1515 - Nanoph 2023 0636Document12 pages10.1515 - Nanoph 2023 0636samam nnanaNo ratings yet

- Fiber Optic TrainingDocument32 pagesFiber Optic TrainingasifaliabidNo ratings yet

- The Opto-Electronic Oscillator (OEO) : Review and Recent ProgressDocument4 pagesThe Opto-Electronic Oscillator (OEO) : Review and Recent ProgressDuong Ly HoangNo ratings yet

- System Characterization of A Passive 40 Gb/s All Optical Clock Recovery Ahead of The ReceiverDocument7 pagesSystem Characterization of A Passive 40 Gb/s All Optical Clock Recovery Ahead of The ReceiverdmsampaNo ratings yet

- EDFA and Optical Fiber Repositioning in An Optical Fiber Communication NetworkDocument8 pagesEDFA and Optical Fiber Repositioning in An Optical Fiber Communication NetworkIJRASETPublicationsNo ratings yet

- Abstract of Fiber Optic SensorsDocument6 pagesAbstract of Fiber Optic SensorsKamal UniyalNo ratings yet

- Dual-Polarised Lens Feed Arrays and End-Fire AntenDocument6 pagesDual-Polarised Lens Feed Arrays and End-Fire AntenRAJA RAMALINGAMNo ratings yet

- IA2 SolutionDocument10 pagesIA2 SolutionKaran MNo ratings yet

- Next Generation Wireless Communication - Free Space Optics (FSO)Document8 pagesNext Generation Wireless Communication - Free Space Optics (FSO)nithyanandhan90No ratings yet

- Wavelength MeterDocument1 pageWavelength Meterhieu dongNo ratings yet

- Fibre-Optic Sagnac Interferometer As Real Sensor of The Physical QuantitiesDocument4 pagesFibre-Optic Sagnac Interferometer As Real Sensor of The Physical QuantitiesThiago CoelhoNo ratings yet

- Fiber-Optic Sensors:: Applications and AdvancesDocument6 pagesFiber-Optic Sensors:: Applications and AdvanceshelenarajNo ratings yet

- Monitoring of Fibre Optic Links With A Machine LeaningDocument7 pagesMonitoring of Fibre Optic Links With A Machine LeaningMohit MahurNo ratings yet

- Optical Components of The NIRSPECDocument12 pagesOptical Components of The NIRSPECojangurenNo ratings yet

- Government Engineering College, Bilaspur: AssignmentDocument7 pagesGovernment Engineering College, Bilaspur: AssignmentJinius MishraNo ratings yet

- Selective Patterning of ITO On Flexible PET Substrate by 1064nm Picosecond LaserDocument8 pagesSelective Patterning of ITO On Flexible PET Substrate by 1064nm Picosecond Laserreza mirzakhaniNo ratings yet

- FREE SPACE OPTICS Seminar ReportDocument20 pagesFREE SPACE OPTICS Seminar ReportNaveen Kumar N50% (2)

- Optical Fiber Technology: Maizatul Zolkapli, Suhairi Saharudin, Sukreen Hana Herman, Wan Fazlida Hanim AbdullahDocument9 pagesOptical Fiber Technology: Maizatul Zolkapli, Suhairi Saharudin, Sukreen Hana Herman, Wan Fazlida Hanim Abdullahirma irmaNo ratings yet

- Two-User 2.5Gbps 100km OCDMA Transmission Experiment Using EPS-SSFBG En/decoderDocument7 pagesTwo-User 2.5Gbps 100km OCDMA Transmission Experiment Using EPS-SSFBG En/decoderHudson M. CerriNo ratings yet

- Wa0029. 1Document30 pagesWa0029. 1Angelina BennyNo ratings yet

- Interior Lighting: Fundamentals, Technology and ApplicationFrom EverandInterior Lighting: Fundamentals, Technology and ApplicationNo ratings yet

- Manajemen Perioperatif Operasi Arterial Switch PadaDocument12 pagesManajemen Perioperatif Operasi Arterial Switch Padacomiza92No ratings yet

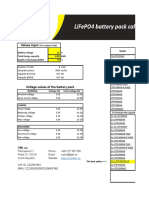

- The Best Suitable Lifepo4 Cells Values Input: (Fill in Yellow Fields)Document2 pagesThe Best Suitable Lifepo4 Cells Values Input: (Fill in Yellow Fields)HirenNo ratings yet

- FAQs On RMIBD - Hedging of Foreign Exchange Risk DTD July 14 2020Document7 pagesFAQs On RMIBD - Hedging of Foreign Exchange Risk DTD July 14 2020Anup SharmaNo ratings yet

- Laravel Security ChecklistDocument18 pagesLaravel Security ChecklistfokavomoNo ratings yet

- Affidavit of DenialDocument1 pageAffidavit of Denialkillua111445100% (1)

- ISPS Code - A Measure To Enhance The Security of Ships and Port FacilitiesDocument11 pagesISPS Code - A Measure To Enhance The Security of Ships and Port FacilitiesGiorgi KandelakiNo ratings yet

- Sports Economics 2017 1st Edition Berri Solutions ManualDocument8 pagesSports Economics 2017 1st Edition Berri Solutions Manualbrendabrownipnmktbzas100% (10)

- Caso CEMEX MarianoDocument2 pagesCaso CEMEX MarianoMariano LopezNo ratings yet

- 2023 March 20. LT Group SR 2022 - FinalDocument65 pages2023 March 20. LT Group SR 2022 - Finalaltheadelacruz121403No ratings yet

- Motorized Gas Damper A-Hva-Rep-000-38132-BDocument31 pagesMotorized Gas Damper A-Hva-Rep-000-38132-Bja3farNo ratings yet

- Republic v. Far East EnterprisesDocument3 pagesRepublic v. Far East EnterprisesJustineNo ratings yet

- Promotion Presentation 2013Document26 pagesPromotion Presentation 2013Skycop OnallagNo ratings yet

- B031910499 - Students Who Study Abroad Achieve Greater SuccessDocument9 pagesB031910499 - Students Who Study Abroad Achieve Greater SuccessIsrat DibaNo ratings yet

- Img 20200829 0001Document3 pagesImg 20200829 0001api-402048659No ratings yet

- TDS - Rheobuild 1100Document3 pagesTDS - Rheobuild 1100Alexi ALfred H. Tago100% (1)

- Responsible Leadership ReportDocument7 pagesResponsible Leadership ReportRNo ratings yet

- Indo-Pacific StrategyDocument24 pagesIndo-Pacific Strategy李修瑩No ratings yet

- NCM 112 EvalDocument16 pagesNCM 112 EvalMartin T ManuelNo ratings yet

- Abdominal Ultrasound For Pediatric Blunt Trauma FAST Is Not Always BetterDocument3 pagesAbdominal Ultrasound For Pediatric Blunt Trauma FAST Is Not Always BetterInryuu ZenNo ratings yet

- Non Destructive TestingDocument16 pagesNon Destructive Testinganishdev6No ratings yet

- Blues Scales - Euphonium (Bass Clef) - LexcerptsDocument2 pagesBlues Scales - Euphonium (Bass Clef) - LexcerptsLexcerptsNo ratings yet

- United States v. Syed Ali Abrar, 58 F.3d 43, 2d Cir. (1995)Document7 pagesUnited States v. Syed Ali Abrar, 58 F.3d 43, 2d Cir. (1995)Scribd Government DocsNo ratings yet

- Case DigestDocument5 pagesCase DigestChrissy SabellaNo ratings yet

- Developmental Counseling Form: The Leader's Facts and Observations Prior To The Counseling.)Document3 pagesDevelopmental Counseling Form: The Leader's Facts and Observations Prior To The Counseling.)Anonymous EpKfz0LNo ratings yet

- 1T6-220 Switched Ethernet Network Analysis and TroubleshootingDocument36 pages1T6-220 Switched Ethernet Network Analysis and TroubleshootingcertvistaNo ratings yet

- History of Perodua Analysis PDFDocument13 pagesHistory of Perodua Analysis PDFaishahrodziNo ratings yet

- Lesson 1 FRANCHISING Introduction Converted 1Document32 pagesLesson 1 FRANCHISING Introduction Converted 1arzeljoyvillanueva3No ratings yet

Toulouse, France 14-17 October 2008: International Conference On Space Optics-ICSO 2008

Toulouse, France 14-17 October 2008: International Conference On Space Optics-ICSO 2008

Uploaded by

jaber resalatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toulouse, France 14-17 October 2008: International Conference On Space Optics-ICSO 2008

Toulouse, France 14-17 October 2008: International Conference On Space Optics-ICSO 2008

Uploaded by

jaber resalatiCopyright:

Available Formats

International Conference on Space Optics—ICSO 2008

Toulouse, France

14–17 October 2008

Edited by Josiane Costeraste, Errico Armandillo, and Nikos Karafolas

From space qualified fiber optic gyroscope to generic fiber optic

solutions available for space application

Thomas Buret

David Ramecourt

Fabien Napolitano

International Conference on Space Optics — ICSO 2008, edited by Josiane Costeraste, Errico Armandillo,

Nikos Karafolas, Proc. of SPIE Vol. 10566, 105660U · © 2008 ESA and CNES

CCC code: 0277-786X/17/$18 · doi: 10.1117/12.2308279

Proc. of SPIE Vol. 10566 105660U-1

Downloaded From: https://www.spiedigitallibrary.org/conference-proceedings-of-spie on 17 Aug 2021

Terms of Use: https://www.spiedigitallibrary.org/terms-of-use

ICSO 2008 Toulouse, France

International Conference on Space Optics 14 - 17 October 2008

FROM SPACE QUALIFIED FIBER OPTIC GYROSCOPE

TO GENERIC FIBER OPTIC SOLUTIONS AVAILABLE FOR SPACE APPLICATION

Thomas Buret (1), David Ramecourt (2), Fabien Napolitano (3)

IXSPACE, 55 avenue Auguste Renoir, 78160 Marly-le-Roi, France ; thomas.buret@ixspace.fr

(1)

(2)

IXSPACE, 55 Avenue Auguste Renoir, 78160 Marly-le-Roi, France ; david.ramecourt@ixspace.fr

(3)

IXSEA, 55 Avenue Auguste Renoir, 78160 Marly-le-Roi, France ; fabien.napolitano@ixsea.com

ABSTRACT

Coil

The aim of this article is to present how the qualification

of the Fiber Optic Gyroscope technology from IXSEA

has been achieved through the qualification of a large

range of optical devices and related manufacturing

processes. These qualified optical devices and

processes, that are now fully mastered by IXSEA

through vertical integration of the technology, can be

used for other space optical sensors. The example of the

SWARM project will be discussed. Fig. 1 FOG Optimum Configuration

By using this type of configuration, known as an ‘all-

1. IXSEA FIBER OPTIC GYROSCOPE digital closed-loop hybrid’, the performance obtained

TECHNOLOGY makes it possible to attain the Holy Grail of rotation

detection : stability better than 0.01 degree per hour.

Basically, a Fiber Optic Gyroscope (or FOG) is based

on the Sagnac effect, which produces a phase difference The ‘heart’ of the system is a LiNbO3 Integrated

Optical Circuit (IOC) which is altogether an Y-junction,

∆Φs proportional to the rotation rate Ω in a ring

a phase modulator and a highly efficient polarizer

interferometer [1]. In the FOG, the ring interferometer is

(>80dB!); it permits to inject light in the coil, to

a coil of optical fiber which can be several kilometres

‘process’ it and to filter it. The optical source is an

long. The phase shift depends on fiber coil dimensions

erbium doped-fiber Amplified Spontaneous Emission

following a simple law:

(ASE) source, which provides an unpolarized light

@1550nm with a wide spectrum (several nm). It is

LD

∆Φ s = 2π Ω (1) composed of a 980nm pump diode, Er-doped fiber,

λc Fiber Bragg Grating (FBG) and Isolator. Last but not

least, the photodetector is a PinFet with high sensitivity

where L and D are the length and the diameter of the and low noise: the signal to be detected is as low as

fiber coil, c is the speed of light in vacuum, λ is the 10-5 µW!

mean wavelength.

This effect is very small, and in order to minimize all 2. THE ASTRIX PRODUCT FAMILY

the others parasitic phase shifts, an all-guided

Reciprocal Configuration is used [2]. EADS-Astrium and IXSPACE have achieved the

industrialisation and the qualification of IXSEA space

The optimum configuration for a FOG offering best Fiber Optic Gyroscopes technology with the support of

performances is shown in figure 1. CNES and ESA. ITAR free ASTRIXTM Inertial

Measurement Unit product family is now available,

covering a large range of inertial performances (from

0.1°/h to 0.001°/h) and applications (Galileo, Planck,

Pleiades) with more than 40 gyroscopes Flight Model

already delivered by IXSPACE.

Proc. of SPIE Vol. 10566 105660U-2

Downloaded From: https://www.spiedigitallibrary.org/conference-proceedings-of-spie on 17 Aug 2021

Terms of Use: https://www.spiedigitallibrary.org/terms-of-use

ICSO 2008 Toulouse, France

International Conference on Space Optics 14 - 17 October 2008

ASTRIX industrial Organization is as follows : • radiation tests (gamma ray cumulated dose up

IXSPACE manufacture the FOG channel that comprise to 300krd and proton particle testing of 60

the electronic board (delivered by ASTRIUM CRISA) MeV, 1,8e11p/cm2). The effect of radiation

and the optical interferometer. Each Gyroscopic tests on iFOG technology is induced by the

Channel is then integrated on a tetrahedron or redundant creation of colored center in the fibre optic

axis structure to obtain an Inertial Measurement Unit : core, increasing the optical fibre insertion loss.

the ASTRIXTM IMU. • thermal tests to demonstrate lifetime of five to

fifteen years in orbit by thermal cycling (up to

Three families of IMU are now available : Astrix 200 500 [-40°C;+85°C]) and ageing testing (up to

(for 200 mm diameter fibre coil), Astrix 120 (for 120 3000 hours at 85°C).

mm diameter fibre coil) and 120 HR. These IMU are • thermal vacuum testing.

composed of FOG with the same electronic and optical • outgasing testing, as any outgasing could lead

source. The difference between Astrix 120 and 120 HR to critical pollution (telescopes are very

(for High Reliability) consists in quality level of sensitive to any deposition of organic material

electronic components, that shall cover 15 years on optical surface)

operational Lifetime. The three configurations have

been successfully implemented, and the required inertial The good results obtained are not that surprising as

performances have been demonstrated on Astrix 200 many components come from the submarine Telecom

and 120 Flight Models. market, for which reliability under very long time (up to

25 years) is also a key issue. They demonstrate also

The Astrix product family is shown in Figure 2 some of the technology key advantages: no wear out

effects due to moving parts or sealed packaging,

Astrix 200

Redundant 3 axis Inertial angular rate

Astrix 120

Redundant 3 axis Inertial angular rate

Astrix 120 HR

Redundant 1 axis Inertial angular

lightweight component.

detection (tetrahedron – 4 axes). detection (tetrahedron – 4 axes). rate detection

In fact the only weariness effect that has been observed

is linked to radiation induced fibre optic darkening, that

deteriorates the overall optical budget.

Typical radiation-induced optical attenuation is shown

Coil Size : 5km Coil Size : 1km Coil Size : 1km in figure 3

Short term Bias stability: 0.001°/h Short term Bias stability: 0.01°/h Short term Bias stability: 0.02°/h

Angular Random walk : 0.0002 °/√h Angular Random walk : 0.002 °/√h Angular Random walk : 0.003 °/√h

Scale factor stability : 30 ppm Scale factor stability : 100 ppm. Scale factor stability : 100 ppm.

Qualification Results : 10 samples gamma irradiated

Budgets : 7 kg, 20 W. Budgets : 7 kg, 20 W. Budgets : 4 kg, 7W 15,0

Customers: Earth Observation Satellite Customers: Scientific Satellite Customers: Telecommunication 14,0

S02 "ON"

0,14dB/krad/km S08 "ON"

CNES (PLEIADES), ESA (AEOLUS) ESA (PLANCK), Export Satellite. ASTRIUM (COMS) S12 "ON"

13,0 S07 "ON"

Operational Lifetime : 5 Years Operational Lifetime : 5 Years Operational lifetime : 15 Years S09 "ON"

12,0 S16 "OFF"

S10 "OFF"

11,0 S06 "OFF"

0,07dB/krad/km S19 "OFF"

Transmission Loss Drift (dB)

10,0 S15 "OFF"

Maximum acceptable drift (FOG120)

Qualification target level (dB)

9,0

8,0

Fig. 2 ASTRIX IMU product family 7,0

Final result ~0,025dB/krad/km

6,0

5,0

4,0

3. A LARGE RANGE OF OPTICAL DEVICES 3,0

2,0

AND PROCESSES QUALIFIED FOR SPACE 1,0

APPLICATION 0,0

0 50 100 150 200 250 300 350

Total dose (kRad[Si])

The IFOG consists of a variety of optical devices: active

optoelectronic component (laser diode, low noise

photodetector, phase modulator), passive optical Fig.3 Fiber Optic radiation-induced loss

components (coupler, isolators, bragg grating) and

special optical fibre (Erbium-doped fibre and fibre coil The long term availability of the optical devices is

for the Sagnac interferometer). ensured by the vertical integration of the FOG

technology. Every critical optical component is either

These optical devices have been thoroughly tested under manufactured by IXSEA (laser diode, low noise photo

very harsh environment. detector) or by a sister company (IXFIBER for special

optical fiber such as Polarization Maintaining Fiber, or

• mechanical tests (vibration to 25 grms and rare Earth doped Fiber). Critical manufacturing

shock up to 1500g, 1ms) that cover mechanical processes have been either internally developed or

stress experienced by the equipment during

launching sequence.

Proc. of SPIE Vol. 10566 105660U-3

Downloaded From: https://www.spiedigitallibrary.org/conference-proceedings-of-spie on 17 Aug 2021

Terms of Use: https://www.spiedigitallibrary.org/terms-of-use

ICSO 2008 Toulouse, France

International Conference on Space Optics 14 - 17 October 2008

acquired and improved by IXSEA (coil winding The SWARM fiber laser is shown in Figure 4.

process, Optical Assembly).

4. AVAILABLE SOLUTIONS FOR NEW

APPLICATION: THE SWARM PROJECT

EXAMPLE

The FOG qualification campaign has been a case study

in many ways for any space qualification engineer.

IXSPACE and EADS ASTRIUM had to tackle with

strong budget constraints, while improving component

quality, adapting key manufacturing process and

qualifying a state of the art inertial sensor (0,001°/h

rotation rate accuracy).

The lessons learned during the FOG qualification

campaign can be extended to many other space

applications as the constraints we had to face are indeed

generic requirements to which every new optical sensor

shall be confronted to during space qualification.

Fig. 4 SWARM Ytterbium fiber laser

Taking advantage of its own expertise in the space field

combined with IXSEA and IXFIBER expertise and

manufacturing capacities, IXSPACE can design

solutions in a large range of space applications requiring

fiber optic technologies: opto-electronics components, 5. CONCLUSION

sensors, fibre laser, assembly on mechanical and/or

electronic board. A very large range of optical components,

manufacturing processes as well as a very broad

The first application of this know how outside the FOG expertise have been built in the frame of the FOG

is the SWARM project on which IXSPACE collaborates qualification campaign. The SWARM project has

with the French Space Agency CNES and the CEA demonstrated the interest of capitalising on this

LETI. IXSPACE is in charge of the integration of the qualification Heritage.

Ytterbium optical fibre laser used in the SWARM

magnetometer. Some key components of the FOG

technology such as IXSEA’s 980nm Laser Diode have

been used. Some key manufacturing processes that were 6. REFERENCES

qualified in the frame of the FOG technology 1, G. Sagnac, L’éther lumineux démontré par l’effet du vent

qualification have been adapted to the application as relatif d’éther dans un interféromètre en rotation uniforme,

[The existence of light ether demonstrated by the effect of the

well.

relative ether wind on a uniformly rotating interferometer],

Comptes Rendus de l’Académie des Sciences Vol.

This Laser used for the pumping of the Helium cell of 95, 1913, pp 708-710.

the magnetometer, is an athermal Bragg grating photo-

written in an active Ytterbium fibre (LFA). 2, H. Lefevre, The Fiber Optic Gyroscope, 1993,Artech

A pump Laser diode at 980nm is used in the pumping of House.

the LFA through an optical Polarizing Maintaining

Multiplexer.

This optical device comprises also an optical fibre

photo-detector; an isolator for the back reflection ; an

electro-optical modulator in the modulation of the Laser

signal for the cell pumping. The commonalities with

FOG optical configuration are obvious, and many

informations from the FOG qualification campaign

proved of great interest for this project.

Proc. of SPIE Vol. 10566 105660U-4

Downloaded From: https://www.spiedigitallibrary.org/conference-proceedings-of-spie on 17 Aug 2021

Terms of Use: https://www.spiedigitallibrary.org/terms-of-use

You might also like

- BP Approved Connection ListDocument10 pagesBP Approved Connection ListEDWIN M.PNo ratings yet

- Selection Criteria For EnginesDocument13 pagesSelection Criteria For EnginesVeda Prasad. RNo ratings yet

- MT6763 Android ScatterDocument12 pagesMT6763 Android ScatterJenny TubaranNo ratings yet

- Proceedings of Spie: Development, Calibration and Characterization of Silicon Photonics Based Optical Phased ArraysDocument9 pagesProceedings of Spie: Development, Calibration and Characterization of Silicon Photonics Based Optical Phased ArraysramyradyNo ratings yet

- Hollow Core Fiber Optic Ring Resonator For Rotation Sensing: ME6 PDFDocument4 pagesHollow Core Fiber Optic Ring Resonator For Rotation Sensing: ME6 PDFSebastian Soto PerdomoNo ratings yet

- Probe Signal, and A Continuous Power Wavelength, A2, Called The PumpDocument13 pagesProbe Signal, and A Continuous Power Wavelength, A2, Called The PumpYenny Isabel BetancourtNo ratings yet

- Range-Gated Active Imaging System For Search and Rescue, and Surveillance OperationsDocument12 pagesRange-Gated Active Imaging System For Search and Rescue, and Surveillance OperationsR_o_M_a_N_c_ENo ratings yet

- A 1-D Photonic Band Gap Tunable Optical Filter in (110) SiliconDocument7 pagesA 1-D Photonic Band Gap Tunable Optical Filter in (110) SiliconYasser SabryNo ratings yet

- Lange 2006Document9 pagesLange 2006isaanisaanNo ratings yet

- Comparative Assessment On Ramp and Bias Voltage Variations of Closed Loop Interferometric Fiber Optic GyroscopeDocument11 pagesComparative Assessment On Ramp and Bias Voltage Variations of Closed Loop Interferometric Fiber Optic Gyroscopejaber resalatiNo ratings yet

- Fiber Optic Sensors and Their Applications: Conference PaperDocument7 pagesFiber Optic Sensors and Their Applications: Conference Paperpaolo.baraldiNo ratings yet

- Chalcogenide Glass Optical Wave Guides For Infrared Bio SensingDocument14 pagesChalcogenide Glass Optical Wave Guides For Infrared Bio SensingHoward NgNo ratings yet

- Sensor 2024Document7 pagesSensor 2024k6bqph7hxbNo ratings yet

- Evaluation of Signal Degradation Due To birefringence-TOMI-2022Document13 pagesEvaluation of Signal Degradation Due To birefringence-TOMI-2022Amelia DemianowiczNo ratings yet

- Exfo - Wpaper113 Spectral Testing Active Systems in Lab and Manufacturing Environments - enDocument7 pagesExfo - Wpaper113 Spectral Testing Active Systems in Lab and Manufacturing Environments - enAbdalmoedAlaiashyNo ratings yet

- Octans Highly CompactDocument8 pagesOctans Highly CompactgeenjunkmailNo ratings yet

- Installation and Commissioning of FLAMES, The VLT Multifibre FacilityDocument52 pagesInstallation and Commissioning of FLAMES, The VLT Multifibre FacilityEuropean Southern ObservatoryNo ratings yet

- Free Space OpticsDocument7 pagesFree Space OpticsDeepäk KümàwätNo ratings yet

- Development of Fiber Optic Radiation Monitor Using Plastic Scintillation FibersDocument9 pagesDevelopment of Fiber Optic Radiation Monitor Using Plastic Scintillation FibersdeellNo ratings yet

- Integrated Frequency-Modulated Optical Parametric OscillatorDocument27 pagesIntegrated Frequency-Modulated Optical Parametric Oscillatorazzaali0909No ratings yet

- Wireless CommunicationDocument8 pagesWireless CommunicationranandmavenNo ratings yet

- FREE SPACEOPTICS (Wireless Communication)Document6 pagesFREE SPACEOPTICS (Wireless Communication)Raja SekharNo ratings yet

- Fiber Optic Components For Fiber Optic Gyroscope ApplicationsDocument2 pagesFiber Optic Components For Fiber Optic Gyroscope ApplicationsDK Photonics100% (1)

- Optical Fibre: Physics Investigatory ProjectDocument22 pagesOptical Fibre: Physics Investigatory ProjectSurendar MVNo ratings yet

- Fiber Optic Monitoring in Openhole Gravel Pack CompletionsDocument14 pagesFiber Optic Monitoring in Openhole Gravel Pack CompletionsKen NgNo ratings yet

- Ring LasersDocument7 pagesRing LasersMansoor KhanNo ratings yet

- History and Vision of Optical Fiber Fusion Splicing TechnologyDocument4 pagesHistory and Vision of Optical Fiber Fusion Splicing TechnologyCHARLES ROBERTNo ratings yet

- 08572252Document4 pages08572252angelikjoliehNo ratings yet

- Highly Sensitive Fiber-Optic Fabry-Perot Geophone With Graphene-Coated PMMA MembraneDocument4 pagesHighly Sensitive Fiber-Optic Fabry-Perot Geophone With Graphene-Coated PMMA MembranebackupzalfaaNo ratings yet

- Aerospace Optical Sensors Handout WEB v2Document2 pagesAerospace Optical Sensors Handout WEB v2ggggggbNo ratings yet

- An Introduction To Fibre Optic Systems - Part IDocument6 pagesAn Introduction To Fibre Optic Systems - Part I5606438No ratings yet

- Presentation ShamimDocument14 pagesPresentation ShamimBINOY KRISHNA GHOSHNo ratings yet

- CONSTRUCTION OF A 700 MHZ PROTOTYPICAL CRYOMODULEDocument6 pagesCONSTRUCTION OF A 700 MHZ PROTOTYPICAL CRYOMODULEvladimirNo ratings yet

- Design Performance Evaluation of A Dipole Antenna Using Various Lengths of Antenna MaterialDocument7 pagesDesign Performance Evaluation of A Dipole Antenna Using Various Lengths of Antenna Materialronak kishorNo ratings yet

- W-Band Optoelectronic OscillatorDocument4 pagesW-Band Optoelectronic OscillatorHari EnthiranNo ratings yet

- Module 3 and 4 PDFDocument30 pagesModule 3 and 4 PDFAyushi SharmaNo ratings yet

- Development of Highly Sensitive Fiber Optic Acosutic Sensor and Its Preliminary Application For Sound LocalizationDocument10 pagesDevelopment of Highly Sensitive Fiber Optic Acosutic Sensor and Its Preliminary Application For Sound LocalizationJoseph ThomasNo ratings yet

- Applications: Optical Fiber Attenuation InterferenceDocument6 pagesApplications: Optical Fiber Attenuation InterferenceezohaibNo ratings yet

- Nphoton 2012 15Document1 pageNphoton 2012 15arkoprobho235No ratings yet

- Fiber GyroDocument5 pagesFiber GyroDanny DeWittNo ratings yet

- Mode Coupling and Equilibrium Mode Distribution Conditions in Plastic Optical FibersDocument3 pagesMode Coupling and Equilibrium Mode Distribution Conditions in Plastic Optical Fibersjianing sunNo ratings yet

- 10.1515 - Nanoph 2023 0636Document12 pages10.1515 - Nanoph 2023 0636samam nnanaNo ratings yet

- Fiber Optic TrainingDocument32 pagesFiber Optic TrainingasifaliabidNo ratings yet

- The Opto-Electronic Oscillator (OEO) : Review and Recent ProgressDocument4 pagesThe Opto-Electronic Oscillator (OEO) : Review and Recent ProgressDuong Ly HoangNo ratings yet

- System Characterization of A Passive 40 Gb/s All Optical Clock Recovery Ahead of The ReceiverDocument7 pagesSystem Characterization of A Passive 40 Gb/s All Optical Clock Recovery Ahead of The ReceiverdmsampaNo ratings yet

- EDFA and Optical Fiber Repositioning in An Optical Fiber Communication NetworkDocument8 pagesEDFA and Optical Fiber Repositioning in An Optical Fiber Communication NetworkIJRASETPublicationsNo ratings yet

- Abstract of Fiber Optic SensorsDocument6 pagesAbstract of Fiber Optic SensorsKamal UniyalNo ratings yet

- Dual-Polarised Lens Feed Arrays and End-Fire AntenDocument6 pagesDual-Polarised Lens Feed Arrays and End-Fire AntenRAJA RAMALINGAMNo ratings yet

- IA2 SolutionDocument10 pagesIA2 SolutionKaran MNo ratings yet

- Next Generation Wireless Communication - Free Space Optics (FSO)Document8 pagesNext Generation Wireless Communication - Free Space Optics (FSO)nithyanandhan90No ratings yet

- Wavelength MeterDocument1 pageWavelength Meterhieu dongNo ratings yet

- Fibre-Optic Sagnac Interferometer As Real Sensor of The Physical QuantitiesDocument4 pagesFibre-Optic Sagnac Interferometer As Real Sensor of The Physical QuantitiesThiago CoelhoNo ratings yet

- Fiber-Optic Sensors:: Applications and AdvancesDocument6 pagesFiber-Optic Sensors:: Applications and AdvanceshelenarajNo ratings yet

- Monitoring of Fibre Optic Links With A Machine LeaningDocument7 pagesMonitoring of Fibre Optic Links With A Machine LeaningMohit MahurNo ratings yet

- Optical Components of The NIRSPECDocument12 pagesOptical Components of The NIRSPECojangurenNo ratings yet

- Government Engineering College, Bilaspur: AssignmentDocument7 pagesGovernment Engineering College, Bilaspur: AssignmentJinius MishraNo ratings yet

- Selective Patterning of ITO On Flexible PET Substrate by 1064nm Picosecond LaserDocument8 pagesSelective Patterning of ITO On Flexible PET Substrate by 1064nm Picosecond Laserreza mirzakhaniNo ratings yet

- FREE SPACE OPTICS Seminar ReportDocument20 pagesFREE SPACE OPTICS Seminar ReportNaveen Kumar N50% (2)

- Optical Fiber Technology: Maizatul Zolkapli, Suhairi Saharudin, Sukreen Hana Herman, Wan Fazlida Hanim AbdullahDocument9 pagesOptical Fiber Technology: Maizatul Zolkapli, Suhairi Saharudin, Sukreen Hana Herman, Wan Fazlida Hanim Abdullahirma irmaNo ratings yet

- Two-User 2.5Gbps 100km OCDMA Transmission Experiment Using EPS-SSFBG En/decoderDocument7 pagesTwo-User 2.5Gbps 100km OCDMA Transmission Experiment Using EPS-SSFBG En/decoderHudson M. CerriNo ratings yet

- Wa0029. 1Document30 pagesWa0029. 1Angelina BennyNo ratings yet

- Interior Lighting: Fundamentals, Technology and ApplicationFrom EverandInterior Lighting: Fundamentals, Technology and ApplicationNo ratings yet

- Manajemen Perioperatif Operasi Arterial Switch PadaDocument12 pagesManajemen Perioperatif Operasi Arterial Switch Padacomiza92No ratings yet

- The Best Suitable Lifepo4 Cells Values Input: (Fill in Yellow Fields)Document2 pagesThe Best Suitable Lifepo4 Cells Values Input: (Fill in Yellow Fields)HirenNo ratings yet

- FAQs On RMIBD - Hedging of Foreign Exchange Risk DTD July 14 2020Document7 pagesFAQs On RMIBD - Hedging of Foreign Exchange Risk DTD July 14 2020Anup SharmaNo ratings yet

- Laravel Security ChecklistDocument18 pagesLaravel Security ChecklistfokavomoNo ratings yet

- Affidavit of DenialDocument1 pageAffidavit of Denialkillua111445100% (1)

- ISPS Code - A Measure To Enhance The Security of Ships and Port FacilitiesDocument11 pagesISPS Code - A Measure To Enhance The Security of Ships and Port FacilitiesGiorgi KandelakiNo ratings yet

- Sports Economics 2017 1st Edition Berri Solutions ManualDocument8 pagesSports Economics 2017 1st Edition Berri Solutions Manualbrendabrownipnmktbzas100% (10)

- Caso CEMEX MarianoDocument2 pagesCaso CEMEX MarianoMariano LopezNo ratings yet

- 2023 March 20. LT Group SR 2022 - FinalDocument65 pages2023 March 20. LT Group SR 2022 - Finalaltheadelacruz121403No ratings yet

- Motorized Gas Damper A-Hva-Rep-000-38132-BDocument31 pagesMotorized Gas Damper A-Hva-Rep-000-38132-Bja3farNo ratings yet

- Republic v. Far East EnterprisesDocument3 pagesRepublic v. Far East EnterprisesJustineNo ratings yet

- Promotion Presentation 2013Document26 pagesPromotion Presentation 2013Skycop OnallagNo ratings yet

- B031910499 - Students Who Study Abroad Achieve Greater SuccessDocument9 pagesB031910499 - Students Who Study Abroad Achieve Greater SuccessIsrat DibaNo ratings yet

- Img 20200829 0001Document3 pagesImg 20200829 0001api-402048659No ratings yet

- TDS - Rheobuild 1100Document3 pagesTDS - Rheobuild 1100Alexi ALfred H. Tago100% (1)

- Responsible Leadership ReportDocument7 pagesResponsible Leadership ReportRNo ratings yet

- Indo-Pacific StrategyDocument24 pagesIndo-Pacific Strategy李修瑩No ratings yet

- NCM 112 EvalDocument16 pagesNCM 112 EvalMartin T ManuelNo ratings yet

- Abdominal Ultrasound For Pediatric Blunt Trauma FAST Is Not Always BetterDocument3 pagesAbdominal Ultrasound For Pediatric Blunt Trauma FAST Is Not Always BetterInryuu ZenNo ratings yet

- Non Destructive TestingDocument16 pagesNon Destructive Testinganishdev6No ratings yet

- Blues Scales - Euphonium (Bass Clef) - LexcerptsDocument2 pagesBlues Scales - Euphonium (Bass Clef) - LexcerptsLexcerptsNo ratings yet

- United States v. Syed Ali Abrar, 58 F.3d 43, 2d Cir. (1995)Document7 pagesUnited States v. Syed Ali Abrar, 58 F.3d 43, 2d Cir. (1995)Scribd Government DocsNo ratings yet

- Case DigestDocument5 pagesCase DigestChrissy SabellaNo ratings yet

- Developmental Counseling Form: The Leader's Facts and Observations Prior To The Counseling.)Document3 pagesDevelopmental Counseling Form: The Leader's Facts and Observations Prior To The Counseling.)Anonymous EpKfz0LNo ratings yet

- 1T6-220 Switched Ethernet Network Analysis and TroubleshootingDocument36 pages1T6-220 Switched Ethernet Network Analysis and TroubleshootingcertvistaNo ratings yet

- History of Perodua Analysis PDFDocument13 pagesHistory of Perodua Analysis PDFaishahrodziNo ratings yet

- Lesson 1 FRANCHISING Introduction Converted 1Document32 pagesLesson 1 FRANCHISING Introduction Converted 1arzeljoyvillanueva3No ratings yet