Professional Documents

Culture Documents

Analox ACG-Plus Breathing Air Analyser Brochure

Analox ACG-Plus Breathing Air Analyser Brochure

Uploaded by

rafaelmelo89Copyright:

Available Formats

You might also like

- COMAC Keg Cleaner - Filler ManualDocument126 pagesCOMAC Keg Cleaner - Filler Manualrafaelmelo89No ratings yet

- Plant Design of Cryogenic Distillation of Air To Oxygen and NitrogenDocument34 pagesPlant Design of Cryogenic Distillation of Air To Oxygen and Nitrogenkumar100% (1)

- SERVOMEX - 2223 TransmitterDocument4 pagesSERVOMEX - 2223 TransmitterdixaxaNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Co2 Sensor For OfficeDocument4 pagesCo2 Sensor For Officeglzi.deniseNo ratings yet

- AAS 920 600C Telaire T3000 121218 WebDocument4 pagesAAS 920 600C Telaire T3000 121218 WebBang NagaNo ratings yet

- HBGS Gas Instructions Manual 006 UKDocument8 pagesHBGS Gas Instructions Manual 006 UK73992677No ratings yet

- Xgard Bright: Addressable Fixed Point Gas Detector With DisplayDocument4 pagesXgard Bright: Addressable Fixed Point Gas Detector With DisplayPunyawich FungthongjaroenNo ratings yet

- 4.1 - 6.3 - 1720E Turbidity SensorDocument4 pages4.1 - 6.3 - 1720E Turbidity Sensorcuongnv_19No ratings yet

- 9510 3 17 14Document2 pages9510 3 17 14Samuel Quintero HerreraNo ratings yet

- Dust & Opacity Analyzer D10.R02Document4 pagesDust & Opacity Analyzer D10.R02KC WangNo ratings yet

- Endress-Hauser Proline Promag W 300 5W3B enDocument5 pagesEndress-Hauser Proline Promag W 300 5W3B ennamNo ratings yet

- Endress-Hauser Promag 10W ENDocument4 pagesEndress-Hauser Promag 10W ENImtiyaz MakandarNo ratings yet

- Gd129Ni Single Point Infra-Red Gas DetectorDocument2 pagesGd129Ni Single Point Infra-Red Gas Detectorryan azzaamNo ratings yet

- Continuous Emissions Monitoring and Process Control: Internationally Approved EN 15267 CertifiedDocument4 pagesContinuous Emissions Monitoring and Process Control: Internationally Approved EN 15267 CertifiedEric Thorania KhanNo ratings yet

- S4 Shock & Vibration Sensor: Available ProductsDocument3 pagesS4 Shock & Vibration Sensor: Available Productsatul vermaNo ratings yet

- Curriculum Vitae - 2019-2Document2 pagesCurriculum Vitae - 2019-2Wilfredo GutierrezNo ratings yet

- Model DS1200-AMT: Single Channel Dew Point Hygrometer Ranges Available Between - 120°C To +20°C (-166°F To +68°F) DewpointDocument4 pagesModel DS1200-AMT: Single Channel Dew Point Hygrometer Ranges Available Between - 120°C To +20°C (-166°F To +68°F) Dewpointmarcello_oliveiraNo ratings yet

- UL or ATEX Certified For Hazardous Areas: GPR-7500 AIS PPM H S AnalyzerDocument36 pagesUL or ATEX Certified For Hazardous Areas: GPR-7500 AIS PPM H S AnalyzerMiguelNo ratings yet

- Brochure Dew Point Sensors - ENDocument12 pagesBrochure Dew Point Sensors - ENosmanyildirim85No ratings yet

- Brosur Orbisphere 3655Document2 pagesBrosur Orbisphere 3655ArifEkoPrasetyoNo ratings yet

- Ultrasonic Oxygen Sensor Module Gasboard7500EDocument6 pagesUltrasonic Oxygen Sensor Module Gasboard7500ECarlos Julián Muñoz QuirogaNo ratings yet

- CODEL CEMS and Process ProductsDocument10 pagesCODEL CEMS and Process ProductsnguyenanhtuanbNo ratings yet

- Watercut Monitors-Delta CDocument8 pagesWatercut Monitors-Delta CShakeel AhmedNo ratings yet

- O2000N Oxygen Analyser: Continuous Emissions Monitoring and Process ControlDocument4 pagesO2000N Oxygen Analyser: Continuous Emissions Monitoring and Process ControlEric Thorania KhanNo ratings yet

- GPL 750 Odorizer DatasheetDocument2 pagesGPL 750 Odorizer DatasheetAvura EdorNo ratings yet

- Manual 8750 CLDocument32 pagesManual 8750 CLSuleyman HaliciogluNo ratings yet

- Opsis O2000.enDocument4 pagesOpsis O2000.enManzoor-ul- HassanNo ratings yet

- g3620 Sgoas Brochure 2012Document4 pagesg3620 Sgoas Brochure 2012Khasin FuadiNo ratings yet

- Continous Hydrocarbons in Water MonitoringDocument2 pagesContinous Hydrocarbons in Water Monitoringdiego pardoNo ratings yet

- LIT2819Document4 pagesLIT2819huyvuNo ratings yet

- Senator 25Document3 pagesSenator 25Marcelo CorrêaNo ratings yet

- Endress-Hauser Analog Chlorine Dioxide Sensor CCS50 ENDocument3 pagesEndress-Hauser Analog Chlorine Dioxide Sensor CCS50 ENTrân Nguyễn Đoàn QuếNo ratings yet

- City Technology Oxygen 40XV Citicel O2 Gas Sensor AAV66 380 SpantechukDocument3 pagesCity Technology Oxygen 40XV Citicel O2 Gas Sensor AAV66 380 Spantechuk68dxtbh7b7No ratings yet

- OPT100 Datasheet B211583EN0010Document4 pagesOPT100 Datasheet B211583EN0010abhishekgupta9990No ratings yet

- Model 872 Ultrasonic Level Transmitter Two-Wire, Loop PoweredDocument2 pagesModel 872 Ultrasonic Level Transmitter Two-Wire, Loop Poweredandres49mNo ratings yet

- ACM2000一氧化碳传感器英文说明书 A0 20220427Document6 pagesACM2000一氧化碳传感器英文说明书 A0 20220427SamNo ratings yet

- A22 OxngDocument4 pagesA22 OxngHappy Photography Page 0No ratings yet

- CD-Pxx-00-0 Series Duct Mount CO Transmitter: Features and BenefitsDocument8 pagesCD-Pxx-00-0 Series Duct Mount CO Transmitter: Features and BenefitsÖzgürNo ratings yet

- HS1101LF - Relative Humidity Sensor: DescriptionDocument6 pagesHS1101LF - Relative Humidity Sensor: DescriptionManuel_DreamNo ratings yet

- Fluke 1630 DatasheetDocument3 pagesFluke 1630 Datasheetpavan kumarNo ratings yet

- Endress-Hauser Proline Promag E 100 5E1B ENDocument4 pagesEndress-Hauser Proline Promag E 100 5E1B ENkhangduongda2No ratings yet

- Ametek Model 3050OLVRev2Document2 pagesAmetek Model 3050OLVRev2Yanto Hasudungan LumbantobingNo ratings yet

- WDG Insitu 210 ObsoleteDocument2 pagesWDG Insitu 210 ObsoleteChinna ThambiNo ratings yet

- Aquavolt 2: High Precision Moisture AnalyzerDocument2 pagesAquavolt 2: High Precision Moisture AnalyzerDoge CaptainNo ratings yet

- M019-01r07 - WatercutMeters - Indd Delta-CDocument8 pagesM019-01r07 - WatercutMeters - Indd Delta-Candrej.marinichNo ratings yet

- OPSISDocument3 pagesOPSISflywheel2006No ratings yet

- WDG-1210 現址式氧氣分析儀Document4 pagesWDG-1210 現址式氧氣分析儀SeanKuoNo ratings yet

- Opacimetro Sensors LCS2400 PDFDocument2 pagesOpacimetro Sensors LCS2400 PDFvictorino044No ratings yet

- Dew Point Meter-Model Amm-15Document2 pagesDew Point Meter-Model Amm-15Juan Ricardo Ordoñez GamezNo ratings yet

- Reliable Online Measurement of ORP - With DULCOTEST SensorsDocument12 pagesReliable Online Measurement of ORP - With DULCOTEST SensorsWillian A. Palacio MurilloNo ratings yet

- MICHELL-2 Easidew-PRO-IS-Datasheet PDFDocument4 pagesMICHELL-2 Easidew-PRO-IS-Datasheet PDFAndres SerranoNo ratings yet

- PPM Brochure AcrulogDocument2 pagesPPM Brochure AcrulogadrianchoingNo ratings yet

- Haffmans In-Line Optical O2 Meter ENGLISHDocument2 pagesHaffmans In-Line Optical O2 Meter ENGLISHBalmer Jhoan Diaz ÁlvarezNo ratings yet

- 5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorDocument4 pages5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorcembozNo ratings yet

- Sensor Nivel de AguasDocument2 pagesSensor Nivel de AguasSasha PereyraNo ratings yet

- Datasheet SGX BLD1 - Rev1.1Document5 pagesDatasheet SGX BLD1 - Rev1.1iyergvNo ratings yet

- Cardinal Health VELA Ventilator Service ManualDocument3 pagesCardinal Health VELA Ventilator Service Manualpatrick1009No ratings yet

- Endress-Hauser Proline Promag E 100 5E1B enDocument4 pagesEndress-Hauser Proline Promag E 100 5E1B enShadab AmeenNo ratings yet

- Wind Speed & Direction Sensor: WindsonicDocument2 pagesWind Speed & Direction Sensor: WindsonicjackNo ratings yet

- Turbidity 10774 - DOC053.52.03714.Apr04.web PDFDocument2 pagesTurbidity 10774 - DOC053.52.03714.Apr04.web PDFsaNo ratings yet

- Centrifuge Product LeafletDocument4 pagesCentrifuge Product Leafletrafaelmelo89No ratings yet

- Data Sheet - APAQ R130 TC ENDocument3 pagesData Sheet - APAQ R130 TC ENrafaelmelo89No ratings yet

- Boiler Data Sheet (J50)Document2 pagesBoiler Data Sheet (J50)rafaelmelo89No ratings yet

- Modicon m171 m172 Tm172pdg18rDocument13 pagesModicon m171 m172 Tm172pdg18rrafaelmelo89No ratings yet

- bm12 Ba 01-3487 en 00 00Document64 pagesbm12 Ba 01-3487 en 00 00rafaelmelo89No ratings yet

- 1aa Boge Brochure C Rotary Screw 4-30hp 7Document20 pages1aa Boge Brochure C Rotary Screw 4-30hp 7rafaelmelo89No ratings yet

- P0149-801 ACG+ User ManualDocument102 pagesP0149-801 ACG+ User Manualrafaelmelo89No ratings yet

- Southern Cross Compressors KHE BrochureDocument7 pagesSouthern Cross Compressors KHE Brochurerafaelmelo89No ratings yet

- Air Nozzle JetsDocument19 pagesAir Nozzle Jetsrafaelmelo89No ratings yet

- Bekomat 8Document28 pagesBekomat 8rafaelmelo89No ratings yet

- Reviewer and Summary of ElsDocument16 pagesReviewer and Summary of ElsKyle Brian Talingting100% (1)

- 02.understanding Process Equipment For Operators & Engineers-53Document5 pages02.understanding Process Equipment For Operators & Engineers-53Aatish ChandrawarNo ratings yet

- FINAL Pck-4 - Lesson-Plan - Solar-SystemDocument9 pagesFINAL Pck-4 - Lesson-Plan - Solar-SystemAngel Diane TalabisNo ratings yet

- Chapter 2 (FM1) (Complete)Document119 pagesChapter 2 (FM1) (Complete)Qazi Muhammed FayyazNo ratings yet

- Exam3 SolutionsDocument7 pagesExam3 SolutionsVu Anh KienNo ratings yet

- Ass Chapter 1 (Mixture) - SolDocument4 pagesAss Chapter 1 (Mixture) - SolDanialNo ratings yet

- Climate ChangeDocument5 pagesClimate ChangeAbdulqadir AzizNo ratings yet

- APES Unit 4.5 Global Winds NotesDocument8 pagesAPES Unit 4.5 Global Winds NotesSam's vrNo ratings yet

- Considerations When Sintering Oxidation Sensitive PM SteelsDocument13 pagesConsiderations When Sintering Oxidation Sensitive PM SteelsSergey ZavadukNo ratings yet

- Module 1 - KINETIC MOLECULAR THEORY, IMF, AND PROPERTIES OF LIQUIDDocument5 pagesModule 1 - KINETIC MOLECULAR THEORY, IMF, AND PROPERTIES OF LIQUIDGabo AlfonsoNo ratings yet

- Geography ProjectDocument22 pagesGeography ProjectpallaviNo ratings yet

- Es Q1 Mod1Document16 pagesEs Q1 Mod1Teacher Charlyn VlogNo ratings yet

- Test Bank For Essentials of Oceanography 6th Edition GarrisonDocument36 pagesTest Bank For Essentials of Oceanography 6th Edition Garrisonnardinenorroysmxs7100% (40)

- Yllana Bay View College, IncDocument7 pagesYllana Bay View College, IncJoel Cabusao LacayNo ratings yet

- Lecture 2 - ERTH 2403Document9 pagesLecture 2 - ERTH 2403Andre YimNo ratings yet

- CHM 101 - Kinetic Theory 2021 Module B StudentsDocument5 pagesCHM 101 - Kinetic Theory 2021 Module B StudentsDanNo ratings yet

- Week 6-8Document3 pagesWeek 6-8Christian John Paul LijayanNo ratings yet

- Chapter 14Document23 pagesChapter 14kshitiz dhamaNo ratings yet

- Flash Evaporator) : Fresh Water GeneratorDocument8 pagesFlash Evaporator) : Fresh Water Generatorpranab sakarNo ratings yet

- Ch-4 AssignmentDocument15 pagesCh-4 AssignmentGamer AditKillsNo ratings yet

- Climate and Weather PresentationDocument99 pagesClimate and Weather PresentationtatendaanopaNo ratings yet

- Bài tập trắc nghiệm UNIT 7-8-9-10 lớp 11Document35 pagesBài tập trắc nghiệm UNIT 7-8-9-10 lớp 11Nlt Mỹ LinhNo ratings yet

- Pogil Boyles LawDocument4 pagesPogil Boyles LawRussel OtillaNo ratings yet

- Reg Serie DCDocument7 pagesReg Serie DCglizamabNo ratings yet

- Science: Quarter 3 - Module 2: Phases of MatterDocument32 pagesScience: Quarter 3 - Module 2: Phases of Matternadia doropan100% (1)

- Practise Test Paper 1 Atmosphere, Weather & Climate Class VIIDocument2 pagesPractise Test Paper 1 Atmosphere, Weather & Climate Class VIIsudarshan_dasNo ratings yet

- Module 3 Unfccc and Kyoto ProtocolDocument33 pagesModule 3 Unfccc and Kyoto ProtocolShiv ShankarNo ratings yet

- Tutorial Chapter2Document6 pagesTutorial Chapter2Rajan KhanalNo ratings yet

- What Are Some Kinds of Weather Fronts?: Week 22 Cold - Warm - Starionary - Occluded Day 1 Cycle 1Document6 pagesWhat Are Some Kinds of Weather Fronts?: Week 22 Cold - Warm - Starionary - Occluded Day 1 Cycle 1Daniela Cordovez HidalgoNo ratings yet

Analox ACG-Plus Breathing Air Analyser Brochure

Analox ACG-Plus Breathing Air Analyser Brochure

Uploaded by

rafaelmelo89Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analox ACG-Plus Breathing Air Analyser Brochure

Analox ACG-Plus Breathing Air Analyser Brochure

Uploaded by

rafaelmelo89Copyright:

Available Formats

ACG+

Compressed Breathing Air Monitor

The ACG+ is a unique compressed breathing air monitor designed to be used

in a fixed installation near your air compressor or as an ideal portable solution

for multi-point air monitoring.

The ACG+ offers the user peace of effects, particularly as the effects of

mind as it continually monitors Oxygen such contaminants are increased at KEY FEATURES

(O2), Carbon Dioxide (CO2), Carbon pressure. Even new, well-sited and

Monoxide (CO), dew point (H2O) and well-maintained compressors can • Portable or fixed

Volatile Organic Compounds (VOC) sometimes fail and contaminants can • Mains, DC and up to 12 hour

and also has a sample port to check also enter into the breathing air through rechargable battery power

for oil mist. Continual monitoring or pe- the intake. As this can theoretically options

riodic checking of these parameters happen at any time, continual monitor- • Proprietary dew point sensor

aids the user in achieving compliance ing is a safer and more accurate best lock out system for fast start up

with breathing air standards and oth- practice than “spot checking” such as - ideal for multi point checking

er local regulations, whilst ensuring using colorimetric tube testing kits at • Proprietary humidifier option

those employees breathing the air are intervals. for continual use to prolong

safeguarded against potentially fatal electrochemical sensor lives

The ACG+ can be used with any breath-

contamination issues. Housed in a ro- (CO & O2)

ing air compressor and simply needs

bust case when used portably or in a

to be connected after the compressor • East-connect purge system -

purpose built housing when used in a

and before the end user (or cylinder) to helps ensure accurate readings

fixed position, the ACG+ is simple to

ensure that contaminants can be de- in minutes

install, use and maintain and has a low

tected before they reach the intended • Robust carry case

cost of ownership.

destination. The pressure needs to be • Sensors now even easier to

The ACG+ offers 90 days of datalog- regulated down to between 5 to 10 Bar. change out

ging, easily retrieved with a USB con- The ACG+ is most commonly situated

• NiMH or Lithium battery options

nection and has audio/visual alarms in the compressor room but when used

and a common relay to connect to a portably it can be used in most envi- • 90 days of datalogging easily

beacon or to shut down the compres- ronments. retrieved via USB connection

sor should an alarm be triggered.

Employers have a duty of care to their

employees to ensure the air they

breathe is of the best quality possi-

ble and contaminants such as CO and

VOCs are maintained at very low lev-

els as they can cause serious health

gas detection designed for support gastech.com

ACG+

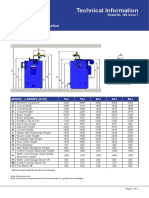

SENSOR SPECIFICATIONS

Gas Range Accuracy Technology

Oxygen 0 to 50% ±(0.035% O2 + 1% of reading + 0.15% of read- Analox MEC intelligent electrochemical

ing/°C) oxygen sensor

Carbon Dioxide 0 to 1000ppm ±(25ppm CO2 + 1% of reading + 1ppm CO2/°C) Analox 5S3 intelligent NDIR sensor

VOC 0 to 100ppm ±(1ppm VOC + 5% of reading + 0.25% of read- Analox MEC intelligent PID sensor

ing/°C)

Carbon Monoxide 0 to 20ppm ±(1ppm CO + 5% of reading + 0.1ppm CO/ºC + Analox MEC intelligent electrochemical

0.5% of reading/°C) sensor

Water Vapour 0 to 100mg/m³ ±(0.15mg/m³ H2O + 20% of reading) Water vapour sensor using capacitive

technology

SPECIFICATIONS Specifications subject to change without notice

Weigh 12 Kg Environmental IP54

Power Input voltage: 24V DC protection rating

Power consumption 24 W (max) Outputs 1x Normally open relay contact

1x Normally closed relay contact

Optional Power Supply Universal mains adaptor;

3x 24V DC switched outputs

Input 95 to 250VAC, 50/60Hz

Certification and BS EN 12021, DEF STAN 68-284,

Sensor Response Time T90 < 120 secs

Approvals Navsea, SS521-AK-1-010, US Navy

T90 < 15 mins (water vapour sensor)

Dive Manual and BS 8478

Flow Rate 5 LPM (max)

Part Number 72-8050-ACG

Inlet Pressure 5 to 10 bar gauge

Operating temperature -5°C to 50°C

Storage temperature -10°C to 60°C

Humidity 0 to 99% RH (non condensing)

HEAD OFFICE SYDNEY OFFICE BRISBANE OFFICE

24 Baretta Road 21/25 Narabang Way PO Box 349

Wangara WA 6065 Belrose NSW 2085 Cannon Hill Qld 4170

Phone: +61 8 6108 0000 Phone: +61 2 9451 0054 Phone: +61 7 3160 0901

DISTRIBUTED BY

You might also like

- COMAC Keg Cleaner - Filler ManualDocument126 pagesCOMAC Keg Cleaner - Filler Manualrafaelmelo89No ratings yet

- Plant Design of Cryogenic Distillation of Air To Oxygen and NitrogenDocument34 pagesPlant Design of Cryogenic Distillation of Air To Oxygen and Nitrogenkumar100% (1)

- SERVOMEX - 2223 TransmitterDocument4 pagesSERVOMEX - 2223 TransmitterdixaxaNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Co2 Sensor For OfficeDocument4 pagesCo2 Sensor For Officeglzi.deniseNo ratings yet

- AAS 920 600C Telaire T3000 121218 WebDocument4 pagesAAS 920 600C Telaire T3000 121218 WebBang NagaNo ratings yet

- HBGS Gas Instructions Manual 006 UKDocument8 pagesHBGS Gas Instructions Manual 006 UK73992677No ratings yet

- Xgard Bright: Addressable Fixed Point Gas Detector With DisplayDocument4 pagesXgard Bright: Addressable Fixed Point Gas Detector With DisplayPunyawich FungthongjaroenNo ratings yet

- 4.1 - 6.3 - 1720E Turbidity SensorDocument4 pages4.1 - 6.3 - 1720E Turbidity Sensorcuongnv_19No ratings yet

- 9510 3 17 14Document2 pages9510 3 17 14Samuel Quintero HerreraNo ratings yet

- Dust & Opacity Analyzer D10.R02Document4 pagesDust & Opacity Analyzer D10.R02KC WangNo ratings yet

- Endress-Hauser Proline Promag W 300 5W3B enDocument5 pagesEndress-Hauser Proline Promag W 300 5W3B ennamNo ratings yet

- Endress-Hauser Promag 10W ENDocument4 pagesEndress-Hauser Promag 10W ENImtiyaz MakandarNo ratings yet

- Gd129Ni Single Point Infra-Red Gas DetectorDocument2 pagesGd129Ni Single Point Infra-Red Gas Detectorryan azzaamNo ratings yet

- Continuous Emissions Monitoring and Process Control: Internationally Approved EN 15267 CertifiedDocument4 pagesContinuous Emissions Monitoring and Process Control: Internationally Approved EN 15267 CertifiedEric Thorania KhanNo ratings yet

- S4 Shock & Vibration Sensor: Available ProductsDocument3 pagesS4 Shock & Vibration Sensor: Available Productsatul vermaNo ratings yet

- Curriculum Vitae - 2019-2Document2 pagesCurriculum Vitae - 2019-2Wilfredo GutierrezNo ratings yet

- Model DS1200-AMT: Single Channel Dew Point Hygrometer Ranges Available Between - 120°C To +20°C (-166°F To +68°F) DewpointDocument4 pagesModel DS1200-AMT: Single Channel Dew Point Hygrometer Ranges Available Between - 120°C To +20°C (-166°F To +68°F) Dewpointmarcello_oliveiraNo ratings yet

- UL or ATEX Certified For Hazardous Areas: GPR-7500 AIS PPM H S AnalyzerDocument36 pagesUL or ATEX Certified For Hazardous Areas: GPR-7500 AIS PPM H S AnalyzerMiguelNo ratings yet

- Brochure Dew Point Sensors - ENDocument12 pagesBrochure Dew Point Sensors - ENosmanyildirim85No ratings yet

- Brosur Orbisphere 3655Document2 pagesBrosur Orbisphere 3655ArifEkoPrasetyoNo ratings yet

- Ultrasonic Oxygen Sensor Module Gasboard7500EDocument6 pagesUltrasonic Oxygen Sensor Module Gasboard7500ECarlos Julián Muñoz QuirogaNo ratings yet

- CODEL CEMS and Process ProductsDocument10 pagesCODEL CEMS and Process ProductsnguyenanhtuanbNo ratings yet

- Watercut Monitors-Delta CDocument8 pagesWatercut Monitors-Delta CShakeel AhmedNo ratings yet

- O2000N Oxygen Analyser: Continuous Emissions Monitoring and Process ControlDocument4 pagesO2000N Oxygen Analyser: Continuous Emissions Monitoring and Process ControlEric Thorania KhanNo ratings yet

- GPL 750 Odorizer DatasheetDocument2 pagesGPL 750 Odorizer DatasheetAvura EdorNo ratings yet

- Manual 8750 CLDocument32 pagesManual 8750 CLSuleyman HaliciogluNo ratings yet

- Opsis O2000.enDocument4 pagesOpsis O2000.enManzoor-ul- HassanNo ratings yet

- g3620 Sgoas Brochure 2012Document4 pagesg3620 Sgoas Brochure 2012Khasin FuadiNo ratings yet

- Continous Hydrocarbons in Water MonitoringDocument2 pagesContinous Hydrocarbons in Water Monitoringdiego pardoNo ratings yet

- LIT2819Document4 pagesLIT2819huyvuNo ratings yet

- Senator 25Document3 pagesSenator 25Marcelo CorrêaNo ratings yet

- Endress-Hauser Analog Chlorine Dioxide Sensor CCS50 ENDocument3 pagesEndress-Hauser Analog Chlorine Dioxide Sensor CCS50 ENTrân Nguyễn Đoàn QuếNo ratings yet

- City Technology Oxygen 40XV Citicel O2 Gas Sensor AAV66 380 SpantechukDocument3 pagesCity Technology Oxygen 40XV Citicel O2 Gas Sensor AAV66 380 Spantechuk68dxtbh7b7No ratings yet

- OPT100 Datasheet B211583EN0010Document4 pagesOPT100 Datasheet B211583EN0010abhishekgupta9990No ratings yet

- Model 872 Ultrasonic Level Transmitter Two-Wire, Loop PoweredDocument2 pagesModel 872 Ultrasonic Level Transmitter Two-Wire, Loop Poweredandres49mNo ratings yet

- ACM2000一氧化碳传感器英文说明书 A0 20220427Document6 pagesACM2000一氧化碳传感器英文说明书 A0 20220427SamNo ratings yet

- A22 OxngDocument4 pagesA22 OxngHappy Photography Page 0No ratings yet

- CD-Pxx-00-0 Series Duct Mount CO Transmitter: Features and BenefitsDocument8 pagesCD-Pxx-00-0 Series Duct Mount CO Transmitter: Features and BenefitsÖzgürNo ratings yet

- HS1101LF - Relative Humidity Sensor: DescriptionDocument6 pagesHS1101LF - Relative Humidity Sensor: DescriptionManuel_DreamNo ratings yet

- Fluke 1630 DatasheetDocument3 pagesFluke 1630 Datasheetpavan kumarNo ratings yet

- Endress-Hauser Proline Promag E 100 5E1B ENDocument4 pagesEndress-Hauser Proline Promag E 100 5E1B ENkhangduongda2No ratings yet

- Ametek Model 3050OLVRev2Document2 pagesAmetek Model 3050OLVRev2Yanto Hasudungan LumbantobingNo ratings yet

- WDG Insitu 210 ObsoleteDocument2 pagesWDG Insitu 210 ObsoleteChinna ThambiNo ratings yet

- Aquavolt 2: High Precision Moisture AnalyzerDocument2 pagesAquavolt 2: High Precision Moisture AnalyzerDoge CaptainNo ratings yet

- M019-01r07 - WatercutMeters - Indd Delta-CDocument8 pagesM019-01r07 - WatercutMeters - Indd Delta-Candrej.marinichNo ratings yet

- OPSISDocument3 pagesOPSISflywheel2006No ratings yet

- WDG-1210 現址式氧氣分析儀Document4 pagesWDG-1210 現址式氧氣分析儀SeanKuoNo ratings yet

- Opacimetro Sensors LCS2400 PDFDocument2 pagesOpacimetro Sensors LCS2400 PDFvictorino044No ratings yet

- Dew Point Meter-Model Amm-15Document2 pagesDew Point Meter-Model Amm-15Juan Ricardo Ordoñez GamezNo ratings yet

- Reliable Online Measurement of ORP - With DULCOTEST SensorsDocument12 pagesReliable Online Measurement of ORP - With DULCOTEST SensorsWillian A. Palacio MurilloNo ratings yet

- MICHELL-2 Easidew-PRO-IS-Datasheet PDFDocument4 pagesMICHELL-2 Easidew-PRO-IS-Datasheet PDFAndres SerranoNo ratings yet

- PPM Brochure AcrulogDocument2 pagesPPM Brochure AcrulogadrianchoingNo ratings yet

- Haffmans In-Line Optical O2 Meter ENGLISHDocument2 pagesHaffmans In-Line Optical O2 Meter ENGLISHBalmer Jhoan Diaz ÁlvarezNo ratings yet

- 5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorDocument4 pages5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorcembozNo ratings yet

- Sensor Nivel de AguasDocument2 pagesSensor Nivel de AguasSasha PereyraNo ratings yet

- Datasheet SGX BLD1 - Rev1.1Document5 pagesDatasheet SGX BLD1 - Rev1.1iyergvNo ratings yet

- Cardinal Health VELA Ventilator Service ManualDocument3 pagesCardinal Health VELA Ventilator Service Manualpatrick1009No ratings yet

- Endress-Hauser Proline Promag E 100 5E1B enDocument4 pagesEndress-Hauser Proline Promag E 100 5E1B enShadab AmeenNo ratings yet

- Wind Speed & Direction Sensor: WindsonicDocument2 pagesWind Speed & Direction Sensor: WindsonicjackNo ratings yet

- Turbidity 10774 - DOC053.52.03714.Apr04.web PDFDocument2 pagesTurbidity 10774 - DOC053.52.03714.Apr04.web PDFsaNo ratings yet

- Centrifuge Product LeafletDocument4 pagesCentrifuge Product Leafletrafaelmelo89No ratings yet

- Data Sheet - APAQ R130 TC ENDocument3 pagesData Sheet - APAQ R130 TC ENrafaelmelo89No ratings yet

- Boiler Data Sheet (J50)Document2 pagesBoiler Data Sheet (J50)rafaelmelo89No ratings yet

- Modicon m171 m172 Tm172pdg18rDocument13 pagesModicon m171 m172 Tm172pdg18rrafaelmelo89No ratings yet

- bm12 Ba 01-3487 en 00 00Document64 pagesbm12 Ba 01-3487 en 00 00rafaelmelo89No ratings yet

- 1aa Boge Brochure C Rotary Screw 4-30hp 7Document20 pages1aa Boge Brochure C Rotary Screw 4-30hp 7rafaelmelo89No ratings yet

- P0149-801 ACG+ User ManualDocument102 pagesP0149-801 ACG+ User Manualrafaelmelo89No ratings yet

- Southern Cross Compressors KHE BrochureDocument7 pagesSouthern Cross Compressors KHE Brochurerafaelmelo89No ratings yet

- Air Nozzle JetsDocument19 pagesAir Nozzle Jetsrafaelmelo89No ratings yet

- Bekomat 8Document28 pagesBekomat 8rafaelmelo89No ratings yet

- Reviewer and Summary of ElsDocument16 pagesReviewer and Summary of ElsKyle Brian Talingting100% (1)

- 02.understanding Process Equipment For Operators & Engineers-53Document5 pages02.understanding Process Equipment For Operators & Engineers-53Aatish ChandrawarNo ratings yet

- FINAL Pck-4 - Lesson-Plan - Solar-SystemDocument9 pagesFINAL Pck-4 - Lesson-Plan - Solar-SystemAngel Diane TalabisNo ratings yet

- Chapter 2 (FM1) (Complete)Document119 pagesChapter 2 (FM1) (Complete)Qazi Muhammed FayyazNo ratings yet

- Exam3 SolutionsDocument7 pagesExam3 SolutionsVu Anh KienNo ratings yet

- Ass Chapter 1 (Mixture) - SolDocument4 pagesAss Chapter 1 (Mixture) - SolDanialNo ratings yet

- Climate ChangeDocument5 pagesClimate ChangeAbdulqadir AzizNo ratings yet

- APES Unit 4.5 Global Winds NotesDocument8 pagesAPES Unit 4.5 Global Winds NotesSam's vrNo ratings yet

- Considerations When Sintering Oxidation Sensitive PM SteelsDocument13 pagesConsiderations When Sintering Oxidation Sensitive PM SteelsSergey ZavadukNo ratings yet

- Module 1 - KINETIC MOLECULAR THEORY, IMF, AND PROPERTIES OF LIQUIDDocument5 pagesModule 1 - KINETIC MOLECULAR THEORY, IMF, AND PROPERTIES OF LIQUIDGabo AlfonsoNo ratings yet

- Geography ProjectDocument22 pagesGeography ProjectpallaviNo ratings yet

- Es Q1 Mod1Document16 pagesEs Q1 Mod1Teacher Charlyn VlogNo ratings yet

- Test Bank For Essentials of Oceanography 6th Edition GarrisonDocument36 pagesTest Bank For Essentials of Oceanography 6th Edition Garrisonnardinenorroysmxs7100% (40)

- Yllana Bay View College, IncDocument7 pagesYllana Bay View College, IncJoel Cabusao LacayNo ratings yet

- Lecture 2 - ERTH 2403Document9 pagesLecture 2 - ERTH 2403Andre YimNo ratings yet

- CHM 101 - Kinetic Theory 2021 Module B StudentsDocument5 pagesCHM 101 - Kinetic Theory 2021 Module B StudentsDanNo ratings yet

- Week 6-8Document3 pagesWeek 6-8Christian John Paul LijayanNo ratings yet

- Chapter 14Document23 pagesChapter 14kshitiz dhamaNo ratings yet

- Flash Evaporator) : Fresh Water GeneratorDocument8 pagesFlash Evaporator) : Fresh Water Generatorpranab sakarNo ratings yet

- Ch-4 AssignmentDocument15 pagesCh-4 AssignmentGamer AditKillsNo ratings yet

- Climate and Weather PresentationDocument99 pagesClimate and Weather PresentationtatendaanopaNo ratings yet

- Bài tập trắc nghiệm UNIT 7-8-9-10 lớp 11Document35 pagesBài tập trắc nghiệm UNIT 7-8-9-10 lớp 11Nlt Mỹ LinhNo ratings yet

- Pogil Boyles LawDocument4 pagesPogil Boyles LawRussel OtillaNo ratings yet

- Reg Serie DCDocument7 pagesReg Serie DCglizamabNo ratings yet

- Science: Quarter 3 - Module 2: Phases of MatterDocument32 pagesScience: Quarter 3 - Module 2: Phases of Matternadia doropan100% (1)

- Practise Test Paper 1 Atmosphere, Weather & Climate Class VIIDocument2 pagesPractise Test Paper 1 Atmosphere, Weather & Climate Class VIIsudarshan_dasNo ratings yet

- Module 3 Unfccc and Kyoto ProtocolDocument33 pagesModule 3 Unfccc and Kyoto ProtocolShiv ShankarNo ratings yet

- Tutorial Chapter2Document6 pagesTutorial Chapter2Rajan KhanalNo ratings yet

- What Are Some Kinds of Weather Fronts?: Week 22 Cold - Warm - Starionary - Occluded Day 1 Cycle 1Document6 pagesWhat Are Some Kinds of Weather Fronts?: Week 22 Cold - Warm - Starionary - Occluded Day 1 Cycle 1Daniela Cordovez HidalgoNo ratings yet