Professional Documents

Culture Documents

AB-036914 - Support Details of Nozzle & Manways For Castable - SAUDI ARAMCO

AB-036914 - Support Details of Nozzle & Manways For Castable - SAUDI ARAMCO

Uploaded by

Akhil GeorgeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AB-036914 - Support Details of Nozzle & Manways For Castable - SAUDI ARAMCO

AB-036914 - Support Details of Nozzle & Manways For Castable - SAUDI ARAMCO

Uploaded by

Akhil GeorgeCopyright:

Available Formats

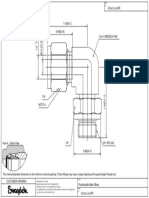

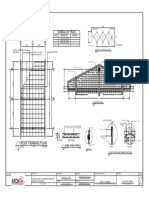

AB-036914 001 03 N 990

NOTES:

1. DESIGN AND INSTALLATION TO BE IN

REV. NO. SHT. NO. DRAWING NUMBER INDEX PLANT NO.

REFRACTORY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

ACCORDANCE WITH SAES-N-110 & N-120.

ANCHORS FLAT COVER PLATE 2. SPACES SHALL NOT BE MADE LESS THAN

SYMMETRICAL 1/2 HEX OR MORE THAN 1 1/2 HEX.

6mm ( 1/4 ")

ABOUT CL

"V" ANCHORS 75mm (3") 3. LOOSE ENDS OF HEXSTEEL ARE NOT

RADIUS ALLOWED.

12mm ( 1/2 ")

4. REFRACTORY ANCHORS TO BE THE "V" TYPE.

PROVIDE RUBBER OR PLASTIC CAPS 12mm (1/2")

LONG AND 0.8mm (0.03") TO 1.3mm (0.05")

THICK ON THE TIP OF EACH ANCHOR LEG.

SAME THICKNESS AS CAPS TO BE INSTALLED PRIOR TO REFRACTORY

HEXSTEEL AND EROSION INSULATING REFRACTORY SHELL INSTALLATION AND AFTER ANCHOR WELDING AND

RESISTANT REFRACTORY ON SHELL 6mm ( 1/4 ") STOP RING POST WELD HEAT TREATMENT REQUIREMENTS.

25mm (1") THICK MANWAY

INSULATING

"T" STUD HEXSTEEL AND EROSION OPENING FLAT COVER PLATE

REFRACTORY

KEEP CLEARANCE RESISTANT REFRACTORY

SHELL AT MINIMUM 25mm (1") THICK

40mm (1 1/2 ") 6mm ( 1/4 ") MINIMUM THICK 6mm ( 1/4 ") MIN. THICK SHELL

DISHED COVER

MINIMUM STEEL RETAINING RING (DO RETAINING RING

"V" ANCHORS

NOT WELD TO HEXSTEEL) CONTINUOUS 5mm ( 3/16 ")

DISSIMILAR WELD

CONTINUOUS 5mm ( 3/16 ") MIN. FILLET WELD

MINIMUM WELD FILLET

MAINTAIN MAX. 75mm (3")

CONTINUOUS OF 12mm ( 1/2 ") MANWAY SINGLE LAYER CAP RADIUS

RING 6mm ( 1/4 ") INSULATING 6mm ( 1/4 ") STOP RING

REFRACTORY

LINING DETAILS

CONTINUOUS

WELDS INTERNAL SLEEVE DISHED COVER PLATE

CAP 6mm ( 1/4 ")

75mm (3") MIN. 75mm (3") MIN.

MAINTAIN MAX.

150mm (6") MAX. 150mm (6") MAX. 19mm ( 3/4 ") HEXSTEEL WITH

OF 12mm ( 1/2 ")

ADD EXTRA "T" 25mm (1") RAISED BAR DIRECTION

6mm x 25mm 6mm x 25mm

STUDS WHERE KEEP CLEARANCE AT OF FLOW

( 1/4 " x 1") 25mm (1") THICK ( 1/4 " x 1")

NECESSARY TO MINIMUM. DO NOT WELD

EDGING BAR REFRACTORY EDGING BARS

PROVIDE REQUIRED TO HEXSTEEL

SHELL 10mm ( 3/8 ")

SUPPORT FOR LINING

ADD EXTRA STUDS WHEN TAPER STRIP

NECESSARY TO PROVIDE

REQUIRED SUPPORT FOR

HEXSTEEL. FLANGE

6mm ( 1/4 ") DIA. 40mm

SHELL HEXSTEEL

VENT HOLE (1 1/2 ")

3" NOZZLE & LARGER MANWAY WITH INTERNAL SLEEVE

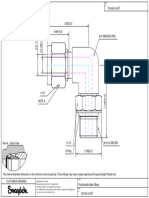

LINER TERMINATION

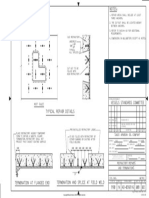

FLANGE TERMINATION

19mm ( 3/4 ") HEXSTEEL WITH

25mm (1") RAISED BAR

END INSULATING AND EROSION

25mm (1") THICK REFRACTORY

REFRACTORY AT "T" STUD

ADJACENT TO UNLINED SECTION 6mm x 25mm ( 1/4 "x1") EDGING

BAR WELDED TO HEXSTEEL

(SEE NOTE 2)

50mm x 50mm x 6mm

(2" x 2" x 1/4 ") ANGLE, 50mm

(2") LONG, INSTALLED ON

APPROXIMATELY 150mm (6")

CENTERS AROUND NOZZLE SHELL SHELL

OPENING OR WELD EACH

HEXSTEEL BAR WHEREVER EXTEND NOZZLE 25mm (1")

100 100 THEY COME IN CONTACT BEYOND SHELL AS SHOWN, OR

SHELL WHEN NOZZLE IS FLUSH WITH

(4") (4") WITH ONE ANOTHER.

SHELL, USE A 6mm x 25mm DRAWING RESPONSIBILITY:

10^ OR 25mm INSULATING HEXSTEEL AND EROSION ( 1/4 "x1") EDGING BAR. VESSEL STANDARDS COMMITTEE

(1") MAX. REFRACTORY RESISTANT REFRACTORY

25mm (1") THICK.

FIELD JOINT NOZZLE NOZZLE

MANHOLE OR

NOZZLE WALL

ESSD

03 JAN96 REVISED NOTES.

RCR

CONTINUOUS WELD WELD TO RING EVERY COMPLETELY REDRAWN

02 06-25-94 CAB

HEX. LOOSE ENDS ARE ON "B" SIZE DWG.

NOT ALLOWED. REV.

DATE BY JO/EWO DESCRIPTION CHKD. CERT. APPD.

NO.

SAUDI ARABIAN OIL COMPANY

SEGMENTED RING 6mm ( 1/4 ") UNLINED NOZZLE DETAIL LINED NOZZLE DETAIL DRAWN BY ESSD/RCR CHECKED BY SCALE NONE

DATE STARTED 09-11-93 DATE COMPLETED 09-12-93

NOZZLE LINED WITH HEXSTEEL OPR’G. DEPT. ENG. DEPT.

APP’D FOR CONSTR.

THIS DRAWING IS NOT TO BE USED FOR CERTIFIED

CONSTRUCTION OR FOR ORDERING

MATERIAL UNTIL CERTIFIED AND DATED BY DATE

SUPPORT DETAILS

AT NOZZLES & MANWAYS

FOR CASTABLE REFRACTORIES

STD. DWG.

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

990 N AB-036914 001 03

Saudi Aramco 2634 ENG. (3/91)

CADD-02

You might also like

- Ab 036396 001 - 06292022Document1 pageAb 036396 001 - 06292022JAWAHAR TNo ratings yet

- Ab 036396 001 - 06292022Document1 pageAb 036396 001 - 06292022JAWAHAR TNo ratings yet

- Ac 036660 003 - 05312022Document1 pageAc 036660 003 - 05312022JAWAHAR TNo ratings yet

- SS 400 1 12 SwagelokCompany 2DSalesDrawing 11 01 2023Document1 pageSS 400 1 12 SwagelokCompany 2DSalesDrawing 11 01 2023JHAIR DE JESÚS GARCÍA FLORESNo ratings yet

- General Notes Table 1: Bearing Baseplate AssemblyDocument20 pagesGeneral Notes Table 1: Bearing Baseplate AssemblyLeon ZhouNo ratings yet

- Type 2.1Document1 pageType 2.1daveglai24No ratings yet

- SS 600 6 4 SwagelokCompany 2DSalesDrawing 04 08 2022Document1 pageSS 600 6 4 SwagelokCompany 2DSalesDrawing 04 08 2022TaQuangDucNo ratings yet

- Detail - B Section 1-1: Left Bank Right BankDocument1 pageDetail - B Section 1-1: Left Bank Right Bankshivendra kumarNo ratings yet

- AB 036090 001 Joints For Cement Lined Pipe PDFDocument1 pageAB 036090 001 Joints For Cement Lined Pipe PDFfdfazfzNo ratings yet

- Uecp-Sd-Cul - 12.1-R00Document3 pagesUecp-Sd-Cul - 12.1-R00Anuradha KoswaththaNo ratings yet

- Tanque Vu 570 m3 DSN-RCT275-50Document2 pagesTanque Vu 570 m3 DSN-RCT275-50Comercial FirenoNo ratings yet

- Ac 036437 001 - 05312022Document1 pageAc 036437 001 - 05312022JAWAHAR TNo ratings yet

- SS 810 2 6PR 20160Document1 pageSS 810 2 6PR 20160armin_kunosic9871No ratings yet

- SS 400 C SwagelokCompany SalesDrawing 01 13 2022Document1 pageSS 400 C SwagelokCompany SalesDrawing 01 13 2022bango7886No ratings yet

- SS 600 2 6ST 23668Document1 pageSS 600 2 6ST 23668armin_kunosic9871No ratings yet

- Schedule of Footings: C4-F3 C5-F3Document1 pageSchedule of Footings: C4-F3 C5-F3Verna Balang MartinezNo ratings yet

- Water Tank Final 1modelDocument1 pageWater Tank Final 1modelamos333No ratings yet

- Elevation Section A-A: Concertina Coil Crank PanelDocument1 pageElevation Section A-A: Concertina Coil Crank PanelDeepak PawarNo ratings yet

- Sdetail Div14 PDFDocument9 pagesSdetail Div14 PDFarticle searchNo ratings yet

- STANDARD CANAL-ModelDocument1 pageSTANDARD CANAL-Modelsupreme100% (1)

- Ba 281842 001Document1 pageBa 281842 001salmanNo ratings yet

- 21A. GA & Structural Details of Stilling BasinDocument1 page21A. GA & Structural Details of Stilling BasinManoranjan SethiNo ratings yet

- As Aigc Ga TCTV 001 3Document1 pageAs Aigc Ga TCTV 001 3engrabbas75No ratings yet

- Detail Pondasi: KontractorDocument1 pageDetail Pondasi: KontractorElgi Permana PutraNo ratings yet

- Structural 1Document9 pagesStructural 1manglicmotabigail11No ratings yet

- Mech DR 301.01Document1 pageMech DR 301.01Aya EzzNo ratings yet

- 2 Expansion Joint DetailDocument1 page2 Expansion Joint Detailbenjamin swokaNo ratings yet

- Ips D TP709Document2 pagesIps D TP709armin boloriNo ratings yet

- Second Floor Reflected Ceiling Plan: Schedule of Ceiling FinishesDocument1 pageSecond Floor Reflected Ceiling Plan: Schedule of Ceiling FinishesMJian VergaraNo ratings yet

- Aacm Standard DrawingsDocument7 pagesAacm Standard Drawingshussein247No ratings yet

- 3.int Door & Corner GuardDocument1 page3.int Door & Corner Guardmohammed amir aliNo ratings yet

- Marcos Village (Proposed Plan)Document18 pagesMarcos Village (Proposed Plan)Jojie PajarillagaNo ratings yet

- Wa-0636860 0001 0001Document1 pageWa-0636860 0001 0001Bilal ChohanNo ratings yet

- Uecp-Sd-Cul - 10.4-R00Document3 pagesUecp-Sd-Cul - 10.4-R00Anuradha KoswaththaNo ratings yet

- As Aigc Ga TCTV 001 7Document1 pageAs Aigc Ga TCTV 001 7engrabbas75No ratings yet

- 17 WLDDocument1 page17 WLDJesusa EstradaNo ratings yet

- Concrete Pedestal Details Anchor Bolt Details City Inspectorate Team City Inspectorate TeamDocument1 pageConcrete Pedestal Details Anchor Bolt Details City Inspectorate Team City Inspectorate TeamBetinol RachelNo ratings yet

- Uecp-Sd-Cul - 10.2-R00Document3 pagesUecp-Sd-Cul - 10.2-R00Anuradha KoswaththaNo ratings yet

- Slab Schedule: Stiffener Column Detail Conc. Ledge DetailDocument1 pageSlab Schedule: Stiffener Column Detail Conc. Ledge DetailLab Dema-alaNo ratings yet

- Arch 2Document1 pageArch 2nicholasomodingNo ratings yet

- LIFT Layout1Document1 pageLIFT Layout1nikita chawlaNo ratings yet

- Beraing Forces & Exp JointDocument3 pagesBeraing Forces & Exp JointTanveer IqbalNo ratings yet

- Aa 036629 002Document1 pageAa 036629 002hai sunNo ratings yet

- S-106 Concrete LayoutDocument1 pageS-106 Concrete Layoutarno assassinNo ratings yet

- S-1.2 Proposed Filling Station (Caltex Station) : Typical Section Thru BDocument1 pageS-1.2 Proposed Filling Station (Caltex Station) : Typical Section Thru BCarmela Andrea BuenafeNo ratings yet

- Foundation Plan: Lintel Beam DetailsDocument1 pageFoundation Plan: Lintel Beam DetailsRod NajarroNo ratings yet

- Wall & Footing Details: Schedule of Reinforced Concrete BeamDocument1 pageWall & Footing Details: Schedule of Reinforced Concrete BeamJaymark SorianoNo ratings yet

- Revision History: 10-V-101 Oil Water Separation DrumDocument1 pageRevision History: 10-V-101 Oil Water Separation DrumKarwanNo ratings yet

- Revision History: 10-V-101 Oil Water Separation DrumDocument1 pageRevision History: 10-V-101 Oil Water Separation DrumShyamPanthavoorNo ratings yet

- 1.detail One (Black-White)Document1 page1.detail One (Black-White)maxNo ratings yet

- D896603002P02Document1 pageD896603002P02Mohammad ShayanNo ratings yet

- Elevation NotesDocument1 pageElevation NotesIamJace C.No ratings yet

- Crude Oil 200 BBL - Ga - RCDocument1 pageCrude Oil 200 BBL - Ga - RCApichart ChoksawadNo ratings yet

- Design of Septic Tank: Cross SectionDocument1 pageDesign of Septic Tank: Cross SectionKarenNikz GuillermoNo ratings yet

- Roof Framing Plan: Schedule of TrussDocument1 pageRoof Framing Plan: Schedule of TrussJan Reche JameroNo ratings yet

- Schedule of Beam: Foundation Plan Second Floor Framing Plan Roof Framing PlanDocument1 pageSchedule of Beam: Foundation Plan Second Floor Framing Plan Roof Framing PlanLeonard Delos ReyesNo ratings yet

- 01.STD DrawingDocument82 pages01.STD Drawingjplaza3074No ratings yet

- Corbel Reinforcement Detail 'X': Reinforcement Details of Approach SlabDocument1 pageCorbel Reinforcement Detail 'X': Reinforcement Details of Approach SlabTari IslamNo ratings yet

- Single Dead End, Terminal Pole, Dead End Riser Pole: Saudi Arabian Oil CompanyDocument1 pageSingle Dead End, Terminal Pole, Dead End Riser Pole: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Type 116 Material Data Sheet - Saudi AramcoDocument1 pageType 116 Material Data Sheet - Saudi AramcoAkhil GeorgeNo ratings yet

- Type 90 Material - Saudi AramcoDocument1 pageType 90 Material - Saudi AramcoAkhil GeorgeNo ratings yet

- AD-036916 - Refractory Repairs and Terminations - Saudi AramcoDocument1 pageAD-036916 - Refractory Repairs and Terminations - Saudi AramcoAkhil GeorgeNo ratings yet

- AB-036400 - Ceramic Board and Blanket Installation - SAUDI ARAMCODocument1 pageAB-036400 - Ceramic Board and Blanket Installation - SAUDI ARAMCOAkhil GeorgeNo ratings yet

- AB-036395 - Fiber Module Installation - SAUDI ARAMCODocument1 pageAB-036395 - Fiber Module Installation - SAUDI ARAMCOAkhil GeorgeNo ratings yet

- JERES-N-100, Jubail Export Refinery Engineering Standard, SATORPDocument25 pagesJERES-N-100, Jubail Export Refinery Engineering Standard, SATORPAkhil GeorgeNo ratings yet

- Kusoo Dhawoow Shirkadda AG Nutrition SomalilandDocument35 pagesKusoo Dhawoow Shirkadda AG Nutrition SomalilandAbdifatah Bashir HassanNo ratings yet

- Leadingthewaytosafety Withvoicealarmand PublicaddressDocument24 pagesLeadingthewaytosafety Withvoicealarmand PublicaddressRonaldo RomeroNo ratings yet

- SMEA2402 - Manufacturing Processes LabDocument15 pagesSMEA2402 - Manufacturing Processes LabPurusothamanManiNo ratings yet

- Naturalism: Created by Mrs. Panna PurohitDocument12 pagesNaturalism: Created by Mrs. Panna PurohitpannapurohitNo ratings yet

- Introduction To Fluid Mechanics Lab Equipment PDFDocument7 pagesIntroduction To Fluid Mechanics Lab Equipment PDFAbdul Rasa MastoiNo ratings yet

- CoverDocument8 pagesCoverTito Carvalho Vital86% (7)

- Solucion Taking Care of The PlanetDocument2 pagesSolucion Taking Care of The PlanetPAOLANo ratings yet

- Asphalt Mix DesignDocument37 pagesAsphalt Mix DesignGerardo Andres Argote ValenciaNo ratings yet

- Image Processing Methods For Food InspectionDocument69 pagesImage Processing Methods For Food InspectionFemilNo ratings yet

- Enterobius Vermicularis: Ciulla Chapter 8 - ParasitologyDocument13 pagesEnterobius Vermicularis: Ciulla Chapter 8 - ParasitologySalve Rachelle BillenaNo ratings yet

- PPP-B-676 e PDFDocument34 pagesPPP-B-676 e PDFffincher4203No ratings yet

- CH 19035Document7 pagesCH 19035Abdul GhaffarNo ratings yet

- Report On Degraded Ecosystem Pashan LakeDocument13 pagesReport On Degraded Ecosystem Pashan LakeArash AhmadNo ratings yet

- Effect of Heat Treatment On An AISI 304 Austenitic Stainless Steel Evaluated by The Ultrasonic Attenuation CoefficientDocument6 pagesEffect of Heat Treatment On An AISI 304 Austenitic Stainless Steel Evaluated by The Ultrasonic Attenuation CoefficientChaguy VergaraNo ratings yet

- Guillian-Barr e Syndrome - A Case StudyDocument11 pagesGuillian-Barr e Syndrome - A Case StudyHecan ComeNo ratings yet

- Reading and Writing Homework w6Document5 pagesReading and Writing Homework w6Nguyễn YếnNo ratings yet

- Affidavit of Undertakings (One PCO & MH) SDocument1 pageAffidavit of Undertakings (One PCO & MH) SEvangeline M. GalimbpNo ratings yet

- Manufacturing & Fitting The Jaipur Above-the-Knee Prosthesis and Jaipur FootDocument122 pagesManufacturing & Fitting The Jaipur Above-the-Knee Prosthesis and Jaipur FootoxideheraNo ratings yet

- Drugs Abuse in RomaniaDocument5 pagesDrugs Abuse in RomaniaGiorcoata AlexandruNo ratings yet

- EDAID121710A (Multi Split R-32 - 2MKC30QVM4-MKC50RVM4 and MKC70SVM4)Document234 pagesEDAID121710A (Multi Split R-32 - 2MKC30QVM4-MKC50RVM4 and MKC70SVM4)yoga pNo ratings yet

- Resident LawsuitDocument332 pagesResident LawsuitIndiana Public Media NewsNo ratings yet

- Name Class Subject:: Fauzan Perdana Ilham: Xii Mipa 3: EnglishDocument3 pagesName Class Subject:: Fauzan Perdana Ilham: Xii Mipa 3: EnglishNo Lep33% (3)

- Transfer of Thermal Energy - Conduction - Convection - Radiation - Applications of Thermal Energy TransferDocument49 pagesTransfer of Thermal Energy - Conduction - Convection - Radiation - Applications of Thermal Energy TransferImmanuel Suman ShijuNo ratings yet

- Industrial Multi Strand Cables HSN CODE: 85.44.60.20 Price List: 1 December 2021 LP NO. KEI/W&F/LP/21-22/06 DT.01.12.2021Document2 pagesIndustrial Multi Strand Cables HSN CODE: 85.44.60.20 Price List: 1 December 2021 LP NO. KEI/W&F/LP/21-22/06 DT.01.12.2021Sanket PhatangareNo ratings yet

- Citrus Fusion CuisineDocument11 pagesCitrus Fusion CuisineLuz Milagros Bencosme MartinezNo ratings yet

- Position Size Calculator NQDocument2 pagesPosition Size Calculator NQKingston GroupNo ratings yet

- Power Quality ToolsDocument15 pagesPower Quality Toolsrize1159No ratings yet

- Stress Physiology: 1 BSC Psychology DR Devi.N.PDocument18 pagesStress Physiology: 1 BSC Psychology DR Devi.N.PRay LennoxNo ratings yet

- Self Help 2Document23 pagesSelf Help 2Freeman KonsultantNo ratings yet

- Dam Safety & Water Resource Planning Project (DSWRPP) BackgroundDocument2 pagesDam Safety & Water Resource Planning Project (DSWRPP) Backgroundchannajayamangala100% (1)