Professional Documents

Culture Documents

WI.42.021 - H14 Aanvoer Van Glas .NL - en

WI.42.021 - H14 Aanvoer Van Glas .NL - en

Uploaded by

Hafsa Boudguig0 ratings0% found this document useful (0 votes)

15 views2 pages1. This document provides work instructions for the tempered glass department at SOLIVER. It details the process for setting up and running glass production runs, including entering glass pack information, measuring glass thickness, and ensuring proper face orientation.

2. Glass packs are to be consumed after removing any unusable pieces, with the number of defects noted. Measured dimensions must match what is stated on form IF.168.

3. At the end of each shift, employees must clean their workstations and sort waste materials correctly.

Original Description:

Original Title

WI.42.021 - H14 Aanvoer van glas .nl.en

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. This document provides work instructions for the tempered glass department at SOLIVER. It details the process for setting up and running glass production runs, including entering glass pack information, measuring glass thickness, and ensuring proper face orientation.

2. Glass packs are to be consumed after removing any unusable pieces, with the number of defects noted. Measured dimensions must match what is stated on form IF.168.

3. At the end of each shift, employees must clean their workstations and sort waste materials correctly.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

15 views2 pagesWI.42.021 - H14 Aanvoer Van Glas .NL - en

WI.42.021 - H14 Aanvoer Van Glas .NL - en

Uploaded by

Hafsa Boudguig1. This document provides work instructions for the tempered glass department at SOLIVER. It details the process for setting up and running glass production runs, including entering glass pack information, measuring glass thickness, and ensuring proper face orientation.

2. Glass packs are to be consumed after removing any unusable pieces, with the number of defects noted. Measured dimensions must match what is stated on form IF.168.

3. At the end of each shift, employees must clean their workstations and sort waste materials correctly.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Translated from Dutch to English - www.onlinedoctranslator.

com

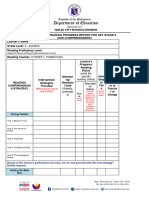

WORK INSTRUCTIONS Document: WI.42.021.F

SOLIVER Department: TEMPERED Page:1/2

Location: Halle 14: Supply glass Date: 31/08/10

1. In production

1.1. When a new production run is started, the department

manager releases a list of 'RESERVED GOODS RECIPES'. This list

is followed when setting up glass packs.

2.1. On the Scanstar 325 (Computer Identics) terminal you will

be asked to enter the glass pack number (this is also

indicated by the flashing red flash lamp). The reception

number is suggested by the system itself and only needs to be

supplemented by the serial number.

You can also enter a glass pack with function key F5.

3.1. Before placing a new glass pack on the turntable support,

remove the empty pack from the previous pack.

Note: The green RESET PROTECTION RESET indicator must

illuminate at all times to preclude automatic turning of

the turntable during pack change.

4.1. Glass packs, accompanied by the form IF.071 “SPECIAL

GOODS TO TRACK”, may be consumed after removing the bad

primitives.

The “Production” section is filled in and the number of

unusable primitives is noted.

The forms IF.071 are collected in the office.

5.1. It is ensured that the measured dimensions (length and

width) correspond to the dimensions stated in form IF.168.

Face-bain side must be respected and completed when putting on

any glass pack.

6.1. Remove packaging so that the depileur can pick up the

first primitive without hindrance (remove plastic).

1.7. Subsequently, the glass thickness is measured with the

micrometer according to BI42-048.

On the Scanstar 325 (Computer Identics) terminal you are asked

to enter the glass thickness. Enter the thickness and follow

the instructions on the screen. In case of problems, enter the

value manually on form IF.168.

In the event of major measurement differences or

irregularities, the team leader will be notified immediately.

WORK INSTRUCTIONS Document: WI.42.021.F

SOLIVER Department: TEMPERED Page:2/2

Location: Halle 14: Supply glass Date: 31/08/10

7.1. Release to the turntable is given by pressing the RESET

PROTECTION RESET button (green pilot lamp off), when selector

switch Post 1 - 5 is set to automatic operation.

8.1. The supplier's identification documents and the internal

identification sheet (IF.022) are stored. At the end of the

production run, all identification tokens are destroyed.

1.9.Windows that are cut for GT3 must always be stamped on the non-

face bain side. Each individual glass pack must therefore be

checked with a face bain lamp (BI.42.065). Registration is

done using CI terminal.

If the face bain is not correct, this is immediately reported

to the supervisor. The glass pack is not released in this

case.

2. Order and tidiness

-Everyone always keeps the workstation clean and ensures that

everything is in order at the end of the shift.

-Glass waste, tire iron and combustible waste are sorted in the

containers provided.

-The parts of the empty racks are neatly stacked.

Storage:Vivaldi QMS File 1 Name Date

Distribution: Drafter DECLERCQ D. 31/08/10

Desk H14 Review VANDENBERGHE L. 31/08/10

Approval VANSTEENKISTE R. 31/08/10

IF 055.1

You might also like

- User Manual Class B Autoclave BKM-Z18B-BiobaseDocument29 pagesUser Manual Class B Autoclave BKM-Z18B-BiobaseLuiggi Escalante73% (11)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Autopilot NP2015/2025: Type 102 - 886 NG001Document105 pagesAutopilot NP2015/2025: Type 102 - 886 NG001Alexey Plekhanov100% (1)

- Atlas Shindler Catalogo de Reposicion de PiezasDocument305 pagesAtlas Shindler Catalogo de Reposicion de PiezasAriel Ariel100% (5)

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Toshiba VTD1552Document65 pagesToshiba VTD1552thomas-stentzelNo ratings yet

- Toshiba VTD1551Document65 pagesToshiba VTD1551thomas-stentzelNo ratings yet

- User Manual KVMDocument17 pagesUser Manual KVMNisar AhmedNo ratings yet

- Toshiba 26W330D LCDTVDocument66 pagesToshiba 26W330D LCDTVvideosonNo ratings yet

- Toshiba VTD2032Document66 pagesToshiba VTD2032thomas-stentzelNo ratings yet

- CRAFTY+ Instructions EnglishDocument33 pagesCRAFTY+ Instructions EnglishGarrick BarberNo ratings yet

- Toshiba VTD1432Document66 pagesToshiba VTD1432thomas-stentzelNo ratings yet

- Sharp Lc-32av22u LCD TV SMDocument100 pagesSharp Lc-32av22u LCD TV SMAnna SantosNo ratings yet

- 32w300p Service Manual2 PDFDocument70 pages32w300p Service Manual2 PDFFakhri AliNo ratings yet

- Belinea 1945 S1W - ENGDocument14 pagesBelinea 1945 S1W - ENGluismontoy.pNo ratings yet

- MMEC-WI-1002 - Cooling Water Exchanger - 110-EP-091A To GDocument7 pagesMMEC-WI-1002 - Cooling Water Exchanger - 110-EP-091A To GRAJESH KUMAR RNo ratings yet

- Setofinstructions Stiles BradDocument18 pagesSetofinstructions Stiles Bradapi-272926884No ratings yet

- Toshiba Vtd1420Document63 pagesToshiba Vtd1420Ionel ColamischiNo ratings yet

- Toshiba Vtd1420 TV-DVD SMDocument107 pagesToshiba Vtd1420 TV-DVD SMAna Paula SoareNo ratings yet

- 42HP16 Toshiba Manual de ServicioDocument89 pages42HP16 Toshiba Manual de ServiciopetacosNo ratings yet

- 42 HP 86Document76 pages42 HP 86plr2000No ratings yet

- 50" Digital Plasma Color Television: Service ManualDocument91 pages50" Digital Plasma Color Television: Service ManualLance100% (4)

- LCD SERVICEDocument70 pagesLCD SERVICEMuhammad NurfajriNo ratings yet

- Bang Olufsen BeoLab BL9 Service ManualDocument40 pagesBang Olufsen BeoLab BL9 Service ManualMark YachadNo ratings yet

- Product Specification: (V) Preliminary Specifications Final SpecificationsDocument35 pagesProduct Specification: (V) Preliminary Specifications Final SpecificationsPablo JavierNo ratings yet

- INFRARED IC HEATER T-962 User ManualDocument6 pagesINFRARED IC HEATER T-962 User ManualBintang AntaresNo ratings yet

- Guidance LOW-E EN ONLINE 2020Document18 pagesGuidance LOW-E EN ONLINE 2020abhijitsumanNo ratings yet

- Ikea Mould Standard 2015-02-25 5.2Document10 pagesIkea Mould Standard 2015-02-25 5.2trangpham2131995No ratings yet

- CHILLER Manual UC-140SP Rev.1 PDFDocument23 pagesCHILLER Manual UC-140SP Rev.1 PDFFrank Lenin Ortiz Galarza0% (1)

- Valve & Flange Box FundamentalsDocument20 pagesValve & Flange Box Fundamentalsautin3:16No ratings yet

- Toshiba LCD TV 20HL85 Service ManualDocument60 pagesToshiba LCD TV 20HL85 Service Manualsm7232No ratings yet

- Mi-0173 Operation Manual Uc-0140 2011 HP (En)Document31 pagesMi-0173 Operation Manual Uc-0140 2011 HP (En)Juan CaceresNo ratings yet

- DSSP24 Manual WebDocument40 pagesDSSP24 Manual Webaris ahmadNo ratings yet

- Hid 2000 BoardDocument56 pagesHid 2000 BoardLuigi SergiNo ratings yet

- Features: Idnet™ I/O DevicesDocument4 pagesFeatures: Idnet™ I/O DevicesNwabuze IwunzeNo ratings yet

- 42HP16 Toshiba Manual de ServicioDocument89 pages42HP16 Toshiba Manual de ServicioDaniel AvecillaNo ratings yet

- Process Development & Control LLCDocument12 pagesProcess Development & Control LLCvyshakhNo ratings yet

- Spare Parts List: Asphalt and Concrete Cutter T400001Document22 pagesSpare Parts List: Asphalt and Concrete Cutter T400001Tadas PNo ratings yet

- Konica Medical Film Processor Srx-201: PrecautionsDocument20 pagesKonica Medical Film Processor Srx-201: Precautionsdarwin_mdozaNo ratings yet

- GFDocument211 pagesGFCatalin StoicescuNo ratings yet

- 32 - 1.X - 2.X - Tower (System) - Procedure To Apply Labels On Tower Walls - 09Document9 pages32 - 1.X - 2.X - Tower (System) - Procedure To Apply Labels On Tower Walls - 09thiagogirouxNo ratings yet

- Service Manual: Pcg-C1Vp/C1VpkDocument20 pagesService Manual: Pcg-C1Vp/C1VpkEnrique CedeñoNo ratings yet

- Service Manual: PCG-FX501/FX502/FX505Document15 pagesService Manual: PCG-FX501/FX502/FX505Frank ElizaldeNo ratings yet

- Ingersoll Rand DS35 Dryer User ManualDocument16 pagesIngersoll Rand DS35 Dryer User ManualNikohl LaineNo ratings yet

- Service Manual: PCG-GRS150/GRS170Document12 pagesService Manual: PCG-GRS150/GRS170Andrei RadulescuNo ratings yet

- Terak Model 8510 InstallationDocument6 pagesTerak Model 8510 InstallationAndreas liemNo ratings yet

- D-90 Parts PN450595 R1Document28 pagesD-90 Parts PN450595 R1naokito AkemiNo ratings yet

- Toshiba LCD TV 37HLX95 - SVM PDFDocument42 pagesToshiba LCD TV 37HLX95 - SVM PDFjonnycoolNo ratings yet

- Service Manual: Conf IdentialDocument25 pagesService Manual: Conf Identialgabi chisNo ratings yet

- Turbine Housing: Industrial GradeDocument20 pagesTurbine Housing: Industrial GradeMIGUELNo ratings yet

- Instructions For Clearing Holter Error 602 US 13jan20 CIL86000270ADocument6 pagesInstructions For Clearing Holter Error 602 US 13jan20 CIL86000270AlaboratorioelectroNo ratings yet

- Service Manual: Conf IdentialDocument25 pagesService Manual: Conf IdentialEnrique CedeñoNo ratings yet

- SH200 - EoL Inst BDocument5 pagesSH200 - EoL Inst BHuyPhạmNo ratings yet

- Ecotec Exclusive User Manual 261415Document16 pagesEcotec Exclusive User Manual 261415zula74No ratings yet

- Polaroid LCD TV FLM-3201 - ServiceManual - 20051205 PDFDocument44 pagesPolaroid LCD TV FLM-3201 - ServiceManual - 20051205 PDFFrancisco PrigueNo ratings yet

- Memorex Mod. Mvdt2002sm Tv-dvd-VhsDocument200 pagesMemorex Mod. Mvdt2002sm Tv-dvd-VhsJuan Carlos PerdomoNo ratings yet

- V NodeDocument1,075 pagesV NodeRicardi Martinelli MartinsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Measuring and Marking Metals for Home Machinists: Accurate Techniques for the Small ShopFrom EverandMeasuring and Marking Metals for Home Machinists: Accurate Techniques for the Small ShopRating: 4 out of 5 stars4/5 (1)

- WI 42 091 NL enDocument4 pagesWI 42 091 NL enHafsa BoudguigNo ratings yet

- CI 43 003 NL enDocument1 pageCI 43 003 NL enHafsa BoudguigNo ratings yet

- Volkswagen VDA4994 GTL VDA 2.0-VW 1.3 DE - De.enDocument11 pagesVolkswagen VDA4994 GTL VDA 2.0-VW 1.3 DE - De.enHafsa BoudguigNo ratings yet

- TP.30.001 - Fragmentatie Getemperd - Nl.enDocument8 pagesTP.30.001 - Fragmentatie Getemperd - Nl.enHafsa BoudguigNo ratings yet

- TP 30 002 NL enDocument6 pagesTP 30 002 NL enHafsa BoudguigNo ratings yet

- Funny People Final Script PDFDocument153 pagesFunny People Final Script PDFHafsa BoudguigNo ratings yet

- IATF - International Automotive Task Force: Rules For Achieving and Maintaining IATF Recognition IATF Rules 5 EditionDocument20 pagesIATF - International Automotive Task Force: Rules For Achieving and Maintaining IATF Recognition IATF Rules 5 EditionHafsa BoudguigNo ratings yet

- 2.7 2012 Influence of Implant Neck Design and Implant-Abutment Connection Type On Peri-Implant Health. Radiological StudyDocument9 pages2.7 2012 Influence of Implant Neck Design and Implant-Abutment Connection Type On Peri-Implant Health. Radiological StudyDuilioJrNo ratings yet

- Discussion and ConclusionDocument16 pagesDiscussion and Conclusionzul hilmiNo ratings yet

- Passenger/Itinerary Receipt: Electronic Ticket 220-2332362081Document2 pagesPassenger/Itinerary Receipt: Electronic Ticket 220-2332362081Dzeri LoganNo ratings yet

- Ks2 NC Reading Progress ReportDocument5 pagesKs2 NC Reading Progress ReportCyndee PamintuanNo ratings yet

- Ls1eng Elem Las21 To-Las31-MergedDocument31 pagesLs1eng Elem Las21 To-Las31-MergedJaypee AturoNo ratings yet

- Once There Were Wolves - AnalysisDocument5 pagesOnce There Were Wolves - AnalysisДаниела ИсаевичNo ratings yet

- Financial Behavior of Millenial Genration On Investment DecisionDocument8 pagesFinancial Behavior of Millenial Genration On Investment DecisionYuslia Nandha Anasta SariNo ratings yet

- Malhotra, Garg, and Rai - Analysing The NDHM Health Data Management PolicyDocument30 pagesMalhotra, Garg, and Rai - Analysing The NDHM Health Data Management Policysimran sabharwalNo ratings yet

- What Is Text, Discourse DefinedDocument2 pagesWhat Is Text, Discourse DefinedChristine BlabagnoNo ratings yet

- Multiple Choice QuestionsDocument3 pagesMultiple Choice QuestionsManthan Gaming YtNo ratings yet

- System LogDocument199 pagesSystem LogAustinNo ratings yet

- Weather and ClimateDocument2 pagesWeather and ClimateLouise GermaineNo ratings yet

- SMK Bandaraya Kota Kinabalu English Language Lesson Plan: MondayDocument6 pagesSMK Bandaraya Kota Kinabalu English Language Lesson Plan: MondaySITI NORZUANI BINTI BAHARUDDIN MoeNo ratings yet

- Mispa I2 User ManualDocument43 pagesMispa I2 User ManualJosef GrapesNo ratings yet

- Cl400e VDocument2 pagesCl400e VCá ThuNo ratings yet

- Decision Trees - 2022Document49 pagesDecision Trees - 2022Soubhav ChamanNo ratings yet

- Vol-IV Approved Vendor ListDocument29 pagesVol-IV Approved Vendor ListabhishekNo ratings yet

- 6.625in CSG PATCHDocument3 pages6.625in CSG PATCHherbster28No ratings yet

- Truck Evo Manual FinalDocument28 pagesTruck Evo Manual FinalRodrigo Zuñiga RosselNo ratings yet

- HMBD 50B Drain ManualDocument14 pagesHMBD 50B Drain Manualindra bayujagadNo ratings yet

- Sol Gel ThesisDocument5 pagesSol Gel Thesiskriscundiffevansville100% (2)

- MENTOR FEEDBACK FORM March 2022Document2 pagesMENTOR FEEDBACK FORM March 2022Darius NixNo ratings yet

- KirkDocument6 pagesKirkSwinlife WinlifeNo ratings yet

- A Review of RhomboidityDocument10 pagesA Review of RhomboidityShrey GulatiNo ratings yet

- Scissor - Platform - Hidral - Tech SpecificationsDocument10 pagesScissor - Platform - Hidral - Tech SpecificationsSajidNo ratings yet

- QGD 20-50 ManualDocument76 pagesQGD 20-50 Manualnanditos75392No ratings yet

- Intelligent Urbanism: Convivial Living in Smart Cities: Stephanie Santoso Andreas KuehnDocument5 pagesIntelligent Urbanism: Convivial Living in Smart Cities: Stephanie Santoso Andreas KuehnAdrian VodițăNo ratings yet

- Martin HeideggerDocument22 pagesMartin HeideggerLayne0% (3)

- Financial Services IBEFDocument34 pagesFinancial Services IBEFsanasarin1311No ratings yet

- DDBMS ArchitectureDocument62 pagesDDBMS ArchitectureFranklin DorobaNo ratings yet