Professional Documents

Culture Documents

RLS-134R MSDS

RLS-134R MSDS

Uploaded by

manderson3297Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RLS-134R MSDS

RLS-134R MSDS

Uploaded by

manderson3297Copyright:

Available Formats

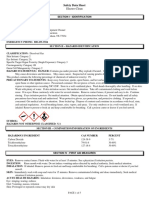

Material Safety Data Sheet

MSDS: RLS-134R SECTION 1: CHEMICAL PRODUCT AND COMPANY INFORMATION Company: IDQ Operating, Inc. 2901 W Kingsley Rd. Garland, Texas 75041 Phone No.: 1-888-396-0422 CHEMTREC Phone No.: 1-800-424-9300 Product Description: R-134a Refrigerant with Leak Sealer, 12 oz. Part Number: MSDS Date: RLS-134 10/05/2009 HAZARD RATING Health 1 Fire: 0 Reactivity: 0 Special: -Toxicity: 1 SCALE 0 = Insignificant 1 = Slight 2 = Moderate 3= High 4 = Extreme

SECTION 2: COMPOSITION AND INFORMATION ON INGREDIENTS No. 1 2 3 Description 1,1,1,2-Tetrafluoroethane Polyalkylene glycol monobutyl ether Leak Sealer CAS Reg. No. 811-97-2 N/A N/A Units % vol % vol % vol Amount 80-95 0-10 0-1

SECTION 3: HAZARDS INFORMATION Portals of Entry: Inhalation, ingestion, eye contact, skin contact, and dermal absorption. Inhalation: Inhalation of high vapor concentrations can cause anesthetic effects including dizziness, weakness, nausea, and unconsciousness. It can act as an asphyxiant by limiting available oxygen. Very high doses can cause abnormal heart rhythm which is potentially fatal. Breathing high concentration vapors or prolonged breathing vapors can cause irritation of the nose, throat, and lungs as well as headaches, drowsiness, and fatigue. Extreme inhalation can cause loss of coordination and unconsciousness. Eye Contact: Liquid splashes or vapor spray may cause freeze burns. Vapors can cause eye irritation. Skin Contact: Vapor spray can cause freeze burns. Product can cause eye irritations. Ingestion: Most of the product is a gas at Standard Temperature and Pressure (STP) which would not allow much of the product to be ingested. The liquid material at STP could cause nausea, gastrointestinal disturbances, headaches, drowsiness, vertigo, and dizziness. Delayed Effects: Prolonged and repeated overexposure can cause irritation of the respiratory tract and mucous membranes, and kidney effects. HEALTH EFFECTS FROM OVEREXPOSURE: Primary Routes of Exposure: Skin and inhalation.

IDQ Operating Inc. Garland, TX

Material Safety Data Sheet RLS-134R Refrigerant with Leak Sealer

October 5, 2009

SECTION 4: FIRST AID MEASURES Inhalation: Inhalation under normal exposure should not cause problems; however if inhalation has resulted in symptoms, move patient to fresh air. If breathing is difficult, give oxygen. Give artificial respiration if breathing has stopped. Get prompt medical attention. Eye Contact: Immediately flush eyes with a large amount of water for at least 15 minutes. If symptoms exist and/or persist, get prompt medical attention. Skin Contact: Wash affected skin areas thoroughly with soap and water. Remove contaminated clothing. If skin irritation persists, see a physician. Ingestion: If swallowed, give large quantities of water to drink. Induce vomiting. Careful gastric lavage may be indicated. Immediately see a physician. Never give anything by mouth nor induce vomiting of an unconscious person. SECTION 5: FIRE FIGHTING MEASURES Unusual Hazards: Toxic fumes are generated when material is exposed to fire and fire conditions. Extinguishing Agents: Use the following extinguishing media when fighting fires involving this material: polar solvent foam, carbon dioxide, dry chemical, and water spray. Personal Protective Equipment: Wear self-contained breathing apparatus and full protective gear. Special Precautions: Use water spray to cool large containers exposed to fire. Vapors are denser than air and will have a tendency to accumulate in lower areas which can cause the vapors to concentrate and suffocate. The relatively small part of the product that is liquid at STP can be flammable. If the products liquid portion is exposed to fire, extinguish with polar solvent foam, carbon dioxide, dry chemical, and water spray. FIRE AND EXPLOSIVE PROPERTIES: Flash Point (C): Auto-Ignition Temperature (C): Lower Explosive Limit (C): Upper Explosive Limit (C): Non-Flammable at STP >350 Non-Flammable at STP Non-Flammable at STP

SECTION 6: ACCIDENTAL SPILL OR LEAK RELEASE INFORMATION Personal Protection: Appropriate protective equipment must be worn when handling a large spill of this material. See the PERSONAL PROTECTION MEASURES Section for recommendations. If exposed to material during cleanup operations, see the FIRST AID PROCEDURES Section for actions to follow. Procedures: Evacuate the spill area. Floor may be slippery if non-volatile components in product (< 10 % volume) have wetted the floor; use care to avoid falling. Ventilate the spill area. Avoid breathing vapor. Contain non-volatile material spills immediately with inert adsorption materials. Transfer liquids and solid adsorption materials and diking material to separate suitable containers for recovery or disposal. CAUTION: Keep spills and cleaning runoff out of municipal sewers and open bodies of water. 2

IDQ Operating Inc. Garland, TX

Material Safety Data Sheet RLS-134R Refrigerant with Leak Sealer

October 5, 2009

SECTION 7: HANDLING AND STORAGE Storage Conditions: Store in a cool, well ventilated place. Keep containers dry. Store product away from reactive and corrosive materials. The minimum recommended storage temperature for this material is -29 C/ -20 F. The maximum storage temperature is 49 C/ 120 F. Handling Procedures: Avoid causing and inhaling high concentrations of vapor. The vapor concentration levels in air need to be keep below occupational exposure limits and keep as low as practicable. Do not mix product with air or oxygen under pressure. Avoid exposure of product to flame or very hot surfaces. Vapors can be evolved when material is being used in processing operations. See FACILITY CONTROL MEASURES Section for types of ventilation required. SECTION 8: EXPOSURE CONTROLS AND PERSONAL PROTECTION Respiratory Protection: A respiratory protection program meeting OSHA 1910.134 and ANSI Z88.2 requirements must be followed whenever workplace conditions warrant a respirators use. If respiratory protection is needed, use, MSHA-NIOSH approved respirator for organic vapors. None required if airborne concentrations are maintained below the TWA/TLVs listed in the COMPONENT EXPOSURE INFORMATION Section. Up to 10 times the TWA/TLV: Wear a half-mask, air purifying respirator. Up to 1000 ppm organic vapor: Wear an approved full-face piece, air-purifying respirator. Above 1000 ppm organic vapor or unknown: Wear an approved positive pressure mode, or an approved full-face piece airline respirator in the positive pressure mode with emergency escape provisions. Air purifying respirators should be equipped with organic vapor cartridges. Eye Protection: Use eye goggles and/or face shield. Hand Protection: The gloves listed below may provide protection against permeation. Gloves of other chemically resistant materials may not provide adequate protection: Polyvinyl alcohol and Viton. Gloves should be removed and replaced immediately if there is any indication of degradation or chemical breakthrough. Other Protection: Use chemically resistant apron or other impervious clothing to avoid prolonged or repeated skin contact. FACILITY CONTROL MEASURES: Ventilation: Use normal local exhaust ventilation with a minimum capture velocity of 100 ft/min (0.5 m/sec) at the point of vapor evolution. Other Protective Equipment: Facilities storing and utilizing this material should be equipped with an eyewash facility and a safety shower. SECTION 9: PHYSICAL AND CHEMICAL PROPERTIES TYPICAL PHYSICAL PROPERTIES:

IDQ Operating Inc. Garland, TX PROPERTY Appearance: Color: State: Odor Characteristics: Viscosity (CP @ 20 C); [CP @ 68 F]: Specific Gravity (d/do 4C); [d/do 39F] Vapor Density (Air = 1.0): Vapor Pressure (mm Hg @ 20 C); [psia]: Melting Point (C); [F]: Boiling Point (C); [F]:

Material Safety Data Sheet RLS-134R Refrigerant with Leak Sealer METRIC UNITS Product in Aerosol Container Colorless Liquid under Gas Pressure Ethereal 20 1.225 3.3 4268 Extremely Low; < -26 C -26.5 0; Non-soluble > 120 <7 97

October 5, 2009

ENGLISH UNITS Product in Aerosol Container Colorless Liquid under Gas Pressure Ethereal 20 1.225 3.3 85.6 Extremely Low; < -15 F -15.7 0; Non-soluble > 120 <7 97

Solubility in Water (gr/100 cm); [lb/100 in]: Evaporation Rate (n-butyl acetate = 1.0): pH (product or water extract) Percent Volatility (% wt):

SECTION 10: STABILITY AND REACTIVITY Stability: Stable under normal conditions. Hazardous Decomposition Products: Thermal decomposition may yield toxic decomposition products which include alkyl low molecular weight components, organic chlorides, COx, SOx, NOx, POx, hydrochloric acid, hydrofluoric acid, organic pyrolytic components, and phosgene. Hazardous Polymerization: Product will not undergo polymerization. Incompatibility: Avoid contact with strong oxidizing and reducing agents, fine particulate metals, magnesium and alloy containing more than 2 percent magnesium. Product can react under certain conditions with alkali or alkali earth metals such as sodium, potassium or barium and other Group IA and IIA of the Periodic Table of Elements.

SECTION 11: TOXICOLOGICAL INFORMATION ACCIDENT PREVENTION INFORMATION: COMPONENT EXPOSURE INFORMATION: 4

IDQ Operating Inc. Garland, TX

Material Safety Data Sheet RLS-134R Refrigerant with Leak Sealer

October 5, 2009

Component Information: No. Description 1 1,1,1,2-Tetrafluoroethane 2 Polyalkylene glycol monobutyl ether 3 Leak Sealer Exposure Information for Specific Component: Health Flammable No. 1 2 3 Rating 1 1 2 Rating 0 1 0 Component Units ppm ppm ppm

CAS Reg. No. 811-97-2 N/A N/A

Units % vol % vol % vol

Amount 80-95 0-10 0-1

OSHA TWA 1000 NA 75 STEL NA NA 150 TWA NA NA 50

ACGIH STEL IDLH NA NA 75 NA NA 5,000 HAP No No Yes

NA: Not Available/Non Hazardous; ppm: parts per million Note: 1 ppm equals 3.8 mg/m; 5 ppm equals 19 mg/m; 10 ppm equals 38 mg/m; 100 ppm equals 380 mg/m. SECTION 12: ECOLOGICAL INFORMATION Persistence and Degradation: Decomposes comparatively rapidly in the lower atmosphere (troposphere). Atmospheric lifetime is 15.6 years. Products of decomposition will be highly dispersed and hence will have a very low concentration. It is not a significant contributor to photochemical smog and is not considered to be a VOC. It is not considered as an ozone depleting chemical. SECTION 13: DISPOSAL INFORMATION WASTE DISPOSAL: For disposal, dispose this material at a facility that complies with local, state, and federal regulations. SECTION 14: TRANSPORTATION INFORMATION DOT Hazard Description: Proper Shipping Name: CONSUMER COMMODITY Hazard Class: ORM-D Identification Number: NA Packing Group: NA Hazardous Substance (RQ): NA IMDG Hazard Description: Proper Shipping Name: AEROSOLS, NON-FLAMMABLE Hazard Class: 2.2 Identification Number: UN1950 Packing Group: NA Hazardous Substance (RQ): NA SECTION 15: REGULATORY INFORMATION EPA Regulation: SARA SECTION 311/312 HAZARDS: Acute Health, Chronic Health 5

IDQ Operating Inc. Garland, TX

Material Safety Data Sheet RLS-134R Refrigerant with Leak Sealer

October 5, 2009

All components of this product are on the TSCA list. SARA Title III Section 313 Supplier Notification: This product contains the indicated * toxic chemical(s) subject to the reporting requirements of Section 313 of the Emergency Planning and Community Right-To-Know Act of 1986 and of 40 CFR 372. This information must be included in all MSDSs that are copied and distributed for this material. SARA TITLE III INGREDIENTS CAS NO. *Methylene Chloride 75-09-2 % WT. REGULATION SECTION 0.99 311, 312, 313, RCRA RQ (LBS) 1000

If 238,000 canisters of this product are in one container the Reportable Quantity RQ of Methylene Chloride is exceeded. Typically this product is packaged in 12 oz containers. State Regulations: This product meets requirements of Southern California AQMD Rule 443.1 and Similar Regulations California Proposition 65: This product contains the following chemical known to the State of California to cause cancer: Methylene Chloride < 1%. SECTION 16: OTHER INFORMATION ********************************************************************************************** All information, recommendations, and suggestions made by IDQ, Inc. (Company) appearing herein concerning our product are based upon tests and data believed to be reliable. However, because of the variable characteristics of analytical procedures and samples, and the inability to control its customers uses of the information and recommendations, or the related products or materials, Company makes NO WARRANTY, EXPRESS OR IMPLIED as to the accuracy of the information or recommendations or that such are fit for any general or specific purpose, whatsoever. Company shall have NO LIABILITY arising from the use by its customers or any third parties of the information and recommendations, and it shall be each customers sole responsibility to determine the suitability for its own use of any information or recommendations provided by Company.

You might also like

- Mortein (PIF-PAF) PowerGard Insect Killer Spray MSDSDocument10 pagesMortein (PIF-PAF) PowerGard Insect Killer Spray MSDSMark DunhillNo ratings yet

- Weld-On 3 MsdsDocument2 pagesWeld-On 3 MsdsSergio SanchezNo ratings yet

- Caustic Soda Flakes MSDSDocument4 pagesCaustic Soda Flakes MSDSShiraz Layin50% (2)

- Msds PDFDocument5 pagesMsds PDFVicky SLayzher SevenfoldismNo ratings yet

- Ccc1-Circ3 - Revised Guidance On The Continued Use of Existing Imo Type Portable Tanks and Road Tank Ve Secretariat 0Document66 pagesCcc1-Circ3 - Revised Guidance On The Continued Use of Existing Imo Type Portable Tanks and Road Tank Ve Secretariat 0Anonymous KIpkFtt6M5No ratings yet

- 783 Sap SD Dangerous Goods ManagementDocument13 pages783 Sap SD Dangerous Goods Managementrohit sharma100% (1)

- MSDS Degreaser - ID Red - 650mL (450g) - Spray CanDocument3 pagesMSDS Degreaser - ID Red - 650mL (450g) - Spray CanGonza PfNo ratings yet

- 175 PacDocument7 pages175 PacRACHMAD ARIFUDDINNo ratings yet

- 5160-5170 SDS QSDocument5 pages5160-5170 SDS QSaldrin de guzmanNo ratings yet

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company IdentificationEdgar Julio Sara TairoNo ratings yet

- Section 1 - Material Identification and Use: Material Safety Data Sheet (Canada) Condensate (Sweet 1% Benzene)Document2 pagesSection 1 - Material Identification and Use: Material Safety Data Sheet (Canada) Condensate (Sweet 1% Benzene)Teguh SetionoNo ratings yet

- Material Safety Data Sheet: CrotonaldehydeDocument6 pagesMaterial Safety Data Sheet: Crotonaldehydeharsh421No ratings yet

- Spray Paint MsdsDocument4 pagesSpray Paint MsdsHillary RyanNo ratings yet

- MSDS Garralube 73Document6 pagesMSDS Garralube 73satriaNo ratings yet

- Asia Wd40 Aerosol Msds 2012Document4 pagesAsia Wd40 Aerosol Msds 2012Sarliza JafarNo ratings yet

- Composition/Information On Ingredients: Material Safety Data SheetDocument6 pagesComposition/Information On Ingredients: Material Safety Data SheetrrebollarNo ratings yet

- MSDS Cim PremixDocument3 pagesMSDS Cim PremixKiệt Lê TuấnNo ratings yet

- Aceite Chiller TRANE PDFDocument5 pagesAceite Chiller TRANE PDFxGsLeugimNo ratings yet

- R 134 AjDocument6 pagesR 134 AjSami ThirunavukkarasuNo ratings yet

- Butyl OctanolDocument7 pagesButyl Octanolanpuselvi125No ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product / Company InformationDocument6 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product / Company Informationceemore300No ratings yet

- Carboline 890 Part ADocument6 pagesCarboline 890 Part AclintonNo ratings yet

- Material Safety Data Sheet: Natural GasDocument5 pagesMaterial Safety Data Sheet: Natural Gasprasad5034No ratings yet

- JKG - Msds Royal Crown Tech Az GreaseDocument6 pagesJKG - Msds Royal Crown Tech Az GreaseEduardo Saúl TapiaNo ratings yet

- d101 A English.10Document5 pagesd101 A English.10Elvert MGNo ratings yet

- Msds Glycerine Oil PDFDocument6 pagesMsds Glycerine Oil PDFknabpshoNo ratings yet

- Material Safety Data Sheets (MSDS) : Hazardous Chemicals - Shamu Stadium, SeaWorldDocument18 pagesMaterial Safety Data Sheets (MSDS) : Hazardous Chemicals - Shamu Stadium, SeaWorldThe Orca Project CorpNo ratings yet

- Material Safety Data Sheet: Section 1: Product IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1: Product Identificationcvolkan1No ratings yet

- DCP MSDSDocument4 pagesDCP MSDSAsima AtharNo ratings yet

- NAF S III Feb 2013.1Document3 pagesNAF S III Feb 2013.1Pedro LacerdaNo ratings yet

- Minimum Oil Circuit BreakerDocument4 pagesMinimum Oil Circuit BreakergshdavidNo ratings yet

- SW 830Document2 pagesSW 830Yến BùiNo ratings yet

- Zeromist - 01 U - MSDSDocument6 pagesZeromist - 01 U - MSDSLuuThiThuyDuongNo ratings yet

- SGP446Document7 pagesSGP446Zulfiqar Ali BhattiNo ratings yet

- Material Safety Data Sheet ISSUED: 10/23/97 Propylene REVISED: 11/01/99Document7 pagesMaterial Safety Data Sheet ISSUED: 10/23/97 Propylene REVISED: 11/01/99Apaq ApacheNo ratings yet

- Data Sheet Mecha Tool ATFDocument2 pagesData Sheet Mecha Tool ATFramsi17No ratings yet

- Turco 5351 MsdsDocument5 pagesTurco 5351 MsdsElías VillegasNo ratings yet

- Material Safety Data Sheet: Development Associates, IncDocument3 pagesMaterial Safety Data Sheet: Development Associates, IncDedi MulyadiNo ratings yet

- Elkon Products - Silica Fume MSDS, April 2013Document11 pagesElkon Products - Silica Fume MSDS, April 2013Sigit PurwandiNo ratings yet

- Msds MethaneDocument7 pagesMsds Methanenirmal_subudhiNo ratings yet

- SSR Ultra CoolantDocument4 pagesSSR Ultra CoolantLIDAIRNo ratings yet

- Msds OctaneDocument5 pagesMsds Octanenirmal_subudhiNo ratings yet

- MsdsDocument6 pagesMsdsRoby SuheriNo ratings yet

- B 2814 B 8 F 54Document11 pagesB 2814 B 8 F 54Jimmy RosenbaumNo ratings yet

- ABRO Spray Paint PDFDocument6 pagesABRO Spray Paint PDFAnonymous QQZcso63% (8)

- TD10379 Water Chiller Treatment MSDS 0715ADocument3 pagesTD10379 Water Chiller Treatment MSDS 0715Averon_xiiiNo ratings yet

- Msds Formalin - 2Document4 pagesMsds Formalin - 2somara natalisNo ratings yet

- Material Safety Data Sheet: Section 1 - Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet: Section 1 - Product and Company IdentificationRudy SkaffNo ratings yet

- Msds Titipan1Document5 pagesMsds Titipan1anitacahyaNo ratings yet

- SW 830Document2 pagesSW 830Yến Bùi100% (2)

- Epoxy Parfilm Ultra 4 MSDSDocument2 pagesEpoxy Parfilm Ultra 4 MSDSZsuzsanna KuruczNo ratings yet

- Sherwin Williams Matt Varnish SDSDocument6 pagesSherwin Williams Matt Varnish SDSJoe de Tracy GouldNo ratings yet

- EthylacetateDocument5 pagesEthylacetateA.Magied MahmoudNo ratings yet

- Material Safety Data Sheet: Texaco Rando® HD 100 - 220Document9 pagesMaterial Safety Data Sheet: Texaco Rando® HD 100 - 220evet cachoNo ratings yet

- Sasol LV3Document8 pagesSasol LV3Dave CNo ratings yet

- Anabond 202 MSDSDocument4 pagesAnabond 202 MSDSPoovannan Prakash0% (1)

- Msds Diaseton AlkoholDocument5 pagesMsds Diaseton AlkoholtakenoveraccountNo ratings yet

- Propylene Glycol USP MSDSDocument6 pagesPropylene Glycol USP MSDSeprastyo_3No ratings yet

- Msds Methylene ChlorideDocument3 pagesMsds Methylene ChlorideCharles FuNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company Identificationsuraj rawatNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- DGR62 Addendum1 ENDocument16 pagesDGR62 Addendum1 ENSafety QualityNo ratings yet

- Catalytic Converter & Oxygen Sensor Cleaner: Safety Data SheetDocument10 pagesCatalytic Converter & Oxygen Sensor Cleaner: Safety Data SheetAsadNo ratings yet

- 12-Msds-Deformer-28 (Wetting Agent) (Liquid)Document9 pages12-Msds-Deformer-28 (Wetting Agent) (Liquid)saddamNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument8 pagesSafety Data Sheet: Section 1. IdentificationSafwan ZuberNo ratings yet

- 065 Isopropyl AlcoholDocument7 pages065 Isopropyl Alcoholeng20072007No ratings yet

- Chemviron Clarcel CBLDocument13 pagesChemviron Clarcel CBLCardoso MalacaoNo ratings yet

- MSDS TmbeDocument14 pagesMSDS Tmbeصلاح الواديNo ratings yet

- Safety Data Sheet: Multi - Active 8 Pre Treatment SprayDocument6 pagesSafety Data Sheet: Multi - Active 8 Pre Treatment SprayJake VergaraNo ratings yet

- Hazardous Material Management ProcedureDocument9 pagesHazardous Material Management ProcedureozerNo ratings yet

- Anthamber ISOESuper SDSDocument13 pagesAnthamber ISOESuper SDSSALMAN M. TABANINo ratings yet

- Suva r401 MsdsDocument10 pagesSuva r401 Msdsadrianhhhh1984No ratings yet

- SDS Loctite AA 324Document9 pagesSDS Loctite AA 324Theophilus ThistlerNo ratings yet

- Consola de Contapulsacion Aortica PDFDocument154 pagesConsola de Contapulsacion Aortica PDFgloria mezaNo ratings yet

- Concure WB309Document46 pagesConcure WB309Sharookhan ShajahanNo ratings yet

- MSDS Silicone SealantDocument10 pagesMSDS Silicone SealantDimitrios KolovosNo ratings yet

- Rotair Food Grade SafetyDocument7 pagesRotair Food Grade SafetyAristideNo ratings yet

- RCM Y Wall AllDocument11 pagesRCM Y Wall AllDa WongNo ratings yet

- Evap O Matic SDSDocument7 pagesEvap O Matic SDSFrank BlancoNo ratings yet

- Safety Data Sheet: 1 Identification of The Substance/mixture and of The Company/undertakingDocument7 pagesSafety Data Sheet: 1 Identification of The Substance/mixture and of The Company/undertakingGERYCO CORTEZNo ratings yet

- Iata Dgr55-Addendum1-En-20131223Document14 pagesIata Dgr55-Addendum1-En-20131223hermanNo ratings yet

- DPC Oil Spil Contingency Plan PDFDocument178 pagesDPC Oil Spil Contingency Plan PDFgummy_lang100% (1)

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument8 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company IdentificationSintyatika PutriNo ratings yet

- 1-Dodecanol (Cas 112-53-8) MSDSDocument6 pages1-Dodecanol (Cas 112-53-8) MSDScandykivNo ratings yet

- Safety Data Sheet: Section 1. Product and Company IdentificationDocument8 pagesSafety Data Sheet: Section 1. Product and Company IdentificationOmar VazquezNo ratings yet

- Nacl/Cacl2 Solution, 10X5Ml: Safety Data SheetDocument10 pagesNacl/Cacl2 Solution, 10X5Ml: Safety Data SheetNabila BasalamahNo ratings yet

- CPE615-Lecture 5-Regulation 2Document16 pagesCPE615-Lecture 5-Regulation 2Naufal Rafif LupikoNo ratings yet

- Yan Feng Us AP KG Guidelines 0Document32 pagesYan Feng Us AP KG Guidelines 0Javier LlovetNo ratings yet