Professional Documents

Culture Documents

MSB 2718r2 Replace Buckeye Fuel Hose

MSB 2718r2 Replace Buckeye Fuel Hose

Uploaded by

Garrett ReeveOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSB 2718r2 Replace Buckeye Fuel Hose

MSB 2718r2 Replace Buckeye Fuel Hose

Uploaded by

Garrett ReeveCopyright:

Available Formats

MANDATORY

SERVICE BULLETIN

Beech

TITLE: FUEL - REPLACEMENT OF MIL-H-6000B HOSE MANUFACTURED BY BUCKEYE RUBBER

PRODUCTS INC.

SYNOPSIS OF CHANGE

This Service Bulletin has been revised and is produced in the new format for Raytheon Aircraft Company Service

Bulletins. This revision adds Model 99 airplanes that require this hose inspection and replacement. Relevant

technical changes are marked with change bars in the outside margins. The FAA has issued Airworthiness

Directive (AD) 98-15-13. This statement has been added to the Compliance Statement. If this Service Bulletin has

been previously complied with no further action is required.

1. Planning Information

A. Effectivity

(1) Airplanes

Part I - Hose Replacement on Airplanes Manufactured January 1, 1994 and after

(a) Civil

Beech King Air Model C90A, Serials LJ-1353 through LJ-1445;

Model B200, Serials BB-1476 through BB-1536;

Model B300, Serials FL-114 through FL-141;

Model B300C, Serial FM-9.

(b) Military

A200CT (RC-12P/Q), Serials FE-32 through FE-36;

B200C (C-12F), Serials BW-1 through BW-21.

Part II - Hose Inspection/Replacement on Airplanes Manufactured Prior to January 1, 1994

(c) Civil

Beech King Air Models 65-90, 65-A90, B90, C90 and C90A, Serials LJ-1 through LJ-1352;

Exported under the authority of license exception: TSU. "These commodities, technology or (a) RAC Authorized Service Centers.

software were exported from the United States in accordance with Export Administration (b) Owners of record on the FAA Aircraft Registration Branch List and the RAC

Regulations. Diversion contrary to U.S. law prohibited."

International Owner Notification/Registration Service List.

Raytheon Aircraft Company (RAC) issues Service Information for the benefit of owners and (c) Those having a publications subscription.

fixed base operators in the form of two classes of Service Bulletins. The first class, Information on Owner Notification Service or subscription can be obtained through any RAC

Mandatory Service Bulletins (red border) includes changes, inspections and modifications Authorized Service Center. As Mandatory Service Bulletins and Service Bulletins are issued,

that could affect safety or crashworthiness. RAC also issues Service Bulletins with no red temporary notification in the Service Bulletin Master Index should be made until the index is

border which are designated as either recommended or optional in the compliance section revised. Warranty will be allowed only when specifically defined in the Service Bulletin and in

within the bulletin. In the case of recommended Service Bulletins, RAC feels the changes, accordance with the RAC Warranty Policy.

modifications, improvements or inspections will benefit the owner/operator and although

highly recommended, Recommended Service Bulletins are not considered mandatory at the Unless otherwise designated, RAC Mandatory Service Bulletins, Service Bulletins and RAC

time of issuance. In the case of Optional Service Bulletins, compliance with the changes, Kits are approved for installation on RAC airplanes in original or RAC modified

modifications, improvements or inspections is at the owner/operator’s discretion. Both configurations only. RAC Mandatory Service Bulletins, Service Bulletins and Kits may not

classes are mailed to: be compatible with airplanes modified by STC installations or modifications other than RAC

approved kits.

Issued: January, 1997

Revised, April, 2000

SB 2718, Rev. 2

1 of 22

MANDATORY

SERVICE BULLETIN

Model E90, Serials LW-1 through LW-347;

Model F90, Serials LA-2 through LA-236;

Models 100 and A100, Serials B-1 through B-94, B-100 through B-247;

Model B100, Serials BE-1 through BE-137;

Models 200 and B200 Serials, BB-2, BB-6 through BB-185, BB-187 through BB-202, BB204

through BB-269, BB-271 through BB-407, BB-409 through BB-468, BB-470 through BB-488,

BB-490 through BB-509, BB-511 through BB-529, BB-531 through BB-550, BB-552 through BB-

562, BB-564 through BB-572, BB-574 through BB-590, BB-592 through BB-608, BB-610

through BB-626, BB-628 through BB-646, BB-648 through BB-664, BB-666 through BB-694,

BB-696 through BB-733, BB-735 through BB-792, BB-794 through BB-797, BB-799 through BB-

822, BB-824 through BB-990, BB-992 through BB-1092, BB-1094, BB-1095, BB-1099 through

BB-1104; BB-1106 through BB-1116, BB-1118 through BB-1476;

Models 200C and B200C, Serials BL-1 through BL-23, BL-25 through BL-57, BL-61 through BL-

140;

Models 200CT and B200CT, Serials BN-1 through BN-4;

Model B200CT (FW-II), Serials FG-1 and FG-2;

Models 200T and B200T, Serials BT-1 through BT-38;

Model 300, Serials FA-1 through FA-230; and FF-1 through FF-19;

Model B300, Serials FL-1 through FL-113;

Model B300C, Serials FM-1 through FM-8, and FN-1;

Models 99 Airliner, 99, 99A, A99A, B99 and C99, Serials U-1 through U-239.

(d) Military

H90 (T-44A), Serials LL-1 through LL-61;

A100 (U-21F), Serials B-95 through B-99;

A100-1, Serials BB-3 through BB-5;

A200 (C12C), Serials BC-1 through BC-75, BD-1 through BD-30;

A200C (UC-12B), Serials BJ-1 through BJ-66;

A200CT (C-12D), Serials BP-1, BP-22, BP-24 through BP-51;

A200CT (C-12F), Serials BP-52 through BP-63;

A200CT (FWC-12D), Serials BP-7 through BP-11;

A200CT (RC-12D), Serials GR-1 through GR-13;

A200CT (RC-12G), Serials FC-1 through FC-3;

A200CT (RC-12H), Serials GR-14 through GR-19;

A200CT (RC-12K), Serials FE-1 through FE-9;

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 2 of 22

MANDATORY

SERVICE BULLETIN

A200CT (RC-12N), Serials FE-10 through FE-24;

A200CT (RC-12P), Serials FE-25 through FE-31;

B200C (UC-12F), Serials BU-1 through BU-10;

B200CT (RC-12F), Serials BU-11 and BU-12;

B200C (UC-12M), Serials BV-1 through BV-10;

B200C (RC-12M), Serials BV-11 and BV-12;

B200C (C-12F), Serials BL-73 through BL-112, BL-118 through BL-123.

If you are no longer in possession of the airplane, please forward this information to the present

owner.

(2) Spares

Inspect all inventory for suspect hose (described in REASON). If found, tag and remove from

inventory. DO NOT use any suspect hose as replacement material on any aircraft.

B. Reason

This Service Bulletin is being issued to direct the replacement of all 1/2 inch to 3 inch diameter MIL-H-

6000B rubber hoses manufactured by Buckeye Rubber Products Inc. (BRP) since January 1, 1994, in fuel

distribution systems of affected airplanes. MIL-H-6000B requires that the inner tube of such hoses have a

seamless construction. RAC has determined that the previously mentioned hoses may have an internal

seam due to weak butt joint bond and or butt joint separation. In the presence of flowing fuel these joints

may open in time and impede that fuel flow and therefore those hoses should be replaced.

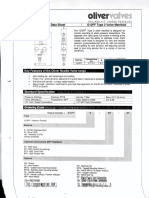

BRP hoses may be identified by a pronounced 3/8-inch wide red or red-orange length-wise stripe with their

manufacturer’s code, 94519, printed periodically along the line in red letters on one side, and/or on the

opposite side by two faint parallel white lines showing quarter year and year of manufacturer, hose size

and specification number. The hoses also have a noticeable spiral pattern on the outer rubber surface with

a fabric-type texture on the rubber surface. Any hoses with a braided fabric exterior, regardless of

markings, are from other manufacturers. Reference Figure 1.

Safety Communique No. "All Beech Models - 126" dated August, 1996 and "All Beech Models - 129" dated

September, 1996 were issued to remove all suspect hoses from spares inventory and to not use any

suspect hoses as replacement material in the future. This Service Bulletin provides information on

handling airplanes in the field that have the suspect hoses installed.

On the Beech King Air C90A, Beech Super King Air B200 Series, Beech Super King Air B300 Series, and

Beech Model 99 Series Airliner, the suspect hoses are used in the fuel system. The suspect hoses were

installed as original equipment on airplanes manufactured January 1, 1994 and after, and may also have

been installed as a replacement part on any airplane manufactured prior to January 1, 1994.

This Service Bulletin is divided into two parts. Part I covers hose replacement on airplanes manufactured

January 1, 1994 and after. Part II covers hose inspection/replacement on airplanes manufactured prior to

January 1, 1994.

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 3 of 22

MANDATORY

SERVICE BULLETIN

C. Description

This Service Bulletin identifies the suspect hoses, the inspection procedure and the replacement

instructions.

D. Compliance

(1) Civil Airplanes

Raytheon Aircraft Company considers this to be a mandatory modification and it should be

accomplished at the next scheduled inspection after receipt of this Service Bulletin, but no later than

the next 200 flight hours.

The FAA has issued Airworthiness Directive (AD) 98-15-13. Accomplishment of Service Bulletin

2718 Rev. 2 is an acceptable means of compliance for this AD.

(2) Military Airplanes

For compliance information on military airplanes affected by this Service Bulletin, contact the

appropriate headquarters.

E. Approval

The engineering data contained in this Service Bulletin is FAA approved.

F. Manpower

The following information is for planning purposes only:

Part I

Estimated man-hours for Model C90A: 6.0 hours.

Suggested number of men for Model C90A: 1 man.

Estimated man-hours for Models 200/300: 40.0 hours.

Suggested number of men for Models 200/300: 2 man.

Part II

Technical Service Representatives will review all warranty claims for proper manpower allowance.

The above is an estimate based on experienced, properly equipped personnel complying with this Service

Bulletin. Occasionally, after work has started, conditions may be found which could result in additional

man-hours.

G. Weight and Balance

None.

H. Electrical Load Data

Not changed.

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 4 of 22

MANDATORY

SERVICE BULLETIN

I. Software Accomplishment Summary

Not applicable.

J. References

The appropriate chapter of the appropriate maintenance manual;

The appropriate chapter of the appropriate Parts Catalog;

Raytheon Aircraft Company Safety Communique No. "All Beech Models -126" (August 1996).

K. Publications Affected

None.

L. Interchangeability of Parts

Not applicable.

M. Warranty Credit

(1) Civil Airplanes

No warranty credit for research and inspection will be allowed on this Service Bulletin.

Warranty credit for labor and parts to the extent noted under MANPOWER and MATERIAL will be

allowed ONLY on Model 99, 99A, A99A, B99 and C99 Airplanes, Serials U-1 through U-239.

Hoses replaced must be returned through Raytheon Aircraft Authorized Service Center before

warranty credit will be allowed.

Warranty coverage offered in this Service Bulletin will expire 12 months from the last day of the

month this Service Bulletin is issued. After that date, the owner/operator assumes the responsibility

for compliance cost. Raytheon Aircraft Company reserves the right to void warranty coverage in the

area affected by this Service Bulletin until the date the Service Bulletin is accomplished by a

Raytheon Aircraft Company Authorized Service Center.

All warranty work must be accomplished by a Raytheon Aircraft Authorized Service Center rated to

perform maintenance on the specific model of Beech Airplane.

All warranty reimbursements are handled through Raytheon Aircraft Company Authorized Service

Centers. The owner/operator should arrange for an Authorized Service Center to perform the work

and the Authorized Service Center must submit the standard Raytheon Aircraft Company warranty

claim.

(2) Military Airplanes

For warranty information on military airplanes affected by this Service Bulletin, contact the

appropriate headquarters.

2. Material Information

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 5 of 22

MANDATORY

SERVICE BULLETIN

A. Materials - Price and Availability

Contact a Raytheon Aircraft Authorized Service Center or RAPID for information.

B. Industry Support

Not applicable.

C. Airplanes

The following parts required for this modification may be ordered through a Raytheon Aircraft

Authorized Service Center or RAPID:

Quantity Per

Model/Serial Part Number Description

Airplane

C90A, Serials LJ-1353 106200H24-22 Hose (Wing Fuel) 2

through LJ-1445

A200CT, Serials FE-32 106200H8-10 Hose (Fuel Distribution) 4

through FE-36

A200CT, Serials FE-32 106200H16-10 Hose (Wing Fuel) 2

through FE-36

A200CT, Serials FE-32 106200H24-14 Hose (Fuel Interconnect) 6

through FE-36

A200CT, Serials FE-32 106200H48-22 Hose (Wing Fuel) 2

through FE-36

B200/B200C 106200H8-10 Hose (Fuel Distribution) 4

B200/B200C 106200H16-10 Hose (Wing Fuel) 2

B200/B200C 106200H24-14 Hose (Wing Fuel) 6

B200/B200C 106200H48-22 Hose (Wing Fuel) 2

B300/B300C 106200H8-10 Hose (Fuel Distribution) 2

B300/B300C 106200H8-10 Hose (Wing Fuel) 2

B300/B300C 106200H16-10 Hose (Wing Fuel) 2

B300/B300C 106200H24-14 Hose (Fuel Interconnect) 6

B300/B300C 106200H48-22 Hose (Wing Fuel) 2

Raytheon Aircraft Company expressly reserves the right to supersede, cancel and/or declare

obsolete, without prior notice, any parts or publications that may be referenced in this Service

Bulletin.

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 6 of 22

MANDATORY

SERVICE BULLETIN

(1) The following materials may be obtained locally:

Quantity Per

Model/Serial Part Number Description

Airplane

200, 300 MS20995C32 Safety Wire As Required

200, 300 100-920033-3 Gasket 2

200, 300 NAS1593-029 "O" Ring (Performed 2

Packing)

200, 300 115-921041 Gasket 4

D. Spares

Not applicable.

E. Reidentified Parts

None.

F. Tooling - Price and Availability

Not applicable.

3. Accomplishment Instructions

This Service Bulletin shall be accomplished as follows:

NOTE

Should any difficulty be encountered in accomplishing this Service Bulletin,

contact Raytheon Aircraft Company at 1-800-429-5372 or 316-676-3140 (for

commercial aircraft, and appropriate headquarters for military aircraft.

A. Airplane

Observe all Warnings and Cautions contained in the aircraft manuals

referred to in this Service Bulletin.

Whenever any part of this system is dismantled, adjusted, repaired or

renewed, detailed investigation must be made on completion to make sure

that distortion, tools, rags or any other loose articles or foreign matter that

could impede the free movement and safe operation of the system are not

present, and that the systems and installations in the work area are clean.

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 7 of 22

MANDATORY

SERVICE BULLETIN

NOTE

Perform all maintenance in accordance with the appropriate chapter of the

appropriate maintenance manual. Hose removal procedures may be made easier

by cutting and splitting the hose with a knife.

Maintenance procedures are typical for both left and right locations. Only the

maintenance procedure for the left location is described.

Part I - HOSE REPLACEMANT ON AIRPLANES MANUFACTURED JANUARY 1. 1994 AND AFTER

C90A Hose Replacement

NOTE

Inspect the hoses called out in Figure 2 to identify the manufacturer. Reference

Figure 1 and the "REASON" statement for methods of identification. Only hoses

identified as manufactured by Buckeye Rubber Products Inc. are to be replaced

under this Service Bulletin. If hoses are of another manufacturer, no further action

is required. Make the necessary maintenance record entries and return the

airplane to service.

(1) Remove all power from the airplane and disconnect the battery. Display warning notices prohibiting

reconnection of airplane electrical power.

Inspect all removed hoses for delamination on the inside of the hose. If

delamination is found, inspect the downstream components (i.e. tubes,

hoses, filters, valves regulators, check valves, etc.) for blockage and clean/

replace as required. Blockage of these components could lead to the

applicable system not operating properly.

(2) Defuel the airplane fuel system prior to removing any hoses in accordance with Chapter 12-10 of the

maintenance manual.

(3) Remove left hand inverter access door P/N 50-120068-70 to gain access to P/N 106200H24-22

interconnect hose located between the P/N 50-921574-133 and the P/N 50-921600-29 tubes.

Reference Figure 2.

(4) Disconnect and remove the bond jumper adjacent to the interconnect hose.

(5) Remove the interconnect hose.

(6) Refer to the MATERIAL section of this Service Bulletin for the replacement hose.

(7) Install the new P/N 106200H24-22 interconnect hose on the P/NM 50-921600-29 and P/N 50-

921574-133 tube assemblies.

(8) Install and tighten the clamps in accordance with Chapters 20- and 28- of the maintenance manual.

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 8 of 22

MANDATORY

SERVICE BULLETIN

(9) Install the bond jumper in accordance with Chapter 20-03 of the maintenance manual.

(10) Perform the same removal and installation procedures for the right hand side.

(11) Refuel the airplane and perform a leak check in accordance with Chapters 12-10 and 28- of the

maintenance manual.

(12) Install the left hand and right hand inverter access door.

(13) Reconnect the airplane battery, remove warning notices and restore power.

A200CT, B200, B200C, B300, B300C Hose Replacement

NOTE

Inspect the hoses called out in Figure 4 through 7 to identify the manufacturer.

Reference Figure 1 and the "REASON" statement for methods of identification.

Only hoses identified as manufactured by Buckeye Rubber Products Inc. are to be

replaced under this Service Bulletin. If hoses are of another manufacturer, no

further action is required. Make the necessary maintenance record entries and

return the airplane to service.

(1) Remove all power from the airplane and disconnect the battery. Display warning notices prohibiting

reconnection of airplane electrical power.

Inspect all removed hoses for delamination on the inside of the hose. If

delamination is found, inspect the downstream components (i.e. tubes,

hoses, filters, valves regulators, check valves, etc.) for blockage and clean/

replace as required. Blockage of these components could lead to the

applicable system not operating properly.

(2) Defuel the airplane fuel system prior to removing any hoses in accordance with Chapter 12-10 of the

maintenance manual.

(3) Remove the P/N 101-980035-9 access panel from the outboard side of the nacelle just forward of

the wing leading edge. See Figure 3.

(4) Remove the access cover from the top of the left hand wing just outboard of the nacelle. See Figure

3.

(5) Remove the access cover from the bottom of the left hand wing just outboard of the nacelle. See

Figure 3.

(6) Remove the bond jumper from the P/N 100-920036-7 elbow. See Figure 4.

(7) Remove the hose clamps from the hose attached to the elbow and P/N 100-920047-3 tube

assembly.

(8) Slide the hose forward towards the elbow and away from the P/N 100-920047-3 tube assembly.

(9) Remove the P/N 99-980000-517 access door to gain access to the nacelle fuel cell. See Figure 3.

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 9 of 22

MANDATORY

SERVICE BULLETIN

(10) Remove the P/N 101-980045-9 nacelle fuel access cover (Figure 3) to gain access to the P/N

24C189 check valve. See Figure 4.

(11) Remove the safety wire and the six bolts from the elbow and rotate approximately 900 down and

remove the P/N 106200H24-14 hose from the elbow and discard the hose.

(12) Install the new P/N 106200H24-14 hose on the elbow far enough to rotate the elbow back in place.

(13) Install new gaskets P/N 115-921041 and a new P/N NAS 1593-29 "O" Ring. See Figure 4.

(14) Rotate the elbow back to the original position.

(15) Slide the P/N 106200H24-14 hose onto the P/N 100-920047-3 tube assembly.

(16) Install the hose clamps over the hose connecting the elbow and tube assembly.

(17) Install the six bolts in the P/N 100-920036-7 elbow, torque the bolts to 45 to 50 inch pounds, and

secure with P/N MS20995C32 safety wire.

(18) Install the P/N 991-980000-517 access door.

(19) Install the bond jumper on the P/N 100-920036-7 elbow and perform an electrical bond connection

per Chapter 20-03 of the maintenance manual.

(20) Remove the bond jumper from the P/N 100-920041-15 and P/N 100-920047-3 tube assemblies.

(21) Remove the hose clamps from the hose connecting the P/N 100-920041-15 and P/N 100-920047-3

tube assemblies.

(22) Remove the P/N 106200H24-14 hose and discard.

(23) Install the P/N 106200H24-14 hose assembly.

(24) Install the hose clamps.

(25) Install the bond jumper connecting the P/N 100-920041-15 and P/N 100-920047-3 tube assemblies

and perform an electrical bond connection per Chapter 20-03 of the maintenance manual.

(26) Perform Steps (3) through (24) on the right hand side.

(27) Remove the P/N 101-120063-31 left hand upper access door. Reference Figure 5.

(28) Remove the bond jumper from the P/N 99-920000-51 tube and P/N 100-920041-15 tube. Reference

Figure 6.

(29) Remove the hose clamps from the P/N 106200H24-14 hose. Reference Figure 6.

(30) Remove the P/N 106200H24-14 hose and discard. Reference Figure 6.

(31) Install the new P/N 106200H24-14 hose. Reference Figure 6.

(32) Install the hose clamps on the P/N 106200H24-14 hose.

(33) Install the bond jumper from the P/N 99-920000-51 tube and P/N 100-920041-15 tube and perform

an electrical bond connection per Chapter 20-03 of the maintenance manual.

(34) Perform steps (27) through (33) for the right hand side.

(35) Remove the P/N 101-120108-7 access door. Reference Figure 5.

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 10 of 22

MANDATORY

SERVICE BULLETIN

(36) Remove the P/N 101-120076-3 fuel tank access cover. Reference Figure 5.

(37) Remove the bond jumper from the P/N 101-920000-15 and P/N 101-920000-57 tube assemblies.

Reference Figure 5.

(38) Remove the hose clamps from the P/N 106200H8-10 hose. Reference Figure 5.

(39) Remove the P/N 106200H8-10 hose. Reference Figure 5.

(40) Install the new P/N 106200H8-10 hose connecting the P/N 101-920000-15 and P/N 101-920000-57

tubes.

(41) Install the hose clamps.

(42) Install the bond jumper on the P/N 101-920000-15 and P/N 101-920000-57 tubes and perform ann

electrical bond connection per Chapter 20-03 of the maintenance manual.

(43) Install the P/N 101-100076-3 fuel tank access cover.

(44) Perform steps (35) through (43) for the right hand side.

(45) Remove the P/N 100-110010-25 access door. Reference Figure 7.

(46) Remove the hose clamps from the P/N 106200H16-10 hose. Reference Figure 7.

(47) Remove the P/N 106200H16-10 hose from the P/N 100-920001-49 tube assembly. Reference

Figure 7.

(48) Install the new P/N 106200H16-10 hose.

(49) Install the hose clamps.

(50) Remove the 100-110010-15 access door. Reference Figure 7.

(51) Remove the hose clamps from the P/N 106200H48-22 hose connecting the P/N 100-920054-1 and

P/N 100-920047-9 tubes.

(52) Remove the P/N 106200H48-22 hose.

(53) Remove the P/N 100-920047-9 tube to gain access to the P/N 100-920001-47 tube assembly.

Reference Figure 7.

(54) Remove the hose clamps from the P/N 106200H8-10 hose.

(55) Remove the P/N 106200H8-10 hose from the P/N 100-920001-47 tube assembly. Reference Figure

7.

(56) Install the new P/N 106200H8-10 hose. Reference Figure 7.

(57) Install the hose clamps.

(58) Install the P/N 100-920047-9 tube assembly with a new P/N 100-920033-3 gasket.

(59) Install the new P/N 106200H48-22 hose.

(60) Install the hose clamps.

(61) Perform steps (45) through (60) for the right hand side.

(62) Reconnect the airplane battery, remove warning notices and restore power.

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 11 of 22

MANDATORY

SERVICE BULLETIN

(63) Refuel the airplane in accordance with Chapter 12-10 of the maintenance manual.

(64) Perform a leak check of all fuel lines and hoses that were removed per Chapter 28-20 of the

maintenance manual.

(65) Install the access cover on the outboard side of the nacelle just forward of the wing leading edge.

Reference Figure 3.

(66) Install the access cover on the left hand wing just outboard of the nacelle. Reference Figure 3.

(67) Install the access cover on the bottom of the left hand wing just outboard of the nacelle. Reference

Figure 3.

(68) Install the P/N 101-120063-31 left hand upper access door. Reference Figure 5.

(69) Install the P/N 101-120108-7 access door. Reference Figure 6.

(70) Install the P/N 100-110010-25 access door. Reference Figure 7.

(71) Install the P/N 100-110010-15 access door. Reference Figure 7.

(72) Ensure all work areas are clean and clear of tools and miscellaneous items of equipment.

(73) Return airplane to service.

PART II - HOSE INSPECTION/REPLACEMENT ON AIRPLANES MANUFACTURED PRIOR TO JANUARY

1, 1994

(1) Research the airplane log books for any P/N 106200H- hose replaced since January 1994 in the fuel

deliver systems only, Reference Figures 2, 4, 5, 6, 7, 8, 9 and 10.

(2) Replace any suspect hose manufactured by Buckeye Rubber Products Inc. (Reference Figure 1 for

identification) per the maintenance manual.

B. Spares

Not applicable.

C. Record of Compliance

Upon completion of this Service Bulletin, make an appropriate maintenance record entry.

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 12 of 22

MANDATORY

SERVICE BULLETIN

WHITE LETTERS AND STRIPE

RED

LAYER DELAMINATION

EXAMPLE OF A WEAK BUTT-JOINT BOND AND BUTT-JOINT SEPARATION

NORMAL MIL-H-6000B HOSE

(SEAMLESS APPEARANCE, NO VISIBLE BUTT-JOINTS)

B271801.AI

Illustration of Hose Construction

Figure 1

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 13 of 22

MANDATORY

SERVICE BULLETIN

P/N 50-120068-70 (LH)

INVERTER ACCESS DOOR

P/N 106200H24-22

HOSE

P/N 50-921574-133 AN737TW66

TUBE CLAMP (2)

P/N 50-921600-29

DETAIL A TUBE ASSY

FWD

A B271802.AI

C90A Fuel Interconnect Hose

Figure 2

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 14 of 22

MANDATORY

SERVICE BULLETIN

P/N 101-980045-9 COVER ASSEMBLY (LH)

P/N 101-980045-10 COVER ASSEMBLY (RH)

B A

DETAIL

P/N 99-980000-517

ACCESS DOOR

LH LEADING EDGE OUTBOARD

LOWER ACCESS COVER

LH LEADING EDGE OUTBOARD

UPPER ACCESS COVER

P/N 101-980035-9 DETAIL A B271803.AI

ACCESS PANEL

200, 300 Nacelle Access

Figure 3

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 15 of 22

MANDATORY

SERVICE BULLETIN

A

B DETAIL A

P/N 24C189 CHECK VALVE BOND JUMPERS

P/N NAS1593-029 "O" RING

P/N 115-921041 GASKET (2)

SAFETY WIRE

P/N 100-920041-15 TUBE ASSY - (LH)

P/N 100-920041-16 TUBE ASSY - (RH)

P/N 106200H24-14 HOSE

P/N 100-920047-3 TUBE ASSY

(1 LH & 1 RH)

P/N 106200H24-14 HOSE

CLAMP (4)

P/N 100-920036-7 ELBOW DETAIL B

B271804.AI

BOLT (6)

F90, 100, 200, 300 Fuel System Interconnect

Figure 4

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 16 of 22

MANDATORY

SERVICE BULLETIN

101-120108-7 DOOR

B

A

DETAIL A

C

P/N 101-120063-31 DOOR

P/N 106200H8-10 HOSE

(1 LH & RH) P/N 101-920000-57 TUBE

BONDING JUMPER

CLAMPS

DETAIL B

P/N 101-120076-3 COVER

P/N 101-920000-15 TUBE (LH)

101-920000-16 TUBE (RH)

DETAIL C

B271805.AI

200, 300 Fuel System Center Section Outboard

Figure 5

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 17 of 22

MANDATORY

SERVICE BULLETIN

B

A

DETAIL A

P/N 106200H24-14 HOSE

GROMMET

P/N 99-920000-51 TUBE

(1 LH & RH)

P/N 100-920041-15 TUBE ASSY - LH

P/N 100-920041-16 TUBE ASSY - RH

CLAMPS

BOND JUMPER

B

B271806.AI

DETAIL

F90, 100, 200, 300 Fuel System Center Section Inboard

Figure 6

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 18 of 22

MANDATORY

SERVICE BULLETIN

P/N 100-110010-15

ACCESS DOOR

P/N 100-110010-25

ACCESS DOOR

A

LOWER

P/N 100-920054-1 LH TUBE ASSY LOOKING UP

P/N 100-920054-2 RH TUBE ASSY FWD P/N 100-920001- 49

P/N 100-920001- 47 TUBE ASSEMBLY

TUBE ASSEMBLY P/N 13090B14 P/N WWD46 CLAMP (2)

BOLT (10)

P/N 106200H16-10

P/N 106200H8-10 HOSE (1 LH & RH)

HOSE

(NOT APPLICABLE

MODEL 100)

P/N 100-920033-3

GASKET

P/N 106200H48-22

HOSE

DETAIL A

P/N AN737TW114

CLAMP (2) P/N 100-920047-9

TUBE B271807.AI

E90, F90, 100, 200, 300 Fuel System Outboard Section

Figure 7

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 19 of 22

MANDATORY

SERVICE BULLETIN

P/N AN737TW66

P/N 106200H24-14 HOSE CLAMP (2)

BOND JUMPER

P/N AN737TW66 CLAMP (2)

BOND JUMPER

P/N 100-920001-123

P/N 106200H24-14 HOSE TUBE LH INTERCONNECT

P/N 100-920001-124 RH

DETAIL A B271808.AI

E90 Fuel Storage, Vent and Interconnect

Figure8

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 20 of 22

MANDATORY

SERVICE BULLETIN

P/N AN737TW56 A

HOSE CLAMP (2) BOND JUMPER

P/N 101-920003-3 TUBE LH

101-920003-33 TUBE RH

P/N 106200H20-12 HOSE

DETAIL A

B271809.AI

200T, B200T Wing Tip Fuel Tank

Figure 9

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 21 of 22

MANDATORY

SERVICE BULLETIN

Model 99 Interconnect

Figure 10

Issued: January, 1997 SB 2718, Rev. 2

Revised, April, 2000 22 of 22

You might also like

- Ceb 72-3285Document2 pagesCeb 72-3285turboshaftNo ratings yet

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- Parts Catalog C90aDocument4,351 pagesParts Catalog C90aluis martinez100% (4)

- Maintenance Manual Instructions For Continued AirworthinessDocument348 pagesMaintenance Manual Instructions For Continued AirworthinessCTM Bravo Aviation100% (1)

- IntroduccionDocument648 pagesIntroduccionAndres DE LA Cruz100% (1)

- MSB 32-2102r7 NLG Shock InspectionDocument17 pagesMSB 32-2102r7 NLG Shock InspectionGarrett ReeveNo ratings yet

- MSB 32-2102r7 NLG Shock InspectionDocument17 pagesMSB 32-2102r7 NLG Shock InspectionGarrett ReeveNo ratings yet

- 85 119Document562 pages85 119Ayrton NobileNo ratings yet

- Beechcraft Service Bulletin Master Index: ATA Chapter 00Document188 pagesBeechcraft Service Bulletin Master Index: ATA Chapter 00Estevam Gomes de Azevedo100% (1)

- Airworthiness Limitations Manual King Air 90 Series PN 90-590024-187 PDFDocument17 pagesAirworthiness Limitations Manual King Air 90 Series PN 90-590024-187 PDFSimon Rosales100% (2)

- Ceb72 6086 PDFDocument4 pagesCeb72 6086 PDFANDREA MIRANDANo ratings yet

- TC10000AFM Rev U - StatementDocument412 pagesTC10000AFM Rev U - Statement韩超100% (1)

- SB 53-3513r1 Aft Pressure Bulkhead InspectionDocument12 pagesSB 53-3513r1 Aft Pressure Bulkhead InspectionGarrett ReeveNo ratings yet

- SB 28-3401 Fuel Cell Cover and Gasket InstallationDocument8 pagesSB 28-3401 Fuel Cell Cover and Gasket InstallationGarrett ReeveNo ratings yet

- Wings - Aileron Drain Hole Inspection SBDocument8 pagesWings - Aileron Drain Hole Inspection SBstiveNo ratings yet

- SB 24-3181 GCU InspectionDocument7 pagesSB 24-3181 GCU InspectionGarrett ReeveNo ratings yet

- SB 27-3459r2 Gust Lock InspectionDocument12 pagesSB 27-3459r2 Gust Lock InspectionGarrett ReeveNo ratings yet

- Beechcraft Service Bulletin Master IndexDocument167 pagesBeechcraft Service Bulletin Master Indexstive100% (2)

- Tcds Beech 3Document35 pagesTcds Beech 3snappish1100% (1)

- 206L-16-179 March 2017Document9 pages206L-16-179 March 2017turboshaftNo ratings yet

- Service Letter: BeechcraftDocument17 pagesService Letter: Beechcraftahmed.19.77.4.5No ratings yet

- C20 Ceb1406 R1Document3 pagesC20 Ceb1406 R1turboshaftNo ratings yet

- TP Ceb A-72-2083Document5 pagesTP Ceb A-72-2083turboshaftNo ratings yet

- Ceb A 72-3247Document4 pagesCeb A 72-3247turboshaftNo ratings yet

- FAA 2012 0721 0009 - Attachment - 5Document119 pagesFAA 2012 0721 0009 - Attachment - 5CHIMONo ratings yet

- Airworthiness Directive Schedule: Aeroplanes Beechcraft 200 Series (Super King Air) 28 August 2014Document10 pagesAirworthiness Directive Schedule: Aeroplanes Beechcraft 200 Series (Super King Air) 28 August 2014Fayçal Mahieddine100% (1)

- 85-120 Chapter 4 and 5Document100 pages85-120 Chapter 4 and 5Luciene OrecchioNo ratings yet

- 04-00-00 Compressed CompressedDocument157 pages04-00-00 Compressed Compresseddarwin galindez100% (1)

- Service Bulletin Revision Transmittal Sheet: MODEL CL-600-2B16 (CL-604)Document40 pagesService Bulletin Revision Transmittal Sheet: MODEL CL-600-2B16 (CL-604)J PerezNo ratings yet

- ASB 407-16-114-RC Page 1 of 2 Approved For Public ReleaseDocument10 pagesASB 407-16-114-RC Page 1 of 2 Approved For Public ReleaseluisNo ratings yet

- ML B 200 B200am8Document13 pagesML B 200 B200am8Sergio LópezNo ratings yet

- BLR-212FF-950 (Ica)Document15 pagesBLR-212FF-950 (Ica)Mantenimiento MelgarNo ratings yet

- Beechcraft Service Bulletin Master Index: ATA Chapter 00Document188 pagesBeechcraft Service Bulletin Master Index: ATA Chapter 00GabrielArriondaNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Replacement: ApplicabilityDocument3 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Replacement: ApplicabilityluisNo ratings yet

- Tpceb A-1312Document11 pagesTpceb A-1312turboshaftNo ratings yet

- HC SB 61 227Document22 pagesHC SB 61 227Hamed BarjestehNo ratings yet

- Hartzell - SB217 R03 WDocument20 pagesHartzell - SB217 R03 WelrennyfulNo ratings yet

- Commercial Engine Bulletin: Engine, Combustion Assembly - Inspection of Outer COMBUSTION CASE P/N M250 - 10404Document8 pagesCommercial Engine Bulletin: Engine, Combustion Assembly - Inspection of Outer COMBUSTION CASE P/N M250 - 10404turboshaftNo ratings yet

- Get Beech or Hawker AttachmentDocument8 pagesGet Beech or Hawker Attachmentmates isNo ratings yet

- Ceb A-72-7002Document7 pagesCeb A-72-7002turboshaftNo ratings yet

- LG2022 02Document26 pagesLG2022 02stanislovas.pNo ratings yet

- Service Bulletin: SB MBB BK117 C 267021Document33 pagesService Bulletin: SB MBB BK117 C 267021Samantha Carrascal SilvaNo ratings yet

- Raisbeck King Air Parts Manual 85-119-D - ODocument562 pagesRaisbeck King Air Parts Manual 85-119-D - Oairjayhawk100% (1)

- Rolls-Royce: Commercial Engine BulletinDocument1 pageRolls-Royce: Commercial Engine BulletinturboshaftNo ratings yet

- Cap 4 King 200Document14 pagesCap 4 King 200jesus francoNo ratings yet

- EASA TCDS A.182 - Bae - 146 - AVRO - 146 - RJ 02 20102010Document18 pagesEASA TCDS A.182 - Bae - 146 - AVRO - 146 - RJ 02 20102010Carlos SantisNo ratings yet

- Bae - 146 - AVRO - 146 - RJ 02Document17 pagesBae - 146 - AVRO - 146 - RJ 02AndreasBenjamin100% (3)

- Easa Airworthiness Directive: AD No.: 2011-0043Document3 pagesEasa Airworthiness Directive: AD No.: 2011-0043Carlos VarrentiNo ratings yet

- Airworthiness Directive: Bell Helicopter Textron Canada (BHTC) 206 and Agusta Bell 206 Series HelicoptersDocument2 pagesAirworthiness Directive: Bell Helicopter Textron Canada (BHTC) 206 and Agusta Bell 206 Series Helicoptersav avNo ratings yet

- Service Bulletin: BeechcraftDocument68 pagesService Bulletin: BeechcraftMeed Bin HameedNo ratings yet

- Summary of FAA Airworthiness DirectivesDocument12 pagesSummary of FAA Airworthiness DirectivesMaryadiNo ratings yet

- 700 29 027 BasicDocument13 pages700 29 027 BasicHimanshu Pant100% (1)

- AW Limitations - LJ992Document6 pagesAW Limitations - LJ992alejandroNo ratings yet

- Asb 407-04-62Document5 pagesAsb 407-04-62turboshaftNo ratings yet

- KSB BEV BEV LO PDFDocument36 pagesKSB BEV BEV LO PDFBernardo Salinas GonzalezNo ratings yet

- Introduction-Loep: List of Effective PagesDocument14 pagesIntroduction-Loep: List of Effective PagesAfandi Mohamad ZainiNo ratings yet

- Air Brake Spec - no.02-ABR-02 PDFDocument73 pagesAir Brake Spec - no.02-ABR-02 PDFGibran Ansari0% (1)

- TCM C90 - 0200 Engine Type Certificate - E-252 - Rev 29Document3 pagesTCM C90 - 0200 Engine Type Certificate - E-252 - Rev 29Randy WaltonNo ratings yet

- Aerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftFrom EverandAerospace Actuators V3: European Commercial Aircraft and Tiltrotor AircraftNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- MTL-57-01r2 Lower Forward Wing Bolt Crush Washer ReplacementDocument10 pagesMTL-57-01r2 Lower Forward Wing Bolt Crush Washer ReplacementGarrett ReeveNo ratings yet

- SB 27-3459r2 Gust Lock InspectionDocument12 pagesSB 27-3459r2 Gust Lock InspectionGarrett ReeveNo ratings yet

- SB 53-3513r1 Aft Pressure Bulkhead InspectionDocument12 pagesSB 53-3513r1 Aft Pressure Bulkhead InspectionGarrett ReeveNo ratings yet

- SB 30-3143 Engine Inlet Anti-Ice Line InspectionDocument6 pagesSB 30-3143 Engine Inlet Anti-Ice Line InspectionGarrett ReeveNo ratings yet

- SB 28-3401 Fuel Cell Cover and Gasket InstallationDocument8 pagesSB 28-3401 Fuel Cell Cover and Gasket InstallationGarrett ReeveNo ratings yet

- SB 24-3181 GCU InspectionDocument7 pagesSB 24-3181 GCU InspectionGarrett ReeveNo ratings yet

- Design and Drawing of RC Structures: Dr. G.S.SureshDocument48 pagesDesign and Drawing of RC Structures: Dr. G.S.SureshDouglas Au Yeung0% (1)

- Buckling of Thin Metal Shells 251Document1 pageBuckling of Thin Metal Shells 251pawkomNo ratings yet

- LANGB1000 Installation Instructions17Document15 pagesLANGB1000 Installation Instructions17alaynnastaabx786No ratings yet

- Concealedhinges Ep Dok Bus $sus $aof $v14Document110 pagesConcealedhinges Ep Dok Bus $sus $aof $v14john smithNo ratings yet

- LG Refrigerator Compressor CatalogueDocument11 pagesLG Refrigerator Compressor CatalogueMilos Lazovic73% (11)

- Consumer Reports Buying Guide 2012 - Vacuum CleanersDocument7 pagesConsumer Reports Buying Guide 2012 - Vacuum Cleanersdesijnk100% (1)

- Embroidery Thread Tension: Technical BulletinDocument4 pagesEmbroidery Thread Tension: Technical BulletinCandle thread TurkeyNo ratings yet

- Technical Data Sheet For The HSA Stud Anchor Technical Information ASSET DOC 2027424Document11 pagesTechnical Data Sheet For The HSA Stud Anchor Technical Information ASSET DOC 2027424Fritz NatividadNo ratings yet

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectDocument1 pageDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectfebousNo ratings yet

- Colunn & Beam DesignsDocument22 pagesColunn & Beam Designsmadhu sudhanNo ratings yet

- Drawing Oliver ValveDocument1 pageDrawing Oliver ValveANTONIUS TRIMARTANTONo ratings yet

- PDS FlexHood ENDocument16 pagesPDS FlexHood ENpatel swetangNo ratings yet

- Dabur AmlaDocument4 pagesDabur AmlaMD Abu Bakar SiddiqueNo ratings yet

- Sheet5-Centrifugal PumpDocument5 pagesSheet5-Centrifugal Pumpyousef mohamedNo ratings yet

- Cengg11 Midterm 2021Document2 pagesCengg11 Midterm 2021Angelo VilleroNo ratings yet

- Janome Jem Gold 660 Sewing Machine Service ManualDocument19 pagesJanome Jem Gold 660 Sewing Machine Service ManualiliiexpugnansNo ratings yet

- KSB Serie MPDocument12 pagesKSB Serie MPJose ValenzuelaNo ratings yet

- Anti-Lock Brake System / Accelera-Tion GeneralDocument165 pagesAnti-Lock Brake System / Accelera-Tion GeneralLe ThanhNo ratings yet

- Pump Control Valve (Implement, Steering) - Test and Adjust: 16M Series 3, 16, 18M Series 3 and 18 Motor GraderDocument18 pagesPump Control Valve (Implement, Steering) - Test and Adjust: 16M Series 3, 16, 18M Series 3 and 18 Motor GraderNasrul arulNo ratings yet

- Conexões Do Compressor ACDocument3 pagesConexões Do Compressor ACAnderson Oliveira SilvaNo ratings yet

- REGO - Pressure Builder - Economizer CBH CBCDocument1 pageREGO - Pressure Builder - Economizer CBH CBCcriuvosNo ratings yet

- Ssit PPT ANK IDocument14 pagesSsit PPT ANK InaveenNo ratings yet

- TYFTW Tuttnauer 3870ELV-D PDFDocument2 pagesTYFTW Tuttnauer 3870ELV-D PDFxscesar100% (1)

- DesignDocument9 pagesDesignDasharath PatelNo ratings yet

- Amf Final ReportDocument98 pagesAmf Final ReportTewodros DereseNo ratings yet

- Spherical TankDocument6 pagesSpherical Tankhgag selimNo ratings yet

- Siemens Steam Turbine Portfolio Steam Turbines From 10 KW To 1,900 MW Siemens - Com - SteamturbinesDocument88 pagesSiemens Steam Turbine Portfolio Steam Turbines From 10 KW To 1,900 MW Siemens - Com - SteamturbinesaminardakaniNo ratings yet

- H2 - MBT - Revision Package - Integration - SolutionsDocument4 pagesH2 - MBT - Revision Package - Integration - SolutionsTimothy HandokoNo ratings yet

- Apex Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsDocument2 pagesApex Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsNyu123456No ratings yet

- DP Barte: DesignsDocument1 pageDP Barte: DesignsJjammppong AcostaNo ratings yet