Professional Documents

Culture Documents

Epilux 155 SF

Epilux 155 SF

Uploaded by

Mohamed NasifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Epilux 155 SF

Epilux 155 SF

Uploaded by

Mohamed NasifCopyright:

Available Formats

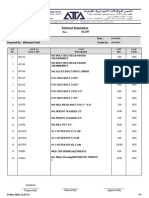

BERGER PRODUCT SPECIFICATIONS

EPILUX 155SF

Epoxy Tank Lining

PRODUCT A two component, chemically resistant, solvent free amine-adduct cured epoxy coating.

DESCRIPTION

DESIGN An internal tank lining suitable for contact with a wide range of chemical cargoes, including

potable water, food chemicals, edible oil etc. Approach your Berger Paints representative for

FEATURES

cargo resistance suitability and advice.

Certified to SS 375 and BS 6920 for use in contact with potable water.

A non-toxic, environment-friendly solvent free coating.

Excellent chemical resistance to a wide range of chemicals.

Excellent hardness and high abrasion resistance.

Suitable for application on both concrete and steel substrates.

PHYSICAL Recommended Application Data Wet [m] Dry [m] m2/l

CHARACTERISTICS Theoretical Coverage 150 150 6.7

Volume solids 100% (based on ASTM D2697)

Dry Film Thickness Range 125 m to 350 m

Flash Point > 90C

Finish Gloss

Colour Range White, Light Buff

Standard Packing Size 20 litres set (15.0 Litres Base : 5.0 litres Hardener)

Mix Ratio ( by volume ) 3 Base : 1 Hardener

APPLICATION AIRLESS SPRAY Tip Size : 0.53 – 0.58 mm ( 21 - 23 thou )

Recommended method of

METHOD application.

Pressure : 140 –165 kg/cm2 (2000 – 2400 psi)

BRUSH OR ROLLER May be used. However, additional coats may be required to

achieve the recommended film thickness. Suitable for stripe

coating, weld-seams, edges, corners, rivets, etc.

* Important: Mix the two components of this product only when ready to apply. Once

mixed, apply immediately. As this product has a very short potlife, delays in application

may adversely affect wetting, adhesion and self-levelling properties and may jam up

airless spray equipment.

DRYING &

CURING TIME Substrate Touch Dry Hard Dry Overcoating Interval Pot Life

Temperature Minimum Maximum

15 C 6 hours 12 hours 16 hours 4 days 1½ hours

25 C 4 hours 8 hours 12 hours 2 days 1 hour

35 C 2 hours 6 hours 8 hours 1 days 40 mins

USEFUL THINNER : Not required

INFORMATION CLEANER : SOLVALUX 7-77

STORAGE : Store in a cool dry shaded area.

SHELF LIFE AT 25 ºC : 18 months when stored as prescribed in the MSDS.

EPILUX 155SF REVISION 06-2018

M2

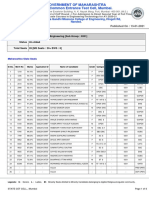

BERGER PRODUCT SPECIFICATIONS

SURFACE The service life span and the service performance of EPILUX 155SF is directly related to the degree of

surface preparation.

PREPARATION STEEL

EPILUX 155SF should be applied to a surface that has been blast cleaned. It may be applied directly

to blast cleaned steel or over a suitable primer, e.g. EPILUX 610.

Remove all wax, oil and grease by solvent cleaning in accordance with the guidelines given by

SSPC-SP1. Where necessaries remove weld spatter and round off all rough weld seams and sharp

edges to a smooth surface.

Abrasive blast clean to a minimum standard of Sa2½ (ISO 8501-1:1988) or SSPC-SP10. An average

surface profile of 75 – 100 microns is required.

Ensure that all surface defects detected after blast cleaning is ground, filled or treated in a suitable

manner.

After blasting, remove dust from the surface. Ensure that the surface to be coated is clean, dry and

free from any contaminants.

Apply Epilux 155SF immediately after blasting to prevent oxidation and recontamination of the steel

surface. The use of a dehumidification system and/or the use of a suitable blast/holding primer such

as Epilux 610, is recommended to prevent oxidation of the blasted steel surface. In case of

oxidation/recontamination, re-blast to the required standard.

CONCRETE

New concrete should be left for at least 21 days to cure before coating.

The moisture content of the concrete surface should be checked and ensured to be below 6% when

measured with a reliable moisture meter, such as the Sovereign Moisture Meter.

The surface should be dry, free from surface contaminants, sound and undamaged.

Apply one coat of suitable concrete primer/sealer such as Luxafloor 1000.

To avoid condensation of moisture onto substrate prior to coating application, relative humidity should not

exceed 85% and substrate temperature should be more than 3 C above Dew Point.

SUITABLE Epilux 610 (for Steel), Luxafloor 1000 (for concrete), Epimastic 3000HS

UNDERCOATS

NOTES The coating specifications given above are typical. For specific recommendations to suit individual

applications, please refer to your Berger Paints representative.

Please consult your Berger Paint Representative for recommendations on suitability for the

containment of specific cargo / cargoes.

Common to all epoxies this product will experience chalking on prolonged exposure to sunlight.

However, this phenomena is not detrimental to coating performance.

Exposure to very low temperatures, high humidity or water ponding during and/or immediately after

application may result in incomplete cure and/or discolouration that may compromise subsequent

intercoat adhesion.

Avoid contact with eyes and skin. Wear suitable protective clothing such as overalls, goggles, dust mask

SAFETY and gloves. Use barrier cream.

PRECAUTION Ensure that there is adequate ventilation in the area where the product is being applied. Do not breathe in

vapour or spray mist.

This product is flammable. Keep away from sources of ignition. Do not smoke.

Take precautionary measures against static discharge.

In case of fire, blanket flames with foam, carbon dioxide or dry chemicals.

FIRST AID Eyes : In the event of accidental splashes, flush eyes with warm water immediately and

seek medical advice.

Skin : Wash skin thoroughly with soap and water or approved industrial cleaner. Do Not

Use solvents or thinners.

Inhalation : Remove to fresh air, loosen collar and keep patient rested.

Ingestion : In case of accidental ingestion, DO NOT INDUCE VOMITING. Obtain immediate

medical attention.

For further safety information, please refer to our Material Safety Data Sheet (MSDS)

DISCLAIMER The information provided on this data sheet is not intended to be complete and is provided as general advice

only. It is the responsibility of the user to ensure that the product is suitable for the purpose for which he

wishes to use it. As we have no control over the treatment of the product, the standard of surface

preparation of the substrate, or other factors affecting the use of this product, we are not responsible for its

performance nor would we accept any liability whatsoever or howsoever arising from the use of this product

unless specifically agreed to in writing by us. The information contained in this data sheet may be modified

by us from time to time, and without notice, in the light of our experience and continuous product

development.

EPILUX 155SF REVISION 06-2018

M2

You might also like

- DGS 6600 010 Rev 2-48Document1 pageDGS 6600 010 Rev 2-48Mohamed NasifNo ratings yet

- Al-Jazeera Epo-Rich Primer12 PDFDocument2 pagesAl-Jazeera Epo-Rich Primer12 PDFAmer Y K100% (1)

- Coaltar Epoxy - Epilux5 - 0474Document2 pagesCoaltar Epoxy - Epilux5 - 0474GautamNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Epoxy Primer - Epilux610 - 4079Document2 pagesEpoxy Primer - Epilux610 - 4079GautamNo ratings yet

- Garlock GSK 3-86 Strainer Gasket 04.2017 en-NADocument2 pagesGarlock GSK 3-86 Strainer Gasket 04.2017 en-NAAbuhurairah MunshiNo ratings yet

- Epilux 78Document2 pagesEpilux 78MuthuKumar100% (1)

- d2) Epilux218 4267Document2 pagesd2) Epilux218 4267Syed FaridNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Microsoft Word - L3 - Epilux82Document2 pagesMicrosoft Word - L3 - Epilux82vitharvanNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- E3) Epimastic5100 4292Document2 pagesE3) Epimastic5100 4292Syed FaridNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsSanjeev Reddy KasulaNo ratings yet

- l2) Steelshield1200 3041Document2 pagesl2) Steelshield1200 3041Syed FaridNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsMuthuKumarNo ratings yet

- b3) Zincanode685 4586Document2 pagesb3) Zincanode685 4586Syed FaridNo ratings yet

- k3) Luxatherm5600 7954Document2 pagesk3) Luxatherm5600 7954Syed FaridNo ratings yet

- k1) Luxatherm1600 3171Document2 pagesk1) Luxatherm1600 3171Syed FaridNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- b6) Zincanode690 2886Document2 pagesb6) Zincanode690 2886Anonymous XVEucVMsENo ratings yet

- l1) Steelshield1100 5833Document2 pagesl1) Steelshield1100 5833Syed FaridNo ratings yet

- g9) Berger Apcofine 905 - 8096Document2 pagesg9) Berger Apcofine 905 - 8096Wasek SarkerNo ratings yet

- Apexior1 7645Document2 pagesApexior1 7645Kalesha Vali ShaikNo ratings yet

- I1) Luxol 1000Document2 pagesI1) Luxol 1000Chan zxNo ratings yet

- b1) Zincanode330 6548Document2 pagesb1) Zincanode330 6548Syed FaridNo ratings yet

- d3) Epilux4 2763Document2 pagesd3) Epilux4 2763Salman KhanNo ratings yet

- k2) Luxatherm5200 5219Document2 pagesk2) Luxatherm5200 5219Syed FaridNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Luxaprime1500 Etching Wash PrimerDocument2 pagesLuxaprime1500 Etching Wash PrimerGurdeep Sungh AroraNo ratings yet

- Luxaprime1200 Alkyd QD PrimerDocument2 pagesLuxaprime1200 Alkyd QD PrimerGurdeep Sungh AroraNo ratings yet

- 19.abcolux18hs Content 237Document3 pages19.abcolux18hs Content 237MbimbikNo ratings yet

- Luxaprime1801 Chromate Free Etch PrimerDocument2 pagesLuxaprime1801 Chromate Free Etch PrimerGurdeep Sungh AroraNo ratings yet

- Luxaprime1400 Alkyd Zinc Phosphate PrimerDocument2 pagesLuxaprime1400 Alkyd Zinc Phosphate PrimerGurdeep Sungh AroraNo ratings yet

- Luxaprime1501 Etch PrimerDocument2 pagesLuxaprime1501 Etch PrimerGurdeep Sungh AroraNo ratings yet

- Luxaprime 1000 Alkyd Anti-Corrosive PrimerDocument2 pagesLuxaprime 1000 Alkyd Anti-Corrosive PrimerGurdeep Sungh AroraNo ratings yet

- b1) Zincanode330 6548Document2 pagesb1) Zincanode330 6548chepurthiNo ratings yet

- Luxaprime1300 Alkyd Zinc Chromate PrimerDocument2 pagesLuxaprime1300 Alkyd Zinc Chromate PrimerGurdeep Sungh AroraNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsDinesh ChouguleNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- Relipoxy P 301: Epoxy Based PrimerDocument3 pagesRelipoxy P 301: Epoxy Based PrimerPRERAKNo ratings yet

- Rust O Cap: Surface Tolerant EpoxyDocument3 pagesRust O Cap: Surface Tolerant EpoxySanthana SaravanaNo ratings yet

- Interzone 954Document0 pagesInterzone 954hennawijayaNo ratings yet

- Apcoglass Mastic 2000Document3 pagesApcoglass Mastic 2000replyrajanNo ratings yet

- Interplus 1180: Protective CoatingsDocument4 pagesInterplus 1180: Protective CoatingsAnindya Aulia PratiwiNo ratings yet

- PDS HEMPADUR 47183 en-USDocument2 pagesPDS HEMPADUR 47183 en-USFreddy Carl Fredricksen0% (1)

- Fire Tank Painting SystemDocument6 pagesFire Tank Painting SystemHassan SleemNo ratings yet

- KANSAI PAINT Paralux - 15HBDocument2 pagesKANSAI PAINT Paralux - 15HBYogalingam ArumugamNo ratings yet

- Apcosil 605 IzssDocument3 pagesApcosil 605 IzssPavul RajNo ratings yet

- Apcosil - PC 2568Document3 pagesApcosil - PC 2568Naren SudarsanNo ratings yet

- Apcosil - PC 2119Document3 pagesApcosil - PC 2119Naren SudarsanNo ratings yet

- Sam Epoxy Primer 50Document3 pagesSam Epoxy Primer 50qcahmedsobhyNo ratings yet

- Sam Epoxy Primer ZP - ECDocument3 pagesSam Epoxy Primer ZP - ECqcahmedsobhyNo ratings yet

- TDS Epoxy Zinc Phosphate Primer HB 50 GreyDocument3 pagesTDS Epoxy Zinc Phosphate Primer HB 50 GreySAlman Khan50% (2)

- j6) Autocareenamel 3087Document2 pagesj6) Autocareenamel 3087vinodNo ratings yet

- Epilux 155Document2 pagesEpilux 155Tejinder KumarNo ratings yet

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerNo ratings yet

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerNo ratings yet

- Berger Coating StandardsDocument9 pagesBerger Coating StandardsHariHaranNo ratings yet

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- Cancellation FormDocument2 pagesCancellation FormMohamed NasifNo ratings yet

- MRQ - 01138 - Paint For NDCDocument9 pagesMRQ - 01138 - Paint For NDCMohamed NasifNo ratings yet

- Sahina CVDocument2 pagesSahina CVMohamed NasifNo ratings yet

- MRQ - 01138 - Paint For NDC-2-9Document8 pagesMRQ - 01138 - Paint For NDC-2-9Mohamed NasifNo ratings yet

- Material Requisition ReportDocument1 pageMaterial Requisition ReportMohamed NasifNo ratings yet

- MRQ - 01246 - PAd Eye MachiningDocument5 pagesMRQ - 01246 - PAd Eye MachiningMohamed NasifNo ratings yet

- Material Requisition ReportDocument1 pageMaterial Requisition ReportMohamed NasifNo ratings yet

- Process Flow ChartDocument22 pagesProcess Flow ChartKumar Ashutosh100% (1)

- A Practical Guide To Free-Energy' DevicesDocument73 pagesA Practical Guide To Free-Energy' DevicesJoe Seserman100% (1)

- Noun (Subject) + Verb + The + Superlative Adjective + Noun (Object)Document6 pagesNoun (Subject) + Verb + The + Superlative Adjective + Noun (Object)anaNo ratings yet

- Student Performance Contract With Parents AgreementDocument1 pageStudent Performance Contract With Parents AgreementCURT KEANU VILLANUEVANo ratings yet

- Curiculum Vitae JurnalisDocument1 pageCuriculum Vitae JurnalisEh Ada UjankNo ratings yet

- Performance: Task in Math 8 House Floor PlanDocument10 pagesPerformance: Task in Math 8 House Floor PlanJoshua Emmanuel LedesmaNo ratings yet

- The Preschooler and The SchoolerDocument16 pagesThe Preschooler and The Schoolerquidditch07No ratings yet

- Rollarc 400Document48 pagesRollarc 400m khNo ratings yet

- Physics Lab Heat and HumidityDocument3 pagesPhysics Lab Heat and HumidityLAUREN YAPNo ratings yet

- Verizon Wiretapping - Comments in Support of MR Cowie's ComplaintDocument8 pagesVerizon Wiretapping - Comments in Support of MR Cowie's ComplaintireportNo ratings yet

- ADSS StandardDocument17 pagesADSS StandardHedi HmidaNo ratings yet

- 2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedDocument8 pages2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedAjit DeshmukhNo ratings yet

- The Spirit of Jugaad / Bricolage For Enhanced Corporate EntrepreneurshipDocument20 pagesThe Spirit of Jugaad / Bricolage For Enhanced Corporate EntrepreneurshippanditpreachesNo ratings yet

- Application Form For Initial Review: Section A - Basic InformationDocument33 pagesApplication Form For Initial Review: Section A - Basic Informationsaptarshi DasNo ratings yet

- "Twist Off" Type Tension Control Structural Bolt/Nut/Washer Assemblies, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthDocument8 pages"Twist Off" Type Tension Control Structural Bolt/Nut/Washer Assemblies, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthMohammed EldakhakhnyNo ratings yet

- 電容器絕緣油BDV 黏度 - SAS 40EDocument10 pages電容器絕緣油BDV 黏度 - SAS 40EShihlinElectricNo ratings yet

- 10 1039@d0mh00081gDocument20 pages10 1039@d0mh00081gHuấn BùiNo ratings yet

- Catalog Stationary Screw Compressors F en V 1 3 WebDocument28 pagesCatalog Stationary Screw Compressors F en V 1 3 WebcristiNo ratings yet

- Tivoli Process Automation Engine Product Coexistenc e Matrix 7.6.xDocument128 pagesTivoli Process Automation Engine Product Coexistenc e Matrix 7.6.xOleksandr KoidaNo ratings yet

- Assignment Activity On Expenditure Cycles - To Be ContinuedDocument3 pagesAssignment Activity On Expenditure Cycles - To Be ContinuedRico, Jalaica B.No ratings yet

- Thesis PDFDocument120 pagesThesis PDFPrajwal NiraulaNo ratings yet

- Lesson Plan in English 8Document66 pagesLesson Plan in English 8Mhairo Akira100% (1)

- Aptis Writing C1Document33 pagesAptis Writing C1Sanjar JumayevNo ratings yet

- Bread Board - Transformer - PCB - Soldering - LectureDocument31 pagesBread Board - Transformer - PCB - Soldering - Lectureananyautkarsh140904No ratings yet

- Application of Irradiation For Food Preservation: Seminar ONDocument19 pagesApplication of Irradiation For Food Preservation: Seminar ONPrashant KumarNo ratings yet

- Chapter 9: TidesDocument40 pagesChapter 9: TidesCarol GirottoNo ratings yet

- Strategic Management LBdA3TJvQgDocument420 pagesStrategic Management LBdA3TJvQgSazzad HossainNo ratings yet

- Renewable Energy Sources and MethodsDocument225 pagesRenewable Energy Sources and MethodsSemir Đedović100% (1)

- Corrosion Detection Midterm LessonDocument52 pagesCorrosion Detection Midterm LessonVv ZoidNo ratings yet

- Error - Failed To Compute Elastoplastic Strain Variables - 1150 - Knowledge Base PDFDocument3 pagesError - Failed To Compute Elastoplastic Strain Variables - 1150 - Knowledge Base PDFmatinNo ratings yet