Professional Documents

Culture Documents

Interim Technical Guidance Note On Capping For Landfill Sites

Interim Technical Guidance Note On Capping For Landfill Sites

Uploaded by

Ronen MarkoCopyright:

Available Formats

You might also like

- Drilling FluidsDocument41 pagesDrilling FluidsGogot Pantja Parijogo100% (2)

- CAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignDocument4 pagesCAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignNICOLAS SANCHEZ GOMEZNo ratings yet

- Rotocol: Soil Treatment Facility Design and Operation For Bioremediation of Hydrocarbon Contaminated SoilDocument9 pagesRotocol: Soil Treatment Facility Design and Operation For Bioremediation of Hydrocarbon Contaminated Soilsarge18No ratings yet

- Offshore Pipeline Decommissioning GuidelineDocument8 pagesOffshore Pipeline Decommissioning GuidelineJonel KrduNo ratings yet

- Earthworks in Landfill EngineeringDocument66 pagesEarthworks in Landfill EngineeringMelissa GrahamNo ratings yet

- Applications of Multiphase Desander TechnologyDocument19 pagesApplications of Multiphase Desander TechnologyanisNo ratings yet

- Application of Multiphase Desander Technology To Oil and Gas ProductionDocument19 pagesApplication of Multiphase Desander Technology To Oil and Gas ProductionJose Rodrigo Salguero DuranNo ratings yet

- Wac 463-42-215 Proposal - Surface-Water RunoffDocument4 pagesWac 463-42-215 Proposal - Surface-Water RunoffBello kabirNo ratings yet

- LFG International DesignDocument12 pagesLFG International Designdzari6738No ratings yet

- Management of DredgedExcavated SedimentDocument17 pagesManagement of DredgedExcavated SedimentMan Ho LamNo ratings yet

- TG 11Document19 pagesTG 11Lorraine BautistaNo ratings yet

- ContioceanDECK HTMLDocument61 pagesContioceanDECK HTMLnithzbloggerNo ratings yet

- MS - 33 Rev 0 - Reinstatement of KNO.06 Lateral Line AsphaltDocument6 pagesMS - 33 Rev 0 - Reinstatement of KNO.06 Lateral Line AsphaltSyed Umair HashmiNo ratings yet

- Part 7 - Shallow Gas BlowoutsDocument8 pagesPart 7 - Shallow Gas BlowoutsJohnSmithNo ratings yet

- Earthworks SummaryDocument3 pagesEarthworks SummarykekaNo ratings yet

- Disposal Requirements Volume3Document8 pagesDisposal Requirements Volume3mcemceNo ratings yet

- Guide To The Preparation of A Working Plan Scrapyard / Elv FacilityDocument6 pagesGuide To The Preparation of A Working Plan Scrapyard / Elv FacilityNebojsa RedzicNo ratings yet

- 53 Wetlands EDocument4 pages53 Wetlands ECương QuốcNo ratings yet

- Collection System Design Plans: Appendix EDocument70 pagesCollection System Design Plans: Appendix EMMMOH200No ratings yet

- Manual - Lining - Irrigation - Canals - West BengalDocument22 pagesManual - Lining - Irrigation - Canals - West Bengalsudheer7320_58503644No ratings yet

- Surface and Sub-Surface Drainage Systems For HighwaysDocument38 pagesSurface and Sub-Surface Drainage Systems For HighwaysJalijash100% (1)

- DPHS Soil Permeability Guidance 2013Document11 pagesDPHS Soil Permeability Guidance 2013javanimeNo ratings yet

- Wastewater Lagoon ConstructionDocument24 pagesWastewater Lagoon ConstructionIrfanullah TunioNo ratings yet

- WAPUG User Note 21Document3 pagesWAPUG User Note 21saurabh singhNo ratings yet

- Chapter 9Document120 pagesChapter 9Aaron RasmussenNo ratings yet

- Garmony Environmental Statement Rev B App BDocument15 pagesGarmony Environmental Statement Rev B App BTAHER AMMARNo ratings yet

- TSF Report KwedijabuDocument15 pagesTSF Report KwedijabuENG BARAKA JOELNo ratings yet

- Der 17Document42 pagesDer 17Robert J MayNo ratings yet

- Lagunas de TratamientoDocument24 pagesLagunas de TratamientoAlex JunkersNo ratings yet

- Hardicrete Heavy Duty Surfacing No.88 1969 Third IssueDocument8 pagesHardicrete Heavy Duty Surfacing No.88 1969 Third Issuecvsatheeh1No ratings yet

- Ed Well ControlDocument18 pagesEd Well ControlAmeer BabylonianNo ratings yet

- United States Environmental Protection Agency: Region Viii 999 18th STREET - SUITE 300 Denver, Colorado 80202-2466Document10 pagesUnited States Environmental Protection Agency: Region Viii 999 18th STREET - SUITE 300 Denver, Colorado 80202-2466Susin LimNo ratings yet

- Pedl 300 1 Doc 4 The ProposalDocument42 pagesPedl 300 1 Doc 4 The ProposalZaky Abdurrasyid MNo ratings yet

- TCLT FD 02.02 200907 Za Podlogu KadaDocument33 pagesTCLT FD 02.02 200907 Za Podlogu KadaMomir StanojevicNo ratings yet

- ASTM D7765 - Foundary Sand For EmbankmentDocument4 pagesASTM D7765 - Foundary Sand For EmbankmentAnantNo ratings yet

- Chapter8 MineClosureandRehabDocument16 pagesChapter8 MineClosureandRehabJonNo ratings yet

- Ogaom Chapter 9 PDFDocument44 pagesOgaom Chapter 9 PDFjohanaristoNo ratings yet

- Well Ops Template SCR 2015 Schedule 9 Well Notification Inspection July 2015Document13 pagesWell Ops Template SCR 2015 Schedule 9 Well Notification Inspection July 2015MartahanManurungNo ratings yet

- Seabed and Sub Seabed Data RequirementsDocument13 pagesSeabed and Sub Seabed Data RequirementsAyman64No ratings yet

- Bunding and Spill Management - NSW EPADocument8 pagesBunding and Spill Management - NSW EPAPhilip LonerganNo ratings yet

- Newitem 133 Msw-ReportDocument49 pagesNewitem 133 Msw-ReportMohana Priya SNo ratings yet

- Shallow GasDocument6 pagesShallow GasYaqoob IbrahimNo ratings yet

- WR WQ Pub Design Criteria Ch9Document15 pagesWR WQ Pub Design Criteria Ch9Brian NyagiloNo ratings yet

- Code of Practice For The Protection of Structures From Ground Gases - Sept 2020Document17 pagesCode of Practice For The Protection of Structures From Ground Gases - Sept 2020Adam ClutterbuckNo ratings yet

- C 9 E I A: C S: Hapter Nvironmental Mpact Ssessment ASE TudiesDocument162 pagesC 9 E I A: C S: Hapter Nvironmental Mpact Ssessment ASE Tudiesjazon fabian hpNo ratings yet

- Attachment J (Draft Offshore Pipelines Decommissioning Guideline)Document6 pagesAttachment J (Draft Offshore Pipelines Decommissioning Guideline)smithworkNo ratings yet

- Secondary Containment of Large Aboveground Storage TanksDocument12 pagesSecondary Containment of Large Aboveground Storage TanksocayliNo ratings yet

- Sghs MGSD Information SheetDocument5 pagesSghs MGSD Information Sheetshoaib KhalilNo ratings yet

- Chapter 62C-27 Conservation of Oil and Gas: DrillingDocument4 pagesChapter 62C-27 Conservation of Oil and Gas: DrillingAry RachmanNo ratings yet

- Bulletin 2011-35: Surface Casing Vent Requirements For WellsDocument5 pagesBulletin 2011-35: Surface Casing Vent Requirements For WellsjagicisiwoNo ratings yet

- NJ SWBMP 9.2 Dry WellsDocument15 pagesNJ SWBMP 9.2 Dry Wellscatalinavillasalazar84No ratings yet

- Highway Drainage Standards Feb 2013Document14 pagesHighway Drainage Standards Feb 2013jusaryorNo ratings yet

- SoakageManual PDFDocument66 pagesSoakageManual PDFabdullah sahib100% (1)

- Npga412 94Document7 pagesNpga412 94Conifer YuNo ratings yet

- Bongaigaon - 3X250 MW Flue Gas Desulfurization System: Technical Specification FOR Glass Flake Lining For DuctDocument14 pagesBongaigaon - 3X250 MW Flue Gas Desulfurization System: Technical Specification FOR Glass Flake Lining For DuctAnonymous 5XvUbWynnNo ratings yet

- Temporary Permanent BPDocument18 pagesTemporary Permanent BPravinder277No ratings yet

- BWM GuideDocument23 pagesBWM GuideAnonymous XtvvG80zu100% (1)

- SPCC GuidanceDocument6 pagesSPCC GuidancejoesuhreNo ratings yet

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Scrapzone Price ListDocument2 pagesScrapzone Price Listshantanukulkarni007No ratings yet

- Provision NWC For SchemesDocument186 pagesProvision NWC For SchemesWjz WjzNo ratings yet

- School WASH Management, Maintenance and Operation GuideDocument66 pagesSchool WASH Management, Maintenance and Operation GuideMesfin HabtemariamNo ratings yet

- Acclivity Noveltine LibertycaDocument5 pagesAcclivity Noveltine Libertycadiko pridieNo ratings yet

- DRAKE - OceanographyDocument472 pagesDRAKE - Oceanographycfisicaster0% (1)

- SOR Civil Engineering Works 2016Document31 pagesSOR Civil Engineering Works 2016guees897067100% (1)

- Set 9 GroundwaterDocument5 pagesSet 9 GroundwaterFM burgosNo ratings yet

- Sdo Wapda Basha DamDocument5 pagesSdo Wapda Basha Damsaifal hameedNo ratings yet

- Coolant VCS Ready MixedDocument6 pagesCoolant VCS Ready Mixedilham septiajiNo ratings yet

- Magur BreedingDocument25 pagesMagur BreedingVishal Solanki100% (1)

- EIA of Pulangi IV Hydroelectric Power PlantDocument2 pagesEIA of Pulangi IV Hydroelectric Power PlantcatherineNo ratings yet

- Meeting Minutes WPC and ISL 21-11-2023Document2 pagesMeeting Minutes WPC and ISL 21-11-2023akalankarNo ratings yet

- Ingersoll Rand Lubricant: XL 700Document9 pagesIngersoll Rand Lubricant: XL 700Ryan KurniaNo ratings yet

- Sustainable Engg. Second ModuleDocument13 pagesSustainable Engg. Second ModuleNRJ2000No ratings yet

- Flow NetsDocument30 pagesFlow NetsMustafa HusseinNo ratings yet

- Notes From Arch Annie PugedaDocument2 pagesNotes From Arch Annie PugedaAlvin John Pajo100% (1)

- Recovery Program Pilot Partnerships With Councils in The NWDocument7 pagesRecovery Program Pilot Partnerships With Councils in The NWGuedjeo SuhNo ratings yet

- Paper 3 10629 6163Document33 pagesPaper 3 10629 6163Umed ADA-ALSATARNo ratings yet

- Force-Pressure-Head Worksheet (ANSWERS AT THE END!)Document7 pagesForce-Pressure-Head Worksheet (ANSWERS AT THE END!)Powerbomb JonesNo ratings yet

- Marpol Day2Document101 pagesMarpol Day2Mark Gideon AgudaNo ratings yet

- Provenance and Sediment Dispersal in Relation To Paleotectonics and Paleogeography of Sedimentary BasinsDocument23 pagesProvenance and Sediment Dispersal in Relation To Paleotectonics and Paleogeography of Sedimentary BasinsIsidro Perez OlanNo ratings yet

- CORALations - ACE - Gmail - San Juan Harbor Dredge - Condado Lagoon FillDocument2 pagesCORALations - ACE - Gmail - San Juan Harbor Dredge - Condado Lagoon FillCORALationsNo ratings yet

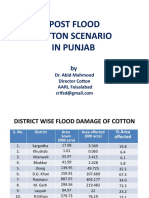

- Flood Damage of Cotton in PunjabDocument15 pagesFlood Damage of Cotton in PunjabbasitNo ratings yet

- Activity Guide and Evaluation RubricDocument2 pagesActivity Guide and Evaluation Rubrickarina meriñoNo ratings yet

- Steel PipeDocument186 pagesSteel PipeMarti H JNo ratings yet

- Vs Cseries BRDocument8 pagesVs Cseries BRFazri Azhar RamdaniNo ratings yet

- ISO 12944 2022 MasterDocument22 pagesISO 12944 2022 MasterJosé Román MenaNo ratings yet

- Eastern Coast Red Sea Sarawat Haraz Mountains 'Asir Hijaz Mountains Midian Shammar Mountains Salma Tuwaiq Hejaz Jabal An-Nabi Shu'ayb Tuwayr Jebel Hafeet OutlierDocument4 pagesEastern Coast Red Sea Sarawat Haraz Mountains 'Asir Hijaz Mountains Midian Shammar Mountains Salma Tuwaiq Hejaz Jabal An-Nabi Shu'ayb Tuwayr Jebel Hafeet Outlierსო ფიაNo ratings yet

- TOEFL Exercises. Tugas Kls 12, 29 S.D 31 Jan 2024Document5 pagesTOEFL Exercises. Tugas Kls 12, 29 S.D 31 Jan 2024X MIPA 7 Arief RamadhanNo ratings yet

- Assessment of Irrigation Water QualityDocument10 pagesAssessment of Irrigation Water Qualitymusa ballah koromaNo ratings yet

Interim Technical Guidance Note On Capping For Landfill Sites

Interim Technical Guidance Note On Capping For Landfill Sites

Uploaded by

Ronen MarkoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Interim Technical Guidance Note On Capping For Landfill Sites

Interim Technical Guidance Note On Capping For Landfill Sites

Uploaded by

Ronen MarkoCopyright:

Available Formats

Capping for landfill sites

SEPA Interim Technical Guidance Note

Capping for Landfill Sites

Summary

All landfills will require a cap and operators should provide site specific justification for

their proposals and any deviations from the landfill directive recommendations. As a

minimum, the capping system should contain a low permeability/sealing layer (ie clay,

LDPE, GCL), a surface water drainage system and cover soils. Whilst the cap design is

to be based on a site specific assessment, for lined sites SEPA would generally favour a

flexible membrane for gas control purposes and controlled recirculation of leachate to

optimise waste decomposition.

1.0 Introduction and Scope

1.1 This note provides interim guidance for SEPA staff on capping for landfill sites

and may be provided to operators and designers as guidance to SEPAs

requirements. The procedures described may be applied to both existing and

new landfill sites.

1.2 This guidance document sets out a brief overview of the main aspects to be

considered when establishing the capping standards at landfill sites. The

Environment Agency has commissioned a research project on guidance for

restoration of landfill sites and it is anticipated that a section on the engineering

aspects of capping of landfills will be included in that research report. That report

is not yet available although outline guidance on capping systems is provided in

Waste Management Paper 26 B.

1.3 This guidance document covers landfill sites closing or closed under the Waste

Management Licensing regime and landfill sites regulated under the PPC regime.

Regardless of the regulatory regime, the standard of cap required is based on

site-specific assessment. Operators will require to establish the site specific

capping requirements for each landfill site based on the overall design and

setting of the landfill. It is not possible to cover all the possible capping options

available in this guidance.

1.4 The choice of capping should be made during the initial design of the site and

details should be provided by the operator along with a permit application.

Appropriate conditions may also be required to be included in the permit relating

to capping of the site. For capping systems the design should be based on

quantified calculation of the infiltration characteristics over the full life cycle of the

landfill in context with the meteorological conditions at the site and all other

aspects of the engineered control systems including gas management.

Rev 7 1 January 2003

Capping for landfill sites

2.0 Regulatory Principles applicable to capping

2.1 This note covers landfill sites closing or closed under the Waste Management

Licensing (WML) regime and landfill sites regulated under the Pollution

Prevention and Control (PPC) regime. The implementation of the Landfill

Directive leads to several scenarios, these are:

Non Landfill Directive Compliant sites

A: Closed before 16 July 2001 under WML and hence not subject to Landfill

Directive (Site Conditioning Plan (SCP) not submitted)

B: Closed after 16 July 2001 and before 16 July 2002 under WML and subject to

Landfill Directive closure procedures only (SCP not submitted)

C: Closed after 16 July 2001 and before 2007 under WML and subject to Landfill

Directive closure procedures only (SCP submitted – either operator or SEPA

initiated closure)

Landfill Directive Compliant sites

D: Existing sites transferred from WML to PPC permit and operating after 2007.

E: New sites issued with WML or PPC permit after 16 July 2002

2.2 Sites that that fall into scenario A are to be capped and closed in accordance

with the requirements of their licence and the Waste Management Licensing

regulations and are not affected by the Landfill Directive.

2.3 Sites that fall into scenarios B & C are also to be closed in accordance with their

licence and the Waste Management Licensing Regulations and in addition will

require to follow the closure procedures of the Landfill Directive. However, it is

only the closure and aftercare procedures that apply to such sites as set out in

article 13 of the Landfill Directive. This includes the monitoring requirements of

annex III and the setting of ‘trigger levels’ of contaminants in groundwater (see

SEPA Interim Technical Guidance Note: Hydrogeological risk assessment for

landfills and the derivation of control and trigger levels). The capping standards

at sites falling into scenarios B & C is to be established in accordance with the

requirements of their licence and the Waste Management Licensing Regulations.

The capping recommendations given in the Landfill Directive may be used as a

guide to the options available for capping.

2.4 Sites falling into scenarios D & E must be fully Landfill Directive compliant both

for operational and closed phases. This means that old closed phases of

existing landfill sites that transfer to the PPC regime (including old phases

technically connected to new phases) must comply with the capping

requirements of the Landfill Directive. The standards of capping for closed

phases can be established on a site specific risk based approach. Operators will

require to justify retaining existing caps and consider any additional works that

may the necessary to improve existing cap performance.

2.5 Nevertheless, regardless of the regulatory regime, the standard of cap required is

to be based on site-specific assessment. The Directive requires that soil,

groundwater and surface water are protected by the geological barrier and a top

liner following closure. The Directive then goes on to provide recommendations

for capping of non-hazardous and hazardous landfills but these can be

established on a site-specific basis by risk assessment (standards can be

increased as well as reduced). The need for and specification of a cap is also

Rev 7 2 January 2003

Capping for landfill sites

related to the gas management system and also the potential need to physically

separate the waste from the environment, even if there is no leachate risk (e.g.

for asbestos waste). However, as a minimum, the capping system should contain

a low permeability/sealing layer (ie clay, LDPE, GCL), a surface water drainage

system and cover soils. All hazardous and non-hazardous landfills will require a

cap and operators should provide site specific justification for their proposals and

any deviations from the landfill directive recommendations.

2.6 The Landfill Directive recommendations for capping are:

Landfill Category Non-hazardous Hazardous

Gas Drainage Layer Required Not-required

Artificial sealing liner Not-required Required

Impermeable mineral layer Required Required

Drainage layer >0.5m Required Required

Top Soil cover >1m Required Required

2.7 The presence of a gas drainage layer has been excluded from the hazardous

landfill. However, depending on the hazardous waste types received, gas

management may still be required, and this may or may not include a gas

drainage layer.

2.8 An artificial sealing liner (such as LDPE) may well be required at a non-

hazardous site in order to act as a seal for gas collection purposes or to minimise

rainfall infiltration. An impermeable mineral layer is recommended in the

Directive for both non-hazardous and hazardous sites. Unfortunately, the term

‘impermeable’ when used in the context of a mineral layer, does not lend clarity

to the regulatory requirements. Mineral layers cannot be impermeable but will

have a certain permeability depending on the mineral used and the field

conditions.

2.9 A drainage layer, is a layer that is above either the low permeability mineral layer

or artificial sealing liner. It does not necessarily require to be a blanket of

drainage stone to be an effective drainage layer but could be a layer of material

with, for example, a herringbone network of field drains lain in that layer.

Similarly the thickness can be established on a site specific basis. There are, for

example, geocomposite systems that can provide drainage of a cap but are only

10 or 20 mm thick. The drainage layer and the effectiveness of the drainage

system is the most important aspect of the cap in terms of controlling infiltration

into the waste mass. All sites will require some form of drainage system.

2.10 Restoration and topsoil cover will require to be established on a site specific

basis depending on restoration and after use proposals. A difference is drawn

between the terms ‘Top soil’ used in the Directive and ‘topsoil’ used as a soil

classification. The Directive appears to mean a top layer of soil as a cover rather

than a 1m thickness of topsoil material. The Environment Agency has

commissioned a research project to prepare guidance on landfill restoration as

an update to WMP26E (draft).

2.11 Inert landfills will require some form of cap but this may not be required to control

infiltration or gas emissions and may just be required for restoration purposes. In

addition an inert landfill may have accepted non-inert wastes in the past and the

capping system should take such previous activities into account.

Rev 7 3 January 2003

Capping for landfill sites

3.0 Technical Objectives of capping

3.1 In terms of hydraulic control, the capping details should be established from a risk

assessment basis considering the whole life cycle of the landfill site. The SEPA

guidance document ‘Framework for Risk Assessment for Landfill Sites: The

Geological Barrier, Mineral Layer and the Leachate Sealing and Drainage System’

sets out the key steps in carrying out a risk assessment. That risk assessment

procedure is used to establish the appropriate basal liner standards by estimating

emission levels of potential pollutants to the groundwater.

3.2 To allow full life cycle analysis of a landfill, the performance of the cap is also of

crucial importance. It is the degree of infiltration of rainwater through the cap that

dictates the leachate generation from the waste. Once the infiltration rate has

been estimated then the water balance for the site can be calculated (including

any recirculation) and from this, the emissions to the environment can be

quantified. The design of the cap must also take into account, gas management

at the site and the proposed aftercare and restoration activities.

3.3 As stated above, the cap primarily requires to fulfill a dual purpose in terms of

environmental protection. To control infiltration rates and as part of the gas

control system. Both aspects must be satisfactorily addressed within any design

and will require a number of engineering components. The final arrangement will

differ from site to site depending on the degree of control required. In addition,

the capping specification may vary from one area of a landfill to another as

different degrees of control may be required. The management of gas is covered

in other SEPA guidance. (ref Guidance on the Management of Landfill Gas)

3.4 The infiltration rate of rain into the waste through the capping system is dependent

on a number of factors (see figure 3.1) including:

• Rainfall characteristics

• Surface slope

• Restoration and grass/plant cover

• Drainage system

• Low permeability layer

3.4 The interrelationship between these factors is complex but there are methods

available to estimate the performance of a capping system. A computer modeling

programme, HELP ‘Hydraulic Evaluation of Landfill Performance’ is a useful tool

for estimating infiltration rates through a cap. However, that model does not have

default Scottish rainfall patterns and if used, advice should be sought from a

hydrologist to derive site specific rainfall characteristics for the landfill under study.

Operators should justify capping performance on the basis of a quantified

calculation of infiltration. Such analysis would not generally be required for inert

landfills.

3.5 However, more simplistic methods are available and based around making

conservative estimates of some of the variables. Whatever method is used, the

operator should justify their specific choice.

3.6 It is not appropriate to specify a low permeability layer in isolation of the overlying

drainage system, as it is the composite performance of these two components

that provides infiltration control in a cap. The basis of the design is that the low

Rev 7 4 January 2003

Capping for landfill sites

permeability layer retains the infiltrating rainwater in the drainage layer in order

that it can be carried away within drains for discharge beyond the landfill.

Discharge from drainage

pipes

Rainfall

Evapotranspiration

Water profile Surface runoff

Low permeability layer

Leachate Drainage through

recirculation restoration layer

Low permeability /

Infiltration into waste sealing layer

Waste mass

Figure 3.1: Factors affecting infiltration though a cap

3.7 Ultimately, there will always be a degree of uncertainly over the estimated

infiltration through a capping system. Modelling programs such as Landsim,

allow this uncertainty of input parameters to be reflected in the model. As the

infiltration rate is primarily the input into calculating the leachate generation at the

site and hence leachate emissions from the site, it is advisable that the sensitivity

to infiltration rate is investigated.

3.8 For example, reducing the infiltration rate into a contained landfill may serve to

increase the polluting lifespan of the landfilled waste mass but reduce the rate of

emissions from that site, and hence reduce the peak pollutant concentration.

Conversely, by increasing the infiltration rate, the polluting lifespan of the site may

be reduced but an increase in the rate of emissions from the site during that

shorter period could occur.

3.9 In general, sites with gas abstraction (all non-hazardous sites and some

hazardous sites) will require a Flexible Membrane cap using synthetic

polyethylene materials (eg LLDPE, VLDPE, HDPE). Depending on the gas

management system, this may require to be welded, to control air ingress into the

gas abstraction system. Low permeability clay may be used in some

circumstances but it is not as effective at controlling gas emission rates as a

flexible membrane, but this does not preclude its use as a capping material.

3.10 The air/gas permeability of a clay will be several orders of magnitude higher than

the permeability of that clay to water due to the difference in viscosity between

air/gas and water. The rate of gas (or air intrusion) release through a clay cap

will also be affected by other factors such as the degree of saturation of the clay

Rev 7 5 January 2003

Capping for landfill sites

layer, atmospheric pressure changes etc. In addition, any surface cracking in the

capping system due to differential settlement or desiccation effects, may become

routes for emissions of gas. Ultimately, the choice of materials and arrangement

will be determined on a site specific basis depending on the gas management

proposals for the site.

3.11 A Flexible Membrane Cap will require to be constructed under a CQA regime in

such a fashion that it is protected from puncture and can accommodate the

anticipated settlements. This will require protection layers both above and below

the liner. Where the membrane is being used to control gas emissions and/or air

entry as part of a gas abstraction scheme, the resultant rainfall infiltration rates will

be insignificant in the early years of the membrane. However, there is a balance

to be struck when using membrane capping. By sealing the waste mass from

infiltration the rate of decomposition reduces, as does the gas generation rate.

3.12 Without some compensatory water management (ie below cap recirculation) the

active lifespan of the site will increase. If moisture addition to the waste mass

ceases, biodegradation will tend not to occur. One potential long term effect from

this, is that sites which are capped with a flexible membrane to exclude all water

ingress and do not have a planned aftercare water balance, pose a potential long

term environmental liability. Should the membrane fail in the long term (ie through

settlement damage, environmental stress cracking, etc) and rain water infiltrates

into dry waste, then biodegradation would recommence, along with associated

gas and leachate emissions. This may happen many years or decades after

closure and does not tie in with the concept of achieving completion within a

generation (30 years)

3.13 Mineral liners on the other hand, allow a far greater infiltration rate from an early

stage in the post closure phase and would be more suited for sites where

compensatory leachate recirculation was not planned. However, mineral liners

are not as effective in terms of gas management control.

Rev 7 6 January 2003

Capping for landfill sites

4.0 Method of approach

4.1 The principal points to be considered when establishing the appropriate standards

for a cap are the control required over water infiltration and the control required for

gas management.

4.2 The level of control over rainfall infiltration required at the site is to be established

from a consideration of the whole life cycle of the site, with the cap being a

component of the sites pollution control measures. This should be addressed by

the operators in their proposals for the operation of the site. The cap performance

should be considered as an integral part of the leachate management strategy for

the site.

4.3 There is no set method of capping that can be universally applied to all landfill sites

and each must be considered in light of the operational and post closure

conditions. Similarly, the capping requirements may vary for one area of a landfill

to another (for example to deal with different final slopes) and may differ depending

on the stage of biodegradation of the waste.

Select capping arrangement compatible with

gas management strategy

Estimate infiltration performance of

capping arrangement

Determine water balance for

Revise capping

whole life of site

arrangement

Feed estimate infiltration

performance into risk

Unacceptable assessment for liner

outcome from design/ groundwater risk Estimate leachate

risk assessment production, abstraction &

assessment treatment requirements

Acceptable

outcome from

risk assessment

Ensure capping components are in

accordance with best practice guidance

(ie GCL liner guidance, CQA for

construction phase etc)

Figure 4.1: Steps in determining capping standards

Rev 7 7 January 2003

Capping for landfill sites

4.4 The steps shown in figure 4.1 should be followed when considering the appropriate

standards for capping at landfills. This process should be carried out at the design

stage of the site and in parallel with the groundwater risk assessment modelling.

See SEPA guidance on ‘Framework for Risk Assessment for Landfill Sites: The

Geological Barrier, Mineral Layer and the Leachate Sealing and Drainage System’.

4.5 For new sites and existing sites applying for a PPC permit, the operator should

present their justified proposals along with the application. The full capping and

restoration proposals must be agreed at the permitting stage. The operator should

provide details of the estimated infiltration characteristics of the cap for the whole

life cycle of the site and be based on the resultant leachate generation and

emissions to the environment.

4.6 For existing landfill sites closed or closing under the WML, the operator should

present their proposals as part of a closure plan and estimate the infiltration

characteristics of the cap and resultant leachate emissions.

4.7 Once the general arrangement of the cap has been decided, each component

should be constructed in accordance with best practice. This involves

consideration of many aspects, including CQA, installation, operation etc. This is

not discussed here and guidance on this aspect is given in other more detailed

Agency guidance on engineering of landfill liner systems. Including:

• Earthworks on landfill sites: Guidance on the design, construction and quality

assurance.

• The use of nuclear density gauges for compliance testing of earthworks on

landfill.

• Guidance on the use of geomembranes in landfill engineering.

• Guidance on the geophysical testing of geomembranes for landfill

engineering.

• Guidance on nonwoven protector geotextiles for landfill engineering.

• Guidance on bentonite enriched soils for landfill engineering.

• Guidance on the use of geosynthetic clay liners in landfill engineering.

• A methodology for cylinder testing of protectors for geomembranes

Rev 7 8 January 2003

You might also like

- Drilling FluidsDocument41 pagesDrilling FluidsGogot Pantja Parijogo100% (2)

- CAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignDocument4 pagesCAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignNICOLAS SANCHEZ GOMEZNo ratings yet

- Rotocol: Soil Treatment Facility Design and Operation For Bioremediation of Hydrocarbon Contaminated SoilDocument9 pagesRotocol: Soil Treatment Facility Design and Operation For Bioremediation of Hydrocarbon Contaminated Soilsarge18No ratings yet

- Offshore Pipeline Decommissioning GuidelineDocument8 pagesOffshore Pipeline Decommissioning GuidelineJonel KrduNo ratings yet

- Earthworks in Landfill EngineeringDocument66 pagesEarthworks in Landfill EngineeringMelissa GrahamNo ratings yet

- Applications of Multiphase Desander TechnologyDocument19 pagesApplications of Multiphase Desander TechnologyanisNo ratings yet

- Application of Multiphase Desander Technology To Oil and Gas ProductionDocument19 pagesApplication of Multiphase Desander Technology To Oil and Gas ProductionJose Rodrigo Salguero DuranNo ratings yet

- Wac 463-42-215 Proposal - Surface-Water RunoffDocument4 pagesWac 463-42-215 Proposal - Surface-Water RunoffBello kabirNo ratings yet

- LFG International DesignDocument12 pagesLFG International Designdzari6738No ratings yet

- Management of DredgedExcavated SedimentDocument17 pagesManagement of DredgedExcavated SedimentMan Ho LamNo ratings yet

- TG 11Document19 pagesTG 11Lorraine BautistaNo ratings yet

- ContioceanDECK HTMLDocument61 pagesContioceanDECK HTMLnithzbloggerNo ratings yet

- MS - 33 Rev 0 - Reinstatement of KNO.06 Lateral Line AsphaltDocument6 pagesMS - 33 Rev 0 - Reinstatement of KNO.06 Lateral Line AsphaltSyed Umair HashmiNo ratings yet

- Part 7 - Shallow Gas BlowoutsDocument8 pagesPart 7 - Shallow Gas BlowoutsJohnSmithNo ratings yet

- Earthworks SummaryDocument3 pagesEarthworks SummarykekaNo ratings yet

- Disposal Requirements Volume3Document8 pagesDisposal Requirements Volume3mcemceNo ratings yet

- Guide To The Preparation of A Working Plan Scrapyard / Elv FacilityDocument6 pagesGuide To The Preparation of A Working Plan Scrapyard / Elv FacilityNebojsa RedzicNo ratings yet

- 53 Wetlands EDocument4 pages53 Wetlands ECương QuốcNo ratings yet

- Collection System Design Plans: Appendix EDocument70 pagesCollection System Design Plans: Appendix EMMMOH200No ratings yet

- Manual - Lining - Irrigation - Canals - West BengalDocument22 pagesManual - Lining - Irrigation - Canals - West Bengalsudheer7320_58503644No ratings yet

- Surface and Sub-Surface Drainage Systems For HighwaysDocument38 pagesSurface and Sub-Surface Drainage Systems For HighwaysJalijash100% (1)

- DPHS Soil Permeability Guidance 2013Document11 pagesDPHS Soil Permeability Guidance 2013javanimeNo ratings yet

- Wastewater Lagoon ConstructionDocument24 pagesWastewater Lagoon ConstructionIrfanullah TunioNo ratings yet

- WAPUG User Note 21Document3 pagesWAPUG User Note 21saurabh singhNo ratings yet

- Chapter 9Document120 pagesChapter 9Aaron RasmussenNo ratings yet

- Garmony Environmental Statement Rev B App BDocument15 pagesGarmony Environmental Statement Rev B App BTAHER AMMARNo ratings yet

- TSF Report KwedijabuDocument15 pagesTSF Report KwedijabuENG BARAKA JOELNo ratings yet

- Der 17Document42 pagesDer 17Robert J MayNo ratings yet

- Lagunas de TratamientoDocument24 pagesLagunas de TratamientoAlex JunkersNo ratings yet

- Hardicrete Heavy Duty Surfacing No.88 1969 Third IssueDocument8 pagesHardicrete Heavy Duty Surfacing No.88 1969 Third Issuecvsatheeh1No ratings yet

- Ed Well ControlDocument18 pagesEd Well ControlAmeer BabylonianNo ratings yet

- United States Environmental Protection Agency: Region Viii 999 18th STREET - SUITE 300 Denver, Colorado 80202-2466Document10 pagesUnited States Environmental Protection Agency: Region Viii 999 18th STREET - SUITE 300 Denver, Colorado 80202-2466Susin LimNo ratings yet

- Pedl 300 1 Doc 4 The ProposalDocument42 pagesPedl 300 1 Doc 4 The ProposalZaky Abdurrasyid MNo ratings yet

- TCLT FD 02.02 200907 Za Podlogu KadaDocument33 pagesTCLT FD 02.02 200907 Za Podlogu KadaMomir StanojevicNo ratings yet

- ASTM D7765 - Foundary Sand For EmbankmentDocument4 pagesASTM D7765 - Foundary Sand For EmbankmentAnantNo ratings yet

- Chapter8 MineClosureandRehabDocument16 pagesChapter8 MineClosureandRehabJonNo ratings yet

- Ogaom Chapter 9 PDFDocument44 pagesOgaom Chapter 9 PDFjohanaristoNo ratings yet

- Well Ops Template SCR 2015 Schedule 9 Well Notification Inspection July 2015Document13 pagesWell Ops Template SCR 2015 Schedule 9 Well Notification Inspection July 2015MartahanManurungNo ratings yet

- Seabed and Sub Seabed Data RequirementsDocument13 pagesSeabed and Sub Seabed Data RequirementsAyman64No ratings yet

- Bunding and Spill Management - NSW EPADocument8 pagesBunding and Spill Management - NSW EPAPhilip LonerganNo ratings yet

- Newitem 133 Msw-ReportDocument49 pagesNewitem 133 Msw-ReportMohana Priya SNo ratings yet

- Shallow GasDocument6 pagesShallow GasYaqoob IbrahimNo ratings yet

- WR WQ Pub Design Criteria Ch9Document15 pagesWR WQ Pub Design Criteria Ch9Brian NyagiloNo ratings yet

- Code of Practice For The Protection of Structures From Ground Gases - Sept 2020Document17 pagesCode of Practice For The Protection of Structures From Ground Gases - Sept 2020Adam ClutterbuckNo ratings yet

- C 9 E I A: C S: Hapter Nvironmental Mpact Ssessment ASE TudiesDocument162 pagesC 9 E I A: C S: Hapter Nvironmental Mpact Ssessment ASE Tudiesjazon fabian hpNo ratings yet

- Attachment J (Draft Offshore Pipelines Decommissioning Guideline)Document6 pagesAttachment J (Draft Offshore Pipelines Decommissioning Guideline)smithworkNo ratings yet

- Secondary Containment of Large Aboveground Storage TanksDocument12 pagesSecondary Containment of Large Aboveground Storage TanksocayliNo ratings yet

- Sghs MGSD Information SheetDocument5 pagesSghs MGSD Information Sheetshoaib KhalilNo ratings yet

- Chapter 62C-27 Conservation of Oil and Gas: DrillingDocument4 pagesChapter 62C-27 Conservation of Oil and Gas: DrillingAry RachmanNo ratings yet

- Bulletin 2011-35: Surface Casing Vent Requirements For WellsDocument5 pagesBulletin 2011-35: Surface Casing Vent Requirements For WellsjagicisiwoNo ratings yet

- NJ SWBMP 9.2 Dry WellsDocument15 pagesNJ SWBMP 9.2 Dry Wellscatalinavillasalazar84No ratings yet

- Highway Drainage Standards Feb 2013Document14 pagesHighway Drainage Standards Feb 2013jusaryorNo ratings yet

- SoakageManual PDFDocument66 pagesSoakageManual PDFabdullah sahib100% (1)

- Npga412 94Document7 pagesNpga412 94Conifer YuNo ratings yet

- Bongaigaon - 3X250 MW Flue Gas Desulfurization System: Technical Specification FOR Glass Flake Lining For DuctDocument14 pagesBongaigaon - 3X250 MW Flue Gas Desulfurization System: Technical Specification FOR Glass Flake Lining For DuctAnonymous 5XvUbWynnNo ratings yet

- Temporary Permanent BPDocument18 pagesTemporary Permanent BPravinder277No ratings yet

- BWM GuideDocument23 pagesBWM GuideAnonymous XtvvG80zu100% (1)

- SPCC GuidanceDocument6 pagesSPCC GuidancejoesuhreNo ratings yet

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Scrapzone Price ListDocument2 pagesScrapzone Price Listshantanukulkarni007No ratings yet

- Provision NWC For SchemesDocument186 pagesProvision NWC For SchemesWjz WjzNo ratings yet

- School WASH Management, Maintenance and Operation GuideDocument66 pagesSchool WASH Management, Maintenance and Operation GuideMesfin HabtemariamNo ratings yet

- Acclivity Noveltine LibertycaDocument5 pagesAcclivity Noveltine Libertycadiko pridieNo ratings yet

- DRAKE - OceanographyDocument472 pagesDRAKE - Oceanographycfisicaster0% (1)

- SOR Civil Engineering Works 2016Document31 pagesSOR Civil Engineering Works 2016guees897067100% (1)

- Set 9 GroundwaterDocument5 pagesSet 9 GroundwaterFM burgosNo ratings yet

- Sdo Wapda Basha DamDocument5 pagesSdo Wapda Basha Damsaifal hameedNo ratings yet

- Coolant VCS Ready MixedDocument6 pagesCoolant VCS Ready Mixedilham septiajiNo ratings yet

- Magur BreedingDocument25 pagesMagur BreedingVishal Solanki100% (1)

- EIA of Pulangi IV Hydroelectric Power PlantDocument2 pagesEIA of Pulangi IV Hydroelectric Power PlantcatherineNo ratings yet

- Meeting Minutes WPC and ISL 21-11-2023Document2 pagesMeeting Minutes WPC and ISL 21-11-2023akalankarNo ratings yet

- Ingersoll Rand Lubricant: XL 700Document9 pagesIngersoll Rand Lubricant: XL 700Ryan KurniaNo ratings yet

- Sustainable Engg. Second ModuleDocument13 pagesSustainable Engg. Second ModuleNRJ2000No ratings yet

- Flow NetsDocument30 pagesFlow NetsMustafa HusseinNo ratings yet

- Notes From Arch Annie PugedaDocument2 pagesNotes From Arch Annie PugedaAlvin John Pajo100% (1)

- Recovery Program Pilot Partnerships With Councils in The NWDocument7 pagesRecovery Program Pilot Partnerships With Councils in The NWGuedjeo SuhNo ratings yet

- Paper 3 10629 6163Document33 pagesPaper 3 10629 6163Umed ADA-ALSATARNo ratings yet

- Force-Pressure-Head Worksheet (ANSWERS AT THE END!)Document7 pagesForce-Pressure-Head Worksheet (ANSWERS AT THE END!)Powerbomb JonesNo ratings yet

- Marpol Day2Document101 pagesMarpol Day2Mark Gideon AgudaNo ratings yet

- Provenance and Sediment Dispersal in Relation To Paleotectonics and Paleogeography of Sedimentary BasinsDocument23 pagesProvenance and Sediment Dispersal in Relation To Paleotectonics and Paleogeography of Sedimentary BasinsIsidro Perez OlanNo ratings yet

- CORALations - ACE - Gmail - San Juan Harbor Dredge - Condado Lagoon FillDocument2 pagesCORALations - ACE - Gmail - San Juan Harbor Dredge - Condado Lagoon FillCORALationsNo ratings yet

- Flood Damage of Cotton in PunjabDocument15 pagesFlood Damage of Cotton in PunjabbasitNo ratings yet

- Activity Guide and Evaluation RubricDocument2 pagesActivity Guide and Evaluation Rubrickarina meriñoNo ratings yet

- Steel PipeDocument186 pagesSteel PipeMarti H JNo ratings yet

- Vs Cseries BRDocument8 pagesVs Cseries BRFazri Azhar RamdaniNo ratings yet

- ISO 12944 2022 MasterDocument22 pagesISO 12944 2022 MasterJosé Román MenaNo ratings yet

- Eastern Coast Red Sea Sarawat Haraz Mountains 'Asir Hijaz Mountains Midian Shammar Mountains Salma Tuwaiq Hejaz Jabal An-Nabi Shu'ayb Tuwayr Jebel Hafeet OutlierDocument4 pagesEastern Coast Red Sea Sarawat Haraz Mountains 'Asir Hijaz Mountains Midian Shammar Mountains Salma Tuwaiq Hejaz Jabal An-Nabi Shu'ayb Tuwayr Jebel Hafeet Outlierსო ფიაNo ratings yet

- TOEFL Exercises. Tugas Kls 12, 29 S.D 31 Jan 2024Document5 pagesTOEFL Exercises. Tugas Kls 12, 29 S.D 31 Jan 2024X MIPA 7 Arief RamadhanNo ratings yet

- Assessment of Irrigation Water QualityDocument10 pagesAssessment of Irrigation Water Qualitymusa ballah koromaNo ratings yet