Professional Documents

Culture Documents

CE155 Quantity Take Off Formworks Installation

CE155 Quantity Take Off Formworks Installation

Uploaded by

ricca javierCopyright:

Available Formats

You might also like

- Design of Plate and Frame Filter PressDocument7 pagesDesign of Plate and Frame Filter PressEula Mae Carla Añonuevo80% (5)

- 3a. - Flexural Members Ce134p - Escruz - LRFDDocument42 pages3a. - Flexural Members Ce134p - Escruz - LRFDJed CernechezNo ratings yet

- Experimental Model of Cracking Induced by Drying ShrinkageDocument6 pagesExperimental Model of Cracking Induced by Drying ShrinkageNouha JhiderNo ratings yet

- A Rectification Manual - ExampleDocument41 pagesA Rectification Manual - Examplesorobanista100% (1)

- Siren BS1 - Rev-E PDFDocument2 pagesSiren BS1 - Rev-E PDFConstantin Gurzu0% (1)

- Masonry - Midterm Project PDFDocument11 pagesMasonry - Midterm Project PDFRaffy BufeteNo ratings yet

- Inbound 5608803688066540769Document12 pagesInbound 5608803688066540769Ceejay PalomaNo ratings yet

- Laboratory Work No. 1 Group 4Document22 pagesLaboratory Work No. 1 Group 4KNARF FRANKNo ratings yet

- 4.10 Design Procedure For Direct Design MethodDocument12 pages4.10 Design Procedure For Direct Design MethodMary Graçe ÇanoyNo ratings yet

- 1 325 1 MadjadoumbayeDocument5 pages1 325 1 MadjadoumbayeVidita RewayaniNo ratings yet

- JETIR1605042Document7 pagesJETIR1605042MeetNo ratings yet

- Geotechnical Engineering Example Exam QuestionsDocument7 pagesGeotechnical Engineering Example Exam Questionss041865No ratings yet

- College of Engineering and Technology Chemical Engineering DepartmentDocument6 pagesCollege of Engineering and Technology Chemical Engineering DepartmentKarl Raymundo100% (2)

- Final Hawassa Univiersity Sumplementary ExamDocument3 pagesFinal Hawassa Univiersity Sumplementary ExamArgaw Asha100% (4)

- Ay1920 Sem 2 Sce5322Document17 pagesAy1920 Sem 2 Sce5322Tsang Siu YiNo ratings yet

- Design Basis Report NewDocument29 pagesDesign Basis Report Newrpdharshan04No ratings yet

- 61562-Article Text-751375261078-1-10-20221220Document12 pages61562-Article Text-751375261078-1-10-20221220Prakash PrajapatiNo ratings yet

- Analysis For Force and Deformation of The Pile and Wall Interaction Based On Three MethodsDocument7 pagesAnalysis For Force and Deformation of The Pile and Wall Interaction Based On Three MethodsKaotzNo ratings yet

- Arakabe WallDocument6 pagesArakabe WallalliancerNo ratings yet

- A Study On A Two-Way Post-Tensioned Concrete Waffle Slab - ScienceDirectDocument8 pagesA Study On A Two-Way Post-Tensioned Concrete Waffle Slab - ScienceDirectusman javedNo ratings yet

- 5 - KhanDocument39 pages5 - KhanMuthu SaravanaNo ratings yet

- Optimal Design of The Shoring System: A Parametric Study: Bhanuchitra, M. Prusty, Sudhansu BhusanDocument4 pagesOptimal Design of The Shoring System: A Parametric Study: Bhanuchitra, M. Prusty, Sudhansu BhusanMalik RizwanNo ratings yet

- Screening and Size ReductionDocument9 pagesScreening and Size ReductionhanzomoniyanNo ratings yet

- Sound-Absorption Mechanism of Structures With Periodic CavitiesDocument13 pagesSound-Absorption Mechanism of Structures With Periodic CavitiesUty VictoriaNo ratings yet

- tmpEF67 TMPDocument4 pagestmpEF67 TMPFrontiersNo ratings yet

- OK CHAPTER 4 C. Technical - AspectDocument17 pagesOK CHAPTER 4 C. Technical - AspectEugene MirasNo ratings yet

- Assignment 2 EcgDocument5 pagesAssignment 2 EcgAtika NadhirahNo ratings yet

- A Study On Properties of Recycled Coarse Aggregate and It's ConcreteDocument11 pagesA Study On Properties of Recycled Coarse Aggregate and It's ConcreteJenish PatelNo ratings yet

- Strengthening of RCC Beams Using Bamboo Sticks: International Journal of Advanced Science and Technology June 2015Document11 pagesStrengthening of RCC Beams Using Bamboo Sticks: International Journal of Advanced Science and Technology June 2015Takko KaalevaNo ratings yet

- CE 316Document59 pagesCE 316Hasyb UllahNo ratings yet

- I. Anastasopoulos, V. Drosos, N. Antonaki, A. RontogianniDocument9 pagesI. Anastasopoulos, V. Drosos, N. Antonaki, A. RontogianniPoojaNo ratings yet

- S U R J S S: Indh Niversity Esearch Ournal (Cience Eries)Document4 pagesS U R J S S: Indh Niversity Esearch Ournal (Cience Eries)Seif EddineNo ratings yet

- Exterior Wood-Concrete Slabs, Experimentation and Modeling of Mechanical Behavior. Part 1Document6 pagesExterior Wood-Concrete Slabs, Experimentation and Modeling of Mechanical Behavior. Part 1Dario QuirogaNo ratings yet

- BT 4 WallDocument5 pagesBT 4 WallJuvelle CambiaNo ratings yet

- Mechanical Behaviour of Straw Construction FollowiDocument9 pagesMechanical Behaviour of Straw Construction FollowiTiberiu-Marius AvramNo ratings yet

- Static Bending Test On Timber SpecimenDocument14 pagesStatic Bending Test On Timber SpecimenEddie BowokuNo ratings yet

- Measures For Improving The Long-Term Durability of A Prestressed Concrete Bridge Using High-Strength ConcreteDocument9 pagesMeasures For Improving The Long-Term Durability of A Prestressed Concrete Bridge Using High-Strength ConcreteoscarariagnaNo ratings yet

- Vibration Analysis of Rotary Cement Kiln Using Fin 2Document5 pagesVibration Analysis of Rotary Cement Kiln Using Fin 2nunchakuNo ratings yet

- Totora1 PDFDocument10 pagesTotora1 PDFJ Armando Gastelo RoqueNo ratings yet

- Deformability Characteristics of Quarried RockfillDocument5 pagesDeformability Characteristics of Quarried Rockfillemreakinay84No ratings yet

- Structural Analysis of Laterally AeratedDocument9 pagesStructural Analysis of Laterally AeratedbailescuNo ratings yet

- Design and Analysis of Cinema TheaterDocument23 pagesDesign and Analysis of Cinema TheaterrajNo ratings yet

- Annen2IASS PDFDocument8 pagesAnnen2IASS PDFErika Paz YanezNo ratings yet

- 2009 JsceDocument11 pages2009 Jscetriple tripleNo ratings yet

- Ay1819 Sem 2 Sce5322Document9 pagesAy1819 Sem 2 Sce5322Tsang Siu YiNo ratings yet

- Chopra, Sharma Professor, Kumar Professor - 2014 - Regression Models For The Prediction of Compressive Strength of Concrete With & WithoDocument8 pagesChopra, Sharma Professor, Kumar Professor - 2014 - Regression Models For The Prediction of Compressive Strength of Concrete With & WithomushfiqueNo ratings yet

- Experimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)Document12 pagesExperimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)emad mohamedNo ratings yet

- 3 Point Bend Test ReportDocument26 pages3 Point Bend Test ReportphschemguyNo ratings yet

- MN6124 Design of Underground StructuresDocument2 pagesMN6124 Design of Underground Structureswilsonaustin963No ratings yet

- 3-R 0.67 in Plaxis Centrifuge and Numerical Investigations of Rotated Box StructuresDocument6 pages3-R 0.67 in Plaxis Centrifuge and Numerical Investigations of Rotated Box StructuresthamiradNo ratings yet

- 12 FORMS Measuring QuanititiesDocument31 pages12 FORMS Measuring Quanititiesdebbydebby121101No ratings yet

- Thesis FulltextDocument354 pagesThesis FulltextcrvishnuramNo ratings yet

- CE-341 Lec 2Document13 pagesCE-341 Lec 2Hexxacord The BetterNo ratings yet

- Fracture Toughness of Ultra High Performance Concrete Subjected To FlexureDocument7 pagesFracture Toughness of Ultra High Performance Concrete Subjected To FlexuregauthamNo ratings yet

- SegmentedSpiral PDFDocument8 pagesSegmentedSpiral PDFErika Paz YanezNo ratings yet

- Application of Bousinesq's and Westergaard's Formulae in Analysing Foundation Stress Distribution For A Failed Telecommunication MastDocument7 pagesApplication of Bousinesq's and Westergaard's Formulae in Analysing Foundation Stress Distribution For A Failed Telecommunication MastJoshua Ian Gallardo AbanNo ratings yet

- Finite Element Analysis of IPN Reinforced Woven Fabric CompositeDocument6 pagesFinite Element Analysis of IPN Reinforced Woven Fabric CompositeCody LeeNo ratings yet

- Interlocking Paver BlocksDocument9 pagesInterlocking Paver BlocksfaresNo ratings yet

- Al Agha 2021Document10 pagesAl Agha 2021Qorry OktaliaNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- 3Q2021 CE123 2 C4 A01 G02 DeLeon Demerin Diones Doblon Dolojan Ebue Endaya Esteron PDFDocument6 pages3Q2021 CE123 2 C4 A01 G02 DeLeon Demerin Diones Doblon Dolojan Ebue Endaya Esteron PDFricca javierNo ratings yet

- Benosa Assesment PDFDocument3 pagesBenosa Assesment PDFricca javierNo ratings yet

- Ce2211 Cip 3ceb Mendoza-Gabilo-1Document3 pagesCe2211 Cip 3ceb Mendoza-Gabilo-1ricca javierNo ratings yet

- Research StudyDocument13 pagesResearch Studyricca javierNo ratings yet

- Cwts Essay#1Document1 pageCwts Essay#1ricca javierNo ratings yet

- OWG000016 WCDMA-CS Basic Conception, Principle and Basic Call Flow Introduction-Modified by 00712925Document78 pagesOWG000016 WCDMA-CS Basic Conception, Principle and Basic Call Flow Introduction-Modified by 00712925haytham_501No ratings yet

- NEW Fees Record 2010-11Document934 pagesNEW Fees Record 2010-11manojchouhan2014No ratings yet

- Astm D3202 - 1 (En)Document3 pagesAstm D3202 - 1 (En)Dinesh SaiNo ratings yet

- Peritonitis Capd-1Document15 pagesPeritonitis Capd-1David SenNo ratings yet

- Sant Rajinder Singh Ji Maharaj - Visions of The New MilleniumDocument8 pagesSant Rajinder Singh Ji Maharaj - Visions of The New MilleniumjjcalderNo ratings yet

- Johns Hopkins RFPDocument7 pagesJohns Hopkins RFPLucky 77No ratings yet

- Pe Lesson 2Document2 pagesPe Lesson 2Jessa De JesusNo ratings yet

- UM Panabo College: Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Document18 pagesUM Panabo College: Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Kenneth PadaoNo ratings yet

- MCQ IadDocument23 pagesMCQ Iads soyaNo ratings yet

- Separators of Different GenerationsDocument46 pagesSeparators of Different GenerationsISLAM I. Fekry100% (8)

- Solution-Focused Nursing Rethinking Prac PDFDocument1 pageSolution-Focused Nursing Rethinking Prac PDFSHUMETNo ratings yet

- Michael Downs - Lacan's Concept of The Object-Cause of Desire (Objet Petit A)Document23 pagesMichael Downs - Lacan's Concept of The Object-Cause of Desire (Objet Petit A)JustinWagnerNo ratings yet

- RESEARCH PROPOSAL Detriorating Standard of Education in PakistanDocument12 pagesRESEARCH PROPOSAL Detriorating Standard of Education in Pakistanjaydee_atc581454% (13)

- Themes: Themes, Motifs and SymbolsDocument6 pagesThemes: Themes, Motifs and SymbolsTanu ManochaNo ratings yet

- IS 15394.2003 Fire Safety in Petroleum RefineriesDocument16 pagesIS 15394.2003 Fire Safety in Petroleum RefineriesnpwalNo ratings yet

- Workshop 9 FUTURE TENSES-2Document3 pagesWorkshop 9 FUTURE TENSES-2FABIAN ANDRES VILLANUEVA SANCHEZNo ratings yet

- 11-40 - SINUMERIK Edge - Concept - AppsDocument15 pages11-40 - SINUMERIK Edge - Concept - AppsAshish PatwardhanNo ratings yet

- Innovative Strategies For Flood-Resilient CitiesDocument50 pagesInnovative Strategies For Flood-Resilient CitiesDaisy100% (1)

- Statements: Sources of The Medical Myths and Quack PracticesDocument6 pagesStatements: Sources of The Medical Myths and Quack PracticesLoreta De GuzmanNo ratings yet

- A Z of Simple Living BookDocument68 pagesA Z of Simple Living Bookdrsubramanian100% (4)

- MiraglianoDocument52 pagesMiraglianohansudongNo ratings yet

- Notice: Medicare: Emergency Medical Treatment and Labor Act Technical Advisory GroupDocument2 pagesNotice: Medicare: Emergency Medical Treatment and Labor Act Technical Advisory GroupJustia.comNo ratings yet

- Result Awaited FormDocument1 pageResult Awaited FormRoshan kumar sahu100% (1)

- Water Availability and Resources 23-06-23Document29 pagesWater Availability and Resources 23-06-23apoorva apoorvaNo ratings yet

- Lecture 14 - FAULT TREE ANALYSIS (FTA) - Cut-Set MethodDocument18 pagesLecture 14 - FAULT TREE ANALYSIS (FTA) - Cut-Set MethodBalamurugan ThirunavukkarasuNo ratings yet

- '21 Kona Bicycles Owner's Manual PDFDocument46 pages'21 Kona Bicycles Owner's Manual PDFInsight PeruNo ratings yet

- Ultra Tech Cement Review 16 9 19Document3 pagesUltra Tech Cement Review 16 9 19vivekNo ratings yet

- Kramapatha DevasthaliDocument11 pagesKramapatha DevasthaliDeepro ChakrabortyNo ratings yet

CE155 Quantity Take Off Formworks Installation

CE155 Quantity Take Off Formworks Installation

Uploaded by

ricca javierOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CE155 Quantity Take Off Formworks Installation

CE155 Quantity Take Off Formworks Installation

Uploaded by

ricca javierCopyright:

Available Formats

MEASURING QUANTITIES AND

ITEMS OF WORK IN

BUILDINGS: FORMWORKS

ENGR. JYZEL CRIS B. FACTOR

INTRODUCTION

The structural members of a building are built-up into its desired shapes and

dimensions through the use of forms. Forms are temporary boarding, sheathing or

pan used to produce the desired shape and size of concrete.

Forms must be simple and economically designed in such a manner that they are

easily removed and reassembled without damage to themselves or concrete.

Selection of FORMS are based on:

1. Cost of Materials;

2. Construction and assembling cost;

3. The number of times it can be used; and

4. Strength and resistance to pressure, tear and wear.

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

GREASING OF FORMS

Forms are constantly greased before using to make the wood waterproof preventing

the absorption of water in the concrete which causes swelling and warping. It also

prevents the adherence of concrete into the pores of the wood.

• Most economical material is Crude Oil. It is usually mixed with motor oil with a

proportion of 1:3 (or varying viscosity depending on the weather condition).

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

PLYWOOD AS CONSTRUCTION FORM

Advantages:

1. Economical

2. Lightweight and Handy

3. Smooth Surface

4. Less Consumption of Nails

5. Ease in Assembling and Disassembling

6. Available

Consideration

1. The thickness of the board to be used

2. The size of the frame

3. Types of framework to be adopted Continuous Rib Type Stud Type

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

PLYWOOD AS CONSTRUCTION FORM

Formula in Finding the Materials for Square and Rectangular Column Forms

1) P = 2(a+b)+0.20

where: P = lateral perimeter of the column

a = shorter side of the column

b = the longer side of the column

0.20 = constant value for the lapping of form joints

2) Multiply P by the height of one column times the member of columns to get the total area

of the forms.

3) Divide the total area found by 2.88 to get the number of plywood forms

4) Multiply the number of plywood found by 29.67 to get the board foot of frame required.

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

PLYWOOD AS CONSTRUCTION FORM

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

SCAFFOLDING AND STAGING

• Scaffolding is a temporary structure of wooden poles and planks providing

platform to stand on while erecting or repairing a building.

• Staging is a more substantial framework progressively built up as tall building

rises up. The term staging is applied because it is built up in stages one story at a

time.

• Different parts of staging are:

• Vertical support

• Footing base

• Horizontal braces

• Blocks and wedges support

• Nails

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

SCAFFOLDING AND STAGING

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

CONSTRUCTION FORMS

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

SAMPLE PROBLEM 1

Six concrete posts at 4m high

with a uniform cross sectional

dimensions of 0.30 x 0.40 m

using a plywood on a 2’’ x 2’’

wood frame. List down the

materials required using

continuous rib type forms.

Specify the use of 6 mm (1/4”).

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

SAMPLE PROBLEM 1

𝑺𝒐𝒍𝒗𝒊𝒏𝒈 𝒇𝒐𝒓 𝒕𝒉𝒆 𝑷𝒍𝒚𝒘𝒐𝒐𝒅 𝒇𝒐𝒓𝒎, 𝑷

𝑃 = 2 𝑎 + 𝑏 + 0.20

= 2 0.30 + 0.40 + 0.20

= 1.60 𝑚

𝐴 = 1.60 𝑥 4 𝑥 6 𝑐𝑜𝑙𝑢𝑚𝑛𝑠

= 38.4 𝑠𝑞𝑚

38.4

𝑁𝑜. 𝑜𝑓 𝑃𝑙𝑦𝑤𝑜𝑜𝑑 = = 𝟏𝟑. 𝟑𝟑 𝒔𝒂𝒚 𝟏𝟒 𝒑𝒊𝒆𝒄𝒆𝒔

2.88

𝑺𝒐𝒍𝒗𝒆 𝒇𝒐𝒓 𝒕𝒉𝒆 𝟐 x 2 wood frame

14 𝑃𝑙𝑦𝑤𝑜𝑜𝑑 𝑥 29.67 = 415.38 𝑏𝑑. 𝑓𝑡.

𝑶𝒓𝒅𝒆𝒓: 𝟏𝟒 𝑷𝒍𝒚𝒘𝒐𝒐𝒅 = 𝟒𝟏𝟔 𝒃𝒅. 𝒇𝒕.

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

SAMPLE PROBLEM 2

Ten concrete reinforced column

with a general cross sectional 0.40

dimensions of 0.40 x 0.60 m by

5.00 m long each requires

plywood form on a 2” x 2” Ht. = 5.00 m

frame. Order the materials 0.60

required.

CROSS SECTION ELEVATION

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

SAMPLE PROBLEM 2

𝑺𝒐𝒍𝒗𝒆 𝒇𝒐𝒓 𝒕𝒉𝒆 𝒍𝒂𝒕𝒆𝒓𝒂𝒍 𝒑𝒆𝒓𝒊𝒎𝒆𝒕𝒆𝒓 𝒐𝒇 𝒐𝒏𝒆 𝒄𝒐𝒍𝒖𝒎𝒏,

𝑃 = 2 𝑎 + 𝑏 + 0.20

0.40

= 2 0.40 + 0.60 + 0.20

= 2.20 𝑚𝑒𝑡𝑒𝑟𝑠

Ht. = 5.00 m

𝐴 = 2.20 𝑥 5.00 𝑥 10

0.60

= 110 𝑠𝑞𝑚

110

𝑁𝑜. 𝑜𝑓 𝑃𝑙𝑦𝑤𝑜𝑜𝑑 = = 𝟑𝟖. 𝟐 𝒔𝒂𝒚 𝟑𝟗 𝒑𝒊𝒆𝒄𝒆𝒔

2.88

CROSS SECTION ELEVATION

𝑺𝒐𝒍𝒗𝒆 𝒇𝒐𝒓 𝒕𝒉𝒆 𝟐 x 2 wood frame

39 𝑃𝑙𝑦𝑤𝑜𝑜𝑑 𝑥 29.67 = 1,157 𝑏𝑑. 𝑓𝑡.

𝑶𝒓𝒅𝒆𝒓: 𝟑𝟗 𝒑𝒄𝒔 𝟏/𝟒" 𝒙 𝟒′ 𝒙 𝟖′ 𝒑𝒍𝒚𝒘𝒐𝒐𝒅

𝟏, 𝟏𝟓𝟕 𝒃𝒐𝒂𝒓𝒅 𝒇𝒆𝒆𝒕 𝟐 x 2 𝒍𝒖𝒎𝒃𝒆𝒓

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

SAMPLE PROBLEM 3

A reinforced concrete building has 9 columns with a clear height of 4.00 meters. Determine the

required scaffolding under the following specifications: 2” x 3” Vertical Support; 2” x 2” Horizontal

and Diagonal braces.

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

SAMPLE PROBLEM 3

A reinforced concrete building has 9 columns with a clear height of 4.00 meters. Determine the

required scaffolding under the following specifications: 2” x 3” Vertical Support; 2” x 2” Horizontal

and Diagonal braces.

𝑺𝒄𝒂𝒇𝒇𝒐𝒍𝒅𝒊𝒏𝒈 𝒇𝒐𝒓 𝑪𝒐𝒍𝒖𝒎𝒏𝒔

𝑇𝑜𝑡𝑎𝑙 𝑙𝑒𝑛𝑔𝑡ℎ

= 4.00 𝑥 9 𝑐𝑜𝑙𝑢𝑚𝑛𝑠 = 36 𝑚𝑒𝑡𝑒𝑟𝑠

𝑈𝑠𝑖𝑛𝑔 2" x 3" 𝑣𝑒𝑟𝑡𝑖𝑐𝑎𝑙 𝑠𝑢𝑝𝑝𝑜𝑟𝑡

= 36 𝑥 7.00 = 252 𝑏𝑑. 𝑓𝑡. 2" x 3" x 14 ft

𝑈𝑠𝑖𝑛𝑔 2 x 2 𝑙𝑢𝑚𝑏𝑒𝑟 ℎ𝑜𝑟𝑖𝑧𝑜𝑛𝑡𝑎𝑙 𝑠𝑢𝑝𝑝𝑜𝑟𝑡

= 36 𝑥 21.00 = 756 𝑏𝑑. 𝑓𝑡. 2" x 3" lumber

𝐷𝑖𝑎𝑔𝑜𝑛𝑎𝑙 𝐵𝑟𝑎𝑐𝑒𝑠:

= 36 𝑥 11.7 = 421 𝑏𝑑. 𝑓𝑡. 2" x 2" lumber

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

SAMPLE PROBLEM 3

A reinforced concrete building has 9 columns with a clear height of 4.00 meters. Determine the

required scaffolding under the following specifications: 2” x 3” Vertical Support; 2” x 2” Horizontal

and Diagonal braces.

𝑺𝒄𝒂𝒇𝒇𝒐𝒍𝒅𝒊𝒏𝒈 𝒇𝒐𝒓 𝒕𝒉𝒆 𝑩𝒆𝒂𝒎𝒔

𝑇𝑜𝑡𝑎𝑙 𝑙𝑒𝑛𝑔𝑡ℎ

= 4.50 𝑥 6 + 4.00 𝑥 6 = 51 𝑚𝑒𝑡𝑒𝑟𝑠

𝑈𝑠𝑖𝑛𝑔 2" x 3" 𝑣𝑒𝑟𝑡𝑖𝑐𝑎𝑙 𝑠𝑢𝑝𝑝𝑜𝑟𝑡

= 51 𝑥 6.00 = 306 𝑏𝑑. 𝑓𝑡.

𝑈𝑠𝑖𝑛𝑔 2 x 2 𝑙𝑢𝑚𝑏𝑒𝑟 ℎ𝑜𝑟𝑖𝑧𝑜𝑛𝑡𝑎𝑙 𝑠𝑢𝑝𝑝𝑜𝑟𝑡

= 51 𝑥 4.70 = 240 𝑏𝑑. 𝑓𝑡.

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

SAMPLE PROBLEM 3

A reinforced concrete building has 9 columns with a clear height of 4.00 meters. Determine the

required scaffolding under the following specifications: 2” x 3” Vertical Support; 2” x 2” Horizontal

and Diagonal braces.

𝑺𝒄𝒂𝒇𝒇𝒐𝒍𝒅𝒊𝒏𝒈 𝒇𝒐𝒓 𝑪𝒐𝒏𝒄𝒓𝒆𝒕𝒆 𝑺𝒍𝒂𝒃

𝐴𝑟𝑒𝑎 𝑜𝑓 𝑡ℎ𝑒 𝑐𝑜𝑛𝑐𝑟𝑒𝑡𝑒 𝑓𝑙𝑜𝑜𝑟 𝑠𝑙𝑎𝑏

𝐴𝑟𝑒𝑎 = 4.50 𝑥 4.00 𝑥 4 𝑢𝑛𝑖𝑡𝑠 = 72 𝑠𝑞. 𝑚

𝑈𝑠𝑖𝑛𝑔 2" x 3" 𝑠𝑢𝑝𝑝𝑜𝑟𝑡

= 72 𝑥 9.10 = 655 𝑏𝑑. 𝑓𝑡.

𝑭𝒍𝒐𝒐𝒓 𝑺𝒍𝒂𝒃 𝑭𝒐𝒓𝒎𝒔

𝐴𝑟𝑒𝑎 𝑜𝑓 𝑡ℎ𝑒 𝑐𝑜𝑛𝑐𝑟𝑒𝑡𝑒 𝑓𝑙𝑜𝑜𝑟 𝑠𝑙𝑎𝑏

𝐴𝑟𝑒𝑎 = (4.50 𝑥 4.00 𝑥 4 𝑢𝑛𝑖𝑡𝑠) = 72 𝑠𝑞. 𝑚

𝐷𝑖𝑣𝑖𝑑𝑒 𝑏𝑦 2.88 𝑒𝑓𝑓𝑒𝑐𝑡𝑖𝑣𝑒 𝑐𝑜𝑣𝑒𝑟𝑖𝑛𝑔 𝑜𝑓 𝑜𝑛𝑒 𝑝𝑙𝑦𝑤𝑜𝑜𝑑

72

= = 25 𝑝𝑐𝑠. 4′ 𝑥 8′ 𝑚𝑎𝑟𝑖𝑛𝑒 𝑝𝑙𝑦𝑤𝑜𝑜𝑑

2.88

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

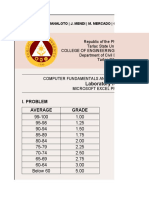

DETAILED UNIT PRICE ANALYSIS (DUPA)

Item No./Description 903(2) Formworks and Falseworks (for two to five-storey building)

Unit of Measurement m2

Output per hour 4.5 m2

Republic of the Philippines

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS Designation No. of Person/s No. of HourIs Hourly Rate Amount (PhP)

OFFICE OF THE SECRETARY A. Labor

Manila Installation

a. Construction Foreman 1 1.00 Labor Rates are variable per Region/District

based on minimum wage as approved by

b. Skilled Laborer 4 1.00

2 2 NOV 2011 c. Unskilled Laborer 6 1.00

DOLE. Refer to the Schedule of Labor Rates.

Stripping

a. Construction Foreman 1 0.56

- b. Unskilled Laborer 6 0.56

DEPARTMENT ORDER ) SUBJECT: Cost Estimation Manual for Low Sub - Total for A

Rise Buildings

NO. 137 l

.) B. Equipment

Name and Capacity Quantity No. of Dayls Daily Rental Rate Amount (PhP)

Series of 201~ ~.""'"'7

=

Area 205.01 m

2

a. H-Frame 1.7 m x 1.2m, set 40 14.00 Rental cost for scaffoldings may vary per

RegionlDistrict.

In line with the Department's Quality Policy to implement projects at the right cost, all 2 pes H-frames

Implementing Offices are hereby directed to adopt the herein Cost Estimation Manual 4 pcs diagonal cross braces

4 pcs horizontal braces

for Low Rise Buildings in the determination of unit cost of Pay Items of Work involved in

8 pcs joint pins

the construction and repair/retrofitting of low rise building projects. b. Shoring Jack, 3.8 m full extension 62 14.00

c. Adjustable U-head Jack, 0.6m 80 14.00

This Manual aims to enhance the technical capability of DPWH engineers in the preparation d. Adjustable Base Jack, 0.6m 80 14.00

and review of Program of Works (POW) and Approved Budget for the Contract (ABC) and to e. 1-1/2" GI Pipe x 6.0 m 62 14.00

f. 1-1/2" GI Pipe x 3.0 m 16 14.00

establish consistency in the format of preparation and serve as a uniform basis/reference in

g. 1-1/2" GI Pipe x 4.0 m 32 14.00

the derivation of unit cost for each item of work. It shall be distributed to all concerned h. 1-1/2" GI Pipe x 1.0 m 216 14.00

offices of the Department and uploaded in the DPWH Intranet. i. Tie Rod x 0.60m 278 14.00 .J

j. Round Wing Nut 558 14.00

Note:

This Order shall be consistent with the implementation of D.O. No. 163, Series of 2015 Area of considerationwas basedon the total area of

"Standard Forms of Program of Works (POW) and Approved Budget for the Contract (ABC)" formworksfor 2 baysof standardschoolbuilding,9.5 m x

9.0 m, and heightof 3.2m.

with modification on its format and description of item numb8'r and scope of works (Annex

A) to conform with the DPWH Standard Specifications for Public Works Structures, Volume Sub - Total for B

C. Sub - Total for C (B + Area)

III (Buildings, Ports and Harbors, Flood Control and Drainage Structures and Water Supply D. Output per Hour =

4.5 m2

Systems) and Standardized Pay Items of Work for Buildings as embodied in D.O. OS, Series E. Direct Unit Cost (A + D) + C

of 2017. Name and Specification Amount (PhP)

Unit Quantity Unit Cost

F. Materials

This Order shall take effect immediately. Prices of materials are variable per Regionl

District based on the prevailing unit prices in

~~----

('

a. Phenolic Board (0.019 x 1.2 x 2.4) - 5 uses pc 0.347 the locality which include payment of local

c. Good Lumber - 3 uses bd ft 4.727 taxes and hauling cost to the project site.

Refer to the Construction Material Price Data

b. Consumables (5% of Materials Cost)

established quarterly by Central Office Price

MARK A. VILLAR' Monitoring Committee.

SecretarY Sub - Total for F

G. Direct Unit Cost (E + F)

H. Overhead, Contingencies & Miscellaneous (OCM) Expenses 15%/12%/10%/8% of G

6.1.3 CSSD/BOC

I. Contractor's Profit (CP) 10%/8% of G

Depa,trrent of Public Works and Highways J. Value Added Tax (VAT) 5% of (G + H + I)

Office of the Secretary

K. Total Unit Cost (G + H + I + J)

1111111111111I11111111111111111111111 Note: 1. This cost sheet analysis is only applicable for Formworks and Falseworks considering steel scaffoldings for two to five

WIN7W02039 storey buildings.

2. Area of consideration includes beams, columns, and suspended slabs.

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

j. Round Wing Nut 558 14.00

Note:

Area of considerationwas basedon the total area of

formworksfor 2 baysof standardschoolbuilding,9.5 m x

9.0 m, and heightof 3.2m.

Sub - Total for B

C. Sub - Total for C (B + Area)

D. Output per Hour = 4.5 m2

E. Direct Unit Cost (A + D) + C

Name and Specification Unit Quantity Unit Cost Amount (PhP)

F. Materials

Prices of materials are variable per Regionl

District based on the prevailing unit prices in

a. Phenolic Board (0.019 x 1.2 x 2.4) - 5 uses pc 0.347 the locality which include payment of local

c. Good Lumber - 3 uses bd ft 4.727 taxes and hauling cost to the project site.

Refer to the Construction Material Price Data

b. Consumables (5% of Materials Cost)

established quarterly by Central Office Price

Monitoring Committee.

Sub - Total for F

G. Direct Unit Cost (E + F)

H. Overhead, Contingencies & Miscellaneous (OCM) Expenses 15%/12%/10%/8% of G

I. Contractor's Profit (CP) 10%/8% of G

J. Value Added Tax (VAT) 5% of (G + H + I)

K. Total Unit Cost (G + H + I + J)

Note: 1. This cost sheet analysis is only applicable for Formworks and Falseworks considering steel scaffoldings for two to five

storey buildings.

2. Area of consideration includes beams, columns, and suspended slabs.

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

6 1.00

Stripping

a. Construction Foreman 1 0.56

b. Unskilled Laborer 6 0.56

Sub - Total for A

Name and Capacity Quantity No. of Dayls Daily Rental Rate Amount (PhP)

B. Equipment

=

Area 205.01 m

2

a. H-Frame 1.7 m x 1.2m, set 40 14.00 Rental cost for scaffoldings may vary per

RegionlDistrict.

2 pes H-frames

4 pcs diagonal cross braces

4 pcs horizontal braces

8 pcs joint pins

b. Shoring Jack, 3.8 m full extension 62 14.00

c. Adjustable U-head Jack, 0.6m 80 14.00

d. Adjustable Base Jack, 0.6m 80 14.00

e. 1-1/2" GI Pipe x 6.0 m 62 14.00

f. 1-1/2" GI Pipe x 3.0 m 16 14.00

g. 1-1/2" GI Pipe x 4.0 m 32 14.00

h. 1-1/2" GI Pipe x 1.0 m 216 14.00

i. Tie Rod x 0.60m 278 14.00 .J

j. Round Wing Nut 558 14.00

Note:

Area of considerationwas basedon the total area of

formworksfor 2 baysof standardschoolbuilding,9.5 m x

9.0 m, and heightof 3.2m.

Sub - Total for B

C. Sub - Total for C (B + Area)

D. Output per Hour =

4.5 m2

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

DETAILED UNIT PRICE ANALYSIS (DUPA)

Item No./Description 903(2) Formworks and Falseworks (for two to five-storey building)

Unit of Measurement m2

Output per hour 4.5 m2

Designation No. of Person/s No. of HourIs Hourly Rate Amount (PhP)

A. Labor

Installation

a. Construction Foreman 1 1.00 Labor Rates are variable per Region/District

based on minimum wage as approved by

b. Skilled Laborer 4 1.00

DOLE. Refer to the Schedule of Labor Rates.

c. Unskilled Laborer 6 1.00

Stripping

a. Construction Foreman 1 0.56

b. Unskilled Laborer 6 0.56

Sub - Total for A

Name and Capacity Quantity No. of Dayls Daily Rental Rate Amount (PhP)

B. Equipment

=

Area 205.01 m

2

a. H-Frame 1.7 m x 1.2m, set 40 14.00 Rental cost for scaffoldings may vary per

MAPUA UNIVERSITY – School of Civil, Environmental and Geological Engineering

You might also like

- Design of Plate and Frame Filter PressDocument7 pagesDesign of Plate and Frame Filter PressEula Mae Carla Añonuevo80% (5)

- 3a. - Flexural Members Ce134p - Escruz - LRFDDocument42 pages3a. - Flexural Members Ce134p - Escruz - LRFDJed CernechezNo ratings yet

- Experimental Model of Cracking Induced by Drying ShrinkageDocument6 pagesExperimental Model of Cracking Induced by Drying ShrinkageNouha JhiderNo ratings yet

- A Rectification Manual - ExampleDocument41 pagesA Rectification Manual - Examplesorobanista100% (1)

- Siren BS1 - Rev-E PDFDocument2 pagesSiren BS1 - Rev-E PDFConstantin Gurzu0% (1)

- Masonry - Midterm Project PDFDocument11 pagesMasonry - Midterm Project PDFRaffy BufeteNo ratings yet

- Inbound 5608803688066540769Document12 pagesInbound 5608803688066540769Ceejay PalomaNo ratings yet

- Laboratory Work No. 1 Group 4Document22 pagesLaboratory Work No. 1 Group 4KNARF FRANKNo ratings yet

- 4.10 Design Procedure For Direct Design MethodDocument12 pages4.10 Design Procedure For Direct Design MethodMary Graçe ÇanoyNo ratings yet

- 1 325 1 MadjadoumbayeDocument5 pages1 325 1 MadjadoumbayeVidita RewayaniNo ratings yet

- JETIR1605042Document7 pagesJETIR1605042MeetNo ratings yet

- Geotechnical Engineering Example Exam QuestionsDocument7 pagesGeotechnical Engineering Example Exam Questionss041865No ratings yet

- College of Engineering and Technology Chemical Engineering DepartmentDocument6 pagesCollege of Engineering and Technology Chemical Engineering DepartmentKarl Raymundo100% (2)

- Final Hawassa Univiersity Sumplementary ExamDocument3 pagesFinal Hawassa Univiersity Sumplementary ExamArgaw Asha100% (4)

- Ay1920 Sem 2 Sce5322Document17 pagesAy1920 Sem 2 Sce5322Tsang Siu YiNo ratings yet

- Design Basis Report NewDocument29 pagesDesign Basis Report Newrpdharshan04No ratings yet

- 61562-Article Text-751375261078-1-10-20221220Document12 pages61562-Article Text-751375261078-1-10-20221220Prakash PrajapatiNo ratings yet

- Analysis For Force and Deformation of The Pile and Wall Interaction Based On Three MethodsDocument7 pagesAnalysis For Force and Deformation of The Pile and Wall Interaction Based On Three MethodsKaotzNo ratings yet

- Arakabe WallDocument6 pagesArakabe WallalliancerNo ratings yet

- A Study On A Two-Way Post-Tensioned Concrete Waffle Slab - ScienceDirectDocument8 pagesA Study On A Two-Way Post-Tensioned Concrete Waffle Slab - ScienceDirectusman javedNo ratings yet

- 5 - KhanDocument39 pages5 - KhanMuthu SaravanaNo ratings yet

- Optimal Design of The Shoring System: A Parametric Study: Bhanuchitra, M. Prusty, Sudhansu BhusanDocument4 pagesOptimal Design of The Shoring System: A Parametric Study: Bhanuchitra, M. Prusty, Sudhansu BhusanMalik RizwanNo ratings yet

- Screening and Size ReductionDocument9 pagesScreening and Size ReductionhanzomoniyanNo ratings yet

- Sound-Absorption Mechanism of Structures With Periodic CavitiesDocument13 pagesSound-Absorption Mechanism of Structures With Periodic CavitiesUty VictoriaNo ratings yet

- tmpEF67 TMPDocument4 pagestmpEF67 TMPFrontiersNo ratings yet

- OK CHAPTER 4 C. Technical - AspectDocument17 pagesOK CHAPTER 4 C. Technical - AspectEugene MirasNo ratings yet

- Assignment 2 EcgDocument5 pagesAssignment 2 EcgAtika NadhirahNo ratings yet

- A Study On Properties of Recycled Coarse Aggregate and It's ConcreteDocument11 pagesA Study On Properties of Recycled Coarse Aggregate and It's ConcreteJenish PatelNo ratings yet

- Strengthening of RCC Beams Using Bamboo Sticks: International Journal of Advanced Science and Technology June 2015Document11 pagesStrengthening of RCC Beams Using Bamboo Sticks: International Journal of Advanced Science and Technology June 2015Takko KaalevaNo ratings yet

- CE 316Document59 pagesCE 316Hasyb UllahNo ratings yet

- I. Anastasopoulos, V. Drosos, N. Antonaki, A. RontogianniDocument9 pagesI. Anastasopoulos, V. Drosos, N. Antonaki, A. RontogianniPoojaNo ratings yet

- S U R J S S: Indh Niversity Esearch Ournal (Cience Eries)Document4 pagesS U R J S S: Indh Niversity Esearch Ournal (Cience Eries)Seif EddineNo ratings yet

- Exterior Wood-Concrete Slabs, Experimentation and Modeling of Mechanical Behavior. Part 1Document6 pagesExterior Wood-Concrete Slabs, Experimentation and Modeling of Mechanical Behavior. Part 1Dario QuirogaNo ratings yet

- BT 4 WallDocument5 pagesBT 4 WallJuvelle CambiaNo ratings yet

- Mechanical Behaviour of Straw Construction FollowiDocument9 pagesMechanical Behaviour of Straw Construction FollowiTiberiu-Marius AvramNo ratings yet

- Static Bending Test On Timber SpecimenDocument14 pagesStatic Bending Test On Timber SpecimenEddie BowokuNo ratings yet

- Measures For Improving The Long-Term Durability of A Prestressed Concrete Bridge Using High-Strength ConcreteDocument9 pagesMeasures For Improving The Long-Term Durability of A Prestressed Concrete Bridge Using High-Strength ConcreteoscarariagnaNo ratings yet

- Vibration Analysis of Rotary Cement Kiln Using Fin 2Document5 pagesVibration Analysis of Rotary Cement Kiln Using Fin 2nunchakuNo ratings yet

- Totora1 PDFDocument10 pagesTotora1 PDFJ Armando Gastelo RoqueNo ratings yet

- Deformability Characteristics of Quarried RockfillDocument5 pagesDeformability Characteristics of Quarried Rockfillemreakinay84No ratings yet

- Structural Analysis of Laterally AeratedDocument9 pagesStructural Analysis of Laterally AeratedbailescuNo ratings yet

- Design and Analysis of Cinema TheaterDocument23 pagesDesign and Analysis of Cinema TheaterrajNo ratings yet

- Annen2IASS PDFDocument8 pagesAnnen2IASS PDFErika Paz YanezNo ratings yet

- 2009 JsceDocument11 pages2009 Jscetriple tripleNo ratings yet

- Ay1819 Sem 2 Sce5322Document9 pagesAy1819 Sem 2 Sce5322Tsang Siu YiNo ratings yet

- Chopra, Sharma Professor, Kumar Professor - 2014 - Regression Models For The Prediction of Compressive Strength of Concrete With & WithoDocument8 pagesChopra, Sharma Professor, Kumar Professor - 2014 - Regression Models For The Prediction of Compressive Strength of Concrete With & WithomushfiqueNo ratings yet

- Experimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)Document12 pagesExperimental Investigation of High Strength Precast Reinforced Concrete Walls Used (Vierendeel Truss Form)emad mohamedNo ratings yet

- 3 Point Bend Test ReportDocument26 pages3 Point Bend Test ReportphschemguyNo ratings yet

- MN6124 Design of Underground StructuresDocument2 pagesMN6124 Design of Underground Structureswilsonaustin963No ratings yet

- 3-R 0.67 in Plaxis Centrifuge and Numerical Investigations of Rotated Box StructuresDocument6 pages3-R 0.67 in Plaxis Centrifuge and Numerical Investigations of Rotated Box StructuresthamiradNo ratings yet

- 12 FORMS Measuring QuanititiesDocument31 pages12 FORMS Measuring Quanititiesdebbydebby121101No ratings yet

- Thesis FulltextDocument354 pagesThesis FulltextcrvishnuramNo ratings yet

- CE-341 Lec 2Document13 pagesCE-341 Lec 2Hexxacord The BetterNo ratings yet

- Fracture Toughness of Ultra High Performance Concrete Subjected To FlexureDocument7 pagesFracture Toughness of Ultra High Performance Concrete Subjected To FlexuregauthamNo ratings yet

- SegmentedSpiral PDFDocument8 pagesSegmentedSpiral PDFErika Paz YanezNo ratings yet

- Application of Bousinesq's and Westergaard's Formulae in Analysing Foundation Stress Distribution For A Failed Telecommunication MastDocument7 pagesApplication of Bousinesq's and Westergaard's Formulae in Analysing Foundation Stress Distribution For A Failed Telecommunication MastJoshua Ian Gallardo AbanNo ratings yet

- Finite Element Analysis of IPN Reinforced Woven Fabric CompositeDocument6 pagesFinite Element Analysis of IPN Reinforced Woven Fabric CompositeCody LeeNo ratings yet

- Interlocking Paver BlocksDocument9 pagesInterlocking Paver BlocksfaresNo ratings yet

- Al Agha 2021Document10 pagesAl Agha 2021Qorry OktaliaNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- 3Q2021 CE123 2 C4 A01 G02 DeLeon Demerin Diones Doblon Dolojan Ebue Endaya Esteron PDFDocument6 pages3Q2021 CE123 2 C4 A01 G02 DeLeon Demerin Diones Doblon Dolojan Ebue Endaya Esteron PDFricca javierNo ratings yet

- Benosa Assesment PDFDocument3 pagesBenosa Assesment PDFricca javierNo ratings yet

- Ce2211 Cip 3ceb Mendoza-Gabilo-1Document3 pagesCe2211 Cip 3ceb Mendoza-Gabilo-1ricca javierNo ratings yet

- Research StudyDocument13 pagesResearch Studyricca javierNo ratings yet

- Cwts Essay#1Document1 pageCwts Essay#1ricca javierNo ratings yet

- OWG000016 WCDMA-CS Basic Conception, Principle and Basic Call Flow Introduction-Modified by 00712925Document78 pagesOWG000016 WCDMA-CS Basic Conception, Principle and Basic Call Flow Introduction-Modified by 00712925haytham_501No ratings yet

- NEW Fees Record 2010-11Document934 pagesNEW Fees Record 2010-11manojchouhan2014No ratings yet

- Astm D3202 - 1 (En)Document3 pagesAstm D3202 - 1 (En)Dinesh SaiNo ratings yet

- Peritonitis Capd-1Document15 pagesPeritonitis Capd-1David SenNo ratings yet

- Sant Rajinder Singh Ji Maharaj - Visions of The New MilleniumDocument8 pagesSant Rajinder Singh Ji Maharaj - Visions of The New MilleniumjjcalderNo ratings yet

- Johns Hopkins RFPDocument7 pagesJohns Hopkins RFPLucky 77No ratings yet

- Pe Lesson 2Document2 pagesPe Lesson 2Jessa De JesusNo ratings yet

- UM Panabo College: Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Document18 pagesUM Panabo College: Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Kenneth PadaoNo ratings yet

- MCQ IadDocument23 pagesMCQ Iads soyaNo ratings yet

- Separators of Different GenerationsDocument46 pagesSeparators of Different GenerationsISLAM I. Fekry100% (8)

- Solution-Focused Nursing Rethinking Prac PDFDocument1 pageSolution-Focused Nursing Rethinking Prac PDFSHUMETNo ratings yet

- Michael Downs - Lacan's Concept of The Object-Cause of Desire (Objet Petit A)Document23 pagesMichael Downs - Lacan's Concept of The Object-Cause of Desire (Objet Petit A)JustinWagnerNo ratings yet

- RESEARCH PROPOSAL Detriorating Standard of Education in PakistanDocument12 pagesRESEARCH PROPOSAL Detriorating Standard of Education in Pakistanjaydee_atc581454% (13)

- Themes: Themes, Motifs and SymbolsDocument6 pagesThemes: Themes, Motifs and SymbolsTanu ManochaNo ratings yet

- IS 15394.2003 Fire Safety in Petroleum RefineriesDocument16 pagesIS 15394.2003 Fire Safety in Petroleum RefineriesnpwalNo ratings yet

- Workshop 9 FUTURE TENSES-2Document3 pagesWorkshop 9 FUTURE TENSES-2FABIAN ANDRES VILLANUEVA SANCHEZNo ratings yet

- 11-40 - SINUMERIK Edge - Concept - AppsDocument15 pages11-40 - SINUMERIK Edge - Concept - AppsAshish PatwardhanNo ratings yet

- Innovative Strategies For Flood-Resilient CitiesDocument50 pagesInnovative Strategies For Flood-Resilient CitiesDaisy100% (1)

- Statements: Sources of The Medical Myths and Quack PracticesDocument6 pagesStatements: Sources of The Medical Myths and Quack PracticesLoreta De GuzmanNo ratings yet

- A Z of Simple Living BookDocument68 pagesA Z of Simple Living Bookdrsubramanian100% (4)

- MiraglianoDocument52 pagesMiraglianohansudongNo ratings yet

- Notice: Medicare: Emergency Medical Treatment and Labor Act Technical Advisory GroupDocument2 pagesNotice: Medicare: Emergency Medical Treatment and Labor Act Technical Advisory GroupJustia.comNo ratings yet

- Result Awaited FormDocument1 pageResult Awaited FormRoshan kumar sahu100% (1)

- Water Availability and Resources 23-06-23Document29 pagesWater Availability and Resources 23-06-23apoorva apoorvaNo ratings yet

- Lecture 14 - FAULT TREE ANALYSIS (FTA) - Cut-Set MethodDocument18 pagesLecture 14 - FAULT TREE ANALYSIS (FTA) - Cut-Set MethodBalamurugan ThirunavukkarasuNo ratings yet

- '21 Kona Bicycles Owner's Manual PDFDocument46 pages'21 Kona Bicycles Owner's Manual PDFInsight PeruNo ratings yet

- Ultra Tech Cement Review 16 9 19Document3 pagesUltra Tech Cement Review 16 9 19vivekNo ratings yet

- Kramapatha DevasthaliDocument11 pagesKramapatha DevasthaliDeepro ChakrabortyNo ratings yet