Professional Documents

Culture Documents

TDS Motor Reprot

TDS Motor Reprot

Uploaded by

Sanju laaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS Motor Reprot

TDS Motor Reprot

Uploaded by

Sanju laaCopyright:

Available Formats

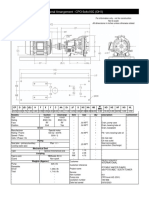

FINAL REPORT

FINAL PACKING REPORT

REPORT DATE 3-Nov-21 PACKED DATE 6-Nov-21

CUSTOMER NAME SHELF DRILLING OFFSHORE IDM JOB NO 66568

CUSTOMER P.O 10349042 MAKE GE

EMAIL: ajay.bhutani@shelfdrilling.com MOTOR SERIAL NO EE98050048

CUSTOMER REFERENCE NO - VOLTS 750

IP - AMPS 1160

RPM 1060 HP/KW/KVA 1105 HP

HZ - TYPE SHUNT

MODEL NO: 752US 2 PART NO:- -

Visual Overview

Before After

DE SIDE VIEW DE SIDE VIEW

LEFT SIDE VIEW LEFT SIDE VIEW

REMARKS

1 Armature - cleaned and overhauled

2 Commutator - machine true and under cut done

3 Fitted new shunt field 1 coil & (rest of coil cleaned and overhauled)

4 Reclaimed de side bearing houisng

5 Fitted new - carbon brushes , terminal leads & bearings

Note As per customer instruction pinion is not fitted

SAYYED. THALHATH

Prepared By: SAYYED. THALHATH Approved By: K PATIL

INT-F087, Rev 00, Dtd; 20-Mar-19 1 of 14 Intersel Dowding Mills

FINAL CONDITION REPORT

PART FAULT CORRECTIVE ACTION RESULT

Armature dirty/contaminated cleaned and overhauled PASS

Stator dirty/contaminated cleaned and overhauled PASS

Shunt Field overheat Fitted 1 ( No's ) coil PASS

Interpole dirty/contaminated cleaned and overhauled PASS

Commutator dirty/contaminated machine true and under cut done PASS

Brush gear dirty/contaminated cleaned and overhauled PASS

Carbon Brushes worn out replaced PASS

Terminals dirty/contaminated replaced PASS

Heaters dirty/contaminated cleaned and overhauled PASS

Housing D.E. Housing measurements are out of tolerance reclaimed PASS

Housing N.D.E. dirty/contaminated cleaned and overhauled PASS

Inner grease cap D.E dirty/contaminated cleaned and overhauled PASS

Inner grease cap N.D.E N/A N/A NA

Outer grease cap D.E dirty/contaminated cleaned and overhauled PASS

Outer grease cap N.D.E dirty/contaminated cleaned and overhauled PASS

Seating D.E. dirty/contaminated cleaned and overhauled PASS

Seating N.D.E. dirty/contaminated cleaned and overhauled PASS

Ext. Shaft dirty/contaminated cleaned and overhauled PASS

TIR Runout ok ok PASS

Bearings D.E. worn replaced PASS

Bearings N.D.E. worn replaced PASS

Assembled By: KASHEM Approved By: RAM

INT-F087, Rev 00, Dtd; 20-Mar-19 2 of 14 Intersel Dowding Mills

FINAL CONDITION REPORT

BEARING DETAILS

ITEM AFTER REPAIR

REMARK

DE NDE

6326 -M-C4

Bearing No. 558830 C ( FAG) Replaced

(FAG)

Bearing Seat 150.03 130.03 cleaned and overhauled

Bearing Housing 320.00 280.01 reclaimed de side bearing housing

DE Bearing Runout outer

0.05 mm Commutator Run out 0.2 mm

Race

DE Bearing radial clearance 0.12 mm Commutator Diameter 420.1 mm

NDE Bearing Runout outer Commutator Mica

0.031 mm 1 mm

Race Undercut

Brush holder to

NDE Bearing radial clearance 0.084 mm 2 mm

commutator clearance

Armature end float 0.20 mm

Pole bore dia. Interpole coils 1-3 499 mm 2-4 499 mm

Pole bore dia. Field coils 1-3 499 mm 2-4 499 mm

Descriptions % Cold Fit C Hot Fit D Advance E Fit Type F

Before Dismantaling - Hub (NDE SIDE) 85%

Final 90% 11.8 mm 8.6 mm 3.2 mm B

COUPLING HUB FIT TYPE

STAND OFF

COLD OFF

Assembled By: KASHEM Approved By: RAM

INT-F087, Rev 00, Dtd; 20-Mar-19 3 of 14 Intersel Dowding Mills

ULTRA SONIC EXAMINATION REPORT

Date 14-Apr-21 Report No 66568

Customer SHELF DRILLING OFFSHORE Equipment Model Arjun 30

Dwg. No.: NA Equipment Serial No AJ0423-9110

Location : IDM Workshop Calibration Certificate 11-C374353

Item Description/ Tested DE Side Calibration Due 12th Jan 2022

Post weld Heat treatment (If

N/A Ref.Calibration block & ID No V1 Block & 17040029/D1.06/C-2

applicable)

Material Grade/Thickness Alloy Steel EN24 Testing Method Manual Contact

Surface Condition Satisfactory Couplant POLYCEL

Material Temperature Ambient Reportable Indication level ASTM SA388

Number of Repairs (If specific

NO Acceptable Indication level ASTM SA388

areas are repaired)

Test Specification Test procedure Acceptance Criteria

ASME SEC-V INT-NDT-UT-01 ASTM SA388

Size/ Extend of

Search Unit/Type Ref: DB Scanning DB T-Correction Screen Range

Frequency examination

0° 10MM/2Mhz 100% 37dB +6dB --- 0-290 mm

45° 10MM/4Mhz 100% 39dB +6dB --- 0- 310 mm

Inspection Photos

Inspection Photo UT Machine Scanning Photo

EXAMINATION RESULT / REMARKS: NO RELEVANT INDICATIONS WAS OBSERVED DURING THE TIME OF INSPECTION.

Quality Control NDT Inspector Client Inspector

Name: K PATIL Name: SAYYED. THALHATH Name:

Sign: Sign: Sign:

INT-F087, Rev 00, Dtd; 20-Mar-19 4 of 14 Intersel Dowding Mills

BALANCING REPORT

PHOTOS DESCRIPTION

INITIAL REPORT

PHOTOS DESCRIPTION

FINAL REPORT

Prepared By: BIJU Approved By: RAM

INT-F087, Rev 00, Dtd; 20-Mar-19 5 of 14 Intersel Dowding Mills

ELECTRICAL STATIC TEST RECORD

ELECTRICAL TEST

CONNECTION TYPE SERIES SHUNT OPEN

1-INSULATION RESISTANCE MEASURED VALUES

o

Stator EQI No Insulation resistance-60s Converted to 40 C Temp Analysis

Shunt Field 30 500 (V) (V)

o

1660 MΩ 1095 MΩ 34 C OK

Armature+Interpole 30 500 (V) (V)

o

916 MΩ 604 MΩ 34 C OK

Acceptence Criteria IR1 Min >5MΩ at 40°C as per IEEE43:2000

2-WINDING RESISTANCE MEASURED VALUES

Ambient

x EQI No Analysis

Temp°C

Shunt Field 47 1.424 Ω 34 OK

Armature+Interpole 47 25.21 mΩ 34 OK

5-SURGE TEST Armature 6-BAKER TEST

RESULT PASS RESULT N/A

7-ACCESSORIES TEST

PARTS EQI No IR Thermistor Resistance RESULT

Heater IR 30 250 (V) 11 GΩ N/A

Heater

583 125.4 Ω CONNECTED IN PARALLEL PASS

Resistance

No of Heater 2 Nos Heater Type EX TYPE

Prepared By: SHAMSUDEEN Approved By: FAREED

INT-F087, Rev 00, Dtd; 20-Mar-19 6 of 14 Intersel Dowding Mills

FINAL NO LOAD TEST RECORD

Shunts Shunts

Amb oC/ Armature Temp. BRG Arm. Volts Arm. Amps Speed NDE Vibration mm/s RMS DE Vibration mm/s RMS

Time/Min Stator Volts Amps

%RH Temp

DE NDE Var Iar Vshunt Ishunt rpm H V A H V A

INITIAL 32 32 32 32 32 176 6.35 40.64 31.75 305

15 Min 32 33 33 33 33 345 8.44 40.9 31.09 604

30 Min 33 34 34 41 34 511 9.27 40.86 30.41 905

45 Min 33 36 36 49 36 509 10.05 40.87 29.94 906

60 Min 33 38 38 54 37 508 10.01 40.89 29.61 909 1.29 1.76 1.88 2.12 1.8 1.66

75 Min 34 40 40 60 38 508 9.36 40.96 29.25 914

90 Min 34 41 41 62 39 508 9.53 40.99 29.1 916

105 Min 34 42 42 63 40 509 9.71 41.15 28.95 919

120 Min 34 43 43 64 40 510 9.92 41.22 28.87 921 1.4 1.87 1.9 2.19 1.98 2.02

Remarks

Prepared By: SHAMSUDEEN Approved By: FAREED

Format Number : INT-F145,Rev 00, Dt-14-Nov-2020 Page 1 of 1 Intersel Dowding & Mills UAE

INT-F087, Rev 00, Dtd; 20-Mar-19 7 of 14 Intersel Dowding Mills

FINAL INSPECTION PHOTOS

PHOTOS DESCRIPTION

STATOR WINDING - CLEANED AND OVERHAULED

PHOTOS DESCRIPTION

ARMATURE DYNAMIC BALANCING DONE

PHOTOS DESCRIPTION

ARMATURE - CLEANED AND OVERHAULED

Prepared By:SAYYED Approved By: GIPIN

INT-F087, Rev 00, Dtd; 20-Mar-19 8 of 14 Intersel Dowding Mills

FINAL INSPECTION PHOTOS

PHOTOS DESCRIPTION

BRUSH GEAR - CLEANED AND OVERHAULED

PHOTOS DESCRIPTION

RECLAIMED DE SIDE BEARING HOUSING

PHOTOS DESCRIPTION

NDE SIDE BEARING HOUSING AND DE SIDE INNER GREASE CAP - CLEANED AND

OVERHAULED

Prepared By:SAYYED Approved By: GIPIN

INT-F087, Rev 00, Dtd; 20-Mar-19 9 of 14 Intersel Dowding Mills

FINAL INSPECTION PHOTOS

PHOTOS DESCRIPTION

NDE SIDE END SHIELD - CLEANED AND OVERHAULED

PHOTOS DESCRIPTION

FITTED NEW DE SIDE BEARING

PHOTOS DESCRIPTION

FITTED NEW NDE SIDE BEARING

Prepared By:SAYYED Approved By: GIPIN

INT-F087, Rev 00, Dtd; 20-Mar-19 10 of 14 Intersel Dowding Mills

FINAL INSPECTION PHOTOS

PHOTOS DESCRIPTION

DE SIDE VIEW

PHOTOS DESCRIPTION

LEFT SIDE VIEW

PHOTOS DESCRIPTION

RIGHT SIDE VIEW

Prepared By:SAYYED Approved By: GIPIN

INT-F087, Rev 00, Dtd; 20-Mar-19 11 of 14 Intersel Dowding Mills

FINAL INSPECTION PHOTOS

PHOTOS DESCRIPTION

NDE SIDE VIEW

PHOTOS DESCRIPTION

NAME PLATE

PHOTOS DESCRIPTION

IDM NAME PLATE

Prepared By:SAYYED Approved By: GIPIN

INT-F087, Rev 00, Dtd; 20-Mar-19 12 of 14 Intersel Dowding Mills

CUSTOMER WITNESS REPORT

Prepared By: SHAMSUDDEN Approved By: AWN

INT-F007, Rev 00, Dtd; 20-Nov-18 13 of 14 Intersel Dowding Mills

Intersel Dowding & Mills

P O Box 18092, Jebel Ali Freezone,

Dubai, UAE

Tel: +971-48833661, Fax: +971-48833662

Certificate of Conformance

Item Description Details

Completion Date 6-Nov-21

Customer Name SHELF DRILLING OFFSHORE

IDM Job Number 66568

Customer PO No 10339042

Customer Refernce No -

Motor Serial No EE98050048

Make GE

Volts 750

HP/KW/KVA 1105 HP

Amps 1160

RPM 1060

HZ -

Declaration

This is to certify that Equipments with details recorded above, has been

overhauled/repaired in accordance with the customer scope of work, the OEM specified

tolerances, and our quotation.

JAMES HARRIS DEWEY

General Manager

6-Nov-21

INT-F087, Rev 00, Dtd; 20-Mar-19 14 of 14 Intersel Dowding Mills

You might also like

- HL510-HL 560 Technical ManualDocument61 pagesHL510-HL 560 Technical ManualAJAYKUMAR PUND83% (6)

- Rockdrill HLX5TDocument72 pagesRockdrill HLX5TJosue100% (2)

- OPL 07 ZSE16 Reporting and TablesDocument12 pagesOPL 07 ZSE16 Reporting and Tablesduran_jxcsNo ratings yet

- p-47 Wn-Book Writing Layout TemplateDocument34 pagesp-47 Wn-Book Writing Layout Templateapi-256878326No ratings yet

- Job Card-TPN 1010-B151Document2 pagesJob Card-TPN 1010-B151Debasis Pattnaik DebaNo ratings yet

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocument2 pagesEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaNo ratings yet

- Job Card-TPN 1010-B150Document2 pagesJob Card-TPN 1010-B150Debasis Pattnaik DebaNo ratings yet

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocument2 pagesEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaNo ratings yet

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocument2 pagesEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaNo ratings yet

- Job Card-TPN 1010-B152Document2 pagesJob Card-TPN 1010-B152Debasis Pattnaik DebaNo ratings yet

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocument2 pagesEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaNo ratings yet

- Job Card-TPN 1010-B147Document2 pagesJob Card-TPN 1010-B147Debasis Pattnaik DebaNo ratings yet

- Numbers Sheet Name Numbers Table NameDocument50 pagesNumbers Sheet Name Numbers Table NameMehul ShuklaNo ratings yet

- Instrument Data Sheets: Revision HistoryDocument9 pagesInstrument Data Sheets: Revision Historyerik masongNo ratings yet

- AHU Report SummaryDocument4 pagesAHU Report SummaryAbdul Rauf KhanNo ratings yet

- IsuzuDocument1 pageIsuzuFarhan Sheikh100% (1)

- Bombas Agua PotableDocument1 pageBombas Agua PotableRafael SalazarNo ratings yet

- Scan 27 Apr 2020Document1 pageScan 27 Apr 2020Ostian MNo ratings yet

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocument2 pagesEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaNo ratings yet

- AJS Geared Motorcycle Maintenance Operation ManualDocument2 pagesAJS Geared Motorcycle Maintenance Operation ManualJoe SmithNo ratings yet

- WO Manual DZ-041 30-12-22Document1 pageWO Manual DZ-041 30-12-22Taufiq SetyaNo ratings yet

- Shutdown Valve Data Sheets: Customer Name: Cpe Job #: Project TitleDocument2 pagesShutdown Valve Data Sheets: Customer Name: Cpe Job #: Project TitleImmanuelNo ratings yet

- Johnston 5000 Series Service Training InformationDocument63 pagesJohnston 5000 Series Service Training InformationVygintas BalciusNo ratings yet

- A43D Transmission Service and Repair ManualDocument126 pagesA43D Transmission Service and Repair Manualrianyuda68No ratings yet

- Toyota A541E Transmission Repair ManualDocument133 pagesToyota A541E Transmission Repair Manualhigas100% (1)

- Pallava Granite Industries (India) PVT - LTD Manubolu Maintenance Prevetive Maintenance PlanDocument13 pagesPallava Granite Industries (India) PVT - LTD Manubolu Maintenance Prevetive Maintenance Planp kishorNo ratings yet

- Assorted Yaounde Inventory Item ListDocument3 pagesAssorted Yaounde Inventory Item ListzekizitoNo ratings yet

- Gad PSVDocument1 pageGad PSVNARAYAN DESAINo ratings yet

- Itr# 23023Document12 pagesItr# 23023moazzaomNo ratings yet

- RG Compressor IGV GE-MS5001PDocument11 pagesRG Compressor IGV GE-MS5001Pejzuppelli8036No ratings yet

- NDT Report - Old.Turbine BearingsDocument3 pagesNDT Report - Old.Turbine BearingsOm Ar TanNo ratings yet

- Service Manual Service Manual: TA-RW255Document106 pagesService Manual Service Manual: TA-RW255JAIME ALBERTO MARTINEZ DIAZNo ratings yet

- Spare Parts ListsDocument9 pagesSpare Parts Liststebohojafta0No ratings yet

- SIR Add. Turbin PT. SMSEDocument4 pagesSIR Add. Turbin PT. SMSEMuhammad ZakiNo ratings yet

- Doosan RSP1 FDocument3 pagesDoosan RSP1 FPartsHeavy HeavyParts0% (1)

- DCS No 12 - Steering Hard - Poor ReturnabilityDocument1 pageDCS No 12 - Steering Hard - Poor Returnabilityservicemanager.bkdNo ratings yet

- Chapter 03Document49 pagesChapter 03Ubeimar Rivera Ospina100% (1)

- Order hc95Document2 pagesOrder hc95Rodrigo Bernal (Subterra)100% (1)

- P030-E-1055A Job Map 2025 TADocument2 pagesP030-E-1055A Job Map 2025 TAabhijeetrnairNo ratings yet

- HMTS PM Check SheetDocument1 pageHMTS PM Check SheetFernando LourençoNo ratings yet

- Inq. 4502Document27 pagesInq. 4502srave_k07No ratings yet

- TW500W 1 20327Document1 pageTW500W 1 20327WilberZangaNo ratings yet

- Chillers Technical SpecificationDocument3 pagesChillers Technical SpecificationPARTHIBAN RETECHNo ratings yet

- Adobe Scan 18 Jul 2023Document1 pageAdobe Scan 18 Jul 2023Anish Krishna AniNo ratings yet

- Planning Job Rni Goh D155a-6Document144 pagesPlanning Job Rni Goh D155a-6Eza IRNo ratings yet

- T Screamer DatasheetDocument6 pagesT Screamer DatasheetEugy AlexNo ratings yet

- PS PC200-8Document1 pagePS PC200-8asvdfmcbdiNo ratings yet

- Yamaha HTR 5890Document91 pagesYamaha HTR 5890Derek HypsNo ratings yet

- Den-Jet Cd25 Series Broshure 2014Document2 pagesDen-Jet Cd25 Series Broshure 2014Welly AndilNo ratings yet

- DCS No 15 - AC Not Working - Less EffecctiveDocument2 pagesDCS No 15 - AC Not Working - Less Effecctiveservicemanager.bkdNo ratings yet

- Minor CAN 3 Issue 4.0.1 (English)Document48 pagesMinor CAN 3 Issue 4.0.1 (English)Ana IancuNo ratings yet

- HRSB ReportDocument6 pagesHRSB ReportelektroservemelakaNo ratings yet

- CD25 enDocument2 pagesCD25 enHugo Medina RodriguezNo ratings yet

- MS DD 3000 HSE FRM 0029 - MEWP - Inspection - ChecklistDocument1 pageMS DD 3000 HSE FRM 0029 - MEWP - Inspection - ChecklistcrystinNo ratings yet

- Minor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsDocument46 pagesMinor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsBogdan NgrNo ratings yet

- Discontinuation of The Filter Assy.: Applicable Models Differential Type IPHMDocument2 pagesDiscontinuation of The Filter Assy.: Applicable Models Differential Type IPHManggieNo ratings yet

- DF 02 031 PDFDocument2 pagesDF 02 031 PDFanggieNo ratings yet

- Datasheet - Chemical Centrifugal PumpDocument4 pagesDatasheet - Chemical Centrifugal PumpSid Esterico SestosoNo ratings yet

- Preventive Maintenance Inspection: Recommended Minimum FormDocument2 pagesPreventive Maintenance Inspection: Recommended Minimum FormJune AlapaNo ratings yet

- Commissioning Sheet 2Document1 pageCommissioning Sheet 2ABHISHEK SHARMANo ratings yet

- Worm HDR Gear Reducer BrochureDocument2 pagesWorm HDR Gear Reducer BrochureWilson Orlando Salinas SalinasNo ratings yet

- Attention-Port Jacking Gearbox-Leg Chord 2-4-09-11-2020Document2 pagesAttention-Port Jacking Gearbox-Leg Chord 2-4-09-11-2020Sanju laaNo ratings yet

- Attention-Bow Jacking Gearbox-Leg Chord 1-1-09-11-2020Document2 pagesAttention-Bow Jacking Gearbox-Leg Chord 1-1-09-11-2020Sanju laaNo ratings yet

- OWS Calibration CertificateDocument1 pageOWS Calibration CertificateSanju laaNo ratings yet

- Mi SwacoDocument8 pagesMi SwacoSanju laaNo ratings yet

- PCB STP DWG220221115 - 17413120Document1 pagePCB STP DWG220221115 - 17413120Sanju laaNo ratings yet

- Rheem CommElec HeavyDutyElec SpecSheetDocument4 pagesRheem CommElec HeavyDutyElec SpecSheetSanju laaNo ratings yet

- PWM Gerorge Brake Lists-Prodlin3-1Document5 pagesPWM Gerorge Brake Lists-Prodlin3-1Sanju laaNo ratings yet

- Data+Safe+ +FAQ+ +january+2024Document8 pagesData+Safe+ +FAQ+ +january+2024itengg52No ratings yet

- 854 Fe 34 TaDocument27 pages854 Fe 34 TapepppeNo ratings yet

- Route CommandDocument5 pagesRoute Commandkapil514No ratings yet

- Plans and DrawingsDocument34 pagesPlans and Drawingsgabriel.dufflisNo ratings yet

- The Hitchhiker's Guide To Operating SystemsDocument16 pagesThe Hitchhiker's Guide To Operating SystemsBùi Thị Như QuỳnhNo ratings yet

- Frame Loss Definition CountersDocument8 pagesFrame Loss Definition CountersPraveenNo ratings yet

- SOS Inventory User GuideDocument92 pagesSOS Inventory User GuideLaura Belana SanchezNo ratings yet

- RTL Compiler SynthesisDocument22 pagesRTL Compiler Synthesissureg7No ratings yet

- OECD Rethinking ApproachesDocument242 pagesOECD Rethinking ApproachesAbiNo ratings yet

- Mobile App DevelopmentDocument198 pagesMobile App Developmentnipuni webNo ratings yet

- Patni ContactsDocument40 pagesPatni ContactsMava SalesNo ratings yet

- Filmora Account 2023Document1 pageFilmora Account 2023حمزة حجازي100% (1)

- MISys - Guide - Level 1 B PDFDocument54 pagesMISys - Guide - Level 1 B PDFcaplusincNo ratings yet

- Disk Scheduling FullDocument12 pagesDisk Scheduling FullAhmad Khairil100% (2)

- Finite Element Analysis (FEA) : About KARE Chief PatronsDocument2 pagesFinite Element Analysis (FEA) : About KARE Chief PatronscvkcvkNo ratings yet

- Boge Ratio Operating InstructionsDocument31 pagesBoge Ratio Operating InstructionsErwan Le GuenNo ratings yet

- Learn Java - Inheritance and Polymorphism Cheatsheet - CodecademyDocument4 pagesLearn Java - Inheritance and Polymorphism Cheatsheet - CodecademyIliasAhmed0% (1)

- Schneider A9F 74206Document2 pagesSchneider A9F 74206Rasek ResolfNo ratings yet

- EU Stage IV Engine: Rigid Backhoe LoaderDocument2 pagesEU Stage IV Engine: Rigid Backhoe LoaderMoklasNo ratings yet

- Brochure-Workshop On Coolant ChannelDocument2 pagesBrochure-Workshop On Coolant ChannelsinghrituspNo ratings yet

- Agile Unit 3Document46 pagesAgile Unit 3SaHiLNo ratings yet

- A118485204 24963 12 2021 AssignmentCHE110Document7 pagesA118485204 24963 12 2021 AssignmentCHE110Akshay GuptaNo ratings yet

- TechData Invoice 8040519962Document2 pagesTechData Invoice 8040519962Vidal RodriguezNo ratings yet

- L1 IT9 Creating Websites (Website Builders)Document3 pagesL1 IT9 Creating Websites (Website Builders)Hannah SageNo ratings yet

- Airline Documentation FinalDocument86 pagesAirline Documentation FinalSuman RijalNo ratings yet

- Uddi - Universal Description, Discovery InterfaceDocument39 pagesUddi - Universal Description, Discovery InterfaceKGS-CSE PSG CTNo ratings yet

- Claude E. Shannon, N.J.A. Sloane, Aaron D. Wyner - Collected Papers of Claude E. Shannon (1993, IEEE Press) PDFDocument954 pagesClaude E. Shannon, N.J.A. Sloane, Aaron D. Wyner - Collected Papers of Claude E. Shannon (1993, IEEE Press) PDFCarlos Eduardo Correa Roque100% (2)

- Autopipe Variante PDFDocument4 pagesAutopipe Variante PDFLe Thanh HaiNo ratings yet