Professional Documents

Culture Documents

QUICRUNWPCRAWLERBRUSHED

QUICRUNWPCRAWLERBRUSHED

Uploaded by

Helmy IhsanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QUICRUNWPCRAWLERBRUSHED

QUICRUNWPCRAWLERBRUSHED

Uploaded by

Helmy IhsanCopyright:

Available Formats

3

01 Introduction

Programmable Items

Those “black background and white text” options are the factory default settings.

USER MANUAL Congratulations and thank you for your trust in Hobbywing product. By purchasing

Programmable Item

1.Running Mode

Option 1

Fwd/Brk

Option 2

Fwd/Rev/Brk

Option 3

Fwd/Rev

Option 4 Option 5 Option 6 Option 7 Option 8 Option 9

the QuicRun WP-Crawler-Brushed, you have chosen a high performance sensored 2.Battery Type LiPo NiMH

ATTENTION brushed electronic speed controller! This speed controller is equipped with 3.Cutoff Voltage Disabled Auto (Low) Auto (Medium) Auto (High)

Brushed Electronic Speed Controller high-tech features to enhance your experience with Hobbywing brushed power 4. Initial Start Force 0% 2% 4% 6% 8% 10% 12% 14% 16%

QuicRun WP Crawler Brushed systems. Improper usage and unauthorized modification to our product is extremely 5.Max. Forward Force 25% 50% 75% 100%

dangerous and may damage the product and related devices. Please take your time 6.Max.Reverse Force 25% 50% 75% 100%

CAUTIONS

and read the following instructions carefully before you start using your speed 7. Max. Brake Force 0% 12.5% 25% 37.5% 50% 62.5% 75% 87.5% 100%

control. We have the right to modify our product design, appearance, features and 8.Initial Brake Force 0% 6.25% 12.5% 18.75% 25% 31.25% 37.5% 43.75% 50%

usage requirements without notification. 9. Drag Brake 0% 5% 10% 50% 60% 70% 80% 90% 100%

10.Drag Brake Rate Level 1 Level 2 Level 3 Level 4 Level 5 Level 6 Level 7 Level 8 Level 9

11.Neutral Range 0.02ms 0.03ms 0.04ms 0.05ms 0.06ms 0.07ms 0.08ms 0.10ms 0.12ms

12. Start Mode/Punch Level 1 Level 2 Level 3 Level 4 Level 5 Level 6 Level 7 Level 8 Level 9

13.PWM Frequency 1K 2K 4K 8K 16K

14.BEC Voltage 6V 7.4V

15.Freewheeling Enabled Disabled

1. Running Mode

02 Warnings

Option 1: Forward with Brake. It’s a racing mode. It has only forward and brake functions.

Option 2: Forward/ Reverse with Brake. This option is known to be the “training” mode with “Forward/ Reverse with Brake” functions. Hobbywing has adopted the “DOUBLE-CLICK” method, that is

your vehicle only brakes on the 1st time you push the throttle trigger forward (brake) (1st push). The motor stops when you quickly release the throttle trigger and then re-push the trigger quickly (2nd

• To avoid short circuits, ensure that all wires and connections must be well insulated before connecting the ESC to related devices. push), only then the vehicle will reverse. The reverse function will not work if your car does not come to a complete stop. The vehicle only reverses after the motor stops. This method is for preventing

• Ensure all devices are well connected to prevent poor connections and avoid damages to your electronic devices. vehicle from being accidentally reversed.

• Read through the manuals of all power devices and chassis and ensure the power configuration is rational before using this unit. Option 3: Forward and Reverse. This mode is often used by special vehicles (rock crawler). It adopts the “SINGLE-CLICK” method. The vehicle will brake immediately when you push the throttle trigger

• Please use a soldering iron with the power of at least 60W to solder all input/output wires and connectors. forward (brake).

• Do not hold the vehicle in the air and rev it up to full throttle, as rubber tires can “expand” to extreme size or even crack to cause serious injury. 2. Battery Type

• Stop immediate usage once the casing of the ESC exceeds 90℃/194℉ as this may cause damages to both the ESC and motor. Hobbywing recommends setting the “ESC Thermal Protection” to Option 1: LiPo. Select this option when you use a LiPo battery and set the cutoff voltage accordingly.

105℃/221℉ (this refers to the internal temperature of the ESC). Option 2: NiMH. Select this option when you use a NiMH battery and set the cutoff voltage accordingly.

3. Cutoff Voltage

• Users must always disconnect the batteries after use as the current on the ESC is consuming continuously if it is connected to the batteries (even if the ESC is turned off). The battery will

Sets the voltage at which the ESC lowers or removes power to the motor in order to either keep the battery at a safe minimum voltage (for LiPo batteries). The ESC monitors the battery voltage all the

completely be discharged and may result in damage to the battery or ESC when it is connected for a long period of time. This WILL NOT be covered under warranty.

time; it will immediately cut off the output when the voltage goes below the cutoff threshold. The RED LED will flash a short, single flash that repeats (☆-, ☆-, ☆-) to indicate the low-voltage cutoff

03 Features

protection is activated.

Option 1: Disabled. The ESC does not cut the power off due to low voltage. Please pay attention to the power change of your vehicle. In general, the battery voltage gets pretty low when your vehicle is

severely losing power, then you should stop using that pack.

• Fully waterproof design for all conditions. (Note: please clean and dry it after use for avoiding rusty connectors) Option 2: Auto (Low). Low cutoff voltage, difficult to get the LVC protection activated, is applicable to batteries with poor discharge capability. The corresponding cutoff voltage is 4.5V for a NiMH pack.

• HOBBYWING patented copper heat-conductive plates attached to the MOSFET board allows the internal heat to be quickly transferred to the CNC-machined aluminum reticular heat sink for Option 3: Auto (Medium). Medium cutoff voltage, prone to getting the LVC Protection activated, is applicable to batteries with ordinary discharge capability. The corresponding cutoff voltage is 5.0V

great heat dissipation. for a NiMH pack.

• High reliable electronic switch design prevents mechanical switch failure due to dirt, water, dust and etc. Option 3: Auto (High). High cutoff voltage, very prone to getting the LVC Protection activated, is applicable to packs with great discharge capability. The corresponding cutoff voltage is 5.5V for a NiMH pack.

• Built-in switch-mode BEC with switchable voltage of 6V/7.4V and cont. /peak current of 4A/6A for usage with high torque and high voltage servos. 4. Initial Start Force

• Tunable drag brake and drag brake rate for different vehicles, tracks and control feel. Adjustable PWM frequency combined with advanced freewheeling (/DEO) technology guarantees great It’s the initial force when you pull the throttle trigger from neutral position toward non-throttle throttle position. A suitable start force can effectively prevent vehicle from sliding when you apply a low

throttle amount.

throttle linearity and driving feel.

5. Max. Forward Force

• 9 levels of acceleration/pun from soft to aggressive for different vehicles, tires and tracks.

It’s the force when throttle trigger is at the full throttle position. It’s adjustable among 25%, 50%, 75% and 100% (by default). You can lower down the value for better driving feel/control when you

• Proportional brake with 9 levels of initial brake force, maximum brake force and drag brake force.

drive a crawler (simulation model) over difficult terrains (and don’t have any requirement against the maximum speed).

• Multiple protections: low-voltage cutoff protection, thermal protection, and throttle signal loss protection.

6. Max. Reverse Force

• Separate programming port to easily connect the LED program card to the ESC.

Different reverse amount will bring different reversing speed. For the safety of your vehicle, we recommend using a low amount.

• Single-button ESC programming and factory reset.

7. Max. Brake Force

• ESC programming via Hobbywing LED program card. The ESC provides proportional braking function; the braking effect is decided by the position of the throttle trigger. It sets what percentage of available braking power when full brake is applied. Large

amount will shorten the braking time but it may damage your pinion and spur. Please select the most suitable brake amount as per your car condition and your preference.

04 Specifications 8. Initial Brake Force

It is also known as “minimum brake force”. It is the force when pushing throttle trigger from neutral zone to the initial brake position. To get a smoother braking effect, the default is equal to the drag brake.

9. Drag Brake

Model QUICRUN WP Crawler Brushed Drag brake is the braking power produced when releasing the throttle trigger from full speed to neutral zone.

Cont. / Peak Current 80A / 400A Attention! Drag brake will consume much power, so apply it cautiously.

10. Drag Brake Rate

Motor Type Brushed Motor (540 / 550 / 775 size motors)

It’s the rate at which the drag brake increases from zero to the pre-set value when the throttle trigger enters the neutral range. A suitable rate can make the vehicle stop stably. You can choose the drag

Applications 1/10th Rock Crawler

brake rate from level 1 (very soft) to level 9 (very aggressive) as per the track, tires’ grip, and etc.

Brushed Motor Limit with 2S LiPo / 6S NiMH: ≥10T or RPM<30000@7.4V (540/550 size motors) 11. Neutral Range

Motor Limit

Brushed Motor Limit with 3S LiPo / 9S NiMH: ≥16T or RPM<20000@7.4V (540/550 size motors) As not all transmitters have the same stability at “neutral position”, please adjust this parameter as per your preference. You can adjust to a bigger value when this happens.

LiPo / NiMH Cells 2-3S LiPo / 5-9S NiMH 12. Start Mode / Punch

BEC Output 6V / 7.4V@ 3A (Switch-mode) You can choose the punch from level 1 (very soft) to level 5 (very aggressive) as per the track, tires, grip, your preference and etc. This feature is very useful for preventing tires from slipping during the

starting-up process. In addition, “level 4” and “level 5” have strict requirement on battery’s discharge capability. It may affect the starting-up if the battery discharges poorly and cannot provide large

Connectors Input End: XT60; Output End: No Connectors

current in a short time. The car stutters or suddenly loses power in the starting-up process indicating the battery’s discharge capability is not good, and then you need to reduce the punch or increase the

Size / Weight 36.2 x 31.6 x 17.0 mm / 58.5g

FDR (Final Drive Ratio).

Programming Port Separate Port 13. PWM Drive Frequency

The acceleration will be more aggressive at the initial stage when the drive frequency is low; a higher drive frequency is smoother but this will create more heat to the ESC.

14. BEC Voltage

05 Begin to Use a New Brushed ESC Option 1: 6.0V. It’s applicable to ordinary servos. Do not use this option with high voltage servos; otherwise your servos may not function normally due to insufficient voltage.

Option 2: 7.4V. It’s applicable to high voltage servos. Do not use this option with ordinary servos; otherwise your servos may be burnt due to high voltage.

15. Freewheeling

For regular vehicles, we recommend disabling this function. With it disabled, your vehicle can have quick acceleration. For a crawler (simulation model), we suggest enabling it. With it enabled, you

This is an extremely powerful brushed crawler can have better linearity during a low-speed running and also less heat.

4

motor system. For your safety and the

Battery ATTENTION

safety of those around you, we ESC Programming

strongly recommend removing the

pinion gear attached to the motor

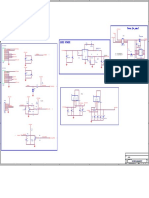

1. Program your ESC with the SET Button • For easy recognition, the motor beeps at the same time when the Red LED

before performing calibration and After entering the Click the SET button to choose the flashes.

Turn off the ESC

programming functions with this Turn on the transmitter corresponding item, the option, the times the red LED ATTENTION

• When “N” (the number) is equal to or bigger than 5, we use a long flash

red LED starts to blink, blinks indicates the option number

system. It is also advisable to keep the the times it blinks you are going to select.

to represent “5”. For example, the Red LED flashes a long flash (and the

Hold the SET key

wheels in the air when you turn on Switch on the ESC represents the current motor beeps a long beep at the same time) indicating you are in the 5th

Motor

option number.

the ESC. Red LED flashes once to choose programmable item; if the Red LED flashes a long flash and a short flash

Red LED flashes

Receiver "Forward with brake"

Electronic Speed Controller Release Press (and the motor beeps a long beep and a short beep at the same time)

Finish programming, switch off the ESC, and then switch it on

SET kye Enter the 1st item SET kye Red LED flashes twice to choose

Red LED flashes "Running Mode" "Forward / Reverse with brake" indicating you are in the 6th programmable item; a long flash and two

once

Red LED flashes 3 times to choose short flashes ( a long beep and two short beeps at the same time)

"Forward / Reverse"

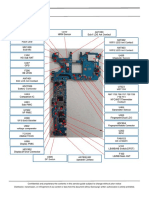

• Motor Wiring Switch Hold SET key for 3 seconds indicating you’re in the 7th programmable item and so on.

There is no polarityon the M+/M- two ESC-to-motor wires, hence, do not worry on how you connect them initially. You may find it necessary to swap two wires if the motor runs in reverse.

Release Press

• Receiver Wiring Red LED flashes SET kye Enter the 2nd item SET kye Red LED flashes once, choose "LiPo"

Plug the throttle control cable on the ESC into the throttle (TH) channel on receiver. The throttle control cable will output the voltage of 6V/7.4V to the receiver and steering servo. Hence, no

twice

"Battery Type " Red LED flashes twice, choose "NiMH" 2. Program your ESC with a LED program card

separate battery can be connected to the receiver. Otherwise, your ESC may be damaged. Hold SET key for 3 seconds A standard LED program card is also included in the product box.

Red LED flashes once, choose

• Battery Wiring "Disabled" Its friendly interface makes the ESC programming easy and quick.

Red LED flashes twice, choose

Proper polariy is esential. Please ensure positive (+) connects to positive (+), and negative (-) connects to negative (-) when plugging in the battery! When reverse polarity is applied to your ESC Release Press "Auto (Low)" Before the programming, you need to connect your ESC to the

Red LED flashes SET kye Enter the 3rd SET kye

from the battery, it WILL damage your ESC. This WILL NOT be covered under warrranty! Red LED flashes 3 times, choose program card via a White/Red/Black PVC cable with two JR male

3 times "Auto (Medium)"

item"Cutoff Voltage " connectors (one end of the cable to the separate programming port

Red LED flashes 4 times, choose External Programming

06 ESC Setup

"Auto (High)" on the ESC and the other end to the port marked with “-/+/S” on Port for Connecting

Hold SET key for 3 seconds

Program Card.

......The following steps are just like the above setps...... the program card), and then turn on the ESC, all programmable

Hold SET key for 3 seconds Press SET key to choose the value, items will show up a few seconds later. You can select the item by

the flash times of the RED LED choosing via “ITEM” & “VALUE” buttons on the program card.

1

Red LED flashes means the option number.

Radio Calibration N times Release

Enter the Nth item

Press

(Once means the 1st option,

twice means the 2nd option, etc.)

Press the “OK” button to save all new settings to your ESC.

SET kye SET kye

IMPORTANT

Begin using your ESC by calibrating with your tramistter. We strongly recommend Hobbywing users to use the “Fail Safe” function on the radio system and set (F/S) to “Output

OFF” or “Neutral Position”. Example of calibrating Neutral range and Endpoint. 5 Factory Reset

• Restore the default values with the SET button

Press and hold the SET button for over 3 seconds anytime when the throttle is at the neutral position (except during the ESC calibration and programming) can factory reset your ESC. The Red LED flahses

1. Turn on the transmitter, ensure all parameters (D/R, Curve, ATL) on the throttle channel are at default (100%). For transmitter

Press and hold Press the ON/OFF button

Release the set without LCD, please turn the knob to the maximum, and the throttle “TRIM” to 0. Please also turn the corresponding knob to the a long flash (the motor beeps a long beep at the same time) and then a short, single flash that repeats indicating that you have successfully restored all the default values within your ESC. Once you power

the SET button

button once the neutral position. For FutabaTM transmitter, the direction of throttle channel shall be set to “REV”, while other radio systems shall be set the ESC off, and then back on, your settings will be back in the default mode.

LED flashes. to “NOR”. Please ensure the “ABS/braking function” of your transmitter must be DISABLED.

• Restore the default values with a LED program card.

2. Start with transmitter on and the ESC turned off but connected to a battery. Holding the SET button and press the ON/OFF button to

turn on the ESC, the RED LED on the ESC starts to flash (Note: the motor beeps at the same time), and then release the SET button After connecting the LED program card to the ESC, press the “RESET” button and the “OK” button to factory reset your ESC.

immediately(The ESC will enter the programming mode if the SET button is not released in 3 seconds, please restart from step 1.).

07 Explanation for LED Status

Note: Beeps from the motor may be low sometimes, and you can check the LED status instead.

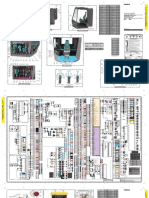

Move the throttle stick to the neutral position and Move the throttle stick to the end position of Move the throttle stick to the end position of

press the set button. forward and press the set button. backward and press the setup button. • The Red LED dies out when the throttle trigger is in throttle neutral zone.

• The Red LED flashes when your vehicle runs forward and it turns solid Red when you pull the throttle trigger to the full throttle endpoint.

The RED LED The RED LED flashes The RED LED flashes

• The Red LED flashes when your vehicle brakes and it turns solid Red when you push the throttle trigger to the full brake endpoint and set the “maximum brake force” to 100%.

flashes once and twice and motor emits twice and motor emits

motor emits “Beep-Beep” “Beep-Beep- • The Red LED flashes when your vehicle runs backward and it runs solid Red when you push the throttle trigger to the full brake endpoint and set the “maximum reverse force” to 100%.

“Beep” tone. tone. Beep” tone.

3. Set the neutral point, the full throttle endpoint and the full brake endpoint.

• Leave transmitter at the neutral position, press the SET button, the RED LED flashes 1 time and the motor beeps 1 time to accept the neutral position.

• Pull the throttle trigger to the full throttle position, press the SET button, the RED LED blinks 2 times and the motor beeps 2 times to accept the full throttle endpoint.

08 Troubleshooting

• Push the throttle trigger to the full brake position, press the SET button, the RED LED blinks 3 times and the motor beeps 3 times to accept the full brake endpoint. Trouble(s) Possible Causes Solution(s)

4. The motor can be started 3 seconds after the ESC/Radio calibration is complete.

The ESC was unable to start the status LED; 1. No power was supplied to the ESC. 1. Check if all ESC & battery joints or connections have been well soldered or firmly connected.

the motor after it was powered on 2. The ESC switch was damaged 2. Replace the broken switch.

2 Power ON/OFF & Warning Tones

The ESC was unable to start the motor (but the Red status

LED flashed) after it was powered on

The vehicle moved forward or backward slowly

The throttle control cable was reversely plugged in or in the

wrong channel on the receiver.

Please plug the throttle control cable in the TH channel (usually CH2) on receiver

or recalibrate the throttle range.

• Power ON/OFF: The throttle range was not calibrated properly. Please recalibrate the throttle range or fine-tune the neutral position on the transmitter.

when the throttle trigger was at the neutral position

(Start with the ESC turned off), press the ON/OFF button to turn on the ESC.

The vehicle ran backward when you pulled the 1. The ESC-to-motor wiring order was incorrect. 1. Swap motor wires.

(Start with the ESC turned on) press and hold the ON/OFF button to turn off the ESC. throttle trigger towards you 2. Incorrectly set the direction of the throttle channel. 2. Change the direction of the throttle channel from “NOR” to “REV” or “REV” to “NOR”.

• Warning Tones: 1. Check all devices and try to find out all possible causes, and check the transmitter’s battery voltage.

1. The receiver was influenced by some foreign interference.

The motor suddenly stopped or significantly 2. The Red LED keeps flashing indicating the LVC protection is activated, so please replace your battery pack.

With the ESC is turned on in the normal way (that is turn it on without pressing and holding the SET button): if you set the “Battery Type” to “LiPo”, the motor will beep N (number) 2. The LVC protection was activated.

reduced its output in operation 3. The Red LED keeps flashing indicating the ESC thermal protection is activated, please let your ESC cool

3. The ESC thermal protection was activated.

beeps to indicate the number of LiPo cells you have plugged in (i.e. 2 beeps indicates a 2S LiPo, 3 beeps indicates a 3S LiPo.) and then a long beep to inform you that your ESC is down before using it again.

ready to work. If you set the “Battery Type” to “NiMH”, the motor will only beep a beep to indicate the ESC is in NiMH mode and then another beep to inform you that your ESC is The throttle neutral position on your transmitter was actually Recalibrate the throttle neutral position. No LED on the ESC will come on when

The vehicle could run forward but could not reverse

in the braking zone. the throttle trigger is at the neutral position.

ready to function.

You might also like

- SM-G950F Tshoo 7 PDFDocument63 pagesSM-G950F Tshoo 7 PDFBrandon CifuentesNo ratings yet

- HSS Range Poster - A3 PDFDocument1 pageHSS Range Poster - A3 PDFJulian De la CruzNo ratings yet

- Braemar Convair Owners Manual HSU-9-24HEK 0912 F WebDocument5 pagesBraemar Convair Owners Manual HSU-9-24HEK 0912 F WebPera PisarNo ratings yet

- 1200 Coater Manual PDFDocument95 pages1200 Coater Manual PDFVIKASH KUMAR SINGH100% (1)

- Suction Cup VAS-8-M5-PUR: Catalogue PageDocument2 pagesSuction Cup VAS-8-M5-PUR: Catalogue Pageabrap_dNo ratings yet

- Schneider Electric Interlock For Use With LC1D Series - DatasheetDocument1 pageSchneider Electric Interlock For Use With LC1D Series - DatasheetSoubhi SabbaghNo ratings yet

- Anchor Selector Chart - U4 - CADocument1 pageAnchor Selector Chart - U4 - CAscottbucknerNo ratings yet

- Masterpact NT Return Masterpact NW Return Ns1600b... 3200 Return Ns630b... 1600 33659Document1 pageMasterpact NT Return Masterpact NW Return Ns1600b... 3200 Return Ns630b... 1600 33659ijul501100% (1)

- (For Gate Driver IC Digital Power) : Mechanical GroundDocument5 pages(For Gate Driver IC Digital Power) : Mechanical GroundficoNo ratings yet

- Inovacne Am400 Cpu1608tn NPN PLC Cpu Product Note English 20 4 20Document2 pagesInovacne Am400 Cpu1608tn NPN PLC Cpu Product Note English 20 4 20Manova JNo ratings yet

- 《MCTC CTW B3轿顶一体箱用户手册》 英文20181015 A00 19010849Document2 pages《MCTC CTW B3轿顶一体箱用户手册》 英文20181015 A00 19010849SyativahNo ratings yet

- Nintendo Switch USB-C Alternative Measurement Locations 20201219aDocument1 pageNintendo Switch USB-C Alternative Measurement Locations 20201219aLuis M GonzálezNo ratings yet

- Ili9806e An V093 20140328 PDFDocument116 pagesIli9806e An V093 20140328 PDFRoman BeránekNo ratings yet

- Fight Klub Terminator StarterDocument6 pagesFight Klub Terminator Starterfactorgames2011No ratings yet

- XBTZN999 DatasheetDocument1 pageXBTZN999 DatasheetAntonio HerreraNo ratings yet

- Creative Chrono QSL Rev ADocument2 pagesCreative Chrono QSL Rev ANard NardNo ratings yet

- NumericalRelaySelectionTable 756179 ENyDocument1 pageNumericalRelaySelectionTable 756179 ENyFaruk PatelNo ratings yet

- DZZSM00237-0 SFDL2 TM Eng 1st 0422 PDFDocument2 pagesDZZSM00237-0 SFDL2 TM Eng 1st 0422 PDFasdrefNo ratings yet

- Light Wiring Schematic: Schematic, Sl120-Ii ElectricalDocument1 pageLight Wiring Schematic: Schematic, Sl120-Ii ElectricalAdrian RangelNo ratings yet

- File USRP N310 N300 MB SchematicDocument24 pagesFile USRP N310 N300 MB SchematicAhsan ShabbirNo ratings yet

- Network - Topology - RevaDocument1 pageNetwork - Topology - RevaJulio VeraNo ratings yet

- BMXFTB2010: Product Data SheetDocument1 pageBMXFTB2010: Product Data SheetsfefasNo ratings yet

- Digital Recorder InstructionsDocument2 pagesDigital Recorder InstructionsHashim Warren100% (31)

- Frequency Inverter Convertidor de Frecuencia Inversor de FrequênciaDocument13 pagesFrequency Inverter Convertidor de Frecuencia Inversor de FrequênciamikeNo ratings yet

- Updated IM 2017Document4 pagesUpdated IM 2017mark joseph cometaNo ratings yet

- Power For Panel Power For Panel Power For Panel Power For PanelDocument8 pagesPower For Panel Power For Panel Power For Panel Power For PanelmarcellobbNo ratings yet

- Videoprojecteur Elephas-Q9Document1 pageVideoprojecteur Elephas-Q9ferniqueNo ratings yet

- MIFD: 2019 Futur: 300438582 Silicone TM Noir1980 2MMD28Document3 pagesMIFD: 2019 Futur: 300438582 Silicone TM Noir1980 2MMD28aichaNo ratings yet

- XB2BD33 DATASHEET AU en-GB PDFDocument1 pageXB2BD33 DATASHEET AU en-GB PDFCaarlosNo ratings yet

- 0936E1001R00Document1 page0936E1001R00Gervasio SimaoNo ratings yet

- Singapore Night Festival 2018 E-BrochureDocument7 pagesSingapore Night Festival 2018 E-BrochuretanloonhanNo ratings yet

- Fuente FB Ra01 CavaDocument1 pageFuente FB Ra01 CavaLeandro ValinottiNo ratings yet

- Fuente FB RA01 CAVADocument1 pageFuente FB RA01 CAVALeandro ValinottiNo ratings yet

- Uenr7613uenr7613-01 SisDocument6 pagesUenr7613uenr7613-01 SisFabrizio JesúsNo ratings yet

- D64 (B), (F), D65 (C)Document1 pageD64 (B), (F), D65 (C)iwan darmawanNo ratings yet

- The Keeper's TaleDocument3 pagesThe Keeper's TalemaitouyenNo ratings yet

- AMEB一级:迷你华尔兹Document2 pagesAMEB一级:迷你华尔兹Cairong HeNo ratings yet

- Electro 323Document2 pagesElectro 323Pușcă MartinNo ratings yet

- PP Rusc1Document10 pagesPP Rusc1mozartNo ratings yet

- Rsag7 820 4900Document10 pagesRsag7 820 4900Isabel Garcia100% (1)

- Israel Board Schematic Ver 1 2 Zl4saeDocument1 pageIsrael Board Schematic Ver 1 2 Zl4saeTEDY-RNo ratings yet

- Fuse Block WiringDocument4 pagesFuse Block WiringGilson RodriguesNo ratings yet

- Der Fluyten Lust-Hof. 2Document77 pagesDer Fluyten Lust-Hof. 2Johnny LopesNo ratings yet

- Shcematics 23 SepDocument1 pageShcematics 23 SepAnal E SNo ratings yet

- Message No. 2 - Format Infrastructure Data Collection 30.01.2019Document1 pageMessage No. 2 - Format Infrastructure Data Collection 30.01.2019Bhaskar Victor DasNo ratings yet

- Exhaust Gas Recirculation ControlDocument1 pageExhaust Gas Recirculation ControlOliver AlfaroNo ratings yet

- Product Manual: CatalogDocument2 pagesProduct Manual: CatalogBan Zangana100% (1)

- TSP Map VL Meiktila - Mandalay MIMU154v05 20apr2020 A1 EngDocument1 pageTSP Map VL Meiktila - Mandalay MIMU154v05 20apr2020 A1 EngWin TunNo ratings yet

- Map PDFDocument1 pageMap PDFmNo ratings yet

- Brosur AVANI Homes PDFDocument2 pagesBrosur AVANI Homes PDFCornelius SvenmorNo ratings yet

- RLS - 02-Room Layoout Sheet 1 - BR - ST Patient Bedroom - 221223 - 132713Document1 pageRLS - 02-Room Layoout Sheet 1 - BR - ST Patient Bedroom - 221223 - 132713Alhassan MahmoudNo ratings yet

- Elite KeyboardDocument1 pageElite KeyboardFrank MatzkaNo ratings yet

- (Cota +4,42) : LegendaDocument1 page(Cota +4,42) : LegendaCorneliu DobreNo ratings yet

- CM TDBDocument1 pageCM TDBPrinceVZLANo ratings yet

- T-Con Power Main Chip Philips Tpm5.1e LaDocument2 pagesT-Con Power Main Chip Philips Tpm5.1e LaKamal AltawilNo ratings yet

- Formulaire PHYSDocument2 pagesFormulaire PHYSjadbechara25No ratings yet

- Concerto For Piano 4 Hands and String Orchestra (Orchestra Score)Document72 pagesConcerto For Piano 4 Hands and String Orchestra (Orchestra Score)Yiğit YÜKSELNo ratings yet

- AZPT Segments and Connectors-Dec-2017Document1 pageAZPT Segments and Connectors-Dec-2017john warningNo ratings yet

- Electrical System 793D Off-Highway Truck: Harness and Wire Electrical Schematic SymbolsDocument10 pagesElectrical System 793D Off-Highway Truck: Harness and Wire Electrical Schematic SymbolsThomas LavertyNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: MathFrom EverandInstant Assessments for Data Tracking, Grade 4: MathRating: 5 out of 5 stars5/5 (2)

- Thermal Properties of MatterDocument9 pagesThermal Properties of MatterTrillionare HackNo ratings yet

- Flexural Strengthening of Reinforced Concrete Beam-Column Joints Using Innovative Anchorage SystemDocument12 pagesFlexural Strengthening of Reinforced Concrete Beam-Column Joints Using Innovative Anchorage SystemmekidesNo ratings yet

- MS Samsung Ar5000 Non Inverter AirconditionerDocument2 pagesMS Samsung Ar5000 Non Inverter AirconditionerMacSparesNo ratings yet

- Common Injection Molding Defects and How To Solve ThemDocument18 pagesCommon Injection Molding Defects and How To Solve ThemIvana MatovićNo ratings yet

- PTFE Bronze Wear - enDocument1 pagePTFE Bronze Wear - enAli AlashryNo ratings yet

- Vad Vag Vav Vah ManualDocument58 pagesVad Vag Vav Vah ManualJonathan Cortes RangelNo ratings yet

- Third Quarterly Test in ScienceDocument9 pagesThird Quarterly Test in ScienceMarilyn EscobillaNo ratings yet

- Rubber, Composite Hose & DuctingDocument1 pageRubber, Composite Hose & DuctingMukkesh KumarNo ratings yet

- Ce 323 - Working Stress DesignDocument12 pagesCe 323 - Working Stress DesignHiru ZenNo ratings yet

- Orbitrol Repairing1Document13 pagesOrbitrol Repairing1Islam ShoukryNo ratings yet

- r5v Sales d049Document6 pagesr5v Sales d049Junior Francisco QuijanoNo ratings yet

- 12mmTMX-UNBS. March23Document3 pages12mmTMX-UNBS. March23Okello StevenNo ratings yet

- Ringo Axial ValvesDocument20 pagesRingo Axial ValvesRIGOBERTO PONCENo ratings yet

- Ahmed Tawfik CV PIP DDocument5 pagesAhmed Tawfik CV PIP DAhmed TawfikNo ratings yet

- Api 675 Metering Pump WorkshopDocument67 pagesApi 675 Metering Pump WorkshopBalinderjit SinghNo ratings yet

- 550.2r 13 Design Guide For Connections in Precast Jointed SystemsDocument20 pages550.2r 13 Design Guide For Connections in Precast Jointed SystemsMohd Sulahuddin RamlyNo ratings yet

- PHS Bearing DetailsDocument9 pagesPHS Bearing DetailsNandan DesignNo ratings yet

- Response of An Undamped SystemDocument6 pagesResponse of An Undamped SystemWacko AsahanNo ratings yet

- Enervent PegasosTwinTropicDocument21 pagesEnervent PegasosTwinTropicbilal almelegyNo ratings yet

- Tutorial 9Document7 pagesTutorial 9Nicole NicoleNo ratings yet

- Ass1 Wall Form Solution N 13 14 RestudyDocument2 pagesAss1 Wall Form Solution N 13 14 RestudyRadhika VeeralaNo ratings yet

- Sievert DW 3000 Leaflet - English - 2018Document8 pagesSievert DW 3000 Leaflet - English - 2018NataliNo ratings yet

- Earthquake Resistant Building Construction: by Koushali Banerjee Barch/10001/14 Semester III Structural MechanicsDocument20 pagesEarthquake Resistant Building Construction: by Koushali Banerjee Barch/10001/14 Semester III Structural Mechanicskaushita banerjeeNo ratings yet

- SAE Viscosity PDFDocument5 pagesSAE Viscosity PDFMusaferNo ratings yet

- Electric Sheet For 1200-350Document4 pagesElectric Sheet For 1200-350Alfiya AnamNo ratings yet

- Design of Piles in Sand: Case Study of Lekki Pennisula, Lagos NigeriaDocument10 pagesDesign of Piles in Sand: Case Study of Lekki Pennisula, Lagos NigeriaLavanyan SatchithananthanNo ratings yet

- EB2ADTXDocument2 pagesEB2ADTXJohn DactilidisNo ratings yet

- Rothoblaas - Ab1.technical Data Sheets - enDocument1 pageRothoblaas - Ab1.technical Data Sheets - enAndrei GheorghicaNo ratings yet