Professional Documents

Culture Documents

PT DRG - Final Modified Lanching of ROR 27-11-22-Model

PT DRG - Final Modified Lanching of ROR 27-11-22-Model

Uploaded by

Basava SrikanthOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT DRG - Final Modified Lanching of ROR 27-11-22-Model

PT DRG - Final Modified Lanching of ROR 27-11-22-Model

Uploaded by

Basava SrikanthCopyright:

Available Formats

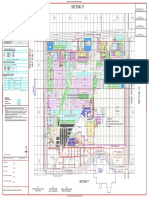

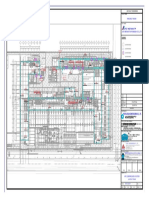

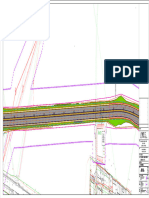

75 Ø (OUTSIDE)

63700

C/L 50 Ø (INSIDE) (OVER ALL LENGTH OF GIRDER)

NOTES:

200

OPEN WEB GIRDER 700 OPEN WEB GIRDER

STAGE- I WOODEN MATTING

180

900

180

STAGE- II 1. All dimensions are in millimeters.

350

C/L OF PRO. BRIDGE C/L OF PRO. BRIDGE 2. Do not scale drawing. Only written dimension shall be followed.

AKOLA KHANDWA AKOLA KHANDWA

3. Girder is pulled from Khandwa end up to existing abutment A2 by connecting the wire ropes to bottom boom on both sides and

wire ropes connected to winches already provided behind the new abutment A1.

80 DIA Ø ROLLERS

2400 4. After reaching the girder up to existing abutment A2 shifting of winch from Khandwa end to Akola end and connecting of wire ropes at

CLEAR SPAN - 61000 CLEAR SPAN - 61000

ANCHOR PULLEY POWER Akola side of girder will be done.

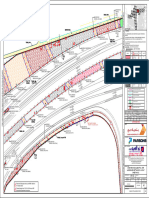

ELEVATION

5. For general arrangement refer Drg,No. CAO/C/D/BR/217-2021/ALT-1 / GM(W)BB-P-18295/ALT-1.

write in Bold

PULLING DIRECTION WINCH

PRO.RL: 315.702 25 t. CAPACITYPRO. RL: 315.702 PRO.RL: 315.702 PRO. RL: 315.702

POWER WINCH WOODEN MATING 350

letters

PRO.FL: 314.964 5861 7875 7875 7875 7875 7875 7875 PRO. FL: 314.964 PRO.FL: 314.964 5861 7875 7875 7875 FORMATION WORK DONE LEVEL: 313.527 PRO. FL: 314.964

1740 1800 1740 25 t. CAPACITY

FORMATION WORK DONE LEVEL.. 513.527 TOP OF BED BLOCK: 313.527 BOTTOM OF GIRDER:313.962

435 RAILS

PRO. BOG: 313.962

WORK DONE LEVE:313.527 FORMATION WORK DONE LEVEL .. 513.527 435 TOP OF BED BLOCK: 313.527 BOTTOM OF GIRDER:313.962 TOBB: 314.964

PRO. BOG: 313.962

RAILS

STEEL CRIBS PREPARATORY WORK: Delete this word

ROLLERS FIXED TO

FOR GIRDER LAUNCHING EXG.FL: 312.7054351200 2300 EXG.FL: 312.705 1200 2271 EXG.FL: 312.705 WOODEN MAT ON CRIB STAGING FOR GIRDER LAUNCHING EXG.FL: 312.705 1200 2300 EXG.FL: 312.705 4351200 2300 EXG.FL: 312.705 1800 600

75 Ø (OUTSIDE)

ROLLER ASSEBLY FIXED TO 1. Earthwork on the Khandawa Side abutment shall be completed upto top of bed block level.

CONTACT LENGTH

150

OVERALL LENGTH

6000 STRINGS REACHED THROUGH PULLIES INVERTED RAILS FIXED TO 6000 INVERTED RAILS FIXED TO STRINGS REACHED THROUGH PULLIES ARE 150

ANCHOR PULLEY

OF ROLLER-670

BOTTOM OF GIRDER WITH WOODEN BLOCKS 50 Ø (INSIDE) WOODEN MATTING

C OF EXG. TRACK (UP MAIN LINE) ARE CONNECTED TO POWER WINCH C OF EXG. TRACK (UP MAIN LINE) PULLING DIRECTION BOTTOM OF GIRDER WITH CONNECTED TO POWER WINCH 2. Widening of exg.embankment between new abutment and existing abutments on both sides to the required width.

63000

(EFFECTIVE SPAN) WOODEN BLOCKS 3. Open Web Girder is assembled on Khandawa side approach.

1800

150

730

550

670

C OF EXG. TRACK (DN MAIN LINE) C OF EXG. TRACK (DN MAIN LINE)

PRO.BERM LEVEL : 308.964 6250 Exg RL: 306.915 Exg RL: 306.945 63700 PRO.BERM LEVEL : 308.964 6250 Exg RL: 306.915 Exg RL: 306.945

(OVER ALL LENGTH OF GIRDER) 80 Ø ROLLER 4. Wooden blocks connected to bottom chords and rails are attached to wooden blocks on bottom side.

EXG. ABUTMENT

IS IN CRS STONE MASONRY.

EXG. ABUTMENT

IS IN CRS STONE MASONRY. STAGE-II - MODUS OPERANDI FOR LAUNCHING OF GIRDER UPTO EXG. ABUTMENT A2: 5. Roller platform erected on approach in line with bottom boom and inverted rails with rail cluster/wooden matting at an interval of 600mm c/c.

5156(SK) 6150(SK) 5154(SK) STAGE-I PREPARATORY WORK: 900 5156(SK) 6150(SK) 5154(SK) 1. Pulliesare to be tied to new abutment (A1) with wire rope and open web girder on Khandwa end. Strings inserted through 6. The Top level of roller shall be top level of bed block plus dia of roller.

GL: 306.455 GL: 306.455 GL: 306.455 GL: 306.455 DETAILS OF

4920(SQ) 4920(SQ) 7. Platforms are to be made on top of cribs for keeping the rollers & rail clusters required.

1. Earthwork on the new bridge approaches i.e., Khandawa Side & Akola side upto new abutment shall be completed upto top of bed block level. pullies are connected to power winch erected on embankment.

CRIB STAGING WITH WOODEN MATTING 8. Power Winches are erected on Khandwa end embankment during stage-I and Stage-II operations. During Stage III and Stage-IV power winches

2. Complete widening of exg.embankment in between new abutments and existing abutments on both sides to the required width. 2. The launching operation started by pulling the girder towards Akola with the help of Pullies and winches.

3. After girder reaches Khandwa side new Abutment (A1), erect the crib staging on exg. embankment at 7.875m c/c and on ON EXISTING FORMATION FOR FIXING are erected on Akola end.

3. Open Web Steel through Girder is to be assembled on Khandawa side approach. PLAN

BOF: 302.855 EXG. ABUTMENT (A2) EXG. ABUTMENT (A1) BOF: 302.855

4. Rails attatched to Wooden blocks are connected to bottom side of bottom chords of open web girder.

BOF: 302.855 EXG. ABUTMENT (A2) EXG. ABUTMENT (A1) BOF: 302.855 the exg. abutments. ROLLER LUSTER ASSEMBLY ON TOP.

4. Place/fix the rollers on crib staging and pull the girder further towards Akola side.

NEW ABUTMENT (A2)

ELEVATION NEW ABUTMENT (A1)

5.

6.

Roller plotform erected on approach in line with bottom boom and inverted rails with rail cluster/wooden matting not exceed 7.875m c/c.

The Top level of roller shall be top level of bed block plus dia of roller.

DETAILS OF ROLLER ASSEMBLY

FIXED TO MATTING OF WOODEN BLOCKS NEW ABUTMENT (A2) ELEVATION NEW ABUTMENT (A1) 5. Pulling operation is repeated till the girder reaches exg. abutment (A2) on Akola side under traffic &power block 3 Hrs.

LAUNCHING:

TO

ON NEW FORMATION FOR MOVEMENT OF GIRDER 6. The maximum cantilever portion of girder at any stage is 7.875m upto existing abutment.

TO

7. On exg.formation, platforms are to be made on top of cribs for keeping the rollers & rail clusters. 1. During launching impose speed restriction & neutralization of OHE at bridge location for 9 days required for a length of 30 m minimum on eitheR

BH

7. The maximum cantilever portion of girder between Akola side exg. abutment to Khandwa side exg. abutment is 16.876m.

E) 8. Winches are erected on Khandwa side embankment beyond girder. E) Existing Abutments,Wing & Return walls

BH

Show in Dark YELLOW side of center line of bridge along the exg. Up & Down lines.

US

E) LIN E) LIN 8. Maximum pressure under the crib is 15.0t/m2

U

IN IN should be show in Yellow Colour with 2. The launching operation started by pulling the girder with the help of winches operated from KNW end till girder reaches on to existing abutment

HW

SH

LIN Dotted lines for the LIN

PRO. TOBB: 313.527

EXECUTED FL/TOP OF BED BLOCK: 313.527

MA MA

PRO. RL: 315.702

PRO. FL: 314.964

A2 during Stage-I & II operations.

Dotted lines- (Yellow Indication is

W

IN IN

AL

PRO. RL: 315.702

DN DN

PRO. FL: 314.964

MA Existing MG Abutments & DETAILS OF TRAFFIC AND POWER BLOCKS REQUIRED FOR LAUNCHING OF NEW OPEN WEB THROUGH TYPE WELDED GIRDER

MA

DETAILS OF TRAFFIC AND POWER BLOCKS REQUIRED FOR LAUNCHING OF NEW OPEN WEB THROUGH TYPE WELDED GIRDER

AL

( ( 3. After girder reaches AK side exg. Abutment A2, crib stagings are placed at @7.875m c/c interval and on the exg. formation on AK end of

K K

(U

P C

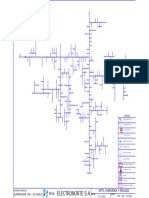

Wing walls. NO. OF DURATION OF TRAFFIC & TOTAL (U

P C Dismantling) DURATION OF TRAFFIC TOTAL

5018 RA 5018 RA NO. OF exg.abutment A2 before stage-III operation.

C C

S.NO. DESCRIPTION OF ACTIVITY DURING BLOCK BLOCK REQD. S.NO. DESCRIPTION OF ACTIVITY DURING BLOCK & POWER BLOCK BLOCK REQD.

CK POWER BLOCK (Hrs) CK

Exg Embankment width 5.50m

T BLOCKS T BLOCKS

RA G. (Hrs)

RA G. (Hrs) (Hrs) 4. Place the rollers on crib staging and pull the girder further towards Akola side.

TC EX T EX 5. Same operation is repeated till the girder reaches Akola side exg. abutment A2 during Stage-III operation.

G. A1 . A1

-- -- -- -- C

--

G 1. LAUNCHING OF NEW ROR GIRDER FROM EXISTING MG ROR BRIDGE

A2 EX A2 EX ABUTMENT (A1) LOCATION TO EXISTING MG ROR BRIDGE 1 3 hrs. 3 hrs. 6. The maximum cantilever portion of girder at any stage is 7.875m after passing the existing abutment A2.

3000 3000 ABUTMENT (A2) LOCATION WITH POWER WINCHES OPERATING 7. The maximum cantilever portion of girder between Akola side exg. abutment to Khandwa side exg. abutment is16.876m.

FROM KNW END 8. Maximum pressure under the crib staging is 5.0 t/m2

5775 5775 5775 5775 9. Maximum deflection during launching (assuming 3 panels length as cantilever) is 19.50mm

Write in Bold Letters

BUSAWAL

BUSAWAL

DETAILS OF TRAFFIC AND POWER BLOCKS REQUIRED FOR LAUNCHING OF NEW OPEN

WEB THROUGH TYPE WELDED GIRDER

12000 11550 11550 12000 11550 11550

Y NO. OF DURATION OF TOTAL

2650

S.NO. DESCRIPTION OF ACTIVITY DURING BLOCK

BLOCKS TRAFFIC & POWER BLOCK REQD.

30738 16460 BLOCK (Hrs) (Hrs)

Exg Embankment

WOODEN BLOCK

WOODEN BLOCK

NEW FOR MATION UPTO TOP OF BED BLOCK NEW FOR MATION UPTO TOP OF BED BLOCK NEW FOR MATION UPTO TOP OF BED BLOCK NEW FOR MATION UPTO TOP OF BED BLOCK

30738 16460

X

C/L OF BEARING

C/L OF BEARING

29486 PRO.WIDENING OF EXG. EMBANKMENT LAUNCHING OF NEW ROR GIRDER FROM EXISTING MG

ROLLER

63700

C/L OF PRO. BRIDGE

C/L OF PRO. BRIDGE

29486

ROLLER

ROR BRIDGE ABUTMENT (A1) LOCATION TO EXISTING

PRO. WIDTH OF NEW EMBANKMENT

1.

PRO. WIDTH OF NEW EMBANKMENT

1 3 hrs. 3 hrs.

NEW EMBANKMENT UPTO TOP OF BED BLOCK

PRO. WIDENING OF EXG. EMBANKMENT POWER MG ROR BRIDGE ABUTMENT (A2) LOCATION WITH

PRO.WIDENING OF EXG. EMBANKMENT

ROLLERS

2650

2650

ROLLERS WINCH PRO. WIDENING OF EXG. EMBANKMENT

PRO.WIDENING OF EXG. EMBANKMENT 1800 POWER WINCHES OPERATING FROM KNW END

SECTION @ X-X

SECTION @ Y-Y

TO A TOP WIDTH OF 11.00m

20 t. CAPACITY

1800

POWER

DISCONNECTING THE PULLY AND WIRE ROPE FROM

EMBANKMENT

WINCH

EMBANKMENT

C/L OF BEARING

C/L OF BEARING

ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS 20 t. CAPACITY NEW ROR GIRDER. SHIFTING OF POWER WINCHES

AKOLA AKOLA

WOODEN MATTING

ROLLERS

RAILS

RAILS

ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS

KHANDWA KHANDWA

EXG.

EXG.

11000

11000

11000

FROM KNW END TO AKOLA END. RECONNECTING THE

5700

7200

5500

5700

5500

C/L OF PRO. TRACK 5156 C/L OF PRO. TRACK 1 2 hrs. 2 hrs.

5500

5500

5156 5153 2.

PULLY AND WIRE ROPE ASSEMBLY AT FRONT SIDE OF

ROR GIRDER AND SETTING THE ROLLER CLUSTERS

BELOW GIRDER NEAR EXISTING MG ROR ABUTMENT

(A2) LOCATION.

2650

2650

ROLLERS

ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS PRO. WIDENING OF EXG. EMBANKMENT ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS

PRO. WIDENING OF EXG. EMBANKMENT

LAUNCHING OF NEW ROR GIRDER FROM EXISTING MG

ROR BRIDGE ABUTMENT (A2) LOCATION WITH POWER

NEW FOR MATION UPTO TOP OF BED BLOCK NEW FOR MATION UPTO TOP OF BED BLOCK X NEW FOR MATION UPTO TOP OF BED BLOCK

EXG. ABUTMENT (A2) EXG. ABUTMENT (A1) NEW FOR MATION UPTO TOP OF BED BLOCK 3. WINCHES OPERATING FROM AKOLA END. REMOVAL

EXG. ABUTMENT - A2 EXG. ABUTMENT - A1 OF ALL PULLY AND WIRE ROPE ASSEMBLY 2 3 hrs. 6 hrs.

KH

(EXG. ABUTMENT TO BE DISMANTLED (EXG. ABUTMENT TO BE DISMANTLED Y CONNECTIONS FROM GIRDER. LIFTING OF NEW

KHANDWA

KHANDWA

A

KH

ND

AFTER ERECTION OF GIRDER) AFTER ERECTION OF GIRDER) GIRDER AND SUPPORTING ON WOODEN BLOCK

AN

11550 11550 11550 11550

W

12000 12000 STAGINGS ON BOTH NEW ABUTMENTS (A1), (A2).

A

DW

A

REMOVAL OF WOODEN BLOCKS AND SERVICE RAILS

All existing structures show in FROM BOTTOM SIDE OF BOTTOM CHORDS ON LHS &

2 3 hrs. 6 hrs.

4. RHS OF NEW GIRDER. REMOVAL OF RAIL AND

Dark Yellow colour with Dotted ROLLER CLUSTERS FROM TOP OF NEW ABUTMENTS

5775 lines. (Yellow indicates 5775 5775 5775

AT BEARING LOCATIONS.

3000

Dismantling) 3000 ADJUSTMENT OF GIRDER TO CORRECT C/C OF

A2 A2 BEARINGS, LEVELLING AND LOWERING OF NEW 1 3 hrs. 3 hrs.

5.

GIRDER COMPLETE OVER ROCKER & ROLLER

A1 A1 BEARINGS ON BOTH ABUTMENTS IN POSITION.

5018 5018

TOTAL REQUIREMENT OF TRAFFIC & POWER BLOCK 20 hrs.

PLAN PLAN

Winch Capacity:

Weight of girder = 250.00 tonnes.

Weight of attachments (assumed) =50.00 tonnes

Winch capacity required = 300.0 x 0.05 = 15.0 tonnes.

63700 Provide winch of capacity 25.00 tonnes -1 NOS.

(OVER ALL LENGTH OF GIRDER)

C/L OF PRO. BRIDGE

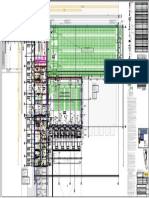

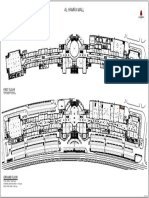

STAGE- III OPEN WEB GIRDER

STAGE- IV OPEN WEB GIRDER

C/L OF PRO. BRIDGE

AKOLA KHANDWA AKOLA KHANDWA Note:-

80 DIA Ø ROLLERS C/L OF BEARING 1. Dirt wall on abutments shall be constructed only after completion

CLEAR SPAN - 61000 CLEAR SPAN - 61000

of launching and lowering of girder on Roller & Rocker bearings.

C/L OF BEARING

POWER WINCH

25 t. CAPACITY

PRO.RL: 315.702

PRO.FL: 314.964 5861 7875 7875 7875

PRO. RL: 315.702

PRO. FL: 314.964 WOODEN MATING 350

PRO.RL: 315.702

POWER

PRO.FL: 314.964

WINCH

PRO. RL: 315.702

PRO. FL: 314.964

The existing formation earth work between new and old abutments as well

EXECUTED FL & TOP OF BED BLOCK: 313.527 435 FORMATION WORK DONE LEVEL: 313.527

as MG bridge CRS masonry work in Abutments,Wing & Return walls will be

PULLING DIRECTION 1740 20t.CAPACITY PULLING DIRECTION 1740

PRO. BOG : 313.962 WOODEN MATTING ON CRIB STAGING

FORMATION WORK DONE LEVEL..513.527 TOP OF BED BLOCK: 313.527 TOBB: 314.964 RAILS

STEEL CRIBS FORMATION WORK DONE LEVEL : 313.527 RAILS PRO. TO OF BED BLOCK: 313.527

TOBB: 314.964

removed/dismantled up to Ground Level after completion of New Open

ROLLERS FIXED TO

FOR GIRDER LAUNCHING 1200 2300 EXG.FL: 312.705 435 EXG.FL: 312.705

WOODEN MAT ON CRIB STAGING 1800 600 EXG.FL: 312.705 4351200 2300 EXG.FL: 312.705 PULLY STRINGS

1200 2300 EXG.FL: 312.705

6000 ANCHOR PULLEY 150 150 6000 ANCHOR OPEN WEB GIRDER

STRINGS REACHED THROUGH PULLIES

ARE CONNECTED TO POWER WINCH

C OF EXG. TRACK (UP MAIN LINE)

PULLIES ARE TO BE SHIFTED TO

AKOLA SIDE ABUTMENT (A2)

PULLEY C OF EXG. TRACK (UP MAIN LINE)

STAGE-IV - MODUS OPERANDI FOR LAUNCHING OF GIRDER UPTO NEW ABUTMENT A2: PRO.RL: 315.702 Web Through Type Girder Launching in all respects.

C OF EXG. TRACK (DN MAIN LINE) STAGE-III - MODUS OPERANDI FOR LAUNCHING OF GIRDER FROM Exg. ABUTMENT A2 LOCATION TO 150 C OF EXG. TRACK (DN MAIN LINE)

6250 6250

PRO.BERM LEVEL : 308.964 Exg RL: 306.915 Exg RL: 306.945

NEW ABUTMENT A2 LOCATION.

PRO.BERM LEVEL : 308.964 Exg RL: 306.915 Exg RL: 306.945 1. The launching operation started by pulling the girder towards Akola with the help of Pullies and winches until

EXG. ABUTMENT / WINGS/RETURNS EXG. ABUTMENT / WINGS/RETURNS 1740

ARE IN CRS STONE MASONRY. ARE IN CRS STONE MASONRY. it reaches new abutment (A2).

5156(SK) 6150(SK) 5154(SK) 1. The Top level of roller shall be top level of bed block plus dia of roller. 5156(SK) 6150(SK) 5154(SK) 2. The maximum cantilever portion of girder at any stage is 7.875m.

GL: 306.455

4920(SQ)

GL: 306.455

2. On exg.formation, roller platforms are to be made on top of cribs for keeping the rollers & rail clusters in line with DETAILS OF GL: 306.455

4920(SQ)

GL: 306.455 PRO. TOBB: 313.527 435 LEGEND:

3. Maximum pressure under the crib is 15.0t/m2 PRO. BOG: 313.962

bottom boom and inverted rails with rail cluster/wooden matting not exceed 7.875m c/c CRIB STAGING WITH WOODEN MATTING 4. After reaching the girder exactly over the new abutment (A2), lift the girder with the help of jacks of suitable 1200 2300 PRO.TEMPORARY ARRANGEMENTS ARE SHOWN IN MEGENTA

3. Winches are to be shifted from Khandwa end to Akola end and erect on embankment beyond new abutment No.2 ON EXISTING FORMATION FOR FIXING capacity and remove the temporary arrangments i.e., wooden blocks & service rails fixed to bottom side of ROLLER/RACKER BEARINGS

4. Reconnecting the pully and wire rope assembly to front side of ROR girder. Strings reached through pullies are connected to PRO. BRIDGE INCLUDING LAUNCHING OFGRDER ARE SHOWN IN RED

BOF: 302.855

EXG. ABUTMENT (A2) EXG. ABUTMENT (A1) BOF: 302.855 ROLLER LUSTER ASSEMBLY ON TOP. BOF: 302.855

EXG. ABUTMENT (A2) EXG. ABUTMENT (A1) BOF: 302.855 bottom chord of open web girder.

power winch on Akola end. EXG. BRIDGE AND FORMATION ARE SHOWN IN BLACK

5. Fix the bearings over the new abutments at correct location as per specifications. LAUNCHING OF GIRDER OVER BEARING

NEW ABUTMENT (A2) ELEVATION NEW ABUTMENT (A2) ELEVATION 6. Lower the girder over the bearings by operating jacks and fix the girder with the bearings in position. EXG. STRUCTURES TO BE DISMANTLED ARE SHOWN IN BLACK DOTTED

TO

Show in YELLOW NEW ABUTMENT (A1) DETAILS OF TRAFFIC AND POWER BLOCKS REQUIRED FOR LAUNCHING OF NEW OPEN WEB THROUGH TYPE WELDED

GIRDER

NEW ABUTMENT (A1)

TO

BH

E)

DOTTED Lines E)

DETAILS OF TRAFFIC AND POWER BLOCKS REQUIRED FOR LAUNCHING OF NEW OPEN WEB

TOTAL

YELLOW DOTTED-----

US

DURATION OF

BH

S.NO. DESCRIPTION OF ACTIVITY DURING BLOCK NO. OF THROUGH TYPE WELDED GIRDER

LIN BLOCKS TRAFFIC & POWER BLOCK REQD. LIN

HW

E) E)

US

LIN AI

N BLOCK (Hrs) (Hrs)

LIN AI

N Existing Abutments ,Wing & Return walls shall be S.NO. DESCRIPTION OF ACTIVITY DURING BLOCK

NO. OF DURATION OF TOTAL

BLOCKS TRAFFIC & POWER BLOCK REQD. This sentence not required.

PRO. TOBB: 313.527

HW

PRO. RL: 315.702

AL

PRO. FL: 314.964

M M

IN N 1. DISCONNECTING THE PULLY AND WIRE ROPE FROM NEW ROR GIRDER. IN N show in Yellow Colour with Dotted Lines.(Yellow BLOCK (Hrs) (Hrs)

MA (D MA (D

AL

SHIFTING OF POWER WINCHES FROM KNW END TO AKOLA END. RECONNECTING LAUNCHING OF NEW ROR GIRDER FROM EXISTING MG ROR BRIDGE

P CK THE PULLY AND WIRE ROPE ASSEMBLY AT FRONT SIDE OF ROR GIRDER AND 1 2 hrs. 2 hrs. P CK Indication is Dismantling)

3. NEW ABUTMENT- A2

5018 (U C

RA 5018 (U C

RA

ABUTMENT (A2) LOCATION WITH POWER WINCHES OPERATING

PRO. TOBB: 313.527

K CK

Exg Embankment width 5.50m

Exg Embankment width 5.50m

T SETTING THE ROLLER CLUSTERS BELOW GIRDER NEAR EXISTING MG ROR T FROM AKOLA END. REMOVAL OF ALL PULLY AND WIRE ROPE

AC G. RA G. CENTRAL RAILWAY HQ APPROVAL SOUTH CENTRAL RAILWAY

PRO. RL: 315.702

PRO. FL: 314.964

ABUTMENT (A2) LOCATION.

TR EX EX

ASSEMBLY CONNECTIONS FROM GIRDER. LIFTING OF NEW GIRDER 2 3 hrs. 6 hrs.

CE NT

T

H

UT

RA

SO

G. A1 . C A1

L

C

EX E XG AND SUPPORTING ON WOODEN BLOCK STAGINGS ON BOTH NEW

CAO/C/O/SC CAO/C/D/BR/ -2022

RA

I L WA Y

A2 A2 ABUTMENTS (A1), (A2). HQ. DRG. NO.

3000 3000 4. REMOVAL OF WOODEN BLOCKS AND SERVICE RAILS FROM BOTTOM

SIDE OF BOTTOM CHORDS ON LHS & RHS OF NEW GIRDER.

5775 5775 5775 5775 REMOVAL OF RAIL AND ROLLER CLUSTERS FROM TOP OF Change as

2 3 hrs. 6 hrs.

ABUTMENTS AT BEARING LOCATIONS.

Dy.CE/Br-II/HQ CBE/HQ

NANDED DIVISION

BUSAWAL

BUSAWAL

ADJUSTMENT OF GIRDER TO CORRECT C/C OF BEARINGS,

LEVELLING AND LOWERING OF NEW GIRDER COMPLETE OVER 1 3 hrs. 3 hrs. DY.CE/BR.DESIGNS/HQ

3

ROCKER & ROLLER BEARINGS ON BOTH ABUTMENTS IN POSITION. CONVERSION OF TRACK FROM M.G. TO B.G.

12000 12000

11550 11550 11550

X1

11550

Introduce one more C. RLY BSL DIVISIONAL APPROVAL BETWEEN AKOLA - KHANDWA SECTION

Row below

Z Dy.CE(Br-II) and

WOODEN BLOCK

WOODEN BLOCK

NEW FOR MATION UPTO TOP OF BED BLOCK NEW FOR MATION UPTO TOP OF BED BLOCK NEW FOR MATION UPTO TOP OF BED BLOCK NEW FOR MATION UPTO TOP OF BED BLOCK

PROPOSED RE BUILDING OF EXISTING ROR

C/L OF BEARING

C/L OF BEARING

30738 16460 30738 16460 PRO.WIDENING OF EXG. EMBANKMENT write as XEN(Br-II) DIV. DRG. NO.

C/L OF PRO. BRIDGE

C/L OF PRO. BRIDGE

29486 29486

ROLLER

ROLLER

BR. No. 570 /2 (1x16.46m MG) AT

SECTION @ X1-X1

PRO.WIDENING OF EXG. EMBANKMENT

PRO.WIDENING OF EXG. EMBANKMENT

ROLLERS ROLLERS

2650

POWER

PRO. WIDENING OF EXG. EMBANKMENT PRO.WIDENING OF EXG. EMBANKMENT

POWER

(C.RLY BG KM. 565/25-27), KM. 570/11-12,

SECTION @ Z-Z

PRO. WIDTH OF NEW EMBANKMENT

PRO. WIDTH OF NEW EMBANKMENT

TO A WIDTH OF 11.00m

TO A WIDTH OF 11.00m

WINCH WINCH

25 t. CAPACITY 25 t. CAPACITY DRM/BSL CH. 570696.084m AS 1x61.00m OPEN WEB

EMBANKMENT

C/L OF BEARING

C/L OF BEARING

AKOLA ROLLERS ROLLERS ROLLERS

AKOLA ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS

Introduce GIRDER BETWEEN KHANDWA

RAILS

RAILS

ROLLERS ROLLERS ROLLERS

KHANDWA KHANDWA

11000

11000

11000

EXG.

5700

5500

one more

5156

5500

5500

C/L OF PRO. TRACK C/L OF PRO. TRACK

5500

AND MORDAR STATIONS

Row below SR.DOM/BSL

DRM/BSL

and Write

LAUNCHING SCHEME

2650

ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS

PRO. WIDENING OF EXG. EMBANKMENT ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS ROLLERS

ADRM/T/

SR.DSTE/BSL SCALE= 1:200

Z BSL

EXG. ABUTMENT (A1)

NEW FOR MATION UPTO TOP OF BED BLOCK EXG. ABUTMENT (A2) (EXG. ABUTMENT TO BE DISMANTLED

NEW FOR MATION UPTO TOP OF BED BLOCK

NEW FOR MATION UPTO TOP OF BED BLOCK X1 EXG. ABUTMENT (A1)

NEW FOR MATION UPTO TOP OF BED BLOCK

(EXG. ABUTMENT TO BE DISMANTLED AFTER ERECTION OF GIRDER)

KH

KH

AFTER ERECTION OF GIRDER) EXG. ABUTMENT (A2) (EXG. ABUTMENT TO BE DISMANTLED

KHANDWA

KHANDWA

(H.K.BHAGHORIA)

AN

AN

(EXG. ABUTMENT TO BE DISMANTLED

AFTER ERECTION OF GIRDER) Sr.DEE / TRD / BSL CE/C/V/SC

DW

DW

12000 11550 11550 12000 11550 11550

AFTER ERECTION OF GIRDER)

A

A

NEW FOR MATION

Sr.DEN/ Co-ORD/BSL DY.CE/C/DESIGNS/SC (P.RAJAGOPAL RAO)

5775 5775 5775 5775

3000 3000 Sr.DEN/North/BSL AXEN/C/DESIGNS/SC (M.SRIDHARA RAO)

A2 A2

A1 A1

5018 5018

SSE/DRG/BSL DY.CE/C/AK (Y. YOGANANDA BABU)

PLAN PLAN

AXEN/C/AK (PURUSHOTHAM BUSSA)

SSE/DRG/C/AK JE/W/C/KNW (AJAY KUMAR KUSHWAHA)

You might also like

- Xiaomi Mi 10t Pro Schematic+PcbDocument66 pagesXiaomi Mi 10t Pro Schematic+PcbTecnicos GeveyNo ratings yet

- Rdso 10415Document5 pagesRdso 10415Basava SrikanthNo ratings yet

- Phase 3Document1 pagePhase 3Himmanshu SabharwalNo ratings yet

- Diagrama Electric Hyundai 730-9sDocument2 pagesDiagrama Electric Hyundai 730-9sFranco SartoriNo ratings yet

- DN#1200 TB1 - 3Document1 pageDN#1200 TB1 - 3Arbaz KhanNo ratings yet

- Sector 76Document1 pageSector 76KaranNo ratings yet

- 1801-FR02-42-R-XD-00008 - C1 - General Arrangement - S42PD528 - S42PD537 Scale Inhibitor Topside - PolyelectrolyteDocument1 page1801-FR02-42-R-XD-00008 - C1 - General Arrangement - S42PD528 - S42PD537 Scale Inhibitor Topside - PolyelectrolyteNam DHNo ratings yet

- Second Reflected Ceiling Layout - Part 01 2: Jordan Ahli Bank HeadquartersDocument1 pageSecond Reflected Ceiling Layout - Part 01 2: Jordan Ahli Bank HeadquartersRabee BataynehNo ratings yet

- ELElDocument1 pageELElALEENA ASLAMNo ratings yet

- 9.06 - Julgado Favoravel - Concessão de Salário-Maternidade A Gestante DesempregadaDocument7 pages9.06 - Julgado Favoravel - Concessão de Salário-Maternidade A Gestante DesempregadaJose Maria AlmeidaNo ratings yet

- Fire Evacuation Layout 18th FloorDocument10 pagesFire Evacuation Layout 18th Floorangelic9146No ratings yet

- NTR 02 Final 05-12-2022Document1 pageNTR 02 Final 05-12-2022Danish DaniNo ratings yet

- 6starmhroof-005 (Sheet 1 of 6)Document1 page6starmhroof-005 (Sheet 1 of 6)Jacob FryeNo ratings yet

- 6starmhconcourse-003 (Sheet 1 of 6)Document1 page6starmhconcourse-003 (Sheet 1 of 6)Jacob FryeNo ratings yet

- HBY - Ground Floor - Incoming Products PDFDocument1 pageHBY - Ground Floor - Incoming Products PDFsupportLSMNo ratings yet

- 9.04 - Julgado Favoravel - Concessão de Salário-Maternidade A Segurada EspecialDocument9 pages9.04 - Julgado Favoravel - Concessão de Salário-Maternidade A Segurada EspecialJose Maria AlmeidaNo ratings yet

- Japanese Zone Neemrana LayoutDocument1 pageJapanese Zone Neemrana Layoutajay singhNo ratings yet

- Makateeb e Sadrul Afazil by Zulfaqar Khan NaimiDocument251 pagesMakateeb e Sadrul Afazil by Zulfaqar Khan Naimisunnivoice100% (2)

- E-06 - TYPE B1 (r2) - Layout1Document1 pageE-06 - TYPE B1 (r2) - Layout1kedai kitaNo ratings yet

- Cotação 5970666 R C Carvalho Industria e Montagem LtdaDocument2 pagesCotação 5970666 R C Carvalho Industria e Montagem LtdaDouglas ChoeNo ratings yet

- 340 BHM Civ Rei 3212 Area-10-Core-Shaft-Puller-Pit FC 00Document1 page340 BHM Civ Rei 3212 Area-10-Core-Shaft-Puller-Pit FC 00Arizteo ZenitNo ratings yet

- Mapa de Evacuación de La Planta de ÓsmosisDocument1 pageMapa de Evacuación de La Planta de ÓsmosisRocio Carbajal PardoNo ratings yet

- Group 2 Electrical CircuitDocument2 pagesGroup 2 Electrical CircuitLuciano SantosNo ratings yet

- Doc-20230121-Wa0039 230126 125959Document3 pagesDoc-20230121-Wa0039 230126 125959Carla ReyesNo ratings yet

- He Who Watches Over Israel (Psalm 121) For OrganDocument1 pageHe Who Watches Over Israel (Psalm 121) For OrganSerban NichiforNo ratings yet

- Single Layout PlanDocument1 pageSingle Layout PlancinchmakNo ratings yet

- Basement Plan: Proposed Villa B+G+1+Ph+ Swimming Pool + Ancillary BlocksDocument1 pageBasement Plan: Proposed Villa B+G+1+Ph+ Swimming Pool + Ancillary BlocksNAHEEMA KPNo ratings yet

- JCB Fastrac 2115 2125 2135 2140 2150 3155 3185 SMDocument1,028 pagesJCB Fastrac 2115 2125 2135 2140 2150 3155 3185 SMDmytro PichkurNo ratings yet

- Joyce NK Architectural Drawing 002Document1 pageJoyce NK Architectural Drawing 002qualitylifearchitectureNo ratings yet

- Other Tenant Area: UdaanDocument1 pageOther Tenant Area: UdaanMohammad SaquibNo ratings yet

- Hs-Sheet 12Document1 pageHs-Sheet 12Reymundo BejaNo ratings yet

- Igi Airport Grid Map 10.08.2023Document1 pageIgi Airport Grid Map 10.08.2023Abhay PatilNo ratings yet

- 6-Letra DDocument135 pages6-Letra DalantramolNo ratings yet

- Meio AbineteDocument58 pagesMeio AbineteAndre SilvaNo ratings yet

- Column Layout As Per Site MeasurementDocument1 pageColumn Layout As Per Site MeasurementDhairya ShahNo ratings yet

- Mya Kyun Thar - Shopping Centre DATE: 8-April-2023: Elv System Layout at Basement FloorDocument7 pagesMya Kyun Thar - Shopping Centre DATE: 8-April-2023: Elv System Layout at Basement Flooraungphyoe tharNo ratings yet

- A101 - General Layout - A1 - 19.07Document1 pageA101 - General Layout - A1 - 19.07Rodhel Mark PalermoNo ratings yet

- BGLR 1080 F1 FinalDocument1 pageBGLR 1080 F1 FinalMani CadNo ratings yet

- Afzal Publications: TaghootDocument12 pagesAfzal Publications: TaghootMohammed IbrahimNo ratings yet

- PlansDocument23 pagesPlansKendy Marr SalvadorNo ratings yet

- Phase 6Document1 pagePhase 6Hasan RaufNo ratings yet

- Minidysk SONY - MDS303 PDFDocument4 pagesMinidysk SONY - MDS303 PDFNerta NaturaNo ratings yet

- 7 2 PDFDocument20 pages7 2 PDFservisNo ratings yet

- Geo Topo Map CanadaDocument1 pageGeo Topo Map CanadafdacunhaNo ratings yet

- MB Can Ho Tang 6Document1 pageMB Can Ho Tang 6Dương ĐinhNo ratings yet

- Construction Drawing: LegendDocument1 pageConstruction Drawing: LegendrajavelNo ratings yet

- Basic Drawing: PT Perusahaan Perdagangan IndonesiaDocument2 pagesBasic Drawing: PT Perusahaan Perdagangan IndonesiaRuby LaNo ratings yet

- Anantraj Plots Sec 63Document1 pageAnantraj Plots Sec 63bhaveshvats194No ratings yet

- Rectangular Tubing Regan CatalogDocument2 pagesRectangular Tubing Regan CatalogJerome BalanoyosNo ratings yet

- CCTV 101Document1 pageCCTV 101Arun UdayabhanuNo ratings yet

- Baylink Dwg.27.8.23pdfDocument12 pagesBaylink Dwg.27.8.23pdfshohugNo ratings yet

- Project Ruby: As Built DrawingDocument1 pageProject Ruby: As Built DrawingTôn Huỳnh ĐoànNo ratings yet

- 83A CommercialDocument1 page83A CommercialKaramjot AroraNo ratings yet

- 21.AII 1.2.3'' Plan Sytuacyjny Odcinek1 Wariant3Document1 page21.AII 1.2.3'' Plan Sytuacyjny Odcinek1 Wariant3Qrvix PlNo ratings yet

- PRA SITEPLAN JABONG VILLAGE-2022 07 04lDocument1 pagePRA SITEPLAN JABONG VILLAGE-2022 07 04lPebriansyah BSNo ratings yet

- Dokumen - Tips Still r70 30 Fork Truck Service Repair ManualDocument23 pagesDokumen - Tips Still r70 30 Fork Truck Service Repair ManualAdrian DivorNo ratings yet

- AHM - 230216 - Municipality LayoutDocument1 pageAHM - 230216 - Municipality LayoutM AzharNo ratings yet

- Cor 202Document1 pageCor 202jitlerjamezNo ratings yet

- Arshia Publications ListDocument8 pagesArshia Publications ListSalmanNo ratings yet

- Equipamientos Administrativos PunoDocument1 pageEquipamientos Administrativos PunoAldahir Sucari BanegasNo ratings yet

- Stresses in KN/M 2Document3 pagesStresses in KN/M 2Basava SrikanthNo ratings yet

- PSC LossessDocument4 pagesPSC LossessBasava SrikanthNo ratings yet

- Technical Schedules - Baghmati - EPC - 25 Oct 2023Document43 pagesTechnical Schedules - Baghmati - EPC - 25 Oct 2023Basava SrikanthNo ratings yet

- Nandagopal Reddy SheetingDocument9 pagesNandagopal Reddy SheetingBasava SrikanthNo ratings yet

- Launching of ROB 58 Notes-85%lDocument1 pageLaunching of ROB 58 Notes-85%lBasava SrikanthNo ratings yet

- Column Design-6Document2 pagesColumn Design-6Basava SrikanthNo ratings yet

- Pile CapDocument7 pagesPile CapBasava SrikanthNo ratings yet

- EstablishmentDocument11 pagesEstablishmentBasava SrikanthNo ratings yet

- Prestressing Effect Ist Stage 2 NosDocument3 pagesPrestressing Effect Ist Stage 2 NosBasava SrikanthNo ratings yet

- Vasista Two Track Pier Stability (P 11)Document34 pagesVasista Two Track Pier Stability (P 11)Basava SrikanthNo ratings yet

- Pier DesignDocument33 pagesPier DesignBasava SrikanthNo ratings yet

- 570-2 DELAUNCHING-04!09!21 (To Be Corrected)Document1 page570-2 DELAUNCHING-04!09!21 (To Be Corrected)Basava SrikanthNo ratings yet

- CCTP Lot N°05 CUVELAGEDocument9 pagesCCTP Lot N°05 CUVELAGELaurent SylvaNo ratings yet

- Door DoorAndFrame 20190514Document10 pagesDoor DoorAndFrame 20190514BeatrizLlamasNo ratings yet

- Test Closet QuestionairreDocument2 pagesTest Closet QuestionairreShujaRehmanNo ratings yet

- Din en 15037-1 BeamsDocument95 pagesDin en 15037-1 BeamsSamuel MbuguaNo ratings yet

- User Manual: International Industry of Metallic Formwork SystemsDocument9 pagesUser Manual: International Industry of Metallic Formwork Systemsjachoijachoi100% (1)

- Contractor To Check and Verify All Dimensions Before Execution of The WorkDocument3 pagesContractor To Check and Verify All Dimensions Before Execution of The Worksarathirv6No ratings yet

- MOCK ALE Set 3A - Day 1 Part 2 Answer KeyDocument31 pagesMOCK ALE Set 3A - Day 1 Part 2 Answer KeyROQUENo ratings yet

- Chinese ArchitectureDocument89 pagesChinese ArchitectureXlyth RodriguezNo ratings yet

- Avigna Tutorials: English Class 12 Section A-AssignmentDocument9 pagesAvigna Tutorials: English Class 12 Section A-Assignmentrishit guptaNo ratings yet

- Brochure TechSpan 2Document2 pagesBrochure TechSpan 2kunal humaneNo ratings yet

- Arts Appreciation: The Meaning and Importance of ArtDocument19 pagesArts Appreciation: The Meaning and Importance of ArtAlkiana SalardaNo ratings yet

- Property Condition Assessment: Brentwood OaksDocument80 pagesProperty Condition Assessment: Brentwood OaksRobert LévesqueNo ratings yet

- TOA 213 - Midterm ExamDocument5 pagesTOA 213 - Midterm ExamJoenard CastroNo ratings yet

- Wall SystemsDocument26 pagesWall SystemsmurdicksNo ratings yet

- FIRECLASS Fire Detection System 4B Bases and AccessoriesDocument12 pagesFIRECLASS Fire Detection System 4B Bases and AccessoriesMariusNo ratings yet

- CementDocument11 pagesCementHerdian NafiNo ratings yet

- 20.04.2022-Snag Report - ADocument9 pages20.04.2022-Snag Report - ASooraj VsNo ratings yet

- IB Steel StructuresDocument8 pagesIB Steel StructuresSuresh RajuNo ratings yet

- Waffle SlabDocument6 pagesWaffle SlabReymond Longtable100% (1)

- Company Profile TMC TOPLINEDocument7 pagesCompany Profile TMC TOPLINEfelipeNo ratings yet

- Method Statement For Precast Concrete Fabrication and InstallationDocument14 pagesMethod Statement For Precast Concrete Fabrication and InstallationEslam NasserNo ratings yet

- FYP 1 Interim ReportDocument29 pagesFYP 1 Interim ReportOdu Paul DukuNo ratings yet

- Work Order Zarwali Khan Solar Energy T.well 23.0875 MDocument3 pagesWork Order Zarwali Khan Solar Energy T.well 23.0875 MNouman AkhtarNo ratings yet

- An Experimental Investigation in Paver Blocks by Replacing Sand With Manufacturing Sand and Its Strength ComparisonDocument13 pagesAn Experimental Investigation in Paver Blocks by Replacing Sand With Manufacturing Sand and Its Strength ComparisonPratik WANKHEDENo ratings yet

- NEP Syllabus IDD 16102021Document32 pagesNEP Syllabus IDD 16102021chandra sagar shindhe.m100% (1)

- Sectiune Transversala Cross Section: Scara/Scale 1:100Document1 pageSectiune Transversala Cross Section: Scara/Scale 1:100MariusHazaparuNo ratings yet

- Fire Damper Install InstructionsDocument14 pagesFire Damper Install InstructionsDongNo ratings yet

- Introduction To Piping FabricationDocument5 pagesIntroduction To Piping FabricationSyed IbrahimNo ratings yet

- Teacher's Ghost Story - Please Feel Free To Use Mine or Create Your Own!Document3 pagesTeacher's Ghost Story - Please Feel Free To Use Mine or Create Your Own!Emily StonesNo ratings yet

- HyperboleDocument2 pagesHyperboleMariam BazerbachiNo ratings yet