Professional Documents

Culture Documents

SI Auto Transm BPT 06 18 Rev2

SI Auto Transm BPT 06 18 Rev2

Uploaded by

deepak.sCopyright:

Available Formats

You might also like

- Science 10 4th Quarter ExamDocument4 pagesScience 10 4th Quarter Examzayd86% (49)

- Iso 8583 PDFDocument10 pagesIso 8583 PDFkartik300881100% (3)

- 330C Excavator Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pages330C Excavator Electrical System: Harness and Wire Electrical Schematic SymbolsGerardo Balboa50% (2)

- DFMEA Examples 29JUN2020 7.2.19Document24 pagesDFMEA Examples 29JUN2020 7.2.19Mani Rathinam RajamaniNo ratings yet

- Modern Digital and Analog Communication Systems 4th Edition by LathiDocument926 pagesModern Digital and Analog Communication Systems 4th Edition by Lathimhmd_4u82% (11)

- Sample On Operation Management in Business by Instant Essay WritingDocument18 pagesSample On Operation Management in Business by Instant Essay WritingInstant Essay Writing100% (1)

- Activity8 - Inspection & Test Plan of Pump SetDocument8 pagesActivity8 - Inspection & Test Plan of Pump SetJoel MinafiNo ratings yet

- Von Willebrand Factor Antigen - 0020002300: Limitations/interfering SubstancesDocument3 pagesVon Willebrand Factor Antigen - 0020002300: Limitations/interfering Substances28850No ratings yet

- 993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsNorman CoetzeeNo ratings yet

- Histogram X-Bar Chart: Company NameDocument1 pageHistogram X-Bar Chart: Company NameSachin RamdurgNo ratings yet

- CX EN Manu DRW171461AB 20180726 WDocument1 pageCX EN Manu DRW171461AB 20180726 WEricsonOSNo ratings yet

- CHK Ksau MCS 00Document7 pagesCHK Ksau MCS 00AhmedNo ratings yet

- 993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsLeoNo ratings yet

- Ex4 01 - SISDocument2 pagesEx4 01 - SISMario Quinteiro0% (1)

- Preventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NODocument1 pagePreventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NOGnanavel GNo ratings yet

- AVK Check-Valves BrochureDocument32 pagesAVK Check-Valves BrochureHadi SofyanNo ratings yet

- Blackodizing CPDocument1 pageBlackodizing CPx yNo ratings yet

- Lifting - Equipment - Matrix1 (Under Constrution)Document1 pageLifting - Equipment - Matrix1 (Under Constrution)PradeepNo ratings yet

- 777D Off-Highway Truck Electrical System and 776D Tractor: Machine Harness Connector and Component LocationsDocument2 pages777D Off-Highway Truck Electrical System and 776D Tractor: Machine Harness Connector and Component LocationsNorman CoetzeeNo ratings yet

- Wind Power ApplicationsDocument2 pagesWind Power Applicationsmiguel itsonNo ratings yet

- en de 170831 1Document8 pagesen de 170831 1trip3milihNo ratings yet

- Belt Drift Switch Safe T Pull STD P D KDocument17 pagesBelt Drift Switch Safe T Pull STD P D K生月No ratings yet

- Tan 2001Document6 pagesTan 2001t123medNo ratings yet

- Skill Matrix RAMSDocument6 pagesSkill Matrix RAMSSiva KumarNo ratings yet

- Day3 Function FMEADocument56 pagesDay3 Function FMEAPaul StarkNo ratings yet

- Rainfall PredictionDocument8 pagesRainfall PredictionANIKET DUBEYNo ratings yet

- Certs Comparison 2009Document1 pageCerts Comparison 2009AnkitNo ratings yet

- 8D ReportDocument1 page8D ReportqualityNo ratings yet

- CHK Ksau Iptv 00Document7 pagesCHK Ksau Iptv 00AhmedNo ratings yet

- H-10207 00 0ea00-001f Fa-Cscs System Configuration Diagram - DDocument1 pageH-10207 00 0ea00-001f Fa-Cscs System Configuration Diagram - Dnguyen rinNo ratings yet

- 9 10 enDocument2 pages9 10 enparth kananiNo ratings yet

- Insulation Resistance Test FormDocument1 pageInsulation Resistance Test FormJohny AdvientoNo ratings yet

- AWS Periodic TableDocument1 pageAWS Periodic Tabledouglas.dvferreiraNo ratings yet

- Potential Failure Mode and Effective Analysis (Process FMEA)Document1 pagePotential Failure Mode and Effective Analysis (Process FMEA)nainarmuthuramalingamNo ratings yet

- 1) Electric Circuits - Basic ConceptsDocument9 pages1) Electric Circuits - Basic ConceptsJOSE AUGUSTO MODESTO HUAYLINOS GUERRERONo ratings yet

- 318C PDFDocument4 pages318C PDFTidjani SallNo ratings yet

- Poster SafetyDocument1 pagePoster SafetyJose Ricardo DuranNo ratings yet

- QAS - ERE 0.09 Bolt Torque Inspection ReportDocument1 pageQAS - ERE 0.09 Bolt Torque Inspection ReportJoanne InciongNo ratings yet

- Electricity 3 Lpt012Document3 pagesElectricity 3 Lpt012Nadah8No ratings yet

- MEA Testing Systems LTD CatalogDocument105 pagesMEA Testing Systems LTD CatalogPawin lothongNo ratings yet

- 966H and 972H Electrical System Wheel LoaderDocument4 pages966H and 972H Electrical System Wheel Loaderleonardo rivero100% (1)

- Sistema Eletrico 226Document4 pagesSistema Eletrico 226f8ytws84csNo ratings yet

- UENR2643UENR2643-05 - SIS Electrico Diagrama PDFDocument4 pagesUENR2643UENR2643-05 - SIS Electrico Diagrama PDFJaime LopezNo ratings yet

- SKETCH 022 Tripping MatrixDocument6 pagesSKETCH 022 Tripping MatrixÖzgür Özdemir100% (1)

- Instabilities Legend Prism Status Chart of Status Instrumentation Legend Vector Legend Prism Legend Prisms ReadingsDocument1 pageInstabilities Legend Prism Status Chart of Status Instrumentation Legend Vector Legend Prism Legend Prisms ReadingsEdson OoNo ratings yet

- Engine Structure Poster 18x24Document1 pageEngine Structure Poster 18x24Алексей Гончаров100% (1)

- Von Willebrand Factor Activity - 0020004700: in Vitro Diagnostic Medical Device In-Vitro DiagnostikumDocument3 pagesVon Willebrand Factor Activity - 0020004700: in Vitro Diagnostic Medical Device In-Vitro Diagnostikum28850No ratings yet

- GOOLOO GE1200 - User ManualDocument1 pageGOOLOO GE1200 - User ManualzoltanpolyakNo ratings yet

- 202301-Quality Management-75053Document30 pages202301-Quality Management-75053SRJ Do ItNo ratings yet

- Indicadores Caratula NigataSeikiDocument26 pagesIndicadores Caratula NigataSeikiJuan Pablo Chumba LaraNo ratings yet

- Productspecificaties Linde H100 H180 Zware HeftrucksDocument2 pagesProductspecificaties Linde H100 H180 Zware HeftrucksJan Hendriks50% (2)

- Composite / Steel Cost Comparison: Utility: Composites Offer The FollowingDocument11 pagesComposite / Steel Cost Comparison: Utility: Composites Offer The FollowingMitu Leonard-GabrielNo ratings yet

- 330C L Electrico CYA00240Document2 pages330C L Electrico CYA00240Mario BaldocedaNo ratings yet

- Mapa Informativo de Controle de Componentes E InspeçõesDocument2 pagesMapa Informativo de Controle de Componentes E InspeçõesLuiza ANo ratings yet

- TH350B, TH355B, and TH360B Electrical System TelehandlerDocument2 pagesTH350B, TH355B, and TH360B Electrical System TelehandlerMohamed Harb100% (1)

- 5kv Insulation Resistance Tester Hioki 3455Document4 pages5kv Insulation Resistance Tester Hioki 3455industrialindiaNo ratings yet

- 23 07 2018 - DAY-Inspection Log SheetDocument1 page23 07 2018 - DAY-Inspection Log SheetArunNo ratings yet

- 78101-40700000-IC-MDL-10000 Copper Alarms Settings For DCS Configuration Rev0BDocument13 pages78101-40700000-IC-MDL-10000 Copper Alarms Settings For DCS Configuration Rev0BGemasgoodasdf DjdjdjNo ratings yet

- D3 - DPS Evc CDocument2 pagesD3 - DPS Evc CGonzalo Villalobos SanchezNo ratings yet

- 02.optical Network TestingDocument1 page02.optical Network Testingphuongnt1710No ratings yet

- Log TMBMC26Y123514233 175210km 108870miDocument3 pagesLog TMBMC26Y123514233 175210km 108870miRosu AlinNo ratings yet

- 02 Oliver NenadovicDocument39 pages02 Oliver NenadovicRinu RavikumarNo ratings yet

- History of The Redstone Missile SystemDocument198 pagesHistory of The Redstone Missile SystemVoltaireZeroNo ratings yet

- P 1 1 Leung DDocument10 pagesP 1 1 Leung DMasha NikolovaNo ratings yet

- Din en Iso 3822-1 - enDocument27 pagesDin en Iso 3822-1 - enDaniel GrobNo ratings yet

- Packet Header FormatDocument6 pagesPacket Header FormatJohnSebastianNo ratings yet

- Site Exploration: Vedprakash C. MarlapalleDocument45 pagesSite Exploration: Vedprakash C. Marlapallevedprakash marlapalle100% (1)

- Low Profile Hammer Union Caps - 2017Document2 pagesLow Profile Hammer Union Caps - 2017Hector Luis MejiaNo ratings yet

- The Ball Piston EngineDocument13 pagesThe Ball Piston EnginedhairyashilNo ratings yet

- CV Rizaljs Indonesia PDFDocument18 pagesCV Rizaljs Indonesia PDFHumairah AnandaNo ratings yet

- General Fitting Guide For Bottle Traps: Installation ProcedureDocument1 pageGeneral Fitting Guide For Bottle Traps: Installation ProcedureAfzal FasehudeenNo ratings yet

- Pile Foundations - IntroductionDocument15 pagesPile Foundations - IntroductionMUHAMMAD BILAL AHMADNo ratings yet

- Vsolution Pon App Example v1.0.1Document60 pagesVsolution Pon App Example v1.0.1Chu Minh ThắngNo ratings yet

- 08 Kaizen CornerDocument3 pages08 Kaizen Corneryasser hannaneNo ratings yet

- Lecture17 Flip FlopsDocument23 pagesLecture17 Flip Flopszoro gohNo ratings yet

- Rs 71 Ball Mill Sizng-1Document4 pagesRs 71 Ball Mill Sizng-1Dilnesa Ejigu100% (1)

- Data Sheet-Cable-24.12.21Document22 pagesData Sheet-Cable-24.12.21YASHASHWYNo ratings yet

- Programat P300-G2 PDFDocument6 pagesProgramat P300-G2 PDFRodica RoscaNo ratings yet

- Gold Cup Application HandbookDocument72 pagesGold Cup Application HandbookMarcelo ArayaNo ratings yet

- An Agent of The Black Nobility Betrays HimselfDocument20 pagesAn Agent of The Black Nobility Betrays Himselfkaren hudes100% (1)

- Receiver Noise Figure MeasurementDocument13 pagesReceiver Noise Figure Measurementعلی بنائیNo ratings yet

- Intro CsamtDocument4 pagesIntro CsamtJoshLeighNo ratings yet

- Underground ConduitsDocument25 pagesUnderground ConduitsAbdul AzimNo ratings yet

- Praxair Tafa CatalogDocument12 pagesPraxair Tafa Catalogperroloco111178No ratings yet

- Parts Guide Manual: HD-514 A1RmDocument17 pagesParts Guide Manual: HD-514 A1RmmemetNo ratings yet

- 2007 - 06 - 01 - Illawarra Escarpment Land Use Review Strategy PT 1Document104 pages2007 - 06 - 01 - Illawarra Escarpment Land Use Review Strategy PT 1NorfolkingNo ratings yet

SI Auto Transm BPT 06 18 Rev2

SI Auto Transm BPT 06 18 Rev2

Uploaded by

deepak.sOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SI Auto Transm BPT 06 18 Rev2

SI Auto Transm BPT 06 18 Rev2

Uploaded by

deepak.sCopyright:

Available Formats

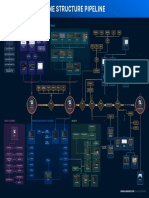

Data-Driven Decisions Through In-Process Test

Automatic Transmission Manufacturing: Final Assembly Testing

LEGEND

Harness the combined power of in-process testing

Key test application End of line tests

Check of Gear Set Check Backlash and data analytics on your production line with Sciemetric.

Sub assembly line Sample Qualityworx™ station(s)

Assembly Check Backlash Test Description: Rotational gear

Test Description: Rotational gear set TIT,

set TIT, gage and vibration check. Visit www.sciemetric.com or email inquiries@sciemetric.com. Main assembly line

gage and vibration check. Signatures/Measurements:

Torque vs. angle, laser vs. angle,

Signatures/Measurements: Torque vs. angle,

accelerometer vs. angle.

laser vs. angle, accelerometer vs. angle.

Defects: Binding, nicks, improper gear sets.

Defects: Binding, nicks, improper gear sets.

SUB ASSEMBLY LINE 10a 10b

Clutch Apply/ Release

Snap Ring Verification Torque Check

Gage Stack-Up Oil Fill/Volume Test Test Description: Torque to turn of

Test Description: Gage seated snap ring with sensor

to determine proper insertion. Test Description: Multiple or single probe Test Description: Oil fill and volume test. clutch.

gaging for stack up (laser or LVDT). Signatures/Measurements: Pressure Signatures/Measurements: Torque

Signatures/Measurements: Based on probe used,

profile, and machine vision images and data. Signatures/Measurements: Profile vs. time test vs. time or mass flow vs. time. vs. angle (run and apply).

or Profile vs. encoder. Defects: No fluid, improper fluid levels. Defects: Verify proper clutch

Defects: Missing snap ring, incorrect size or not

seated. Defects: Defective stack up from mis- installation and clutch operation.

assembled or mis-aligned components.

Improperly sized components.

MAIN ASSEMBLY LINE 10 20 30 40 50 60 70 80 End Play Check Input Shaft

Test Description: End play check of main

input shaft.

Signatures/Measurements: Load vs. distance.

Force-Distance Checks Seal Integrity Check Shim Size Verification for Bearing Case Ground/Rotational Clutch Flow Defects: Verify proper input shaft installation.

Test Description: Verify proper insertion Test Description: Verify sealing integrity Pre-Load Test Description: Torque to turn of rotational clutch

of dowel pins, cup plugs or seals. of rear transmission seal using a standard and flow test. 90

Test Description: Gage shim height with advancing

Signatures/Measurements: Force vs. time, pressure or flow test. Signatures/Measurements: Torque vs. angle,

probe for correct shim size.

distance vs. time and force vs. distance. Signatures/Measurements: Pressure Flow vs. time.

Signatures/Measurements: Distance measurement.

Defects: Missing dowel pins, seal or plugs, decay vs. time or mass flow vs. time. Defects: Verify proper clutch installation.

Defects: Determine proper sizing for shims.

incorrect size, misalignment, insertion to Defects: Missing seal, incorrect seal, rolled

proper depth. seal, defective seal, cocked seal.

Liquid Gasket Verification

Test Description: Check liguid sealing, gathering

machine vision images and data.

Signatures/Measurements: Flow vs. pressure

and pressure vs. pump.

Defects: Air bubbles, blocked nozzles, incorrect

100 nozzle, too little or too much sealant, etc.

Oil Fill Check Final Wet Torque/Run Out Check Oil Fill/Volume Test Final Leak Test

DATA COLLECTION, MANAGEMENT AND ANALYSIS Test Description: Oil fill Check. Test Description: Final Wet Torque and Run Test Description: Oil fill and volume test. Test Description: Final Leak Test.

out Check.

Signatures/Measurements: Signatures/Measurements: Signatures/Measurements: Pressure

Collect and store data

Pressure test vs. time or mass

flow.

Signatures/Measurements: Pressure test vs. time

or mass flow vs. time.

Pressure test vs. time or mass flow

vs. time.

decay vs. time or mass flow vs. time. 110

Defects: Missing seal, incorrect seal,

for each test. Generate Defects: No fluid, improper fluid Defects: Improper drag torque, TIR profile on Defects: No fluid, improper fluid levels. rolled seal, defective seal, cocked seal. Dynamic Radial Shaft Seal

reports on production levels. Verification of fluid. input shaft. Run out signature. Leak Test/Final Dry Torque

quality or specific parts. Test Description: Dynamic Radial shaft

seal leak test and final dry torque.

Analyze information to

Signatures/Measurements: Torque vs. angle,

Q20 identify the root causes 170 150 140 130 120 Pressure decay vs. time or mass, flow vs. time.

of issues affecting Defects: Improper drag torque, improper

yield, to optimize seal installation.

manufacturing test

cycles, management

TRS Check/Electrical

limits and more. 160 160 160 Continuity Test

Test Description: TRS Check Electrical

Continuity Check.

Signatures/Measurements: Current vs. time,

electric continuity vs. time.

Q10 Defects: Defective sensors, electrical shorts.

END OF LINE TESTS

End of Line Tests

Test Description: Final Test Stands Check.

Signatures/Measurements: Accelerometers vs.

angle FFT vs. angle.

REPAIR BAY MANAGER

Defects: Disassembly, gear mesh, bent parts.

Nicks, burrs, sub-micron machining errors. Using QualityWorX,

collects information about

the parts under repair.

Associates test and

operation step failures

to defects and repairs.

Provides statistical data to

enable defect avoidance.

© 2018 Sciemetric Instruments, Inc. All brand and product names are trademarks or registered trademarks of their respective companies. BPT-auto-transmission-rev2-June18

You might also like

- Science 10 4th Quarter ExamDocument4 pagesScience 10 4th Quarter Examzayd86% (49)

- Iso 8583 PDFDocument10 pagesIso 8583 PDFkartik300881100% (3)

- 330C Excavator Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pages330C Excavator Electrical System: Harness and Wire Electrical Schematic SymbolsGerardo Balboa50% (2)

- DFMEA Examples 29JUN2020 7.2.19Document24 pagesDFMEA Examples 29JUN2020 7.2.19Mani Rathinam RajamaniNo ratings yet

- Modern Digital and Analog Communication Systems 4th Edition by LathiDocument926 pagesModern Digital and Analog Communication Systems 4th Edition by Lathimhmd_4u82% (11)

- Sample On Operation Management in Business by Instant Essay WritingDocument18 pagesSample On Operation Management in Business by Instant Essay WritingInstant Essay Writing100% (1)

- Activity8 - Inspection & Test Plan of Pump SetDocument8 pagesActivity8 - Inspection & Test Plan of Pump SetJoel MinafiNo ratings yet

- Von Willebrand Factor Antigen - 0020002300: Limitations/interfering SubstancesDocument3 pagesVon Willebrand Factor Antigen - 0020002300: Limitations/interfering Substances28850No ratings yet

- 993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsNorman CoetzeeNo ratings yet

- Histogram X-Bar Chart: Company NameDocument1 pageHistogram X-Bar Chart: Company NameSachin RamdurgNo ratings yet

- CX EN Manu DRW171461AB 20180726 WDocument1 pageCX EN Manu DRW171461AB 20180726 WEricsonOSNo ratings yet

- CHK Ksau MCS 00Document7 pagesCHK Ksau MCS 00AhmedNo ratings yet

- 993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsLeoNo ratings yet

- Ex4 01 - SISDocument2 pagesEx4 01 - SISMario Quinteiro0% (1)

- Preventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NODocument1 pagePreventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NOGnanavel GNo ratings yet

- AVK Check-Valves BrochureDocument32 pagesAVK Check-Valves BrochureHadi SofyanNo ratings yet

- Blackodizing CPDocument1 pageBlackodizing CPx yNo ratings yet

- Lifting - Equipment - Matrix1 (Under Constrution)Document1 pageLifting - Equipment - Matrix1 (Under Constrution)PradeepNo ratings yet

- 777D Off-Highway Truck Electrical System and 776D Tractor: Machine Harness Connector and Component LocationsDocument2 pages777D Off-Highway Truck Electrical System and 776D Tractor: Machine Harness Connector and Component LocationsNorman CoetzeeNo ratings yet

- Wind Power ApplicationsDocument2 pagesWind Power Applicationsmiguel itsonNo ratings yet

- en de 170831 1Document8 pagesen de 170831 1trip3milihNo ratings yet

- Belt Drift Switch Safe T Pull STD P D KDocument17 pagesBelt Drift Switch Safe T Pull STD P D K生月No ratings yet

- Tan 2001Document6 pagesTan 2001t123medNo ratings yet

- Skill Matrix RAMSDocument6 pagesSkill Matrix RAMSSiva KumarNo ratings yet

- Day3 Function FMEADocument56 pagesDay3 Function FMEAPaul StarkNo ratings yet

- Rainfall PredictionDocument8 pagesRainfall PredictionANIKET DUBEYNo ratings yet

- Certs Comparison 2009Document1 pageCerts Comparison 2009AnkitNo ratings yet

- 8D ReportDocument1 page8D ReportqualityNo ratings yet

- CHK Ksau Iptv 00Document7 pagesCHK Ksau Iptv 00AhmedNo ratings yet

- H-10207 00 0ea00-001f Fa-Cscs System Configuration Diagram - DDocument1 pageH-10207 00 0ea00-001f Fa-Cscs System Configuration Diagram - Dnguyen rinNo ratings yet

- 9 10 enDocument2 pages9 10 enparth kananiNo ratings yet

- Insulation Resistance Test FormDocument1 pageInsulation Resistance Test FormJohny AdvientoNo ratings yet

- AWS Periodic TableDocument1 pageAWS Periodic Tabledouglas.dvferreiraNo ratings yet

- Potential Failure Mode and Effective Analysis (Process FMEA)Document1 pagePotential Failure Mode and Effective Analysis (Process FMEA)nainarmuthuramalingamNo ratings yet

- 1) Electric Circuits - Basic ConceptsDocument9 pages1) Electric Circuits - Basic ConceptsJOSE AUGUSTO MODESTO HUAYLINOS GUERRERONo ratings yet

- 318C PDFDocument4 pages318C PDFTidjani SallNo ratings yet

- Poster SafetyDocument1 pagePoster SafetyJose Ricardo DuranNo ratings yet

- QAS - ERE 0.09 Bolt Torque Inspection ReportDocument1 pageQAS - ERE 0.09 Bolt Torque Inspection ReportJoanne InciongNo ratings yet

- Electricity 3 Lpt012Document3 pagesElectricity 3 Lpt012Nadah8No ratings yet

- MEA Testing Systems LTD CatalogDocument105 pagesMEA Testing Systems LTD CatalogPawin lothongNo ratings yet

- 966H and 972H Electrical System Wheel LoaderDocument4 pages966H and 972H Electrical System Wheel Loaderleonardo rivero100% (1)

- Sistema Eletrico 226Document4 pagesSistema Eletrico 226f8ytws84csNo ratings yet

- UENR2643UENR2643-05 - SIS Electrico Diagrama PDFDocument4 pagesUENR2643UENR2643-05 - SIS Electrico Diagrama PDFJaime LopezNo ratings yet

- SKETCH 022 Tripping MatrixDocument6 pagesSKETCH 022 Tripping MatrixÖzgür Özdemir100% (1)

- Instabilities Legend Prism Status Chart of Status Instrumentation Legend Vector Legend Prism Legend Prisms ReadingsDocument1 pageInstabilities Legend Prism Status Chart of Status Instrumentation Legend Vector Legend Prism Legend Prisms ReadingsEdson OoNo ratings yet

- Engine Structure Poster 18x24Document1 pageEngine Structure Poster 18x24Алексей Гончаров100% (1)

- Von Willebrand Factor Activity - 0020004700: in Vitro Diagnostic Medical Device In-Vitro DiagnostikumDocument3 pagesVon Willebrand Factor Activity - 0020004700: in Vitro Diagnostic Medical Device In-Vitro Diagnostikum28850No ratings yet

- GOOLOO GE1200 - User ManualDocument1 pageGOOLOO GE1200 - User ManualzoltanpolyakNo ratings yet

- 202301-Quality Management-75053Document30 pages202301-Quality Management-75053SRJ Do ItNo ratings yet

- Indicadores Caratula NigataSeikiDocument26 pagesIndicadores Caratula NigataSeikiJuan Pablo Chumba LaraNo ratings yet

- Productspecificaties Linde H100 H180 Zware HeftrucksDocument2 pagesProductspecificaties Linde H100 H180 Zware HeftrucksJan Hendriks50% (2)

- Composite / Steel Cost Comparison: Utility: Composites Offer The FollowingDocument11 pagesComposite / Steel Cost Comparison: Utility: Composites Offer The FollowingMitu Leonard-GabrielNo ratings yet

- 330C L Electrico CYA00240Document2 pages330C L Electrico CYA00240Mario BaldocedaNo ratings yet

- Mapa Informativo de Controle de Componentes E InspeçõesDocument2 pagesMapa Informativo de Controle de Componentes E InspeçõesLuiza ANo ratings yet

- TH350B, TH355B, and TH360B Electrical System TelehandlerDocument2 pagesTH350B, TH355B, and TH360B Electrical System TelehandlerMohamed Harb100% (1)

- 5kv Insulation Resistance Tester Hioki 3455Document4 pages5kv Insulation Resistance Tester Hioki 3455industrialindiaNo ratings yet

- 23 07 2018 - DAY-Inspection Log SheetDocument1 page23 07 2018 - DAY-Inspection Log SheetArunNo ratings yet

- 78101-40700000-IC-MDL-10000 Copper Alarms Settings For DCS Configuration Rev0BDocument13 pages78101-40700000-IC-MDL-10000 Copper Alarms Settings For DCS Configuration Rev0BGemasgoodasdf DjdjdjNo ratings yet

- D3 - DPS Evc CDocument2 pagesD3 - DPS Evc CGonzalo Villalobos SanchezNo ratings yet

- 02.optical Network TestingDocument1 page02.optical Network Testingphuongnt1710No ratings yet

- Log TMBMC26Y123514233 175210km 108870miDocument3 pagesLog TMBMC26Y123514233 175210km 108870miRosu AlinNo ratings yet

- 02 Oliver NenadovicDocument39 pages02 Oliver NenadovicRinu RavikumarNo ratings yet

- History of The Redstone Missile SystemDocument198 pagesHistory of The Redstone Missile SystemVoltaireZeroNo ratings yet

- P 1 1 Leung DDocument10 pagesP 1 1 Leung DMasha NikolovaNo ratings yet

- Din en Iso 3822-1 - enDocument27 pagesDin en Iso 3822-1 - enDaniel GrobNo ratings yet

- Packet Header FormatDocument6 pagesPacket Header FormatJohnSebastianNo ratings yet

- Site Exploration: Vedprakash C. MarlapalleDocument45 pagesSite Exploration: Vedprakash C. Marlapallevedprakash marlapalle100% (1)

- Low Profile Hammer Union Caps - 2017Document2 pagesLow Profile Hammer Union Caps - 2017Hector Luis MejiaNo ratings yet

- The Ball Piston EngineDocument13 pagesThe Ball Piston EnginedhairyashilNo ratings yet

- CV Rizaljs Indonesia PDFDocument18 pagesCV Rizaljs Indonesia PDFHumairah AnandaNo ratings yet

- General Fitting Guide For Bottle Traps: Installation ProcedureDocument1 pageGeneral Fitting Guide For Bottle Traps: Installation ProcedureAfzal FasehudeenNo ratings yet

- Pile Foundations - IntroductionDocument15 pagesPile Foundations - IntroductionMUHAMMAD BILAL AHMADNo ratings yet

- Vsolution Pon App Example v1.0.1Document60 pagesVsolution Pon App Example v1.0.1Chu Minh ThắngNo ratings yet

- 08 Kaizen CornerDocument3 pages08 Kaizen Corneryasser hannaneNo ratings yet

- Lecture17 Flip FlopsDocument23 pagesLecture17 Flip Flopszoro gohNo ratings yet

- Rs 71 Ball Mill Sizng-1Document4 pagesRs 71 Ball Mill Sizng-1Dilnesa Ejigu100% (1)

- Data Sheet-Cable-24.12.21Document22 pagesData Sheet-Cable-24.12.21YASHASHWYNo ratings yet

- Programat P300-G2 PDFDocument6 pagesProgramat P300-G2 PDFRodica RoscaNo ratings yet

- Gold Cup Application HandbookDocument72 pagesGold Cup Application HandbookMarcelo ArayaNo ratings yet

- An Agent of The Black Nobility Betrays HimselfDocument20 pagesAn Agent of The Black Nobility Betrays Himselfkaren hudes100% (1)

- Receiver Noise Figure MeasurementDocument13 pagesReceiver Noise Figure Measurementعلی بنائیNo ratings yet

- Intro CsamtDocument4 pagesIntro CsamtJoshLeighNo ratings yet

- Underground ConduitsDocument25 pagesUnderground ConduitsAbdul AzimNo ratings yet

- Praxair Tafa CatalogDocument12 pagesPraxair Tafa Catalogperroloco111178No ratings yet

- Parts Guide Manual: HD-514 A1RmDocument17 pagesParts Guide Manual: HD-514 A1RmmemetNo ratings yet

- 2007 - 06 - 01 - Illawarra Escarpment Land Use Review Strategy PT 1Document104 pages2007 - 06 - 01 - Illawarra Escarpment Land Use Review Strategy PT 1NorfolkingNo ratings yet