Professional Documents

Culture Documents

FS 4 Commercial Refrigeration Oct 2015

FS 4 Commercial Refrigeration Oct 2015

Uploaded by

Daddy LeviOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FS 4 Commercial Refrigeration Oct 2015

FS 4 Commercial Refrigeration Oct 2015

Uploaded by

Daddy LeviCopyright:

Available Formats

UNEP Ozone Secretariat

Fact Sheets on HFCs and Low GWP Alternatives

October 2015

FACT SHEET 4

Commercial Refrigeration

1. Description of market sector

This market sector includes commercial refrigeration systems and appliances used for storage and

display of products in food and drink retail (supermarkets, convenience stores, shops etc.) and in food

service (restaurants, hotels etc.).

Market sub-sectors

This sector uses three distinct types of equipment. These are:

a) Stand-alone factory sealed equipment: small systems using technology with similarities to

domestic refrigerators

b) Condensing units: “split systems” with a cooling evaporator in the refrigerated space (e.g. a

retail display) connected to a remotely located compressor and condenser.

c) Centralised systems: large distributed systems with a number of cooling evaporators

connected to a remotely located compressor pack and external condenser.

Each sub-sector has different characteristics, especially in terms of the amount of refrigerant used (in

each system). The options for alternative refrigerants vary considerably between these sub-sectors.

Operating temperature

Commercial refrigeration systems operate at two distinct temperature levels:

o o

Medium temperature (MT) for chilled products held at between 0 C and +8 C

o o

Low temperature (LT) for frozen products held at between -18 C and -25 C

Typical system design

Almost all commercial refrigeration systems use direct expansion (DX) vapour compression

refrigeration cycles. Most current HFC systems use single stage compression. Each system is

dedicated to a particular temperature level (MT or LT). Stand-alone systems only serve one cooling

load (e.g. a single food display case). Condensing units can serve up to 3 loads and centralised

systems can serve numerous food display cases and cold storage rooms.

Alternative technologies

There is no use of technologies other than vapour compression. An alternative to the widely used DX

system for centralised systems is an “indirect system” which uses a chiller to cool a secondary

refrigerant (e.g. glycol, brine or pumped CO2) which is circulated to provide cooling. They require much

less primary refrigerant than a DX system. Multi-stage compression can be used to improve efficiency.

Changes driven by ODS phase out

Prior to 1990 most MT systems used CFC-12 and most LT systems used R-502. In non-Article 5

countries, HCFC-22 was used in new systems for about 10 years from the late 1980s, although most

have now been replaced. From around 1997 R-404A1 became a widely used refrigerant for both LT

and MT systems. There is also some use of HFC-134a in MT systems. In Article 5 countries the use

of HCFC-22 remains dominant and use of R-404A is becoming more widespread in new equipment.

1 R-507A is also used for commercial refrigeration systems although less widely than R-404A. Comments about

R-404A in this Fact Sheet also apply to R-507A.

Fact Sheet 4: Commercial Refrigeration 1 Version 2, October 2015

UNEP Ozone Secretariat – Background Material on HFC Management

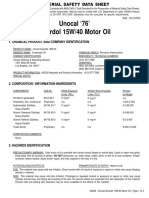

Table 1: Commercial refrigeration: summary of characteristics for HFC equipment

Market sub-sector: Stand-alone Condensing Unit Centralised

Typical refrigerant charge 0.1 to 0.5 kg 1 to 10 kg 20 to 200 kg

Typical cooling duty 0.1 to 1 kW 2 to 20 kW 40 to 200 kW

HFC refrigerants widely used R-404A (GWP 39222) HFC-134a (GWP 1430)

Factory sealed

Refrigeration circuit design Distributed direct expansion

direct expansion

Manufacture / installation Factory built Site installed refrigerant pipework

Class A (access by persons not acquainted with safety

Typical location of equipment

precautions)

Typical annual leakage rate < 1% 5% to 20% 10% to 30%

Main source of HFC emissions Losses at end-of-life Operating leakage Operating leakage

New

Approximate split of 90% 50% 30%

systems

annual refrigerant

demand

Maintenance 10% 50% 70%

Stand-alone hermetically sealed systems

2 All GWP values are based on the IPCC 4th Assessment Report

Fact Sheet 4: Commercial Refrigeration 2 Version 2, October 2015

UNEP Ozone Secretariat – Background Material on HFC Management

Small condensing unit:

1 compressor and

condenser connected to

1 or 2 display cabinets in

retail shop

Centralised system:

Rack of 7

compressors

connected to

numerous display

cabinets in

supermarket and

connected to an

externally located

condenser

Factory built stand-alone systems have a small refrigerant charge and low leakage rates.

The larger condensing units and central systems require long runs of site installed refrigerant pipework.

This leads to considerably larger refrigerant charge and the potential for much higher leakage rates.

For centralised systems, the use of refrigerant to top up leaks dominates the total HFC consumption.

R-404A is the dominant HFC refrigerant used in all 3 sub-sectors of the commercial refrigeration market,

for both MT and LT systems. It has a very high GWP (3922). In many countries R-404A represents

more than 90% of the GWP-weighted HFC consumption in the commercial sector.

Fact Sheet 4: Commercial Refrigeration 3 Version 2, October 2015

UNEP Ozone Secretariat – Background Material on HFC Management

2. Alternatives to currently used HFC refrigerants

Table 2: Lower GWP alternatives for commercial refrigeration

Refrigerant3 GWP Flammability4 Comments

Alternatives to avoid use of R-404A (can be used in both new equipment and for retrofit of existing)

R-407A 2107 1 There has been significant use of these blends in

Europe as R-404A alternatives (both for new systems

and for retrofit). Can have higher efficiency than R-404A

R-407F 1825 1 systems.

R-407H* 1495 1

R-442A 1888 1

Newly developed blends with properties similar to

R-448A 1387 1 R-404A, but lower GWP. Currently there is limited

commercial experience.

R-449A 1397 1

R-449B 1412 1

Alternatives, new equipment only

HC-600a HCs are suitable for stand-alone equipment (e.g. in ice

HC-290 cream freezers and bottle coolers) and are already in

widespread use in both Article 5 and non-Article 5

HC-1270 countries.

Various HC HCs can be considered for very small condensing units

1 to 5 3 subject to safety regulations.

blends:

R-432A, B, C HCs are used in some large supermarkets with multiple

stand-alone units rejecting heat into a water circuit.

R-436A, B HCs can be used as primary refrigerant for chillers in

R-441A indirect systems and cascade R-744 systems.

Stand-alone: used in bottle coolers and other equipment

Condensing units: some use, but capital cost is a barrier

R-744 (CO2) 1 1 for small condensing units.

Centralised: there is significant use of R-744 in new

systems in both transcritical and cascade configurations

R-717 Used in indirect systems, but energy efficiency can be

0 2L

(ammonia) low if liquid secondary refrigerants are used

HFO-1234yf 4 2L Not currently used, but being considered for

HFO-1234ze 7 2L stand-alone systems and MT condensing units.

3

Refrigerants and text shown in italics have been added in this latest version of the Fact Sheet

* R-numbers marked with an asterisk are awaiting final approval from ASHRAE

4 Flammability categories based on ISO 817 and ISO 5149

3 = higher flammability; 2 = flammable; 2L = lower flammability; 1 = no flame propagation

Fact Sheet 4: Commercial Refrigeration 4 Version 2, October 2015

UNEP Ozone Secretariat – Background Material on HFC Management

Table 2 (continued): Lower GWP alternatives for commercial refrigeration

Refrigerant GWP Flammability Comments

Alternatives, new equipment only

R-450A 601 1

Newly developed blends with properties similar to

R-513A 631 1

HFC-134a. Being considered for MT systems. The non-

R-513B* 596 1 flammable blends can be considered for large systems.

The lower flammability (2L) blends may be suitable for

R-451A 140 2L

condensing units.

R-451B 150 2L

R-454A 239 2L Newly developed blends with properties similar to

R-404A. Being considered for LT and MT condensing

R-455A* 145 2L units.

R-446A 460 2L

Newly developed blends with properties similar to

R-447A 582 2L

R-410A. Being considered for condensing units.

R-454B 466 2L

HFC-32 675 2L Being considered for condensing units.

Blends awaiting Blends under development with properties similar to

150 to

ASHRAE 2L R-404A and R-410A. Being considered for LT and MT

600

number condensing units.

Stand-alone systems

There is wide-spread use of hydrocarbons (HCs) in this market sub-sector. Over three million ice cream

freezers using HC-290 are already in use and range of other types of stand-alone system are available

using HCs including retail display cases, water coolers and ice making machines. R-744 has been

used successfully in bottle coolers. HFO-1234yf and HFO-1234ze are possible alternatives when HCs

are restricted by regional safety codes, as they have lower flammability. Non-flammable HFC/HFO

blends with properties similar to HFC-134a are available with GWPs around 600.

Condensing units

A more difficult sub-sector than stand-alone systems because the refrigerant charge is higher and

flammability is an important issue. Various non-flammable R-404A alternatives are available with

GWPs in the 1400 to 2100 range. These can be used in new equipment and some can be retrofitted

into existing systems. Non-flammable HFC-134a alternatives are available with GWP around 600.

R-744 is an option, although getting high efficiency and low capital cost is proving a challenge for

condensing units. Various lower flammability (2L) refrigerants such as R-454A and R-455A are under

development and may be safe to use in many condensing unit applications, subject to safety

regulations.

Fact Sheet 4: Commercial Refrigeration 5 Version 2, October 2015

UNEP Ozone Secretariat – Background Material on HFC Management

Centralised systems – new equipment

For new systems, R-744 is now in widespread use, especially in Europe. In mild climates transcritical

R-744 booster systems are a popular configuration5. In hot climates it has been considered more

energy efficient to use a cascade system6, although the latest innovations for transcritical systems (e.g.

parallel compression and ejectors) are allowing efficient use of booster systems in relatively hot

climates. There are various other alternatives that can also be considered for new centralised systems.

For example, some use has been made of stand-alone HC units, cooled by a water circuit.

Centralised systems – exisiting

Various options are available to retrofit R-404A in exisiting systems. There are several of non-flammable

alternatives with GWPs in the 1400 to 2100 range. Case studies have shown that there can be energy

efficiency improvements of 5% to 10% following retrofit, especially for MT systems.

3. Discussion of key issues

Safety and practicality

Stand-alone: Use of HCs is a safe option in many stand-alone applications as the refrigerant charge

is small. In some countries, including the United States, safety codes limit the charge size for HCs.

A recent announcement by the US EPA’s SNAP programme, lists as acceptable additional HCs for

stand-alone commercial refrigeration. Where higher flammability refrigerants are unacceptable

various other refrigerants listed in Table 2 can be considered, including those with flammability

categories 1 and 2L. HFOs have lower flammability (2L), so safety issues still need to be addressed.

Standards such as IEC 60335-2-89 do not currently distinguish between flammability categories,

which is a barrier to use of lower flammability refrigerants.

Condensing units: A potentially difficult market sub-sector from a safety perspective. Systems are

usually too large for use of HCs. R-744 is a possibility, but cost and efficiency may be a challenge

in these small systems. Another option is use of lower flammability alternatives such as HFC-32,

pure HFOs and HFO/HFC blends. Safety standards may need updating for use of lower flammability

refrigerants in condensing units.

Centralised: Widespread use of R-744 in some regions shows that this refrigerant can be used safely

and cost effectively in centralised systems. Significant improvements in system designs and

specialised components during the last 5 years can make the latest systems highly effective.

Prevention of leakage is an important design issue as R-744 has very high operating pressures.

Commercial availability

Stand-alone: There is reasonable availability of HC equipment in most regions. A much wider range

of HC, R-744, HFC / HFO blends, and HFO stand-alone equipment is likely to become available

during the next 5 years.

5 o o

R-744 has a very low critical temperature (only 31 C compared to over 70 C for most refrigerants). This has a

significant impact on the way R-744 systems operate. Transcritical booster systems use direct expansion R-744

for both LT and MT cooling, with heat rejected into the atmosphere from an R-744 condenser / gas cooler. When

o

the ambient temperature is below approximately 20 C, the system operates in a conventional sub-critical mode.

In hot weather the system operates with heat rejection above the critical temperature.

6 Cascade systems are designed to avoid operation above the critical temperature of R-744. They use direct

expansion R-744 for the LT cooling and a pumped R-744 secondary system for MT cooling. Heat is rejected via

a “cascade refrigeration chiller” which uses a different refrigerant. The chiller is usually located in a special

machinery room or on a roof-top, so it can use a range of possible refrigerants including HC-290, R-717,

HFO-1234ze or HFO-1234yf. Use of a cascade arrangement keeps the R-744 well below its critical temperature

under all ambient temperature conditions – this gives improved efficiency in hot climates.

Fact Sheet 4: Commercial Refrigeration 6 Version 2, October 2015

UNEP Ozone Secretariat – Background Material on HFC Management

Condensing units: There is little commercial experience of using either R-744 or lower flammability

refrigerants in this sub-sector. Significant work is required on development of components and of

safety standards before widespread use is likely.

Centralised: There is good availability of R-744 equipment in several regions such as the EU and

North America. There is also good availability of central systems based on water cooled stand-alone

units.

Cost

Stand-alone: Capital cost of HCs units is close to HFC units, although there are some investment

costs at factories making stand-alone equipment for safe handling of flammable refrigerants. R-744

and HFO-1234yf equipment are likely to be slightly more expensive due to higher cost of components

(for R-744) or refrigerant (for HFOs).

Condensing units: If lower flammability refrigerants are acceptable then there will be little difference

in hardware cost, but some of the lower GWP refrigerants may be more costly than R-404A. Small

R-744 systems are currently considerably more expensive than HFC systems.

Centralised: R-744 systems are currently more expensive than R-404A – 10% to 20% extra is

typical. However, the cost increment is falling as usage becomes more widespread. Some of the

latest equipment is within 5% or less of current HFC system cost.

Energy efficiency

Stand-alone: HC systems have better efficiency than current HFC designs. There is little data

available for HFOs and HFO/HFC blends, but equal or better efficiency than R-404A may be possible.

Condensing units: Information is not yet available on efficiency of HFC-32, HFOs and HFO/HFC

blends in condensing units. The expectation is for better efficiency than current R-404A designs

Centralised: R-744 systems can have better efficiency than current R-404A designs. In cold and

mild climates transcritical R-744 systems show good efficiency. In hot climates it may be necessary

to use cascade systems to get good efficiency, although use of innovations such as parallel

compression and ejectors enables efficient use of transcritical systems in hotter climates than

previously thought possible.

Applicability in high ambient

Stand-alone: There are no extra difficulties designing HC or HFO stand-alone systems for operation

in high ambient temperatures (compared to using R-404A or HFC-134a). R-744 is more difficult to

use with good efficiency in small equipment at high ambient temperature and may not be suitable for

all stand-alone equipment applications.

Condensing units: Little data is yet available on performance of new HFO/HFC blends. For MT

systems, blends with properties similar to HFC-134a may be the best option at high ambient

temperature as they have a low discharge pressure. For LT systems, blends with properties similar

to R-404A may be more suitable. Higher pressure refrigerants such as HFC-32 and new blends with

properties similar to R-410A may be more difficult to use at high ambient because of high discharge

temperatures, although liquid and vapour injection can mitigate this problem at some added cost.

Centralised: Transcritical R-744 systems have lower energy efficiency and reduced capacity at high

ambient temperatures, although this can be mitigated with some new innovations (such as parallel

compression and ejectors). R-744 used in hot countries can be based on a cascade design, which

uses R-744 in sub-critical conditions, with heat rejected into a separate high temperature cooling

circuit (which could use a range of refrigerants including HCs, ammonia or HFO-1234ze). Cascade

designs are already used in some existing installed systems and have been shown to be efficient

and cost effective.

Fact Sheet 4: Commercial Refrigeration 7 Version 2, October 2015

UNEP Ozone Secretariat – Background Material on HFC Management

Opportunities to retrofit existing equipment

There are good opportunities to retrofit centralised R-404A systems with various refrigerants with

much lower GWPs as shown in Table 2. Retrofit of centralised commercial systems can lead to

significant early reductions in HFC consumption.

There are also possibilities to retrofit condensing units (although it is usually less cost effective than

for centralised systems). Retrofit is not appropriate for stand-alone systems.

Technician training

HCs: Technicians doing maintenance need training that addresses handling of higher flammability

refrigerants. There are well established training courses available in regions already using HCs.

Training related to stand-alone units is widespread. Training for use of higher flammability

refrigerants in larger systems (e.g. chillers for cascade systems) is less common.

Lower flammability HFCs/ HFOs: Training will also be essential for maintenance of systems with

lower flammability refrigerants. These are not yet in widespread use for commercial refrigeration, so

little training is currently available.

R-744: Systems using R-744 operate at much higher pressure than HFC systems and may be based

on unfamiliar system design. Technicians need significant extra training to work on R-744 systems.

There are well established training courses available in regions already using R-744.

For all new refrigerants, training is also required for system design engineers.

Minimising HFC emissions from existing equipment

Stand-alone: The majority of HFC emissions from stand-alone systems occur at end-of-life

(operational leak rates are very low and mostly occur through accidental damage). End-of-life

recovery procedures must be established to minimise these potential emissions.

Condensing units and centralised systems: Most emissions occur through leakage during the

operating life of this equipment. Applying best practice in design, installation and maintenance

practices can lead to significant leakage reductions. Case studies have shown that for existing

installed systems it is possible to reduce average leakage from over 20% per year to under 10%.

Best practice design has been shown to reduce average leakage from newly designed and

installed systems to well below 5% per year. There is a useful financial benefit for minimising

leakage as it helps ensure that maximum energy efficiency can be maintained. During plant

maintenance it is important to ensure that refrigerant is not vented to atmosphere. At end-of-life it is

possible to recover well over 95% of refrigerant from old systems if good recovery procedures are

used.

It is interesting to note that many low GWP alternatives require much better design to achieve low

leakage. R-744 systems operate at very high pressure, so leak prevention is crucial. Preventing

leaks of flammable refrigerants is also crucial if safety risk is to be minimised. New HFO/HFC blends

will be more expensive, creating a driver to minimise leakage. If the same good design practices are

applied to conventional HFC systems, leakage levels could be considerably reduced. Good

refrigerant conservation practices should be encouraged.

Fact Sheet 4: Commercial Refrigeration 8 Version 2, October 2015

You might also like

- Tecumseh Guidelines For Utilization of R134aDocument7 pagesTecumseh Guidelines For Utilization of R134aAnibal RiosNo ratings yet

- 123Document7 pages123Jennifer Damasco100% (2)

- Material Safety Data Sheet: KAN-HB Epoxy Zinc Phosphate PrimerDocument6 pagesMaterial Safety Data Sheet: KAN-HB Epoxy Zinc Phosphate PrimeroliviaNo ratings yet

- FS 3 Domestic Refrigeration Oct 15Document3 pagesFS 3 Domestic Refrigeration Oct 15Jitbahan MohantaNo ratings yet

- Future Refrigerants Sales SheetDocument8 pagesFuture Refrigerants Sales SheetDaniel MachadoNo ratings yet

- Technical Topic Refrigeration Oils (Jan 2011) - EN PDFDocument4 pagesTechnical Topic Refrigeration Oils (Jan 2011) - EN PDFPreeti gulatiNo ratings yet

- Alternatives in Unitary Air Conditioning: Transitioning To Low-GwpDocument3 pagesAlternatives in Unitary Air Conditioning: Transitioning To Low-GwpGraciaVelitarioNo ratings yet

- Embraco Position Paper InglesDocument16 pagesEmbraco Position Paper InglesVivekNo ratings yet

- An Introduction To A2L Refrigerants and Their Use in Refrigeration, Air Conditioning and Heat Pump ApplicationsDocument15 pagesAn Introduction To A2L Refrigerants and Their Use in Refrigeration, Air Conditioning and Heat Pump ApplicationsHasib KhanNo ratings yet

- HSE Guidance Refrigeration and Halon ManagementDocument2 pagesHSE Guidance Refrigeration and Halon Managementlethanhvan186No ratings yet

- R202 FluidDocument10 pagesR202 Fluidzoran_stevNo ratings yet

- Condensing Units: Air CooledDocument12 pagesCondensing Units: Air Cooledkskr_44No ratings yet

- 471 All PDFDocument88 pages471 All PDFNishantNo ratings yet

- Module 1 - Introduction To Alternative RefrigerantsDocument47 pagesModule 1 - Introduction To Alternative RefrigerantsMark BrewardNo ratings yet

- Vertiv Refrigerants - of - The - Future WP Uk Low Rev.1 09.2018 - 246049 - 0Document10 pagesVertiv Refrigerants - of - The - Future WP Uk Low Rev.1 09.2018 - 246049 - 0boombloomNo ratings yet

- 12 Bucati Catalog Intreg-Technical Topic Refrigeration Oils (Jan 2011) - enDocument4 pages12 Bucati Catalog Intreg-Technical Topic Refrigeration Oils (Jan 2011) - enDiaconescu AdrianNo ratings yet

- Out With The Old & in With The New:: Freon Vs Ammonia & Glycol Refrigeration SystemsDocument4 pagesOut With The Old & in With The New:: Freon Vs Ammonia & Glycol Refrigeration SystemsHarsha Vardhan BNo ratings yet

- FD Series High Performance Air-Conditioners 2023Document120 pagesFD Series High Performance Air-Conditioners 2023Mohamad Zakwan SezeliNo ratings yet

- Forum: R22 Replacement StatusDocument7 pagesForum: R22 Replacement StatusAby Torres HernándezNo ratings yet

- Trends For Refrigerants in Compression Systems: Dr.-Ing. Jürgen SüssDocument3 pagesTrends For Refrigerants in Compression Systems: Dr.-Ing. Jürgen Süsshonghai_dlNo ratings yet

- Refrigeration Retrofitt GuidelinesDocument52 pagesRefrigeration Retrofitt GuidelinesAurelio Jr TambigaNo ratings yet

- Residential and Commercial Air Conditioning and Heating: Coordinating Lead Authors Lead AuthorsDocument26 pagesResidential and Commercial Air Conditioning and Heating: Coordinating Lead Authors Lead AuthorsAshok KumarNo ratings yet

- RefigerantsDocument22 pagesRefigerantsabikshaya venugopalNo ratings yet

- Freon 404A enDocument12 pagesFreon 404A enisturmanNo ratings yet

- R22 Phase Out and F-Gas RegulationsDocument19 pagesR22 Phase Out and F-Gas Regulationsamarnath jagirdarNo ratings yet

- Retrofitting With Non-Cfc Substitutes: September 1994Document51 pagesRetrofitting With Non-Cfc Substitutes: September 1994SK SARFARAZ UDDINNo ratings yet

- Data Sheet Solenoid ValveDocument76 pagesData Sheet Solenoid ValveijaNo ratings yet

- Refrigerant Transition Under F-Gas Regulation 517-2014Document4 pagesRefrigerant Transition Under F-Gas Regulation 517-2014daniel.hinczewskiNo ratings yet

- HFC Phasedown Webinar Presentation - 508cDocument49 pagesHFC Phasedown Webinar Presentation - 508cChoi Fu ChuenNo ratings yet

- RefrigerantS & LubricantsDocument62 pagesRefrigerantS & LubricantskelkararNo ratings yet

- Exploring The Differences Between R-410A and R-22Document4 pagesExploring The Differences Between R-410A and R-22aungwinnaingNo ratings yet

- CAC 05 11 MurphyDocument12 pagesCAC 05 11 MurphyzetseatNo ratings yet

- Myths and Facts of Hvac Refrigerants: Fact: HCFCS, Including R123, Are Being Phased OutDocument4 pagesMyths and Facts of Hvac Refrigerants: Fact: HCFCS, Including R123, Are Being Phased OutSiva SivaNo ratings yet

- 7877-E-Kigali FS02 Current UsesDocument4 pages7877-E-Kigali FS02 Current UsesOrlando Mican BuitragoNo ratings yet

- REFRIG PRODUCTS EQUIPMENT Brochure-FNL-040714Document6 pagesREFRIG PRODUCTS EQUIPMENT Brochure-FNL-040714yaozhihua85No ratings yet

- Zone Mechanical PresentationDocument58 pagesZone Mechanical Presentationspymaster1027No ratings yet

- Refrigerant TypesDocument4 pagesRefrigerant Typesch pavan kumar0% (1)

- Refrigerant RetrofittingDocument54 pagesRefrigerant RetrofittingHarpreet Randhawa100% (1)

- Sroc 04Document44 pagesSroc 04ambuenaflorNo ratings yet

- Comparacion 407c y 410aDocument5 pagesComparacion 407c y 410aAlan Q'amaháNo ratings yet

- Transcritical Co2 Refrigeration - PDFDocument11 pagesTranscritical Co2 Refrigeration - PDFHector Fabian Hernandez Algarra100% (1)

- C r407c GuideDocument32 pagesC r407c Guidezam_ramliNo ratings yet

- 7884-E-Kigali FS09 High Ambient TempDocument3 pages7884-E-Kigali FS09 High Ambient TempOrlando Mican BuitragoNo ratings yet

- Danfoss r290 en PDFDocument4 pagesDanfoss r290 en PDFAli Al-Sayyab100% (1)

- Inlocuire R410A Cu R466ADocument9 pagesInlocuire R410A Cu R466AClaudia MadalinaNo ratings yet

- Pearson 2008Document7 pagesPearson 2008Carlos DelgadoNo ratings yet

- The Use of R-407CDocument6 pagesThe Use of R-407CdokundotNo ratings yet

- City Multi R32 VRFDocument6 pagesCity Multi R32 VRFAmer GaladNo ratings yet

- Applying VRF?: Don't Overlook Standard 15Document7 pagesApplying VRF?: Don't Overlook Standard 15Eric G. MagnayeNo ratings yet

- Moldova Slides 1Document89 pagesMoldova Slides 1Igor GîdeiNo ratings yet

- Efficiency Increase in Carbon Dioxide Refrigeration Technology With Parallel CompressionDocument10 pagesEfficiency Increase in Carbon Dioxide Refrigeration Technology With Parallel CompressionIvana MacedoNo ratings yet

- Solutions For Cold Rooms - InstallersContractors EuropeDocument8 pagesSolutions For Cold Rooms - InstallersContractors Europeannt.cavtechNo ratings yet

- Natural Refrigerant Based Airconditioning With Module On R290 SystemsDocument55 pagesNatural Refrigerant Based Airconditioning With Module On R290 SystemsÁlvaro ArangoNo ratings yet

- D4.1 Refrigerants: Regulations: Properties of Industrial Heat Transfer MediaDocument94 pagesD4.1 Refrigerants: Regulations: Properties of Industrial Heat Transfer MediaANo ratings yet

- Two-Stage Semi-Hermetic Reciprocating Compressors: FCAT105.1-EN Product Selection Catalogue Version 50 HZ / 60Hz v1Document28 pagesTwo-Stage Semi-Hermetic Reciprocating Compressors: FCAT105.1-EN Product Selection Catalogue Version 50 HZ / 60Hz v1Ricardo Morán SilvaNo ratings yet

- Introduction To Alternative Refrigerants Other Than HFCDocument15 pagesIntroduction To Alternative Refrigerants Other Than HFCe4erkNo ratings yet

- Danfoss 2020 Refrigerantes Actuales y FuturoDocument24 pagesDanfoss 2020 Refrigerantes Actuales y FuturoArturo VelascoNo ratings yet

- Day 2 Session VI - 03 K. Jayakumar - EmersonDocument16 pagesDay 2 Session VI - 03 K. Jayakumar - EmersonMeghan WoodsNo ratings yet

- Overcoming Clean Fuels ChallengesDocument5 pagesOvercoming Clean Fuels ChallengesBilal KhashanNo ratings yet

- Bock R410A Compressor GBDocument20 pagesBock R410A Compressor GBRodrigo GonçalvesNo ratings yet

- What Is Going On in The World of Supermarket Refrigeration?: Buyer's GuideDocument6 pagesWhat Is Going On in The World of Supermarket Refrigeration?: Buyer's Guideali zalatNo ratings yet

- Sustainable Retail RefrigerationFrom EverandSustainable Retail RefrigerationJudith A. EvansRating: 5 out of 5 stars5/5 (1)

- CE 428 Secondary ClarifierDocument5 pagesCE 428 Secondary ClarifierTiinaa GoncalvesNo ratings yet

- Technical Data FSV-EX - OutdoorDocument947 pagesTechnical Data FSV-EX - OutdoorHải NguyễnNo ratings yet

- Transforming To Sustainable Building and Cost Analysis of Parameters For Green Building: Case StudyDocument13 pagesTransforming To Sustainable Building and Cost Analysis of Parameters For Green Building: Case StudyIAEME PublicationNo ratings yet

- Univolt N61B (MSDS)Document11 pagesUnivolt N61B (MSDS)Anonymous F2TxS3YoaNo ratings yet

- MSDS 15W40Document4 pagesMSDS 15W40Sukhjeet SinghNo ratings yet

- Atmhyd TheoryDocument17 pagesAtmhyd TheoryluthfiNo ratings yet

- Piping Systems For Industrial ApplicationsDocument2 pagesPiping Systems For Industrial ApplicationsJoshua MagatNo ratings yet

- Understanding TSS Method and Procedure From Cole-ParmerDocument3 pagesUnderstanding TSS Method and Procedure From Cole-ParmerPatrick ramotlopiNo ratings yet

- Land Laws Projects 2011Document5 pagesLand Laws Projects 2011Thakur Digvijay SinghNo ratings yet

- S12H PtaDocument4 pagesS12H Ptasultan ali100% (2)

- Aquaponics TilapiaFeasibiltyStudyDocument100 pagesAquaponics TilapiaFeasibiltyStudymarkdeguzman78833350% (2)

- Ethane c2h6 Safety Data Sheet Sds p4592Document9 pagesEthane c2h6 Safety Data Sheet Sds p4592Lucious LightNo ratings yet

- Chapter 1 - Water Demand PDFDocument25 pagesChapter 1 - Water Demand PDFDream 11No ratings yet

- Settlement 1Document16 pagesSettlement 1AliNo ratings yet

- Area Under The CurveDocument3 pagesArea Under The CurveReyland DumlaoNo ratings yet

- Presentation On PipesDocument33 pagesPresentation On PipesgshazaidiNo ratings yet

- UPVC Pressure Pipes FittingspdfDocument12 pagesUPVC Pressure Pipes FittingspdfpinaNo ratings yet

- Aqua CellDocument23 pagesAqua CellPeterMulcahy2000No ratings yet

- SyllabusDocument3 pagesSyllabusSuraj VishwakarmaNo ratings yet

- MSDS - Pidicryl 3699Document4 pagesMSDS - Pidicryl 3699Vivek PatilNo ratings yet

- Fosroc Solvent 102 SDS Promain 17 09 2018Document11 pagesFosroc Solvent 102 SDS Promain 17 09 2018QADEER SHANNo ratings yet

- Toward A Standard Thermistor Calibration Method: Data Correction SpreadsheetsDocument7 pagesToward A Standard Thermistor Calibration Method: Data Correction Spreadsheetsjrlr65No ratings yet

- Actividad 2 Exp Apdzje 6Document4 pagesActividad 2 Exp Apdzje 6Eduardo CernaNo ratings yet

- Property Tables and Charts (English Units) : AppendixDocument41 pagesProperty Tables and Charts (English Units) : AppendixStephy Marie PhillipsNo ratings yet

- Explanation: "Explanation Texts Are Frequently Incorporated Into Other Texts, Used To Provide InformationDocument4 pagesExplanation: "Explanation Texts Are Frequently Incorporated Into Other Texts, Used To Provide InformationJocelineNo ratings yet

- Himalayan System IndiaDocument24 pagesHimalayan System IndiaNamkha Wangden LhasungpaNo ratings yet

- World's Greatest Books 19 Travel&AdventureDocument152 pagesWorld's Greatest Books 19 Travel&AdventureBrindusacNo ratings yet