Professional Documents

Culture Documents

DRONELAB

DRONELAB

Uploaded by

icxnc1Copyright:

Available Formats

You might also like

- How To Read A SchematicDocument4 pagesHow To Read A Schematicjeanjean33No ratings yet

- Selection of Power CablesDocument4 pagesSelection of Power Cablesa.wNo ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument29 pagesInsulation Resistance (IR) Values - Electrical Notes & ArticlesNikhil Chakravarthy Vatsavayi100% (1)

- VG95218 PDFDocument35 pagesVG95218 PDFPugalenthi SekarNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Boat ElectricsDocument34 pagesBoat ElectricsSquinkle100% (1)

- What Is Cable Testing. How Is Cable Testing DoneDocument8 pagesWhat Is Cable Testing. How Is Cable Testing DoneAbdul JabbarNo ratings yet

- Analyze Ampacity ACDocument2 pagesAnalyze Ampacity ACLedred1No ratings yet

- Using and Choosing WireDocument5 pagesUsing and Choosing WirebharateshNo ratings yet

- Cable Accessories: Systems, IncDocument4 pagesCable Accessories: Systems, IncLuis MurilloNo ratings yet

- What Is Cable Testing. How Is Cable Testing DoneDocument8 pagesWhat Is Cable Testing. How Is Cable Testing DoneNaveed IrshadNo ratings yet

- Co Axial CablesDocument4 pagesCo Axial CablesKCTV NEWS PUNGANURNo ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument31 pagesInsulation Resistance (IR) Values - Electrical Notes & ArticlesKush SharmaNo ratings yet

- Selecting CableDocument2 pagesSelecting CableidanzbhNo ratings yet

- Earth Fault Loop ImpedenceDocument3 pagesEarth Fault Loop Impedencemsn-silva100% (1)

- Testing of Distribution CablesDocument11 pagesTesting of Distribution CablesHashimi JuniNo ratings yet

- Department of Electrical Engineering: Riphah International University, Islamabad, PakistanDocument6 pagesDepartment of Electrical Engineering: Riphah International University, Islamabad, PakistanBaqir HussainNo ratings yet

- Joints and TerminationDocument20 pagesJoints and TerminationMannu KiruiNo ratings yet

- Underground Cable Ampacity With Neher McGrathDocument7 pagesUnderground Cable Ampacity With Neher McGrathJesus RodriguezNo ratings yet

- Choose The Correct Wire Size - BoatUSDocument9 pagesChoose The Correct Wire Size - BoatUSangelNo ratings yet

- Ten Deadly Conditions in Electrical SystemsDocument11 pagesTen Deadly Conditions in Electrical SystemsNelson Aguirre BravoNo ratings yet

- Keystone Medium Voltage Catalogue (Export)Document52 pagesKeystone Medium Voltage Catalogue (Export)Mehdi Hajd KacemNo ratings yet

- Electrical For ALLDocument51 pagesElectrical For ALLvaithy2011No ratings yet

- Electrical Tests Uncured RR CoilsDocument2 pagesElectrical Tests Uncured RR CoilsTiagoFaleiros100% (1)

- Cable Short Circuit RatingsDocument2 pagesCable Short Circuit Ratingstees220510No ratings yet

- Why Do My Contactor Coils Keep Burning OutDocument2 pagesWhy Do My Contactor Coils Keep Burning Out666667No ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument37 pagesInsulation Resistance (IR) Values - Electrical Notes & Articlesnyong dro100% (1)

- QUALITY TOOL BOX - Hipot TestingDocument5 pagesQUALITY TOOL BOX - Hipot TestingVijayan Thekke VeeduNo ratings yet

- Presentation Module IIEE Elec Enthusiast 09102022 PDFDocument29 pagesPresentation Module IIEE Elec Enthusiast 09102022 PDFEarl Jenn AbellaNo ratings yet

- Experimental ElectricalDocument40 pagesExperimental ElectricalPIYUSHNo ratings yet

- Testing WeldsDocument16 pagesTesting Weldschokrib100% (2)

- Fluke - How Cables and Connectors Impact Measurement UncertaintyDocument4 pagesFluke - How Cables and Connectors Impact Measurement UncertaintyMatias RamosNo ratings yet

- Comment Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument41 pagesComment Insulation Resistance (IR) Values - Electrical Notes & ArticlesMunazar HussainNo ratings yet

- BS88 Bussman Fuse Links Zs To 800ADocument1 pageBS88 Bussman Fuse Links Zs To 800Arobpeter2425No ratings yet

- Cable Selcetion2 Afte RM Rev4Document9 pagesCable Selcetion2 Afte RM Rev4Stephen BridgesNo ratings yet

- Cabling Products and Solutions: CATALOGUE 2010/2011Document196 pagesCabling Products and Solutions: CATALOGUE 2010/2011Georgi PanayotovNo ratings yet

- MVcables DesignDocument40 pagesMVcables DesigniyyaniNo ratings yet

- 12T0020X00 Anixter WW Temperature Ratings W&C EN USDocument1 page12T0020X00 Anixter WW Temperature Ratings W&C EN USFelipe GustavoNo ratings yet

- Electrical Wiring Residential Canadian 7th Edition Mullin Solutions ManualDocument4 pagesElectrical Wiring Residential Canadian 7th Edition Mullin Solutions Manualallisondoylenqmsgyicjb97% (32)

- Screw Less Cage ClampDocument23 pagesScrew Less Cage ClampApurbaNo ratings yet

- Cable CrimpingDocument12 pagesCable CrimpingSuresh RamNo ratings yet

- Initiation: Components Used in Electric BlastingDocument18 pagesInitiation: Components Used in Electric BlastingariellopezNo ratings yet

- Loadbreak Products: Experience & ReliabilityDocument8 pagesLoadbreak Products: Experience & ReliabilityCbdtxd PcbtrNo ratings yet

- Sizing Cables, Conduit and TrunkingDocument56 pagesSizing Cables, Conduit and TrunkingChanel Maglinao100% (9)

- Voltage DropDocument6 pagesVoltage Dropmohd_mohaisen100% (1)

- 28AWG 32AWG Patch Cord - White Paper - ENGDocument5 pages28AWG 32AWG Patch Cord - White Paper - ENGAlex QuintanaNo ratings yet

- ANSI MV TechTopics85 ENDocument2 pagesANSI MV TechTopics85 ENArunava DasguptaNo ratings yet

- Cable Calculation and Selection WorksheetDocument22 pagesCable Calculation and Selection WorksheetLedred1No ratings yet

- NFC Aaac Al4 - 34.4&54.6 Ees CableDocument5 pagesNFC Aaac Al4 - 34.4&54.6 Ees CableazzouzimedNo ratings yet

- Tan Delta FAQDocument6 pagesTan Delta FAQDev SwainNo ratings yet

- 22kV-Cable-Termination-Failure (Chapter 6) PDFDocument6 pages22kV-Cable-Termination-Failure (Chapter 6) PDFTarikfaraj100% (1)

- 06 - Fire Resistant CablesDocument13 pages06 - Fire Resistant CablesmlutfimaNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Essential Boat Electrics: Carry Out Electrical Jobs On Board Properly & SafelyFrom EverandEssential Boat Electrics: Carry Out Electrical Jobs On Board Properly & SafelyNo ratings yet

- Understanding Your Boats Systems and Choices.From EverandUnderstanding Your Boats Systems and Choices.Rating: 3 out of 5 stars3/5 (1)

- Water Level Indicator Circuit Using Bipolar Junction TransistorFrom EverandWater Level Indicator Circuit Using Bipolar Junction TransistorRating: 4.5 out of 5 stars4.5/5 (7)

- High-Performance D/A-Converters: Application to Digital TransceiversFrom EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Deep Learning Isn't Deep Enough Unless It Copies From The Brain - IEEE SpectrumDocument19 pagesDeep Learning Isn't Deep Enough Unless It Copies From The Brain - IEEE Spectrumicxnc1No ratings yet

- ManualDocument187 pagesManualicxnc1No ratings yet

- Marketing For Photographers PDFDocument193 pagesMarketing For Photographers PDFicxnc1100% (1)

- Chassis Bolts and Nuts: Item N.M KGF.M Ib-FtDocument1 pageChassis Bolts and Nuts: Item N.M KGF.M Ib-Fticxnc1No ratings yet

- Colour gsx1400 - Full - Manual - k2 - To - Final - EditionDocument1 pageColour gsx1400 - Full - Manual - k2 - To - Final - Editionicxnc1No ratings yet

- Fit Yoshimura ST-1 CamsDocument16 pagesFit Yoshimura ST-1 Camsicxnc1No ratings yet

- Afr Autotune PCVDocument93 pagesAfr Autotune PCVicxnc1No ratings yet

- PCV User'S Guide.: The Latest Software and Maps Can Be Found atDocument4 pagesPCV User'S Guide.: The Latest Software and Maps Can Be Found aticxnc1No ratings yet

- Funai Wd6d-d4413db E9tf3edDocument113 pagesFunai Wd6d-d4413db E9tf3edLaurent CAUFRIEZNo ratings yet

- Voltcraft p9-2 SCH PDFDocument1 pageVoltcraft p9-2 SCH PDFkandi abdNo ratings yet

- S W A N 1 0 0 0: Installation InstructionsDocument2 pagesS W A N 1 0 0 0: Installation InstructionsLuisAlbertoSaldañaRmzNo ratings yet

- Course: Electronic Circuit Design Lab No: 08 Title: Characterization of The MOS Transistor CID: - DateDocument6 pagesCourse: Electronic Circuit Design Lab No: 08 Title: Characterization of The MOS Transistor CID: - DateAamir ChohanNo ratings yet

- Basic Electronics MCQ QuestionsDocument6 pagesBasic Electronics MCQ QuestionsRai Ali Raza KharalNo ratings yet

- Promag 50 53 Resistance Check PDFDocument4 pagesPromag 50 53 Resistance Check PDFAllisson MacedoNo ratings yet

- Partial Discharge Sensors HSENS-T Rugged MonitoringDocument2 pagesPartial Discharge Sensors HSENS-T Rugged MonitoringRugged Monitoring100% (1)

- Indus Lecture 2 PartialDocument69 pagesIndus Lecture 2 PartialIris Jean Mosquera100% (1)

- Lab 2 Simple Electric CircuitsDocument7 pagesLab 2 Simple Electric CircuitsKai ShiroNo ratings yet

- Cen-Tech 63758Document8 pagesCen-Tech 63758GregNo ratings yet

- Ec8453 Linear Integrated Circuits Year/Sem: Ii/Iv Dept: R&A Part-BDocument1 pageEc8453 Linear Integrated Circuits Year/Sem: Ii/Iv Dept: R&A Part-BARUNKUMARNo ratings yet

- Test and MeasurenmentDocument4 pagesTest and MeasurenmentNiña Angelica AligaenNo ratings yet

- Relay Selection Criteria 1Document1 pageRelay Selection Criteria 1jenixson tamondongNo ratings yet

- Installation Manual: EnglishDocument152 pagesInstallation Manual: EnglishJakub GráčikNo ratings yet

- Dgca M-4 Mcqs Part-1Document20 pagesDgca M-4 Mcqs Part-1Abhishek SoniNo ratings yet

- Kenya Power Attachment ReportDocument17 pagesKenya Power Attachment ReportRouxcel abuto100% (1)

- 9 Way Clap Switch!!Document8 pages9 Way Clap Switch!!Trilok Sawant100% (1)

- Technological University of The Philippines Visayas: An Example of Schematic DiagramDocument5 pagesTechnological University of The Philippines Visayas: An Example of Schematic DiagramMary SenilloNo ratings yet

- 091-0226A MK2000A PowerSupplyDocument29 pages091-0226A MK2000A PowerSupplySneyder YepesNo ratings yet

- NX TehnilineDocument92 pagesNX TehnilineAhmad AlswalhiNo ratings yet

- Ecowise EW20/1 EW30/1: The Ultimate Smart Grid Solution Instruction ManualDocument14 pagesEcowise EW20/1 EW30/1: The Ultimate Smart Grid Solution Instruction ManualManuel MendezNo ratings yet

- Listening 2 JanDocument3 pagesListening 2 JanRia YuliantiNo ratings yet

- MSE - Electrical & Instruments Tool ListDocument1 pageMSE - Electrical & Instruments Tool ListAnto DamanikNo ratings yet

- A Short Review of Reactive Power Management For Distributed GenerationDocument4 pagesA Short Review of Reactive Power Management For Distributed GenerationHai Pham ManhNo ratings yet

- 1746894Document3 pages1746894Marius BudauNo ratings yet

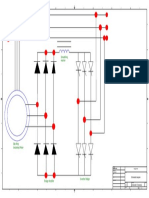

- Smoothing Reactor: Schematic DiagramDocument1 pageSmoothing Reactor: Schematic DiagramHARSUN A/L PARANTHAMAN STUDENTNo ratings yet

- Engineer'S Manual: SeriesDocument154 pagesEngineer'S Manual: SeriesMuhammad IrfanNo ratings yet

- Grounding at Points Other Than System NeutralDocument15 pagesGrounding at Points Other Than System NeutralWendy DuncanNo ratings yet

- A4447 High Voltage Step Down Regulator: Features and Benefits DescriptionDocument12 pagesA4447 High Voltage Step Down Regulator: Features and Benefits DescriptionCiprian UngureanuNo ratings yet

DRONELAB

DRONELAB

Uploaded by

icxnc1Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DRONELAB

DRONELAB

Uploaded by

icxnc1Copyright:

Available Formats

DRONELAB https://dronelab.se/siliconewire.

html

All articles

Silicone wire tests

YouTube channel

Wed 19 September 2018

Tests We at dronelab highly recommend using exclusively silicone wire for drones and other

About us RC craft. The high strand count and silicon insolation material guarantee excellent

flexibility and resistance to vibration. Additionally, thanks to the high temperature

tolerance of the silicon, soldering these wires is very easy. To choose the proper gauge

(thickness) of wire, we performed the following wire current capacity tests.

Video

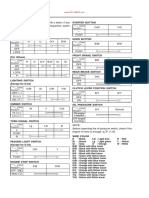

Maximum current

The most basic and important takeaway from these tests is how much current can each

wire handle. This chart represents our somewhat conservative recommendations. The 10

second "punch" time we assumed is longer than what some pilots ever need, and this

1 din 5 20.09.2021, 01:37

DRONELAB https://dronelab.se/siliconewire.html

time plays an important role in the current capacity. Do not expect this relation to be

proportional (half the time does NOT allow double the current!). We have not performed

enough tests to comfortably give any recommendations for shorter loads, so for now we

can only say that very short burst (1-2 seconds) can be 50% over the rating in the table.

We have noticed that the 18 AWG wire seemed to underperform, as the results for it

stand out from the remaining wires. This is especially visible in the voltage drop charts

below. All tests were performed multiple times, so it was not a measurement error. We

believe that the wire we have was mis-manufactured - contains fewer wire strands than it

should. This anomaly is within a reasonable tolerance (+/- 5%). We believe that the wire

should have passed the 60A test, however we will not adjust our results to match our

expectations. We might repeat this test if we purchase more 18 AWG wire from a

different production batch and update the results here.

Voltage drop

2 din 5 20.09.2021, 01:37

DRONELAB https://dronelab.se/siliconewire.html

These charts show the voltage drop over 20cm of wire (a 10cm battery lead with positive

and negative wire) at a given current. This is part of the "sag" that is noticable when

running at high current. The results for wires with connectors are simulated, based on our

measurements of wire resistance and connector resistance.

Weight

The benefit of a thicker wire comes at the cost of a higher weight. For a small drone with

50A punch, it might be benefitial to have a 18AWG wire + XT30 connector over a 14AWG

wire + XT60 connector. At 10cm of battery lead, this will only increase the sag by 0.1V,

but will reduce the weight of the system by 8g (5g connector, 3g wires).

3 din 5 20.09.2021, 01:37

DRONELAB https://dronelab.se/siliconewire.html

To close the loop, a "maximum recommended current per gram of wire per meter" chart

was compiled. The flatness of this result suggests that all of our measurements were

consistant. More copper means more weight, but also more current capacity. The results

check out.

Resistance

For the sake of completness, we provide a measured resistance over 1 meter on a warm

wire (approx 60-100C).

24 AWG 20 AWG 18 AWG 16 AWG 14 AWG 12 AWG 10 AWG

87.0 mΩ/m 40.0 mΩ/m 28.3 mΩ/m 15.3 mΩ/m 11.2 mΩ/m 6.80 mΩ/m 4.12 mΩ/m

Methodology

The wires were tested in a "burst" scenario, where the tested current was applied for 10

seconds. Prior to a "burst", a lower current was held, to keep the wire pre-warmed to

approximately 30-50 degrees. A test would be considered failed, if any smoke was

noticed, indicating heat damage to the insulation. All tested wires were the same length

(17cm), and were connected directly to the terminals of the 600 Ampere power supply.

Note that the voltage applied to the wire during the test has no significance to the

experiment - the power a wire can carry is only limited by the current capacity, and - in

practice - independent from the voltage.

The tests were performed on a chilly Swedish afternoon with an ambient temperature of

just 5 degrees C, but this should not influence the results too much, as the point of failure

of the wires is well beyond 200C, and each tested wire was pre-heated before the 10

second punch. Most of the wires were purchased at Hobbyking, and were initially

inspected for build quality - we confirmed the high strand count, and confirmed that the

insulation material was indeed silicone, as it did not melt at 250 degrees. You should

expect similar results from wires purchased at similarly reputable vendors.

Signal wires

For all the connections that don’t carry motor current - like the power and signal to a

camera, receiver or VTX, we also recommend silicone wire due to its resistance to

vibration and ease of soldering. Although we omitted it in the video, a tiny 30AWG wire

was tested to handle 5A of continuous current and a resistance of 400mΩ/m. However,

that gauge is so slim, that for additional mechanical robustness we would recommend

AWG28 or even AWG26 for such connections.

Final note

We try our best to offer usable data and make your drone building experience easier.

4 din 5 20.09.2021, 01:37

DRONELAB https://dronelab.se/siliconewire.html

However, DRONELAB is a not for profit venture, that we run as an afternoon hobby. We

take absolutely no responsibility for anything you find on this site or our youtube channel.

Nonetheless, if you disagree with our recommendations or you found a mistake in our

data, don't hesitate to contact us.

5 din 5 20.09.2021, 01:37

You might also like

- How To Read A SchematicDocument4 pagesHow To Read A Schematicjeanjean33No ratings yet

- Selection of Power CablesDocument4 pagesSelection of Power Cablesa.wNo ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument29 pagesInsulation Resistance (IR) Values - Electrical Notes & ArticlesNikhil Chakravarthy Vatsavayi100% (1)

- VG95218 PDFDocument35 pagesVG95218 PDFPugalenthi SekarNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Boat ElectricsDocument34 pagesBoat ElectricsSquinkle100% (1)

- What Is Cable Testing. How Is Cable Testing DoneDocument8 pagesWhat Is Cable Testing. How Is Cable Testing DoneAbdul JabbarNo ratings yet

- Analyze Ampacity ACDocument2 pagesAnalyze Ampacity ACLedred1No ratings yet

- Using and Choosing WireDocument5 pagesUsing and Choosing WirebharateshNo ratings yet

- Cable Accessories: Systems, IncDocument4 pagesCable Accessories: Systems, IncLuis MurilloNo ratings yet

- What Is Cable Testing. How Is Cable Testing DoneDocument8 pagesWhat Is Cable Testing. How Is Cable Testing DoneNaveed IrshadNo ratings yet

- Co Axial CablesDocument4 pagesCo Axial CablesKCTV NEWS PUNGANURNo ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument31 pagesInsulation Resistance (IR) Values - Electrical Notes & ArticlesKush SharmaNo ratings yet

- Selecting CableDocument2 pagesSelecting CableidanzbhNo ratings yet

- Earth Fault Loop ImpedenceDocument3 pagesEarth Fault Loop Impedencemsn-silva100% (1)

- Testing of Distribution CablesDocument11 pagesTesting of Distribution CablesHashimi JuniNo ratings yet

- Department of Electrical Engineering: Riphah International University, Islamabad, PakistanDocument6 pagesDepartment of Electrical Engineering: Riphah International University, Islamabad, PakistanBaqir HussainNo ratings yet

- Joints and TerminationDocument20 pagesJoints and TerminationMannu KiruiNo ratings yet

- Underground Cable Ampacity With Neher McGrathDocument7 pagesUnderground Cable Ampacity With Neher McGrathJesus RodriguezNo ratings yet

- Choose The Correct Wire Size - BoatUSDocument9 pagesChoose The Correct Wire Size - BoatUSangelNo ratings yet

- Ten Deadly Conditions in Electrical SystemsDocument11 pagesTen Deadly Conditions in Electrical SystemsNelson Aguirre BravoNo ratings yet

- Keystone Medium Voltage Catalogue (Export)Document52 pagesKeystone Medium Voltage Catalogue (Export)Mehdi Hajd KacemNo ratings yet

- Electrical For ALLDocument51 pagesElectrical For ALLvaithy2011No ratings yet

- Electrical Tests Uncured RR CoilsDocument2 pagesElectrical Tests Uncured RR CoilsTiagoFaleiros100% (1)

- Cable Short Circuit RatingsDocument2 pagesCable Short Circuit Ratingstees220510No ratings yet

- Why Do My Contactor Coils Keep Burning OutDocument2 pagesWhy Do My Contactor Coils Keep Burning Out666667No ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument37 pagesInsulation Resistance (IR) Values - Electrical Notes & Articlesnyong dro100% (1)

- QUALITY TOOL BOX - Hipot TestingDocument5 pagesQUALITY TOOL BOX - Hipot TestingVijayan Thekke VeeduNo ratings yet

- Presentation Module IIEE Elec Enthusiast 09102022 PDFDocument29 pagesPresentation Module IIEE Elec Enthusiast 09102022 PDFEarl Jenn AbellaNo ratings yet

- Experimental ElectricalDocument40 pagesExperimental ElectricalPIYUSHNo ratings yet

- Testing WeldsDocument16 pagesTesting Weldschokrib100% (2)

- Fluke - How Cables and Connectors Impact Measurement UncertaintyDocument4 pagesFluke - How Cables and Connectors Impact Measurement UncertaintyMatias RamosNo ratings yet

- Comment Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument41 pagesComment Insulation Resistance (IR) Values - Electrical Notes & ArticlesMunazar HussainNo ratings yet

- BS88 Bussman Fuse Links Zs To 800ADocument1 pageBS88 Bussman Fuse Links Zs To 800Arobpeter2425No ratings yet

- Cable Selcetion2 Afte RM Rev4Document9 pagesCable Selcetion2 Afte RM Rev4Stephen BridgesNo ratings yet

- Cabling Products and Solutions: CATALOGUE 2010/2011Document196 pagesCabling Products and Solutions: CATALOGUE 2010/2011Georgi PanayotovNo ratings yet

- MVcables DesignDocument40 pagesMVcables DesigniyyaniNo ratings yet

- 12T0020X00 Anixter WW Temperature Ratings W&C EN USDocument1 page12T0020X00 Anixter WW Temperature Ratings W&C EN USFelipe GustavoNo ratings yet

- Electrical Wiring Residential Canadian 7th Edition Mullin Solutions ManualDocument4 pagesElectrical Wiring Residential Canadian 7th Edition Mullin Solutions Manualallisondoylenqmsgyicjb97% (32)

- Screw Less Cage ClampDocument23 pagesScrew Less Cage ClampApurbaNo ratings yet

- Cable CrimpingDocument12 pagesCable CrimpingSuresh RamNo ratings yet

- Initiation: Components Used in Electric BlastingDocument18 pagesInitiation: Components Used in Electric BlastingariellopezNo ratings yet

- Loadbreak Products: Experience & ReliabilityDocument8 pagesLoadbreak Products: Experience & ReliabilityCbdtxd PcbtrNo ratings yet

- Sizing Cables, Conduit and TrunkingDocument56 pagesSizing Cables, Conduit and TrunkingChanel Maglinao100% (9)

- Voltage DropDocument6 pagesVoltage Dropmohd_mohaisen100% (1)

- 28AWG 32AWG Patch Cord - White Paper - ENGDocument5 pages28AWG 32AWG Patch Cord - White Paper - ENGAlex QuintanaNo ratings yet

- ANSI MV TechTopics85 ENDocument2 pagesANSI MV TechTopics85 ENArunava DasguptaNo ratings yet

- Cable Calculation and Selection WorksheetDocument22 pagesCable Calculation and Selection WorksheetLedred1No ratings yet

- NFC Aaac Al4 - 34.4&54.6 Ees CableDocument5 pagesNFC Aaac Al4 - 34.4&54.6 Ees CableazzouzimedNo ratings yet

- Tan Delta FAQDocument6 pagesTan Delta FAQDev SwainNo ratings yet

- 22kV-Cable-Termination-Failure (Chapter 6) PDFDocument6 pages22kV-Cable-Termination-Failure (Chapter 6) PDFTarikfaraj100% (1)

- 06 - Fire Resistant CablesDocument13 pages06 - Fire Resistant CablesmlutfimaNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Essential Boat Electrics: Carry Out Electrical Jobs On Board Properly & SafelyFrom EverandEssential Boat Electrics: Carry Out Electrical Jobs On Board Properly & SafelyNo ratings yet

- Understanding Your Boats Systems and Choices.From EverandUnderstanding Your Boats Systems and Choices.Rating: 3 out of 5 stars3/5 (1)

- Water Level Indicator Circuit Using Bipolar Junction TransistorFrom EverandWater Level Indicator Circuit Using Bipolar Junction TransistorRating: 4.5 out of 5 stars4.5/5 (7)

- High-Performance D/A-Converters: Application to Digital TransceiversFrom EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Deep Learning Isn't Deep Enough Unless It Copies From The Brain - IEEE SpectrumDocument19 pagesDeep Learning Isn't Deep Enough Unless It Copies From The Brain - IEEE Spectrumicxnc1No ratings yet

- ManualDocument187 pagesManualicxnc1No ratings yet

- Marketing For Photographers PDFDocument193 pagesMarketing For Photographers PDFicxnc1100% (1)

- Chassis Bolts and Nuts: Item N.M KGF.M Ib-FtDocument1 pageChassis Bolts and Nuts: Item N.M KGF.M Ib-Fticxnc1No ratings yet

- Colour gsx1400 - Full - Manual - k2 - To - Final - EditionDocument1 pageColour gsx1400 - Full - Manual - k2 - To - Final - Editionicxnc1No ratings yet

- Fit Yoshimura ST-1 CamsDocument16 pagesFit Yoshimura ST-1 Camsicxnc1No ratings yet

- Afr Autotune PCVDocument93 pagesAfr Autotune PCVicxnc1No ratings yet

- PCV User'S Guide.: The Latest Software and Maps Can Be Found atDocument4 pagesPCV User'S Guide.: The Latest Software and Maps Can Be Found aticxnc1No ratings yet

- Funai Wd6d-d4413db E9tf3edDocument113 pagesFunai Wd6d-d4413db E9tf3edLaurent CAUFRIEZNo ratings yet

- Voltcraft p9-2 SCH PDFDocument1 pageVoltcraft p9-2 SCH PDFkandi abdNo ratings yet

- S W A N 1 0 0 0: Installation InstructionsDocument2 pagesS W A N 1 0 0 0: Installation InstructionsLuisAlbertoSaldañaRmzNo ratings yet

- Course: Electronic Circuit Design Lab No: 08 Title: Characterization of The MOS Transistor CID: - DateDocument6 pagesCourse: Electronic Circuit Design Lab No: 08 Title: Characterization of The MOS Transistor CID: - DateAamir ChohanNo ratings yet

- Basic Electronics MCQ QuestionsDocument6 pagesBasic Electronics MCQ QuestionsRai Ali Raza KharalNo ratings yet

- Promag 50 53 Resistance Check PDFDocument4 pagesPromag 50 53 Resistance Check PDFAllisson MacedoNo ratings yet

- Partial Discharge Sensors HSENS-T Rugged MonitoringDocument2 pagesPartial Discharge Sensors HSENS-T Rugged MonitoringRugged Monitoring100% (1)

- Indus Lecture 2 PartialDocument69 pagesIndus Lecture 2 PartialIris Jean Mosquera100% (1)

- Lab 2 Simple Electric CircuitsDocument7 pagesLab 2 Simple Electric CircuitsKai ShiroNo ratings yet

- Cen-Tech 63758Document8 pagesCen-Tech 63758GregNo ratings yet

- Ec8453 Linear Integrated Circuits Year/Sem: Ii/Iv Dept: R&A Part-BDocument1 pageEc8453 Linear Integrated Circuits Year/Sem: Ii/Iv Dept: R&A Part-BARUNKUMARNo ratings yet

- Test and MeasurenmentDocument4 pagesTest and MeasurenmentNiña Angelica AligaenNo ratings yet

- Relay Selection Criteria 1Document1 pageRelay Selection Criteria 1jenixson tamondongNo ratings yet

- Installation Manual: EnglishDocument152 pagesInstallation Manual: EnglishJakub GráčikNo ratings yet

- Dgca M-4 Mcqs Part-1Document20 pagesDgca M-4 Mcqs Part-1Abhishek SoniNo ratings yet

- Kenya Power Attachment ReportDocument17 pagesKenya Power Attachment ReportRouxcel abuto100% (1)

- 9 Way Clap Switch!!Document8 pages9 Way Clap Switch!!Trilok Sawant100% (1)

- Technological University of The Philippines Visayas: An Example of Schematic DiagramDocument5 pagesTechnological University of The Philippines Visayas: An Example of Schematic DiagramMary SenilloNo ratings yet

- 091-0226A MK2000A PowerSupplyDocument29 pages091-0226A MK2000A PowerSupplySneyder YepesNo ratings yet

- NX TehnilineDocument92 pagesNX TehnilineAhmad AlswalhiNo ratings yet

- Ecowise EW20/1 EW30/1: The Ultimate Smart Grid Solution Instruction ManualDocument14 pagesEcowise EW20/1 EW30/1: The Ultimate Smart Grid Solution Instruction ManualManuel MendezNo ratings yet

- Listening 2 JanDocument3 pagesListening 2 JanRia YuliantiNo ratings yet

- MSE - Electrical & Instruments Tool ListDocument1 pageMSE - Electrical & Instruments Tool ListAnto DamanikNo ratings yet

- A Short Review of Reactive Power Management For Distributed GenerationDocument4 pagesA Short Review of Reactive Power Management For Distributed GenerationHai Pham ManhNo ratings yet

- 1746894Document3 pages1746894Marius BudauNo ratings yet

- Smoothing Reactor: Schematic DiagramDocument1 pageSmoothing Reactor: Schematic DiagramHARSUN A/L PARANTHAMAN STUDENTNo ratings yet

- Engineer'S Manual: SeriesDocument154 pagesEngineer'S Manual: SeriesMuhammad IrfanNo ratings yet

- Grounding at Points Other Than System NeutralDocument15 pagesGrounding at Points Other Than System NeutralWendy DuncanNo ratings yet

- A4447 High Voltage Step Down Regulator: Features and Benefits DescriptionDocument12 pagesA4447 High Voltage Step Down Regulator: Features and Benefits DescriptionCiprian UngureanuNo ratings yet