Professional Documents

Culture Documents

Daily Checklist For SWP

Daily Checklist For SWP

Uploaded by

tfpl hseCopyright:

Available Formats

You might also like

- Hazards ChecklistDocument7 pagesHazards ChecklistRemeras TartagalNo ratings yet

- Leaf SpringDocument16 pagesLeaf SpringThayumanavan KSNo ratings yet

- Vturn-NP16 NP20Document12 pagesVturn-NP16 NP20José Adalberto Caraballo Lorenzo0% (1)

- Monthly HSSE Inspection ChecklistDocument5 pagesMonthly HSSE Inspection ChecklistEric TNo ratings yet

- GAS-HSE-GEN-002 Rev 0 Fire Drill Checklist RecordDocument2 pagesGAS-HSE-GEN-002 Rev 0 Fire Drill Checklist RecordRafeeq Ur RahmanNo ratings yet

- Management Responsibility Draft 4 10 March 2014Document101 pagesManagement Responsibility Draft 4 10 March 2014mkpqNo ratings yet

- Chemical Risk AssessmentDocument14 pagesChemical Risk AssessmentChand NaiduNo ratings yet

- Managing Hazardous Chemicals in Department of Education Workplaces Risk AssessmentDocument10 pagesManaging Hazardous Chemicals in Department of Education Workplaces Risk AssessmentNur E Alam NuruNo ratings yet

- HSE Induction Checklist-ContractorDocument1 pageHSE Induction Checklist-ContractorAnil SaiNo ratings yet

- Safety Health & Environment MethodologyDocument14 pagesSafety Health & Environment MethodologymusengemNo ratings yet

- Competency Assessment Form - New Vendor RegistrationDocument9 pagesCompetency Assessment Form - New Vendor Registrationmadhusri002No ratings yet

- Ppe Inspection Form: Personal Protective EquipmentDocument2 pagesPpe Inspection Form: Personal Protective EquipmentRaj Engineering ServicesNo ratings yet

- Road Safety QuestionnaireDocument4 pagesRoad Safety QuestionnaireNicolne LorraineNo ratings yet

- Emami Infrastructure Limited: Safety Inspection ReportDocument1 pageEmami Infrastructure Limited: Safety Inspection ReportvarunstuffNo ratings yet

- ISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFDocument5 pagesISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFpurva02No ratings yet

- HSE Inspection Guideline & ChecklistsDocument20 pagesHSE Inspection Guideline & ChecklistsWaelBouNo ratings yet

- HSE Calendar Jan 2023Document4 pagesHSE Calendar Jan 2023RathikaNo ratings yet

- PM - 7.06 Production Control and Product ProvisionDocument4 pagesPM - 7.06 Production Control and Product ProvisionsriNo ratings yet

- H S ChecklistDocument17 pagesH S ChecklistkhajaimadNo ratings yet

- Contoh Workplace Inspection Procedure and Checklist PDF 1.1MBDocument10 pagesContoh Workplace Inspection Procedure and Checklist PDF 1.1MBmae_blurNo ratings yet

- PPE Inspection PDFDocument1 pagePPE Inspection PDFLamtua PurbaNo ratings yet

- PGP Contracting: Stop Work PolicyDocument4 pagesPGP Contracting: Stop Work Policywinston11No ratings yet

- 5S ChecklistDocument8 pages5S Checklistta3kobahokaNo ratings yet

- Pre Use and Monthly Inspection Checklist For Overhead Cranes and HoistsDocument1 pagePre Use and Monthly Inspection Checklist For Overhead Cranes and HoistsAnsarNo ratings yet

- Chemical Health Risk AssessmentDocument1 pageChemical Health Risk AssessmentAbu Abbas AiyubNo ratings yet

- Safety Data SheetDocument6 pagesSafety Data SheetWici WiciNo ratings yet

- Business Procedure: Event Management HSEQDocument16 pagesBusiness Procedure: Event Management HSEQAmr EssamNo ratings yet

- Factory Compliance Check ListDocument5 pagesFactory Compliance Check ListvermaamanvermaNo ratings yet

- Fire Safety CeklistDocument4 pagesFire Safety CeklistRindy Novianti PramitaNo ratings yet

- HSE Briefing 1Document6 pagesHSE Briefing 1TarikTaliHidungNo ratings yet

- Guidance Material OM BVLOS Drone Operations Over Sparsely Populated Areas - v1Document10 pagesGuidance Material OM BVLOS Drone Operations Over Sparsely Populated Areas - v1prasenjitdey786No ratings yet

- 10 Audit and Management Review Procedure FINALDocument3 pages10 Audit and Management Review Procedure FINALDayne Ocampo-SolimanNo ratings yet

- CoP - 9.0 - Workplace WellnessDocument9 pagesCoP - 9.0 - Workplace WellnessAnonymous y1pIqcNo ratings yet

- Guidelines On Personal Protective Equipment (PPE) : Ppe To Be Used Page No 4-11Document51 pagesGuidelines On Personal Protective Equipment (PPE) : Ppe To Be Used Page No 4-11upt vadodaraNo ratings yet

- Confined SpacesDocument4 pagesConfined Spaceshello3232No ratings yet

- HSE AwarenessDocument85 pagesHSE AwarenessMrityunjay DhanrajNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatePanchdev KumarNo ratings yet

- Know - Workplace Health and Safety Principles (International)Document25 pagesKnow - Workplace Health and Safety Principles (International)Afroz SheikhNo ratings yet

- Hse - The Selection and Management of Mobile Elevating Work PlatformsDocument6 pagesHse - The Selection and Management of Mobile Elevating Work PlatformsrewmarineNo ratings yet

- 1 2016 NWRA Journey Risk Management Plan POLICY GuidanceDocument5 pages1 2016 NWRA Journey Risk Management Plan POLICY GuidanceJayant Mukherjee100% (1)

- Cold Work PermitDocument2 pagesCold Work Permitimranul haqNo ratings yet

- (Inspection Inprocess)Document15 pages(Inspection Inprocess)loserambujNo ratings yet

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- Scaffold Inspection ChecklistDocument1 pageScaffold Inspection ChecklistAli HadiNo ratings yet

- Safety ChecklistDocument2 pagesSafety ChecklistsammeikNo ratings yet

- 02-012 Working at Heights PolicyDocument7 pages02-012 Working at Heights PolicyJoachimNo ratings yet

- QA-IMCO-HSE-P-QT-015 Hot Work Procedure PDFDocument16 pagesQA-IMCO-HSE-P-QT-015 Hot Work Procedure PDFFrancis Enriquez TanNo ratings yet

- Fire Drill Audit ChecklistDocument5 pagesFire Drill Audit ChecklistGoh Boon Tiong0% (1)

- Storage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsDocument1 pageStorage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsArshad MahmoodNo ratings yet

- GRN Goods Received Note Adjusted JSDocument1 pageGRN Goods Received Note Adjusted JSIbrahim PatelNo ratings yet

- Iso 14001 Checklist DemoDocument4 pagesIso 14001 Checklist DemoAristantia PrastiwiNo ratings yet

- Accident Investigation For SupervisorsDocument32 pagesAccident Investigation For SupervisorsgoldenridgeNo ratings yet

- Sample SWMS SP003 - Margate Parade Boardwalk Concrete WorkDocument10 pagesSample SWMS SP003 - Margate Parade Boardwalk Concrete WorkadiNo ratings yet

- Safe Use of Chemicals: 1.0 PurposeDocument10 pagesSafe Use of Chemicals: 1.0 PurposeFuzail AyazNo ratings yet

- Machine Guarding Checklist: Questions Requirements For All SafeguardsDocument2 pagesMachine Guarding Checklist: Questions Requirements For All SafeguardsAVENON MardocheeNo ratings yet

- SIMOPS ChecklistDocument3 pagesSIMOPS ChecklistAbderrahmene SaciNo ratings yet

- Simpos ChecklistDocument3 pagesSimpos ChecklistAsad MaherNo ratings yet

- Audit FormDocument3 pagesAudit FormJyotiranjan RoutNo ratings yet

- Hot Work ChecklistDocument1 pageHot Work ChecklistloganathanNo ratings yet

- Confined Space Work PermitDocument2 pagesConfined Space Work PermitHariharan MuthukrishananNo ratings yet

- Light Vehicle Inspection Checklist: Merlinda Pagalan - 0915-8816660Document5 pagesLight Vehicle Inspection Checklist: Merlinda Pagalan - 0915-8816660RCGNo ratings yet

- Component Activities in Liquid Mixture, Using NRTL - File Exchange - MATLAB Central PDFDocument3 pagesComponent Activities in Liquid Mixture, Using NRTL - File Exchange - MATLAB Central PDFbakhtyar21No ratings yet

- Lec-1.pdf Thermodynamics Application - Engineering Thermodynamics-01Document15 pagesLec-1.pdf Thermodynamics Application - Engineering Thermodynamics-01Saurabh GuptaNo ratings yet

- QuestionsDocument20 pagesQuestionsmaheshNo ratings yet

- KAR Products - Penetrating OilDocument5 pagesKAR Products - Penetrating Oiljaredf@jfelectric.com100% (2)

- RRLDocument3 pagesRRLrogelyn samilinNo ratings yet

- Mechanical Relay-Type PDFDocument17 pagesMechanical Relay-Type PDFSaleCvetkovicNo ratings yet

- Acropolis Institute of Technology & Research, IndoreDocument19 pagesAcropolis Institute of Technology & Research, IndoreRrr320No ratings yet

- Zinc Precipitation On Gold RecoveryDocument18 pagesZinc Precipitation On Gold RecoveryysioigaNo ratings yet

- Silo Data Sheet PDFDocument4 pagesSilo Data Sheet PDFMohamed ElfawalNo ratings yet

- CC505 - 2 Slope Deflection Method For BeamDocument34 pagesCC505 - 2 Slope Deflection Method For BeamIzzSyieNo ratings yet

- 9 Dam Break PDFDocument13 pages9 Dam Break PDFBrandon ArmeroNo ratings yet

- ABB Electrical Wiring AccessoriesDocument2 pagesABB Electrical Wiring Accessoriesവർഗീസ് ജോസഫ്0% (1)

- DESCH Complete Press DriveDocument8 pagesDESCH Complete Press DriveSerdar FildisNo ratings yet

- JETYD Brochure PDFDocument24 pagesJETYD Brochure PDFpicottoNo ratings yet

- Fisa Tehnica Ultra Series-Sapa Cu Polistiren - CT12F3D1.6Document1 pageFisa Tehnica Ultra Series-Sapa Cu Polistiren - CT12F3D1.6rovandabilNo ratings yet

- Request For Inspection Summary: Project Name: ClientDocument2 pagesRequest For Inspection Summary: Project Name: ClientAmit MaityNo ratings yet

- Final ME-Construction Chemicals MarketDocument11 pagesFinal ME-Construction Chemicals MarketAlaz FofanaNo ratings yet

- RSW Ex 01 BackgroundDocument4 pagesRSW Ex 01 BackgroundTạ ThốnNo ratings yet

- Oracle Interview QuestionDocument87 pagesOracle Interview QuestionfahdaizazNo ratings yet

- Deformation Mechanism Maps - Oct27Document41 pagesDeformation Mechanism Maps - Oct27Fame Boy SamNo ratings yet

- CC-VT230W QS-M ENG v1 PDFDocument18 pagesCC-VT230W QS-M ENG v1 PDFSunil RaoNo ratings yet

- Industrial & Commercial Refrigeration Products: 800.96.HENRYDocument10 pagesIndustrial & Commercial Refrigeration Products: 800.96.HENRYDASIHER2111No ratings yet

- LUBCON Printing ServicesDocument2 pagesLUBCON Printing ServicesOmin PostingNo ratings yet

- Gate ValveDocument27 pagesGate ValveYogesh Kumar Bhatnagar0% (1)

- Document in EDI Process Overview - v5 - Compatibility ModeDocument11 pagesDocument in EDI Process Overview - v5 - Compatibility Modevishnu_spicNo ratings yet

- Nec450 3ADocument9 pagesNec450 3AArmando Jr GamutanNo ratings yet

- Example Beam ProblemDocument2 pagesExample Beam ProblemxicaodocetNo ratings yet

- Geometric ModellingDocument37 pagesGeometric Modellingphanirao1No ratings yet

Daily Checklist For SWP

Daily Checklist For SWP

Uploaded by

tfpl hseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daily Checklist For SWP

Daily Checklist For SWP

Uploaded by

tfpl hseCopyright:

Available Formats

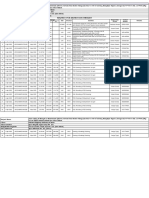

Daily Checklist

SWP number: Location:

Permit Executor: Permit Issuer:

Day Tuesday Wednesday Thursday Friday Saturday Sunday

Date

S. No. Precautions to be taken Yes No/NA Yes No/NA Yes No/NA Yes No/NA Yes No/NA Yes No/NA

A General Work

1 Simultaneous operations/affected personnel managed

2 Performing operators have necessary knowledge of procedures applicable for work

3 A toolbox talk will be conducted and agreed with all personnel involved

4 PPE requirements identified and will be adhered too

Controls to prevent dropped objects identified and will be implemented (area cordoned off, tools/equipment secured etc.)

5

6 Tools and equipment verified and concluded safe

7 Sufficient communication measures identified and will be implemented

8 Required fire, first aid- and emergency preparedness equipment identified and implemented

9 Energy-isolation (Lock-Out/Tag-Out) will be established

B Hot Work

1 Is the area around the hot work spot clean and free of combustible & flammable material?

2 Are all combustible materials protected (kept 35ft away from the place of hot work) ?

3 Are all operations in the surrounding area suspended, in order to prevent leakage / splash of inflammable material?

4 Are suitable fire extinguishers, in adequate numbers, kept ready for firefighting? Specify the type:

5 Gas test required? If “Yes’ attach gas test record sheet.

6 Is Fire watch personnel is provided? Name:

7 Are the persons taking up the job adequately trained?

8 Are necessary PPEs used by the personnel carrying out the work?

9 Is a proper escape route ensured and adequately marked? Are the personnel made aware of The same?

10 Does the welding machine / gas cutting set or any other power tool used have a valid inspection tag?

11 Are earthing & electrical insulations proper for hand tools and Portable Electrical Equipment used?

12 Are all the power cables in the vicinity adequately protected?

13 Have NRV / Flash back Arrestor been provided in the cutting nozzles and the cylinder outlet ?

14 Are Compressed gas cylinders located at a safe distance from the area of hot work and protected from sparks?

15 Is a "Hot Work Under Progress" caution sign board available at the spot?

16 Is the site of hot work enclosed from all sides with GI Sheets/fire blankets?

17 Has the area been surveyed to identify the presence of any additional potential hazards?

18 Is the Contract supervisor present at the job site till the time the job is completed?

19 Firewatch shall be present at work location after completion of work for 15 mins.

Done by Area Engineer/Supervisor

Verified by Contractor HSE officer

Daily Checklist

SWP number: Location:

Permit Executor: Permit Issuer:

Day Tuesday Wednesday Thursday Friday Saturday Sunday

Date

S. No. Precautions to be taken Yes No/NA Yes No/NA Yes No/NA Yes No/NA Yes No/NA Yes No/NA

C Height Work

Is the area cordoned off using barricading tape and caution sign board is prominently Displayed at the site of operation?

1

2 Are Scaffolding / ladder used, in good condition and safe for use? Are inspection tags Available on them?

3 Ladder\Scaffolding\MEWP Inspected\Approved along with the checklist?

Is the safety harness provided in good condition and having the inspection tag? Is the anchor point identified and adequate?

4

5 Is the area clear from over-head electrical lines?

Is it ensured that none of the persons working at elevation is suffering from ailments like Low/high blood pressure, vertigo and

6

epilepsy?

7 Is a Safety net provided below the work area?

8 Is a proper escape route ensured and adequately marked? Are the personnel made aware of the same?

9 All hand tools are secured against accidental fall?

10 Loose materials at height are secured?

11 Open areas/gratings are adequate covered and protected. Warning signs are conspicuously posted?

12 Steel erection work has safe access and egress and secure anchor points?

13 Adequate illumination provided in the work area?

14 100% Fall Protection complied toe board, guard rails are secured. Static line provided where required?

D Excavation Work

1 Does the dig involve deep excavations i.e. greater than 1.2?

2 Have the proposed dig location(s) been surveyed for presence of existing services?

Have underground services been established in the location of the excavation(s)? (if yes fill up the underground utilities section)

3

4 Are there any overhead lines in the vicinity of the excavations? (if yes fill up the overhead services section)

5 Has a Risk Assessment being carried out and control measures actioned ?

Has a Work Method Statement (WMS) been completed and communicated for all high-risk construction works identified?

6

7 Is underground utility information checked and attached to this permit?

8 Have all services marked on the ground?

9 Excavator or Equipment / Tool inspected, and checklist attached?

10 Cordoned off the area and caution signage’s displayed?

Overhead Services

1 Is the approach distance within prescribed clearances?

2 Do power line risks need to be controlled by isolation or placed into a protected state?

3 What is the voltage of the power line?

4 What is the clearance distance between power line and excavator / equipment?

Done by Area Engineer/Supervisor

Verified by Contractor HSE officer

You might also like

- Hazards ChecklistDocument7 pagesHazards ChecklistRemeras TartagalNo ratings yet

- Leaf SpringDocument16 pagesLeaf SpringThayumanavan KSNo ratings yet

- Vturn-NP16 NP20Document12 pagesVturn-NP16 NP20José Adalberto Caraballo Lorenzo0% (1)

- Monthly HSSE Inspection ChecklistDocument5 pagesMonthly HSSE Inspection ChecklistEric TNo ratings yet

- GAS-HSE-GEN-002 Rev 0 Fire Drill Checklist RecordDocument2 pagesGAS-HSE-GEN-002 Rev 0 Fire Drill Checklist RecordRafeeq Ur RahmanNo ratings yet

- Management Responsibility Draft 4 10 March 2014Document101 pagesManagement Responsibility Draft 4 10 March 2014mkpqNo ratings yet

- Chemical Risk AssessmentDocument14 pagesChemical Risk AssessmentChand NaiduNo ratings yet

- Managing Hazardous Chemicals in Department of Education Workplaces Risk AssessmentDocument10 pagesManaging Hazardous Chemicals in Department of Education Workplaces Risk AssessmentNur E Alam NuruNo ratings yet

- HSE Induction Checklist-ContractorDocument1 pageHSE Induction Checklist-ContractorAnil SaiNo ratings yet

- Safety Health & Environment MethodologyDocument14 pagesSafety Health & Environment MethodologymusengemNo ratings yet

- Competency Assessment Form - New Vendor RegistrationDocument9 pagesCompetency Assessment Form - New Vendor Registrationmadhusri002No ratings yet

- Ppe Inspection Form: Personal Protective EquipmentDocument2 pagesPpe Inspection Form: Personal Protective EquipmentRaj Engineering ServicesNo ratings yet

- Road Safety QuestionnaireDocument4 pagesRoad Safety QuestionnaireNicolne LorraineNo ratings yet

- Emami Infrastructure Limited: Safety Inspection ReportDocument1 pageEmami Infrastructure Limited: Safety Inspection ReportvarunstuffNo ratings yet

- ISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFDocument5 pagesISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFpurva02No ratings yet

- HSE Inspection Guideline & ChecklistsDocument20 pagesHSE Inspection Guideline & ChecklistsWaelBouNo ratings yet

- HSE Calendar Jan 2023Document4 pagesHSE Calendar Jan 2023RathikaNo ratings yet

- PM - 7.06 Production Control and Product ProvisionDocument4 pagesPM - 7.06 Production Control and Product ProvisionsriNo ratings yet

- H S ChecklistDocument17 pagesH S ChecklistkhajaimadNo ratings yet

- Contoh Workplace Inspection Procedure and Checklist PDF 1.1MBDocument10 pagesContoh Workplace Inspection Procedure and Checklist PDF 1.1MBmae_blurNo ratings yet

- PPE Inspection PDFDocument1 pagePPE Inspection PDFLamtua PurbaNo ratings yet

- PGP Contracting: Stop Work PolicyDocument4 pagesPGP Contracting: Stop Work Policywinston11No ratings yet

- 5S ChecklistDocument8 pages5S Checklistta3kobahokaNo ratings yet

- Pre Use and Monthly Inspection Checklist For Overhead Cranes and HoistsDocument1 pagePre Use and Monthly Inspection Checklist For Overhead Cranes and HoistsAnsarNo ratings yet

- Chemical Health Risk AssessmentDocument1 pageChemical Health Risk AssessmentAbu Abbas AiyubNo ratings yet

- Safety Data SheetDocument6 pagesSafety Data SheetWici WiciNo ratings yet

- Business Procedure: Event Management HSEQDocument16 pagesBusiness Procedure: Event Management HSEQAmr EssamNo ratings yet

- Factory Compliance Check ListDocument5 pagesFactory Compliance Check ListvermaamanvermaNo ratings yet

- Fire Safety CeklistDocument4 pagesFire Safety CeklistRindy Novianti PramitaNo ratings yet

- HSE Briefing 1Document6 pagesHSE Briefing 1TarikTaliHidungNo ratings yet

- Guidance Material OM BVLOS Drone Operations Over Sparsely Populated Areas - v1Document10 pagesGuidance Material OM BVLOS Drone Operations Over Sparsely Populated Areas - v1prasenjitdey786No ratings yet

- 10 Audit and Management Review Procedure FINALDocument3 pages10 Audit and Management Review Procedure FINALDayne Ocampo-SolimanNo ratings yet

- CoP - 9.0 - Workplace WellnessDocument9 pagesCoP - 9.0 - Workplace WellnessAnonymous y1pIqcNo ratings yet

- Guidelines On Personal Protective Equipment (PPE) : Ppe To Be Used Page No 4-11Document51 pagesGuidelines On Personal Protective Equipment (PPE) : Ppe To Be Used Page No 4-11upt vadodaraNo ratings yet

- Confined SpacesDocument4 pagesConfined Spaceshello3232No ratings yet

- HSE AwarenessDocument85 pagesHSE AwarenessMrityunjay DhanrajNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatePanchdev KumarNo ratings yet

- Know - Workplace Health and Safety Principles (International)Document25 pagesKnow - Workplace Health and Safety Principles (International)Afroz SheikhNo ratings yet

- Hse - The Selection and Management of Mobile Elevating Work PlatformsDocument6 pagesHse - The Selection and Management of Mobile Elevating Work PlatformsrewmarineNo ratings yet

- 1 2016 NWRA Journey Risk Management Plan POLICY GuidanceDocument5 pages1 2016 NWRA Journey Risk Management Plan POLICY GuidanceJayant Mukherjee100% (1)

- Cold Work PermitDocument2 pagesCold Work Permitimranul haqNo ratings yet

- (Inspection Inprocess)Document15 pages(Inspection Inprocess)loserambujNo ratings yet

- Incident Checklist: Other ActionsDocument1 pageIncident Checklist: Other Actionsloveson709No ratings yet

- Scaffold Inspection ChecklistDocument1 pageScaffold Inspection ChecklistAli HadiNo ratings yet

- Safety ChecklistDocument2 pagesSafety ChecklistsammeikNo ratings yet

- 02-012 Working at Heights PolicyDocument7 pages02-012 Working at Heights PolicyJoachimNo ratings yet

- QA-IMCO-HSE-P-QT-015 Hot Work Procedure PDFDocument16 pagesQA-IMCO-HSE-P-QT-015 Hot Work Procedure PDFFrancis Enriquez TanNo ratings yet

- Fire Drill Audit ChecklistDocument5 pagesFire Drill Audit ChecklistGoh Boon Tiong0% (1)

- Storage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsDocument1 pageStorage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsArshad MahmoodNo ratings yet

- GRN Goods Received Note Adjusted JSDocument1 pageGRN Goods Received Note Adjusted JSIbrahim PatelNo ratings yet

- Iso 14001 Checklist DemoDocument4 pagesIso 14001 Checklist DemoAristantia PrastiwiNo ratings yet

- Accident Investigation For SupervisorsDocument32 pagesAccident Investigation For SupervisorsgoldenridgeNo ratings yet

- Sample SWMS SP003 - Margate Parade Boardwalk Concrete WorkDocument10 pagesSample SWMS SP003 - Margate Parade Boardwalk Concrete WorkadiNo ratings yet

- Safe Use of Chemicals: 1.0 PurposeDocument10 pagesSafe Use of Chemicals: 1.0 PurposeFuzail AyazNo ratings yet

- Machine Guarding Checklist: Questions Requirements For All SafeguardsDocument2 pagesMachine Guarding Checklist: Questions Requirements For All SafeguardsAVENON MardocheeNo ratings yet

- SIMOPS ChecklistDocument3 pagesSIMOPS ChecklistAbderrahmene SaciNo ratings yet

- Simpos ChecklistDocument3 pagesSimpos ChecklistAsad MaherNo ratings yet

- Audit FormDocument3 pagesAudit FormJyotiranjan RoutNo ratings yet

- Hot Work ChecklistDocument1 pageHot Work ChecklistloganathanNo ratings yet

- Confined Space Work PermitDocument2 pagesConfined Space Work PermitHariharan MuthukrishananNo ratings yet

- Light Vehicle Inspection Checklist: Merlinda Pagalan - 0915-8816660Document5 pagesLight Vehicle Inspection Checklist: Merlinda Pagalan - 0915-8816660RCGNo ratings yet

- Component Activities in Liquid Mixture, Using NRTL - File Exchange - MATLAB Central PDFDocument3 pagesComponent Activities in Liquid Mixture, Using NRTL - File Exchange - MATLAB Central PDFbakhtyar21No ratings yet

- Lec-1.pdf Thermodynamics Application - Engineering Thermodynamics-01Document15 pagesLec-1.pdf Thermodynamics Application - Engineering Thermodynamics-01Saurabh GuptaNo ratings yet

- QuestionsDocument20 pagesQuestionsmaheshNo ratings yet

- KAR Products - Penetrating OilDocument5 pagesKAR Products - Penetrating Oiljaredf@jfelectric.com100% (2)

- RRLDocument3 pagesRRLrogelyn samilinNo ratings yet

- Mechanical Relay-Type PDFDocument17 pagesMechanical Relay-Type PDFSaleCvetkovicNo ratings yet

- Acropolis Institute of Technology & Research, IndoreDocument19 pagesAcropolis Institute of Technology & Research, IndoreRrr320No ratings yet

- Zinc Precipitation On Gold RecoveryDocument18 pagesZinc Precipitation On Gold RecoveryysioigaNo ratings yet

- Silo Data Sheet PDFDocument4 pagesSilo Data Sheet PDFMohamed ElfawalNo ratings yet

- CC505 - 2 Slope Deflection Method For BeamDocument34 pagesCC505 - 2 Slope Deflection Method For BeamIzzSyieNo ratings yet

- 9 Dam Break PDFDocument13 pages9 Dam Break PDFBrandon ArmeroNo ratings yet

- ABB Electrical Wiring AccessoriesDocument2 pagesABB Electrical Wiring Accessoriesവർഗീസ് ജോസഫ്0% (1)

- DESCH Complete Press DriveDocument8 pagesDESCH Complete Press DriveSerdar FildisNo ratings yet

- JETYD Brochure PDFDocument24 pagesJETYD Brochure PDFpicottoNo ratings yet

- Fisa Tehnica Ultra Series-Sapa Cu Polistiren - CT12F3D1.6Document1 pageFisa Tehnica Ultra Series-Sapa Cu Polistiren - CT12F3D1.6rovandabilNo ratings yet

- Request For Inspection Summary: Project Name: ClientDocument2 pagesRequest For Inspection Summary: Project Name: ClientAmit MaityNo ratings yet

- Final ME-Construction Chemicals MarketDocument11 pagesFinal ME-Construction Chemicals MarketAlaz FofanaNo ratings yet

- RSW Ex 01 BackgroundDocument4 pagesRSW Ex 01 BackgroundTạ ThốnNo ratings yet

- Oracle Interview QuestionDocument87 pagesOracle Interview QuestionfahdaizazNo ratings yet

- Deformation Mechanism Maps - Oct27Document41 pagesDeformation Mechanism Maps - Oct27Fame Boy SamNo ratings yet

- CC-VT230W QS-M ENG v1 PDFDocument18 pagesCC-VT230W QS-M ENG v1 PDFSunil RaoNo ratings yet

- Industrial & Commercial Refrigeration Products: 800.96.HENRYDocument10 pagesIndustrial & Commercial Refrigeration Products: 800.96.HENRYDASIHER2111No ratings yet

- LUBCON Printing ServicesDocument2 pagesLUBCON Printing ServicesOmin PostingNo ratings yet

- Gate ValveDocument27 pagesGate ValveYogesh Kumar Bhatnagar0% (1)

- Document in EDI Process Overview - v5 - Compatibility ModeDocument11 pagesDocument in EDI Process Overview - v5 - Compatibility Modevishnu_spicNo ratings yet

- Nec450 3ADocument9 pagesNec450 3AArmando Jr GamutanNo ratings yet

- Example Beam ProblemDocument2 pagesExample Beam ProblemxicaodocetNo ratings yet

- Geometric ModellingDocument37 pagesGeometric Modellingphanirao1No ratings yet