Professional Documents

Culture Documents

WI Safety Welding-Rev4

WI Safety Welding-Rev4

Uploaded by

alvin lpasti21Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WI Safety Welding-Rev4

WI Safety Welding-Rev4

Uploaded by

alvin lpasti21Copyright:

Available Formats

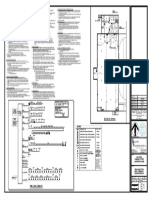

WORK INSTRUCTION - SAFETY WELDING

Job Preparation

PPE Routine Inspection

1 Power distribution box to

Safety provide integrity verified 30mA ELCB

Mask glasses powered outlets, QC-pass

≤ 20 m

labeled

2 Power distribution box is

Welding Apron 1

Power

positioned within 20 meter radius Outlet 2

helmet

with arc VRD

flash filter 3 Power cabling, including (Voltage Reduce

FR leather Devices)

extension cords, are integrity

gloves

verified and QC-pass labeled

3

Long 4 Welding machine is integrity

pants Thick rubber verified and QC labeled;

soled safety no damage, VRD is ’ON’,

shoes

confirming open voltage <10-12VAC 4

Install Safety Barricade 5 Cabling properly plugged

into/ tightened to the welding

machine, fully insulated

5 6 7

6 Extension cords’ female/

male connectors, if applicable,

to be commercially made and

fully insulated

Electrode holder

7 Electrode holder is fully

insulated and intact, no damage

8 Power cabling run above 8

ground on insulated hooks

9 Work/return clamp to be

installed close to welding object/

Electrode holder is put into its holder,

area 9

when not used ≤1m

Safety Devices Welder & fitter Housekeeping

Not permitted in area :

Clean area

Rubber mat/mattress

Fire blanket

Fire

Extinguisher

Welder and fitter

LOTO Devices First Aid Combustible material

are competent

PT. WILMAR NABATI INDONESIA –GRESIK

WORK INSTRUCTION - SAFETY WELDING

Welding

Good Practice Bad Practice

5 3

1 4

1. Wear PPE correctly 3. Fitter & Fire watcher Combustible material

2. There is rubber mat 4. Fire Extinguisher 5. Barricade There’s no rubber mat Not wear PPE correctly

(cloth, plastics, etc)

Job Verification

PPE checklist

□√ Welding helmet

with arc flash filter

□√ Safety glasses Devices checklist

□√ Mask Welding Inspection

□√ Power distribution box

□√ Apron □√ Safety devices

□√ Power cabling

□√ FR leather gloves □√ Welding machine □√ Fire watcher

□√ Long pants □√ Welding cabling □√ Barricade

□√ Safety shoes □√ Electrode holder □√ Housekeeping

Verification PPE of worker Verification all devices are safe for used Verification welding jobs

End of Jobs

!!!! NEVER LEAVE A POWERED-UP WELDING MACHINE UNATTENDED !!!

When job is still in progress and needs to be left unattended;

1. Welding machine to be switched off, unplugged and LOTO-ed by the welder

When job finished, clean up area

2. Provide tag “Work In Progress” or similar at point of barricading the area

PT. WILMAR NABATI INDONESIA –GRESIK

You might also like

- 35kv Xlpe Phelps Dodge PDFDocument2 pages35kv Xlpe Phelps Dodge PDFRodney LanagNo ratings yet

- PE8210W2000GDocument1 pagePE8210W2000GARY TOGINHONo ratings yet

- Huawei CXLLN Hardware DescriptionDocument30 pagesHuawei CXLLN Hardware Descriptionchiting ZhangNo ratings yet

- BE46 648 2 - JupiterDocument36 pagesBE46 648 2 - Jupitercraig.bakerNo ratings yet

- Trex Onics Overall Shielded Cflex Multi Conductor CableDocument2 pagesTrex Onics Overall Shielded Cflex Multi Conductor CableAnonymous wBsGm1No ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- Serial Controller Installation & Interface GuideDocument40 pagesSerial Controller Installation & Interface GuideViệt Thảo TrầnNo ratings yet

- XS1-M / XS2-M: Danger / Peligro / DangerDocument2 pagesXS1-M / XS2-M: Danger / Peligro / DangerNaipe DobleutesNo ratings yet

- 15LIC200 MinDocument3 pages15LIC200 MinJoãoNo ratings yet

- Type - 2 CoordinationDocument3 pagesType - 2 CoordinationSudhir SainiNo ratings yet

- Tds New 1c Cu 25kvDocument2 pagesTds New 1c Cu 25kvButch BuciaNo ratings yet

- Oil Watchman SonicDocument2 pagesOil Watchman SonicDaniel Lastra EncaboNo ratings yet

- Instruction Manual: Rishabh Instruments Pvt. LTDDocument3 pagesInstruction Manual: Rishabh Instruments Pvt. LTDShiaTVfanNo ratings yet

- Model RS: Cable Operated Safety Stop Switch For ConveyorsDocument3 pagesModel RS: Cable Operated Safety Stop Switch For ConveyorsVictor MuñozNo ratings yet

- All Classes & Groups: Silver BulletDocument4 pagesAll Classes & Groups: Silver BulletPARIETALNo ratings yet

- Light Curtain Guide For ElevatorsDocument10 pagesLight Curtain Guide For ElevatorsFERNSNo ratings yet

- TRA For Fabrication, Cutting, Grinding and WeldingDocument3 pagesTRA For Fabrication, Cutting, Grinding and WeldingSaif Ali100% (1)

- Tds New 1c Cu 35kvDocument2 pagesTds New 1c Cu 35kvButch BuciaNo ratings yet

- 35kv Xlpe Phelps DodgeDocument2 pages35kv Xlpe Phelps DodgeCommercial One100% (2)

- KM430TB - G - LCA 09 Revision 7 PDFDocument9 pagesKM430TB - G - LCA 09 Revision 7 PDFPaulo CardosoNo ratings yet

- 2016 10 03 Tender Joel Steele Community Centre Design 1Document1 page2016 10 03 Tender Joel Steele Community Centre Design 1parallax1957No ratings yet

- Sony VX550 PDFDocument59 pagesSony VX550 PDFcrm102bNo ratings yet

- Hot Work TRA Workshop NightDocument3 pagesHot Work TRA Workshop Nightmarvin100% (1)

- Electrical Cable Pulling RSW-SAF-015-DT 9/23/16 1 of 6 06 09/23/21 Environmental, Safety and Security 1.0 PurposeDocument6 pagesElectrical Cable Pulling RSW-SAF-015-DT 9/23/16 1 of 6 06 09/23/21 Environmental, Safety and Security 1.0 Purposealitopan9900No ratings yet

- FM Stereo FM-AM Receiver: STR-DE575 STR-K502Document54 pagesFM Stereo FM-AM Receiver: STR-DE575 STR-K502Eduardo da Costa LeiteNo ratings yet

- Quick Installation Guide: Attention!Document2 pagesQuick Installation Guide: Attention!Leo NunesNo ratings yet

- Electrical Rating Safety Procedures: WarningDocument7 pagesElectrical Rating Safety Procedures: WarningBasel Hilal HaiderNo ratings yet

- Trex Onics High Flex Profinet 2Document1 pageTrex Onics High Flex Profinet 2Ricardo GonzalezNo ratings yet

- HS Transition JointDocument2 pagesHS Transition Jointvivek jayswalNo ratings yet

- (3AUA0000001558) - ACS550-U1 - QS - REVF FG KNDDocument2 pages(3AUA0000001558) - ACS550-U1 - QS - REVF FG KNDPrdptiwariNo ratings yet

- sc76 ManDocument2 pagessc76 ManErwinNo ratings yet

- Raychem Screened, Separable Connection System RSTI-Large For Large Cross Sections 1250 A Up To 42 KVDocument4 pagesRaychem Screened, Separable Connection System RSTI-Large For Large Cross Sections 1250 A Up To 42 KVgiovany_vq91No ratings yet

- Medium Voltage Cables: Refineries & Petrochemical - OnshoreDocument2 pagesMedium Voltage Cables: Refineries & Petrochemical - OnshoreSriniNo ratings yet

- TMA Installation GuideDocument3 pagesTMA Installation GuideTarek DeghedyNo ratings yet

- Products & Solutions Overview: Cleverson TakiguchiDocument11 pagesProducts & Solutions Overview: Cleverson TakiguchiIvan HandjievNo ratings yet

- FM Stereo FM-AM Receiver: STR-DE975 STR-DE875Document72 pagesFM Stereo FM-AM Receiver: STR-DE975 STR-DE875gepetosdNo ratings yet

- Siemon Industrial Max - Spec SheetDocument7 pagesSiemon Industrial Max - Spec SheetAnthony ToalaNo ratings yet

- Everyday Electronics 1972-01Document60 pagesEveryday Electronics 1972-01Toni TursićNo ratings yet

- XS3-P / XS4-P: Danger / Peligro / DangerDocument2 pagesXS3-P / XS4-P: Danger / Peligro / Dangerkareem gastunNo ratings yet

- AccuTrak Silver BulletDocument4 pagesAccuTrak Silver BulletMaximilianoNo ratings yet

- Hazardous Heavy DutyDocument5 pagesHazardous Heavy DutyNisarg BavishiNo ratings yet

- CP 18 Welding ChecklistDocument1 pageCP 18 Welding Checklistmech.cmrlug01No ratings yet

- Raychem Screened, Separable Connection System RSTI-58 800 A Up To 24 KVDocument4 pagesRaychem Screened, Separable Connection System RSTI-58 800 A Up To 24 KVGiovany Vargas QuirozNo ratings yet

- 02JHA On Welding and Gas CuttingDocument8 pages02JHA On Welding and Gas CuttingPiyush SinghNo ratings yet

- GVR Recloser: For Pole Mounting and Substation ApplicationsDocument2 pagesGVR Recloser: For Pole Mounting and Substation ApplicationsOscar MorenoNo ratings yet

- Risk Assessment (Electrical Supply) - 1Document1 pageRisk Assessment (Electrical Supply) - 1jafarrahimNo ratings yet

- Attachment 13.1 Safety Risk Assessment Plan: Installation of M.V SwitchgearDocument5 pagesAttachment 13.1 Safety Risk Assessment Plan: Installation of M.V SwitchgearehteshamNo ratings yet

- Motor Control Center Fahim, Nanji & Desouza (PVT.) Ltd. Gul Ahmed Fiber Bleaching Plant, Landhi, KarachiDocument12 pagesMotor Control Center Fahim, Nanji & Desouza (PVT.) Ltd. Gul Ahmed Fiber Bleaching Plant, Landhi, KarachiQasim RizviNo ratings yet

- ADC Complete Industrial Catalog-1Document67 pagesADC Complete Industrial Catalog-11819 Roy GordonNo ratings yet

- 17.5/24kV Deadbreak 250A Elbow ConnectorDocument4 pages17.5/24kV Deadbreak 250A Elbow ConnectorAngel StragliatiNo ratings yet

- True Hermetic Sealing For Load Cells: The Load Cell CableDocument2 pagesTrue Hermetic Sealing For Load Cells: The Load Cell CableAldo Angel ValdiviaNo ratings yet

- Medium Voltage Fuses: Powr-Gard Fuse DatasheetDocument10 pagesMedium Voltage Fuses: Powr-Gard Fuse DatasheetSusana HernándezNo ratings yet

- Logic Probe: Usage NotesDocument1 pageLogic Probe: Usage NotesJC ZuletNo ratings yet

- Environmental Health and Safety: Indianauniversitysoutheast 4201 Grant Line Rd. Newalbany, in 47150 (812) 941-2333Document3 pagesEnvironmental Health and Safety: Indianauniversitysoutheast 4201 Grant Line Rd. Newalbany, in 47150 (812) 941-2333Ryuu YamadaNo ratings yet

- MS228 Insta Heat Press ManualDocument18 pagesMS228 Insta Heat Press ManualDamien OlverNo ratings yet

- Surge ArrestersDocument4 pagesSurge ArresterscrcruzpNo ratings yet

- IEC 309 Plugs and Interlocks 5P: Hazardous Heavy DutyDocument5 pagesIEC 309 Plugs and Interlocks 5P: Hazardous Heavy DutyMasterGNo ratings yet

- Mxr-225 Up 11 04 Single Sheet en v04Document2 pagesMxr-225 Up 11 04 Single Sheet en v04Petr BruzaNo ratings yet

- Wire Stripper Ian 353781 - 2010Document2 pagesWire Stripper Ian 353781 - 2010nemapit785No ratings yet

- PLP INDONESIA Product - Showcase - April - May - 2020 - 2 Edit55Document11 pagesPLP INDONESIA Product - Showcase - April - May - 2020 - 2 Edit55Turinto MarjonoNo ratings yet

- Painting Procedure: Project Quality Manager: Project ManagerDocument11 pagesPainting Procedure: Project Quality Manager: Project ManagerachusanachuNo ratings yet

- Altium WP DC Analysis of A PDNDocument12 pagesAltium WP DC Analysis of A PDNaafeletronicaNo ratings yet

- Sa WMSP87Document12 pagesSa WMSP87electrofepNo ratings yet

- Selectable Output Horns, Strobes, and Horn StrobesDocument4 pagesSelectable Output Horns, Strobes, and Horn StrobesSupriyadi JasminNo ratings yet

- Sidewinder PartsDocument4 pagesSidewinder PartsKhalidNo ratings yet

- Segui 6e ISM Ch08Document105 pagesSegui 6e ISM Ch08miraj patelNo ratings yet

- Saudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechphilipyapNo ratings yet

- 23718Document12 pages23718Judy SongNo ratings yet

- Lab Manual ESMS PDFDocument108 pagesLab Manual ESMS PDFAbhishek KumarNo ratings yet

- How ToDocument58 pagesHow TojaphetjakeNo ratings yet

- How Offset Printing WorksDocument2 pagesHow Offset Printing Workspavan4samudralaNo ratings yet

- Shaking Table Experiment For Philippine Full-Scale Concrete Hollow Blocks (CHB) Masonry HousesDocument7 pagesShaking Table Experiment For Philippine Full-Scale Concrete Hollow Blocks (CHB) Masonry HousesRhobbie NolloraNo ratings yet

- Triangular NumbersDocument2 pagesTriangular Numbersayu7kajiNo ratings yet

- Tandler Angle GearsDocument2 pagesTandler Angle GearsEmerson IpialesNo ratings yet

- Solution ArchitectureDocument2 pagesSolution ArchitecturesaqlainNo ratings yet

- Tutorial 3 (Kom)Document2 pagesTutorial 3 (Kom)patelsandip1990No ratings yet

- Carrier Ducted Controller ManualDocument33 pagesCarrier Ducted Controller ManualMechanical PowerNo ratings yet

- Fixed Capital Cost Estimation: The University of Jordan School of Engineering Department of Chemical EngineeringDocument12 pagesFixed Capital Cost Estimation: The University of Jordan School of Engineering Department of Chemical Engineeringsocial peopleNo ratings yet

- BangladeshDocument27 pagesBangladeshJubzfree HuqNo ratings yet

- Ymc Technical HandbookDocument70 pagesYmc Technical HandbookYou TubeNo ratings yet

- 80-NET U Rev.8 10 2008Document86 pages80-NET U Rev.8 10 2008mad___maxNo ratings yet

- DKP202 DKP203 DKP204 DKP204W CAMPOLE User Guide M210373EN CDocument82 pagesDKP202 DKP203 DKP204 DKP204W CAMPOLE User Guide M210373EN CNoah MusundiNo ratings yet

- Structural Properties of High Strength Concrete and Its Implications For Precast Prestressed ConcreteDocument16 pagesStructural Properties of High Strength Concrete and Its Implications For Precast Prestressed ConcreteShamsul IslamNo ratings yet

- Appendix H Planet Gear Bearing Analysis ReportDocument13 pagesAppendix H Planet Gear Bearing Analysis ReportCarloK98No ratings yet

- Management of Change FormDocument2 pagesManagement of Change FormdilaNo ratings yet

- System Sensor MDL3R Data SheetDocument2 pagesSystem Sensor MDL3R Data SheetJMAC SupplyNo ratings yet

- CV EngDocument1 pageCV EngViktor HeNo ratings yet