Professional Documents

Culture Documents

Formulation and Evaluation of Aceclofenac Liposome

Formulation and Evaluation of Aceclofenac Liposome

Uploaded by

Nikita jainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formulation and Evaluation of Aceclofenac Liposome

Formulation and Evaluation of Aceclofenac Liposome

Uploaded by

Nikita jainCopyright:

Available Formats

Kaur et al Journal of Drug Delivery & Therapeutics.

2021; 11(5):71-79

Available online on 15.09.2021 at http://jddtonline.info

Journal of Drug Delivery and Therapeutics

Open Access to Pharmaceutical and Medical Research

Copyright © 2021 The Author(s): This is an open-access article distributed under the terms of the CC BY-NC 4.0

which permits unrestricted use, distribution, and reproduction in any medium for non-commercial use provided

the original author and source are credited

Open Access Full Text Article Research Article

Formulation and Evaluation of Aceclofenac Liposomes

Gurleen Kaur* , Zaquiyya Naaz, Kapil Kumar , Deepak Teotia

Department of Pharmaceutics, Global Institute of Pharmaceutical Education and Research, Kashipur- 244713, Uttarakhand, India

Article Info: Abstract

_________________________________________ ______________________________________________________________________________________________________

Article History: Patients who suffered from rheumatic disease and osteoarthritis are generally prescribed the

Received 06 July 2021 non-steroidal anti-inflammatory drug (NSAIDs). Osteoarthritis is a common musculoskeletal

Reviewed 27 August 2021 disorder, which impairs body function and acts as an economic burden. Due to the repetitive

Accepted 05 September 2021 use of ACE by oral route, it may cause gastrointestinal complications such as ulceration,

Published 15 September 2021 bleeding, pain, perforation. To decrease the side effects of ACE, it is given by topical route in

_________________________________________ the form of ointment. This review highlights reducing gastrointestinal problems and

Cite this article as: promotes the safety and efficacy of the ACE. The Aceclofenac liposomes were prepared by the

thin film hydration technique and evaluated by various methods such as in- vitro release

Kaur G, Naaz Z, Kumar K, Teotia D, Formulation and study, % yield, drug entrapment efficiency, pH of the prepared formulation. The prepared

Evaluation of Aceclofenac Liposomes, Journal of

system was also characterized by Fourier transform infra-red spectrophotometer to identify

Drug Delivery and Therapeutics. 2021; 11(5):71-79

the drug- excipients interaction. The maximum entrapment efficiency of liposomes was

DOI: http://dx.doi.org/10.22270/jddt.v11i5.4998 found to be 90%. The main aim of this study was to develop and characterized a vesicular

______________________________________________ drug carrier system for topical delivery of Aceclofenac to overcome the problem related with

*Address for Correspondence: oral route.

Gurleen Kaur, Department of Pharmaceutics, Global Keywords: Liposomes, Aceclofenac, topical delivery, transdermal delivery, rheumatic

institute of pharmaceutical and research, Kashipur disease and osteoarthritis

- 244713, Uttarakhand, India

ORCID ID: https://orcid.org/0000-0001-7753-6880

INTRODUCTION: deliver the drug at a targeted site. Due to their phospholipid

bilayer structure, liposomes can easily cross the drug from

The Liposomes are specifically targeted drug delivery the blood-brain barrier (BBB) in the case of the hydrophilic

system which helps to carry the drug at a specific site and nature of anti-depressant drugs.5,6

shows its therapeutic effect. Over the past few decades,

liposomes have received widespread attention as a carrier The structure of phospholipid is amphipathic in nature, due

system for therapeutically active compounds, due to having to this it helps to incorporate water-soluble drug as well as a

a specialized characteristic such as the capability to lipid-soluble drug as well as lipid-soluble drug. The tail of

incorporate both hydrophilic as well as in hydrophobic lipophilic is repelled by the water and the head of

drugs, low toxicity, good compatibility, lack of immune hydrophilic is repelled by the lipid.7

system activation and targeted delivery of a bioactive Liposomes play a major role in the pharmaceutical industry,

compound to the site of action.1 Liposomes are colloidal cosmetic and dermatologist and carry both hydrophilic and

vesicular structures composed of one and more than one lipophilic drugs and entrap the drug by liposomes and target

lipid bilayer surrounding an equal number of aqueous the drug at a specific-organs. Due to their structure,

compartments. Generally, liposomes are simple, small liposomes also help to prevent the drug from oxidation.

microscopic vesicle structures that incorporate both the Liposome helps to penetrate the dermatological preparation

type of drug either it is hydrophilic and lipophilic.2 The main into the deeper skin.8 The objective of this delivery system

aim of any drug delivery system is to minimize toxicity and is to target the drug at specific site during the time period of

increase its effectiveness, safety, target specificity, and target treatment as to produce the stable, efficacious and safe

ability at a particular site. The liposomes are so formed to delivery system of Aceclofenac to overcome complications

targeting and site-specific delivery of a drug, to increase the related to oral route by formulating the liposomes of

circulation, time of drug and release slowly for the extended Aceclofenac for topical use. Aceclofenac used in the pain

action of a drug, drug protective from degradative enzymes. induced by rheumatoid arthritis and osteoporosis, which

The liposomes are directly delivered to the drug at a reduce the level of PGE2 in synovial fluid & suppresses the

targeted site of action and provide maximum therapeutic production from blood polymorphonuclear leukocytes

efficacy and help to prevent the drug from any degradation (mononuclear leukocytes). This delivery system is used in

and protect the body from any inappropriate and adverse study because of their specialized characteristics and helps

drug reaction.3,4 to incorporate the Aceclofenac efficiently and used as

Liposomes provide a wide range of attention, it provides a topically and ultimately reduce the oral side effects of

targeted carrier for many drugs such as anticancer, anti- Aceclofenac.9

depressant, anti-asthmatic, anti-fungal and also helps to

ISSN: 2250-1177 [71] CODEN (USA): JDDTAO

Kaur et al Journal of Drug Delivery & Therapeutics. 2021; 11(5):71-79

and Chloroform were taken from the Global Institute of

pharmaceutical education and research institute Kashipur

Laboratory. All other materials and chemicals used were of

either pharmaceutical or analytical grade.

Method:

Preparation of topical drug-loaded Aceclofenac liposomes

was prepared by the thin-film hydration method. In this

method, 3gm of mannitol powder and cholesterol in 3%, 2%,

4%, and were placed in ml F and held at a

temperature of - and also flas rotated at a speed of

85±5 rpm for 25-30 min in a rotatory evaporator.11

Aceclofenac (50mg) and lecithin with a ratio of 0.1:1, 0.1:2,

0.1:3 and 0.1:4 was dissolved in methanol and chloroform in

the ratio of 1:4 v/v and add 0.5ml aliquot of the above

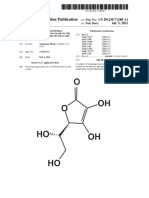

Figure 1: Liposome10 organic solution were introduced in RBF containing mannitol

MATERIALS AND METHOD: and cholesterol at 37⸰C. After drying a second aliquot (0.5ml)

of the solution was added and then dried, a thin film is

MATERIALS formed on the surface of RBF and placed in a desiccator

overnight and the sieved with 100 mesh. The Aceclofenac-

Aceclofenac was received as a gift sample from S. P Pharma,

loaded liposomes were prepared and mentioned as f1, f2, f3,

Chandigarh India. Lecithin, Methanol, Cholesterol, Mannitol,

and f4.12

Composition of different formulation:

Formulation Drug (mg) Chloroform Methanol(ml) Lecithin(gm) Mannitol(gm) Cholesterol

code (ml) (%)

F1 50 4 1 1 3 3%

F2 50 4 1 2 3 2%

F3 50 4 1 3 3 4%

F4 50 4 1 4 3 5%

Organoleptic properties: -

Color: - Powder of white crystalline

Odour - Odourless

Taste: - tasteless

Solubility: - Water insoluble, in acetone soluble freely

and solubilise in alcohol.

Angle of repose

It is done to check the flow property of powder. It is range

from 0 to 90 degree. In this method, glass funnel is used.15

Tan Ɵ – h/r

Figure 2: Lipid Film Hydration Method13

Whereas,

Pre-formulation studies

Ɵ =Angle of repose

Pre-formulation study related to drug is necessary to

develop the effective and safe dosage form. It is the first step h- heap height

to form any dosage form. It is also helping to shows the r- Heap Radius

compatibility between excipients and drug and also finds out

the physical and chemical characteristic. Relation b/w flowability and angle of repose

Pre-formulation study is necessary to develop the: - Angle of repose Flowability

Safe and effective use of drug. <20 Excellence

Compatibility study of drug with different excipients. 20 to 30 good

To find the release kinetics.14 30 to 40 Passable

Physical appearance of drug is also observed, its color, >40 Very poorly

odour, taste.

ISSN: 2250-1177 [72] CODEN (USA): JDDTAO

Kaur et al Journal of Drug Delivery & Therapeutics. 2021; 11(5):71-79

Bulk density complete solubilization. On the next, solution was sonicated

for some time after that a small amount of solution is pipette

It depends on size of particle, its shape and adhering

out around 0.1ml and further dilutions were prepared by

tendency. For this, a powder mass is taken in 10ml

using this. After a several dilutions were prepared,

measuring cylinder. And then, filling was done; cylinders

absorbance was determined with different concentration by

dropped at the surface from one inch height in 2sec interval.

using UV spectrophotometer with the blank solution. By

The bulk density determination calculated by: - using the calibration curve, amount of dissolve drug was

calculated.16

Pb = M/Vb

Determination of melting point

Whereas,

In this method, the melting point of Aceclofenac was

Pb- Bulk dens. determined to check the purity of drug. At which

M- Powder wt. temperature, a substance starts melts known as melting

point. It is carried out by M.P apparatus, in this drug filled in

Tapped density capillary and one ended of the capillary sealed with the help

In this, sample is taken in measuring cylinder and tapped of flame and attached with thermometer. Note the time at

and then calculated by following method. which drug starts melts.

Pt = M/Vt Moisture content Determination

Whereas, Formulation was allowed to content of moisture study by

Infra-red moisture balance by placing liposomes for 10

Pt = Tapped density minutes in 105⸰C.

M= powder weight Calibration curve preparation: -

Vt = Tapped density Calibration curve of Aceclofenac prepared in PO4 3- buffer

6.8.

Carr’s Compressibility Index: This method is used for

determining weight uniformity. Calibration curve preparation in phosphate buffer 6.8

ar’s Index = ul density – Tapped density/Tapped density In this method, 10mg of Aceclofenac powder were dissolved

×100 in 10ml of PO43- buffer having 6.8 PH to produce 1000ug/ml.

After that several dilutions were prepared by using the

Car’s compressibility Index

above solution having 0.5ml, 1ml, 2ml, 3ml, 4ml was taken

Percentage Compressibility Description of flow and diluted with phosphate buffer 6.8 up to 100ml. The

prepared dilutions were analysed by UV- spectrophotometer

5 to15 Excellence at 273nm. 17

12 to 16 good Compatibility studies of drug- excipients: FTIR study

18 to 21 Fairly FTIR studies were done for determining compatibility b/w

drug and excipients. This study was performed by using the

23 to 28 Poorly

saturated potassium bromide. Drug sample were prepared

28 to 35 Poorly with KBr pellets i.e., 2mg sample in 200mg KBr with a

hydrostatic force for 5.2N cm-2 for 3 minutes.

35 to 38 very poorly

Development of Aceclofenac liposomes by thin film

Greater than 40 Extreme poorly hydration tech.

In this, a specified lipid &drug amount were dissolved with

Solubility analysis chloroform in an RBF. After that, evaporation of solvents

takes place to produce the thin film by reducing the

The solubility of Aceclofenac was done by using a different pressure. Trace’s solvent was removed by using vacuum by

solvent. In this method, an amount of solvent taken in a test- storing the flask overnight and then film was hydrated with

tube after that drug also added in it and left overnight for the phosphate buffer 6.8.18

RESULT:

Flow property of Aceclofenac powder

S.NO Properties of powder F1 F2 F3 F4

1 Angle of repose 31.5±0.02 31.2±0.10 30.1±0.07 31.4±0.04

2 Bulk density(gm/ml) 0.65±0.05 0.66±0.05 0.68±0.03 0.62±0.01

3 Tapped density 0.72±0.09 0.74±0.11 0.78±0.07 0.73±0.05

4 arr’s index 9.76±0.06 9.75±0.08 9.72±0.06 9.8±0.06

ISSN: 2250-1177 [73] CODEN (USA): JDDTAO

Kaur et al Journal of Drug Delivery & Therapeutics. 2021; 11(5):71-79

Organoleptic properties of Aceclofenac Compatibility study: - Compatibility study was done to

determine the interaction of drug with excipients. The

S.NO Properties Results peak of Aceclofenac and peak of Aceclofenac and mannitol

1. Physical White crystalline powder is almost similar. So, the sample of Aceclofenac properties

appearance matched with the standard value.13

2. Odor Odorless

3. Taste Tasteless FTIR Spectra of API Aceclofenac

4. Solubility Practically Insoluble in water,

freely soluble in acetone, soluble

in alcohol (95%)

5. Melting point 149-153◦C

6 Moisture 0.6%

content

Solubility: - The solubility study of Aceclofenac performed

and result observed in the form of calibration curve.

Calibration of Aceclofenac in methanol

S.no Concentration(µg/ml) Absorbance(nm)

1. 2 0.049±0.02

FTIR Spectra of Aceclofenac and Mannitol

2. 4 0.086±0.04

3. 6 0.0139±0.012

4. 8 0.198±0.010

5. 10 0.246±0.14

6. 12 0.298±0.016

Calibration curve of aceclofenac in methanol

16

14 y = 2x - 2

12 R2 = 1

Absorbance

10

8

6

4

2

0

0 1 2 3 4 5 6 7 8 9

concentration

Calibration Curve of Aceclofenac in Methanol

FTIR Spectra Interpretation

FUNCTIONAL GROUP (wave number cm)

O-H C-H C=O NH2 P=O S-OR

Aceclofenac 3399.78 2941.64 1788.78 1577.92 1247.99 844.85

3317.18 613.08 1718.70 1146.76 881.81

Aceclofenac 3276.24 3028.41 1770.71 1579.75 1145.75 896.00

+Mannitol

2833.83 2994.23 1718.70 848.71

ISSN: 2250-1177 [74] CODEN (USA): JDDTAO

Kaur et al Journal of Drug Delivery & Therapeutics. 2021; 11(5):71-79

Characterization of liposomes of Aceclofenac

Batch code Yield (%) Entrapment Efficiency (%)

F1 56.37±0.003 95±0.05

F2 60.23±0.06 85±0.03

F3 65.46±0.04 89.45±0.07

F4 62.45±0.07 79.15±0.02

% Entrapment Efficiency 200 % Drug Entrapment Efficiency of liposomes of aceclofenac

of Batch F1 to F4

150

100

50

0

F1 F2 F3 F4

Batch code

yield % Entrapment Efficiency

Comparison of Entrapment Efficiency of Different Liposomes of Aceclofenac

In vitro cumulative percent drug release profile of Aceclofenac of batch F1 to F4

Time(hour) F1 F2 F3 F4

0 0 0 0 0

1 37±0.007 34±0.06 27±0.05 18±0.02

2 48±0.002 37±0.07 32±0.003 22±0.019

3 51±0.03 42±0.05 35±0.01 24±0.002

4 64±0.014 52±0.02 41±0.012 27±0.005

5 67±0.020 58±0.04 46±0.008 46±0.09

80

IN VITRO CUMULATIVE % DRUG RELEASE OF LIPOSOMES OF ACECLOFENAC OF

BATCH F1 TO F4

70

CUMULATIVE % DRUG RELEASE

60

50

40

30

20

10

0

0 1 2 3 4 5 6

TIME IN HOURS

F1 F2 F3 F4

Percentage of Drug Released From Liposomes of Aceclofenac of Batch F1 to F4

Release kinetic study

Kinetic study of formulation F1

Time Square root Log time Cumulative percent Log Cumulative % ARA Log cumulative %

(hour) of time drug release percent drug release drug remaining

1 1 0 37 1.56 63 1.79

2 1.4 0.30 48 1.68 52 1.71

3 1.7 0.47 51 1.70 49 1.69

4 2 0.60 64 1.80 36 1.55

5 2.2 0.69 67 1.82 33 1.51

ISSN: 2250-1177 [75] CODEN (USA): JDDTAO

Kaur et al Journal of Drug Delivery & Therapeutics. 2021; 11(5):71-79

Kinetic study of formulation F2

Time Square root Log Cumulative percent Log Cumulative % Log cumulative %

(hour) of time time drug release percent drug release ARA drug remaining

1 1 0 34 1.53 66 1.81

2 1.4 0.30 37 1.56 63 1.79

3 1.7 0.47 42 1.62 58 1.76

4 2 0.60 52 1.71 48 1.68

5 2.2 0.69 58 1.76 42 1.62

Kinetic study of formulation F3

Time Square root Log Cumulative percent Log Cumulative percent % Log cumulative %

(hour) of time time drug release drug release ARA drug remaining

1 1 0 27 1.43 73 1.86

2 1.4 0.30 32 1.50 68 1.83

3 1.7 0.47 35 1.54 65 1.81

4 2 0.60 41 1.61 59 1.77

5 2.2 0.69 46 1.66 54 1.73

Kinetic study of formulation F4

Time Square root Log Cumulative percent Log Cumulative percent % Log cumulative %

(hour) of time time drug release drug release ARA drug remaining

1 1 0 18 1.25 82 1.91

2 1.4 0.30 22 1.34 78 1.89

3 1.7 0.47 24 1.38 76 1.88

4 2 0.60 27 1.43 73 1.86

5 2.2 0.69 46 1.66 54 1.73

Drug release kinetic with model fitting

Formulation R2 n value Best fit model Mechanism of

code release

Zero order First order Higuchi matrix

F1 0.987 0.9875 0.9676 0.4407 First order Non-Fickian diffusion

F2 0.9811 0.888 0.9703 0.3836 First order Non-Fickian diffusion

F3 0.9886 0.9301 0.8807 0.3923 First order Non-Fickian diffusion

F4 0.9298 0.9341 0.8929 0.5859 Zero order Fickian diffusion

80

% CUMULATIVE DRUG RELEASE

70

60

50

40

30

20

10

0

0 1 2 3 4 5 6

TIME(hr)

F1 F2 F3 F4

Kinetic release model of zero order release

ISSN: 2250-1177 [76] CODEN (USA): JDDTAO

Kaur et al Journal of Drug Delivery & Therapeutics. 2021; 11(5):71-79

100

80

60

LOG % ARA

40

20

0

0 1 2 3 4 5 6

TIME(hr)

f1 f2 f3 f4

Kinetic release model of first order release

80

% CUMULATIVE DRUG

60

RELEASE

40

20

0

0 0.5 1 1.5 2 2.5

SQUARE ROOT OF TIME

F1 F2 F3 F4

Kinetic release model of Higuchi release

1.5

LOG % CR

0.5

0

0 0.2 0.4 0.6 0.8

TIME (hr)

F1 F2 F3 F4

Kinetic release model of Korsmeyer peppas release

DISCUSSION: Melting point: - The melting point of Aceclofenac liposomes

was found to be 150◦C and the standard range is 149-153◦C.

Preformulating studies: Preformulating study of

Aceclofenac was done by placing the following test: -i.e., Flow property of Aceclofenac

melting point, solubility, flow property was done according Angle of repose: - It was found to be 31.5, it

to I.P. indicates the powder is passable.

Physical appearance: - The organoleptic properties of

Bulk density: - It was found to be 0.65 having good

liposome were observed by physical and visual method,

flow property.

properties were matched with the standard drug and the

prepared Aceclofenac liposomes were sticky in appearance. Tapped density: - It was found to be 0.72.

Solubility: - Aceclofenac is freely soluble in acetone, soluble Preparation of calibration curve

in alcohol (95%) and practically insoluble in water.

Aceclofenac liposome solubility matched with the standard The calibration curve of Aceclofenac was plotted in

drug. phosphate buffer having pH 6.8 and the graph was plotted

ISSN: 2250-1177 [77] CODEN (USA): JDDTAO

Kaur et al Journal of Drug Delivery & Therapeutics. 2021; 11(5):71-79

between concentration (x-axis) and absorbance (y-axis). The of skin so, the Aceclofenac liposomes was prepared

results of calibration curve of Aceclofenac were shown in successfully and have good therapeutic effect.

Figure 16. Table 10 shows the absorbance of Aceclofenac

standard solution containing 10-50 µg/ml of drug in CONCLUSION

phosphate buffer pH 6.8. In this study, it has been concluded that the formulation of

In vitro drug release studies of liposome Aceclofenac liposomes provides the sustained action of drug.

The Aceclofenac liposomes were successfully formulated by

In vitro- drug release study was carried out in USP XIII using cholesterol, Mannitol and chloroform for topical use.

dissolution test apparatus type II. In this, the polymer used as a carrier for Aceclofenac drug

In this, a temperature was set at 37◦C ±5◦C and set at 50rpm. release.20 The Aceclofenac liposomes have a capability to

penetrate the lipoidal structure easily and produce a

phosphate buffer of 1000 ml and set for 12 hours. Release of prolonged action. When the Aceclofenac given orally, it will

drug at different time interval has been analyzed by UV produce the gastrointestinal complication so, to overcome

spectrophotometer at 274 nm. this, the topical preparation of Aceclofenac liposomes can be

formulated; it is used in the treatment of rheumatoid

Compatibility study

arthritis, osteoarthritis and ankylosing spondylitis.21

Compatibility study of drug and excipient was done by FTIR

From the above experiments, it has been concluded that: -

method. The peak of alone Aceclofenac and peak of

Aceclofenac with excipients was almost same but a little i) Different pre-formulation studies were done on the

different due to presence of excipients. There was no sample of Aceclofenac.

appearance or disappearance of peaks found in the drug-

lipid mixture which confirms the absence of any chemical ii) The liposome of Aceclofenac prepared by using different

interaction between the drug and excipients. excipients such as methanol, chloroform, mannitol,

lecithin, etc.

Release kinetics: -

The liposome of Aceclofenac has been prepared by the thin-

Drug release kinetic model are used to illustrate the drug film hydration method and the rotary film evaporator

release mechanism. For this various model are used like zero equipment were used.22

order, first order, Higuchi, korsmeyer peppas model to

obtain the value of R2 and n-value for the determination of The prepared Aceclofenac liposomes to be a novel drug

best fit model. R2 value was compared for all the approach for treating the arthritis through transdermal

formulation which shows the best fit model and by noticing route in which drug can permeate through skin and also

n value which is from korsmeyer peppas model. Release show a sustained action. The prepared formulation was

mechanism was described by an equation.19 found to have better bioavailability, analgesic activity and

anti- inflammatory action as compared to existing

Mt/M∞ = tn formulations of the mentioned drug.23

Followed by standard release mechanism According to the results obtained from this study, it was

concluded that the Aceclofenac liposome were successfully

N value Release mechanism

prepared to obtain ointment. Aceclofenac ointment showed

0.5 Fickian diffusion good pH value, Spreadability, good entrapment efficiency.

The kinetic study was also performed for the prepared

0.5<n<1 Non-Fickian diffusion Aceclofenac liposomes and the observed data of kinetic

1 Supercase Ⅱ transport model shows the best- fit model for prepared Aceclofenac

liposome was determined by regression coefficient (r2) in all

formulation. The best model of formulation F4 shows zero

order release because the drug release is independent of

The observed data of kinetic model shows the best fit model

concentration and it shows the Fickian diffusion.24

for prepared Aceclofenac liposomes was determined by

regression coefficient (r2) in all formulation. The highest r2 Therefore, it was concluded that the formulation could be

value determine the best fit model, the observed data shows very promising alternative for the topical or transdermal

the First order release in F1, F2 and F3 formulation it shows treatment.

the drug release is dependent on concentration and in F4 it

shows zero- order release i.e., the drug release is Conflict Of Interest: The authors have no conflicts of

independent of concentration. Formulation F1, F2 & F3 interest regarding this investigation.

shows the non-Fickian diffusion and F4 shows the Fickian

diffusion which means F1, F2 & F3 is anomalous drug

Acknowledgement: Authors acknowledges to Global

release as it is erosion-controlled release rate and diffusion Institute of Pharmaceutical education and research for all

release rate. The best formulation is F4 formulation because support and encouragement for writing this research article.

the drug release is independent of concentration. REFERENCES:

Entrapment Efficiency: - The drug entrapment efficiency of 1. Kong F, Zhou, Ge, Liu, Wang, Zhou. Mannosylated liposomes for

liposomes formulations is given in Table 12. The loading targeted gene delivery. International Journal of Nanomedicine.

efficiency calculated for all liposome from batch F1 to F4 2012; 1079. https://doi.org/10.2147/IJN.S29183

ranged from 79.15 to 95%. For this, it is clear that drug

2. Liu Q, Boyd BJ. Liposomes in biosensors. Analyst, 2012; in press.

entrapment efficiency changed by changing the ratio of 2021.

excipients. The highest loading efficiency was found for the

F1 formulation is 95% and F3 is 89.45 3. Allison, Anthony C., and Gregory. Gregoriadis. Liposomes in

Biological Systems. Chichester: John Wiley & Sons, Ltd., 1980.

Determination of PH: - The pH of prepared Aceclofenac Print.

liposomes was found to be 5 which is matched with the pH

ISSN: 2250-1177 [78] CODEN (USA): JDDTAO

Kaur et al Journal of Drug Delivery & Therapeutics. 2021; 11(5):71-79

4. Deamer D. From "Banghasomes" to liposomes: A memoir of Alec 14. Elsaied EH, Dawaba HM, Ibrahim ESA, Afouna MI. Effect of

Bangham, 1921-2010. The FASEB Journal. 2010; 24(5):1308- pegylated edge activator on Span 60 based nanovesicles:

1310. https://doi.org/10.1096/fj.10-0503 comparison between Myrj 52 and Myrj 59. Universal Journal of

Pharmaceutical Research 2019; 4(4):1-8.

5. Chioma E. Formulation and Evaluation of Etodolac Niosomes by https://doi.org/10.22270/ujpr.v4i4.290

Modified Ether Injection Technique. Universal Journal of

Pharmaceutical Research. 2016; 1(1):1-6. 15. Nagasany Venkatesh Dhandapani. Liposomes as Novel drug

https://doi.org/10.22270/ujpr.v1i1.R1 delivery system: A Comprehensive Review, Int J, Res. Pharm Sci,

4(2):187-193.

6. Anwar W, Dawaba HM, Afouna MI, Samy AM. Screening study

forformulation variables in preparation and characterization of 16. Kulkarni K, Priyanka R, Yadav JD, Vaidya KA. Liposomes a novel

candesartan cilexetil loaded nanostructured lipid carriers. drug delivery system. International Journal of Current

Universal Journal of Pharmaceutical Research 2019; 4(6):8-19. Pharmaceutical Research. 2011; 3(2):10-18.

https://doi.org/10.22270/ujpr.v4i6.330

17. Sharma A. Liposomes in drug delivery: Progress and limitations.

7. Singh B, Mehta G, Kumar R, Bhatia A, Ahuja N, Katare O. Design, International Journal of Pharmaceutics. 1997; 154(2):123-140.

Development and Optimization of Nimesulide-Loaded https://doi.org/10.1016/S0378-5173(97)00135-X

Liposomal Systems for Topical Application. Current Drug

Delivery. 2005; 2(2):143-153. 18. Shaheen SM, Ahmed FRS, Hossen MN, Ahmed M, Amran MS,

https://doi.org/10.2174/1567201053585985 Anwar-UL-Islam M, Liposome as a Carrier for Advanced Drug

Delivery. Pakistan Journal of Biological Sciences. 2006;

8. Andhale A Varsha, Patil Priyanka R, Dhas Ahuja U, Chauhan 9(6):1181-1191. https://doi.org/10.3923/pjbs.2006.1181.1191

Priyanka D, Desai Seema V, liposomes an emerging tool in drug

carrier system. International journal of pharmacy and 19. Ugochukwu AE, Nnedimkpa OJ, Rita NO. Preparation and

technology. 2016; 8(1): 10988- 11011. characterization of Tolterodine tartrate proniosomes. Universal

Journal of Pharmaceutical Research 2017; 2(2):1-3.

9. Nwobodo NN, Adamude FA, Dingwoke EJ, Ubhenin A. Formulation https://doi.org/10.22270/ujpr.v2i2.R1

and evaluation of elastic liposomes of decitabine prepared by

rotary evaporation method. Universal Journal of Pharmaceutical 20. Mishra H, Kaur G, Kumar K, Teotia D. Formulation and

Research 2019; 4(3):1-5. evaluation of liposomes of Indomethacin. Journal of advanced

https://doi.org/10.22270/ujpr.v4i3.267 scientific research, 2019; 10(4):180-185.

10. Dua J.S. et. al. Liposomes: Methods of preparation and 21. Akbarzadeh A, Rezaei-Sadabady R, Davaran S, Joo S, Zarghami N,

application: International Journal of Pharmaceutical studies and Hanifehpour Y et al. Liposome: classification, preparation, and

research. 2012; 4:14-20. applications. Nanoscale Research Letters. 2013; 8(1).

https://doi.org/10.1186/1556-276X-8-102

11. Mishra H, Chauhan V, Kumar K, Teotia D. A comprehensive

review on Liposomes: a novel drug delivery system. Journal of 22. Mathur P, Mathur CK, Mathur K. Oral drug delivery of insulin in

Drug Delivery and Therapeutics. 2018; 8(6):400-404. diabetes mellitus: an attractive alternate to overcome invasive

https://doi.org/10.22270/jddt.v8i6.2071 route. Universal Journal of Pharmaceutical Research 2018; 3(6):

45-48. https://doi.org/10.22270/ujpr.v3i6.221

12. John DF, Yunus AA, Chigbo UJ, Paul US, Ikenna E. Tolnaftate

loaded liposomes-design, and in-vitro evaluation. Universal 23. Jadhav M, Gaikwad R, Kshirsagar N, Nagarsenker M, Samad A.

Journal of Pharmaceutical Research 2016; 1(2): 29-31. Formulation and evaluation of long circulating liposomal

https://doi.org/10.22270/ujpr.v1i2.R6 Amphotericin B: A scinti-kinetic study using99mTc in BALB/C

mice. Indian Journal of Pharmaceutical Sciences. 2011; 73(1):57.

13. Subhash Chandran M.p, Prasbh G.R Jaghatha T, Aswathy B.S, https://doi.org/10.4103/0250-474X.89757

Remya S.B. An overview on Liposomal drug delivery system.

International Journal of Pharmaceutical and 24. Riaz Mohammad. Liposomes Preparation Methods. Pakistan

phytopharmcological research. 2019; 9(2):61-69. Journal of Pharmaceutical Sciences.1991; 19(1):65-77.

ISSN: 2250-1177 [79] CODEN (USA): JDDTAO

You might also like

- Quiz 1 On Cosmetic Product DevelopmentDocument22 pagesQuiz 1 On Cosmetic Product DevelopmentMerrene Bright Divino JudanNo ratings yet

- Formulation and Evaluation of Sustained Release Tablet of Aceclofenac by Film CoatingDocument9 pagesFormulation and Evaluation of Sustained Release Tablet of Aceclofenac by Film CoatingQoriNo ratings yet

- Role of Polymers in Sustained Released Microbeads Formulation: A ReviewDocument9 pagesRole of Polymers in Sustained Released Microbeads Formulation: A ReviewVinayNo ratings yet

- Liposomal Drug DeliveryDocument26 pagesLiposomal Drug DeliveryLina Marcela Reyes Solis100% (2)

- A Review On Proniosomes Drug Delivery: An Innovative ApproachDocument13 pagesA Review On Proniosomes Drug Delivery: An Innovative ApproachGaurav ShuklaNo ratings yet

- Novel Vesicular Drug Delivery Systems: A Review: ArticleDocument16 pagesNovel Vesicular Drug Delivery Systems: A Review: ArticlenadudaduNo ratings yet

- Recent Progress in Drug DeliveryDocument18 pagesRecent Progress in Drug DeliveryAyush SapkotaNo ratings yet

- Nanoemulgel A Novel Nano Carrier As A Tool For TopDocument28 pagesNanoemulgel A Novel Nano Carrier As A Tool For TopAdindaNo ratings yet

- Lipid Nanoparticles For Transdermal Delivery of Urbiprofen: Formulation, in Vitro, Ex Vivo and in Vivo StudiesDocument16 pagesLipid Nanoparticles For Transdermal Delivery of Urbiprofen: Formulation, in Vitro, Ex Vivo and in Vivo StudiesmwdhtirahNo ratings yet

- Formulation And Evaluation Of Levofloxacin-Chitosan / Β-Cyclodextrin Nanoparticles By Ionic GelationDocument5 pagesFormulation And Evaluation Of Levofloxacin-Chitosan / Β-Cyclodextrin Nanoparticles By Ionic Gelationikwan ciptadiNo ratings yet

- Pulsatile Dds PDFDocument19 pagesPulsatile Dds PDFSiva PrasadNo ratings yet

- International Journal of Pharma and Bio Sciences Issn 0975-6299Document13 pagesInternational Journal of Pharma and Bio Sciences Issn 0975-6299Nadya PrafitaNo ratings yet

- Drug Design and DeliveryDocument34 pagesDrug Design and DeliveryAida MalikovaNo ratings yet

- Pharmaceutics QWDocument29 pagesPharmaceutics QWMr. Ashutosh PareekNo ratings yet

- A Comprehensive Review On The Role of Polymers in Ocular Drug DeliveryDocument22 pagesA Comprehensive Review On The Role of Polymers in Ocular Drug DeliverytrongndNo ratings yet

- Wet Milling Particle CharacterizationDocument20 pagesWet Milling Particle Characterizationsuhas.lavhekarNo ratings yet

- Polymeric Micelle As A New Carrier in Oral Drug Delivery SystemsDocument9 pagesPolymeric Micelle As A New Carrier in Oral Drug Delivery SystemsErisa MawaddahNo ratings yet

- Oral Lipid-Based Drug Delivery Systems - An OverviDocument13 pagesOral Lipid-Based Drug Delivery Systems - An OverviSara HussienNo ratings yet

- 51 Vol. 5 Issue 5 May 2014IJPSR RA 3450 Paper 51Document12 pages51 Vol. 5 Issue 5 May 2014IJPSR RA 3450 Paper 51yurlinzha ChyntiaTandipareNo ratings yet

- AtenololDocument21 pagesAtenololAbdul QadirNo ratings yet

- International Journal of Biological MacromoleculesDocument7 pagesInternational Journal of Biological MacromoleculesUday BaruahNo ratings yet

- Na DastinibDocument20 pagesNa DastinibPradheep SNo ratings yet

- 59 1036 1 PBDocument10 pages59 1036 1 PBgritty gallantNo ratings yet

- Ace Lofe Nac ContainingDocument16 pagesAce Lofe Nac ContainingUmeerNo ratings yet

- 5154-Article Text-15276-1-10-20220107Document7 pages5154-Article Text-15276-1-10-20220107jimi jamalNo ratings yet

- Ophthalmic Drug Delivery SystemDocument16 pagesOphthalmic Drug Delivery SystemSourabh JainNo ratings yet

- Studies On Design, Development and Characterization of Colon Targeted Drug Delivery of Mesalamine Using Coexcipient PolymerDocument7 pagesStudies On Design, Development and Characterization of Colon Targeted Drug Delivery of Mesalamine Using Coexcipient PolymerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Applications of Liposomes in Ophthalmic Drug Delivery SystemDocument40 pagesApplications of Liposomes in Ophthalmic Drug Delivery SystemBalisa MosisaNo ratings yet

- A Mini-Review On New Developments in Nanocarriers and Polymers For Ophthalmic Drug Delivery StrategiesDocument21 pagesA Mini-Review On New Developments in Nanocarriers and Polymers For Ophthalmic Drug Delivery StrategiestrongndNo ratings yet

- V6I105 28 January 2021Document9 pagesV6I105 28 January 2021Harrizul RivaiNo ratings yet

- Vesicular Drug Delivery Systems A NovelDocument10 pagesVesicular Drug Delivery Systems A NovelJERIN REJINo ratings yet

- Chapter-7 SummaryDocument10 pagesChapter-7 SummaryZara KhanNo ratings yet

- Biopharmaceutics and Pharmacokinetics: S. Lakshmana Prabu, T.N.K. Suriyaprakash, K. Ruckmani and R. ThirumuruganDocument20 pagesBiopharmaceutics and Pharmacokinetics: S. Lakshmana Prabu, T.N.K. Suriyaprakash, K. Ruckmani and R. ThirumuruganAkshay PNo ratings yet

- JurnalDocument9 pagesJurnalYanuar Ahsan OfficialNo ratings yet

- Content ServerDocument10 pagesContent ServerAllysa hannah TriaNo ratings yet

- Nanostructured Lipid Carrier System For Topical deDocument13 pagesNanostructured Lipid Carrier System For Topical deJonathas MoreiraNo ratings yet

- 44 Vol. 11 Issue 6 June 2020 IJPSR RA 12795Document8 pages44 Vol. 11 Issue 6 June 2020 IJPSR RA 12795Aurora ArabellaNo ratings yet

- Journal of Drug Delivery and Therapeutics: Ocular in Situ Gel: An OverviewDocument11 pagesJournal of Drug Delivery and Therapeutics: Ocular in Situ Gel: An OverviewRaj PatelNo ratings yet

- Emerging Trend of Microemulsion in PDFDocument30 pagesEmerging Trend of Microemulsion in PDFrahmiadelianiNo ratings yet

- Liposome Assisted Drug Deliveryan Updated ReviewDocument15 pagesLiposome Assisted Drug Deliveryan Updated ReviewvinayNo ratings yet

- Development of Controlled Porosity Osmotic Pump of Ritonavir: Design, Optimization and CharacterizationDocument9 pagesDevelopment of Controlled Porosity Osmotic Pump of Ritonavir: Design, Optimization and Characterizationgritty gallantNo ratings yet

- Review On Ophthalmic InsertsDocument9 pagesReview On Ophthalmic InsertsIoana Bojescu RoșuNo ratings yet

- Articulo Biofarmacia InglesDocument16 pagesArticulo Biofarmacia InglesJuan Sebastián Mateus SánchezNo ratings yet

- 5 Vol. 11 Issue 3 Mar 2020 IJPSR RE 3211Document15 pages5 Vol. 11 Issue 3 Mar 2020 IJPSR RE 3211Shubhrajit MantryNo ratings yet

- Specialized Drug Delivery SystemsDocument2 pagesSpecialized Drug Delivery SystemsSyed Shabbir HaiderNo ratings yet

- International Journal of Applied PharmaceuticsDocument4 pagesInternational Journal of Applied Pharmaceuticsศรุต พึ่งพระNo ratings yet

- 5586-Article Text-16700-1-10-20220912Document9 pages5586-Article Text-16700-1-10-20220912Azizurrehman KhanNo ratings yet

- Zhang 2017Document15 pagesZhang 2017Alyna AlynaNo ratings yet

- Pharmaceutics 15 00753Document16 pagesPharmaceutics 15 00753Fabio GreenNo ratings yet

- IJPSRDocument8 pagesIJPSRNithin VijayakumarNo ratings yet

- Saudi Pharmaceutical JournalDocument8 pagesSaudi Pharmaceutical Journalrefilda suhailiNo ratings yet

- How To Achieve High Encapsulation Efficiencies For Macromolecular and Sensitive Apis in LiposomesDocument13 pagesHow To Achieve High Encapsulation Efficiencies For Macromolecular and Sensitive Apis in LiposomeslmNo ratings yet

- Slnreview 2010Document28 pagesSlnreview 2010emilija.kostadinovNo ratings yet

- Zahid, 2450-Naila Masood Galley ProofDocument12 pagesZahid, 2450-Naila Masood Galley ProofNaila MasoodNo ratings yet

- Journal of Drug Delivery and TherapeuticsDocument7 pagesJournal of Drug Delivery and TherapeuticsKunal BhambarNo ratings yet

- NanovesiclesDocument3 pagesNanovesiclesSelvaNo ratings yet

- Chiappetta 2007Document15 pagesChiappetta 2007Imene MechkourNo ratings yet

- Kusum D.V., Bhosale U.V. - Formulation and Optimization of Polymeric Nano Drug Delivery System of Acyclovir Using 3 (2) Full Factorial DesignDocument10 pagesKusum D.V., Bhosale U.V. - Formulation and Optimization of Polymeric Nano Drug Delivery System of Acyclovir Using 3 (2) Full Factorial DesignJordy CanalesNo ratings yet

- Chapter 7 Solid Forms and PharmacokineticsDocument26 pagesChapter 7 Solid Forms and PharmacokineticsVanessa Fernanda Zurita GuerraNo ratings yet

- Vesicular Drug Delivery System A Novel ApproachDocument15 pagesVesicular Drug Delivery System A Novel ApproachSemakinsehat IdNo ratings yet

- NANOTECHNOLOGY REVIEW: LIPOSOMES, NANOTUBES & PLGA NANOPARTICLESFrom EverandNANOTECHNOLOGY REVIEW: LIPOSOMES, NANOTUBES & PLGA NANOPARTICLESNo ratings yet

- 2856-Article Text-8673-1-10-20190615Document12 pages2856-Article Text-8673-1-10-20190615Nikita jainNo ratings yet

- Pharmaceutics 13 00401Document17 pagesPharmaceutics 13 00401Nikita jainNo ratings yet

- Document From Rushabh JainDocument117 pagesDocument From Rushabh JainNikita jainNo ratings yet

- Pharmaceutics 12 00446Document24 pagesPharmaceutics 12 00446Nikita jainNo ratings yet

- Admin,+journal+manager,+02 AJP 583 16 R1 OADocument14 pagesAdmin,+journal+manager,+02 AJP 583 16 R1 OANikita jainNo ratings yet

- Article Wjpps 1538219689 PDFDocument12 pagesArticle Wjpps 1538219689 PDFMeidy WanNo ratings yet

- Liposome Preparation MethodsDocument13 pagesLiposome Preparation MethodsAshish GajeraNo ratings yet

- Dinesh Dhumal Formatted CVDocument9 pagesDinesh Dhumal Formatted CVManoharNo ratings yet

- A Review On Use of Herbal Drugs For Solid Lipid NanoparticlesDocument6 pagesA Review On Use of Herbal Drugs For Solid Lipid NanoparticlesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Pelepasan Polimer LangerDocument7 pagesPelepasan Polimer LangerUntia Kartika Sari RamadhaniNo ratings yet

- Target Drug Deliovery System UNIT - IVDocument18 pagesTarget Drug Deliovery System UNIT - IVS N A INSTITUTE OF PHARMACYNo ratings yet

- Journal of Drug Delivery and TherapeuticsDocument7 pagesJournal of Drug Delivery and TherapeuticsKunal BhambarNo ratings yet

- Nanostructured Material A Review On Smart Drug Delivery SystemDocument13 pagesNanostructured Material A Review On Smart Drug Delivery SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Ethanol Injection Method Liposomes PDFDocument2 pagesEthanol Injection Method Liposomes PDFElizabeth100% (1)

- Avanti Brochure LiposomesDocument2 pagesAvanti Brochure LiposomestroceanNo ratings yet

- Targeted Drug Delivery Systems - BRAINDocument51 pagesTargeted Drug Delivery Systems - BRAINsunil100% (6)

- Phytosomes: Potential Carriers For Herbal Drugs: January 2013Document14 pagesPhytosomes: Potential Carriers For Herbal Drugs: January 2013Siva PrasadNo ratings yet

- An Overview of Encapsulation Technologies For Food ApplicationsDocument10 pagesAn Overview of Encapsulation Technologies For Food ApplicationsMuhammad Husain NurNo ratings yet

- PharmaceuticsDocument25 pagesPharmaceuticsvera GaborNo ratings yet

- Beyond The Lipid-Bilayer Interaction of Polymers and Nanoparticles With MembranesDocument16 pagesBeyond The Lipid-Bilayer Interaction of Polymers and Nanoparticles With MembranesМирјана МићевићNo ratings yet

- Official: Á1001Ñ in Vitro Release Test Methods For Parenteral Drug PreparationsDocument6 pagesOfficial: Á1001Ñ in Vitro Release Test Methods For Parenteral Drug PreparationsDilawar BakhtNo ratings yet

- Nanoparticles Drug Delivery ThesisDocument5 pagesNanoparticles Drug Delivery Thesisafcngocah100% (2)

- Scholtz JC Chapter2Document17 pagesScholtz JC Chapter2Monalisha MitraNo ratings yet

- Micelles, Bilayers, and LiposomesDocument32 pagesMicelles, Bilayers, and LiposomesRHEY ANNE TEHENGNo ratings yet

- Liposome EvaluationDocument32 pagesLiposome EvaluationSajesh Joseph100% (1)

- Patent Liposomas Vitamina CDocument20 pagesPatent Liposomas Vitamina CJomertron100% (1)

- Formulation and Evaluation of Aceclofenac LiposomeDocument9 pagesFormulation and Evaluation of Aceclofenac LiposomeNikita jainNo ratings yet

- Author's Accepted Manuscript: TalantaDocument43 pagesAuthor's Accepted Manuscript: TalantaAnh Quản Vũ HoàngNo ratings yet

- Method of Stabilization AND Accelerated Stability TestingDocument23 pagesMethod of Stabilization AND Accelerated Stability TestingMr. HIMANSHU PALIWALNo ratings yet

- Fucoxanthin From Phaeodactylum Tricornutum NanoencapsulationDocument22 pagesFucoxanthin From Phaeodactylum Tricornutum NanoencapsulationalmaliagustiningrumNo ratings yet

- Engineering Precision Nanoparticles For Drug DeliveryDocument24 pagesEngineering Precision Nanoparticles For Drug Deliverypota potNo ratings yet

- Formulation and Standardization of NutraceuticalsDocument10 pagesFormulation and Standardization of Nutraceuticalssudhindra kini100% (3)

- Zeal AADocument9 pagesZeal AAkanishk luhachNo ratings yet

- Document (1) PharmaceuticsDocument14 pagesDocument (1) PharmaceuticsHanaa Abo SweirhNo ratings yet