Professional Documents

Culture Documents

Compressor

Compressor

Uploaded by

fvaefaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compressor

Compressor

Uploaded by

fvaefaCopyright:

Available Formats

DAHEJ PETROCHEMICAL

COMPLEX

ONGC Petro additions Ltd.

Dual Feed Cracker Unit

EIL

SEZ, Dahej, Gujarat, India & Associated Units JOB NO. 6987

Page: 1 of 33

DATA SHEET

CENTRIFUGAL COMPRESSOR

11-KC-301

CRACKED GAS COMPRESSOR

05 31.03.11 AS-BUILT Bussink Hendewerk Prunner

04 11.10.10 Updated After Order Bussink Hendewerk Prunner

03 29.09.09 For Order Bussink Hendewerk Prunner

2.1 27.07.09 Revised case 15 and revised gas composition (all) Bussink Hendewerk

02 18.05.09 For Inquiry updated Bussink Hendewerk Prunner

01 06.03.09 For Inquiry Bussink Hendewerk Prunner

Issue Date Reason for Issue / Remark Prepared Checked Approved OPaL/EIL

ENGINEERING Linde Proj. No.: 3110 A9NK

DIVISION Linde Project Code : DAHEJ

Samsung Proj. No.: SC 2252

Samsung Job Code : OPaL

Contract No / PO No.: Item No.:

MR/OW/MM/DFC/02/2007 11-KC-301

Originator's Doc. No.: Project Doc. No.:

&AA-11-M-DE 3101.001 6987-LEPC1-AA-11-M-DE-3101.001

Intellectual property rights reserved - refer to protection notice ISO 16016

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 2 of 33

1 05 APPLICABLE TO: { PROPOSAL { PURCHASE z AS BUILT

2 03 LINDE INQUIRY NO. 001-2KC640 LINDE ORDER 001-2KC640

3 FOR ONGC UNIT ETHYLENE PLANT

4 05 SITE DAHEJ; GUJARAT / INDIA SERIAL NO. LP: R09T013102 / MP: R09T013103

5 05 SERVICE CRACKED GAS COMPRESSION HP: R09T013104

6 05 NBR. REQUIRED 1

7 OPERATION: z CONTINUOUS { INTERMITTENT { STANDBY

8

9 03 MANUFACTURER ELLIOTT EBARA MODEL 88MD2-2+88M4I+60M4/4I

10 03 DRIVER TYPE STEAM TURBINE DRIVER MFR. ELLIOTT EBARA

11 DRIVER ITEM NO. 11-KT-301 RATED POWER KW 66642 (PER API)

12 EC MACHINERY DIRECTIVE / ATEX / PED APPLICABLE { YES z NO

13 NOTE: INFORMATION TO BE COMPLETED: z BY PURCHASER BY MANUFACTURER

14 OPERATING CONDITIONS AS PER PROCESS DATA SHEET 11-P-DP 3101 REV. 04 DATED 17.07.09

15 z OPERATING POINT CASE 1-100 (WITHOUT WATER INJECTION)

16 z PROCESS STAGE 1 2 3 4 5

17 z PROCESS STR. NO. 31-019 31-028 31-029 31-039 31-031

18 CASING LP MP HP

19 z GAS ANALYSIS DATA SEE PAGE # 7

20 02 z WEIGHT FLOW KG/H 461 085 471 835 456 431 428 017 401 852

21 z WATER INJECTION KG/H NO NO NO NO NO

22 TOTAL WEIGHT FLOW KG/H

23 INLET CONDITIONS

24 02 z PRESSURE SPECIFIED BAR A 1.20 2.20 4.40 9.03 18.27 1)

25 04 ACTUAL BAR A 1.20 2.37 4.69 9.21 18.57

26 03 z MAX. ALLOW. PRESS. TOLER. % +0/-0

27 02 z TEMPERATURE °C 38.0 33.1 35.8 36.9 36.6

28 RELATIVE HUMIDITY %

29 02 z MOLECULAR WEIGHT G/MOL 25.92 25.70 25.23 24.21 23.15

30 04 CP/CV (K1) OR (KAVG) 1.217 1.227 1.237 1.258 1.301

31 04 COMPRESSIBILITY (Z1) OR (ZAVG) 0.994 0.988 0.979 0.965 0.937

32 04 INLET VOLUME (WET) OR (DRY) M³/H 381128 195072 97586 47730 23222

33 DISCHARGE CONDITIONS

34 z PRESSURE SPECIFIED BAR A 2.40 4.60 9.30 19.10 38.47 1)

35 04 ACTUAL BAR A 2.57 4.89 9.48 19.40 38.47

36 02 z MAX. ALLOW. PRESS. TOLER. % + 10 / - 5 + 10 / - 5 +5/-5 +5/-5 +5/-0

37 04 TEMPERATURE: ACTUAL/MAX.ALLOW. °C 87 / 95 79 / 95 83 / 95 88 / 95 91 / 95 2)

38 CP/CV (K2) OR (KAVG) 1.197 1.208 1.219 1.243 1.290

39 04 COMPRESSIBILITY(Z2) OR (ZAVG) 0.992 0.986 0.975 0.959 0.933

40 02 z MAX PRESS. DROP BTW. STAGES BAR 0.20 0.20 0.27 0.83 1)

41 05

42 05

43 04 TOTAL POWER / TOLERANCE KW / % EXPECTED: 57872 // GARANTEED.: 58816 / + 0 % 3)

44 04 SPEED RPM 3673

45 04 ESTIM. SURGE @ RPM ABOVE M³/H 288904 145063 69392 35832 17981

46 04 POLYTROPIC HEAD KJ/KG 81.4 76.28 75.37 82.62 82.33

47 POLYTROPIC HEAD @ SURGE KJ/KG

48 04 POLYTROPIC EFFICIENCY % 87.8 88.8 85.9 86.2 82.2 5)

49 z CERTIFIED POINT (GUARANTEE) YES

50 PERFORMANCE CURVE NO.

51 04 z SETTLING OUT PRESSURE BAR G MAX.: 4.5 MAX.: 22.0 4)

52 z RV-VALVE SETTING PRESSURE BAR G 8.0 14.0 41,5

53 REMARKS:

54 1) INTERMEDIATE PRESSURE MAY VARY WITHIN ABOVE TOLERANCE; SPECIFIED INTERSTAGE PRESSURE DROPS SHALL BE MET

55 2) DISCHARGE TEMPERATURE OF NEITHER STAGE SHOULD EXCEED +90°C (WITH WATER INJECTION) and +95 °C DRY

56 3) SHAFT POWER SHALL BE GUARANTEED WITH ZERO PLUS TOLERANCE.

57 04 MECH. LOSSES INCL. ARE: 324 kW (for BEARINGS & SEALS)

58 4) PRELIMINARY / SUBJECT OF CONFIRMATION

59 5) FLANGE TO FLANGE

60

03.11.03 Copying is only allowed after approval by LINDE AG

DAHEJ

Code

3110 A9NK

Job No.

Data Sheet Item No.

11-KC-301

CENTRIFUGAL COMPRESSOR &AA-11-M-DE 3101.001

Doc. No.

CRACKED GAS COMPRESSION 05 / 31.03.11

Issue / Date

Page3 of 33

1 02 THE MOLECULAR WEIGHT OF THE CRACKED GAS AT THE SUCTION OF THE 1ST STAGE CAN VARY BETWEEN 24.5 KG/KMOLE AND

2 02 26.0 KG/MOLE FOR COMPRESSOR OPERATION WHERE KICKBACK LINES ARE CLOSED (I.E. WHERE THE NET FEED TO EACH STAGE

3 02 EXCEEDS THE MINIMUM FLOW OF THE RESPECTIVE STAGE). VENDOR TO SUBMIT PERFORMANCE CURVES THESE 2 CASES 1-100

4

5 WASH OIL INJECTION:

6 VENDOR SHALL PROVIDE INJECTION NOZZLES FOR INTERMITTENT WASH OIL INJECTION INTO EACH SUCTION LINE AND

7 03 AND COMPRESSOR CASING OF STAGE 1-4.

8 NUMBER OF NOZZLE ASSEMBLIES REQ'D TO ACHIEVE EVEN WASH OIL DISTRIBUTION SHALL BE DETERMINED BY VENDOR.

9 02 WASH OIL INJECTION WILL TAKE PLACE AT ONE STAGE ONLY AT A TIME. THE BFW INJECTION WILL CONTINUE TO FLOW TO ALL

10 02 STAGES WHILE WASH OIL IS BEING INJECTED

11

12 04 WASH OIL INJECTION FLOW RATE: REFER TO ELLIOTT UTILITY LIST: 0012KC6401-11-P-CU 3100.001, PAGE 4

13 - PROPERTIES OF WASH OIL: TYPICAL MIN. MAX. TEST METHOD

14 - API GRAVITY @ 60° F 14 12.5 16.0 ASTM D 287

15 - FLASH POINT (PMCC) ( °F) 180 150 ASTM D 93

16 - AROMATICS CONTENT ( %) 95 90

17 - CLOUD POINT ( °F) < 30

18 - KAURI BUTANOL VALUE 100

19 - DISTILLATION RANGE (°F) IBP = 400; 50% = 475; 95% = 550; EP = 580; ASTM D 86

20 - COLOR DARK GREEN VISUAL

21 - NORMAL TEMP. 30°C (AMBIENT)

22 02 - PRESS. (UPSTREAM OF CONTR: VALVE) 42 BAR A

23 02 - DENSITY RANGE 750 – 1100 KG/M3

24 02 - VISCOSITY RANGE 0.9 cP – 4.5 cP

25 02 HYDROGENATED C9+ PRODUCT FROM THE PYROYSIS GASOLINE HYDROGENATION IS NORMALLY USED AS WASH OIL.

26 04

27 02 FLOW RATES AND COMPOSITIONS SHOWN UNDER PROCESS STREAMS 31-019, 31-028, 31-029 AND 31-039 DO NOT INCLUDE

28 02 VALUES FOR ANY KIND OF LIQUID INJECTION (BFW and/or WASHOIL). Æ REFER TO SKETCH ON PAGE 5

29 04 A MAX WASH OIL FLOW RATED OF 2 WT-% PER STAGE HAS BEEN ASSUMED // WASH OIL PUMP IS DESIGNED FOR 13M³/H

30 05 MECHAN. DESIGN FOR THE WASH OIL SYSTEM: 82 BARG / 110°C

31

32 METALLURGY OF CRACKED GAS COMPRESSOR PARTS SHALL TAKE INTO CONSIDERATION THE FOLLOWING SOUR GAS CONTENT:

33 02 - MAX CO2 CONTENT OF 165 VOL PPM (DURING KICKBACK OPERATION)

34 02 - MAX H2S CONTENT OF 115 VOL PPM DURING DECOKING OF FURNACES THE H2S CONTENT MAY REACH 250 WT PPM

35 02 THESE MAXIMUM CONCENTRATIONS DO NOT OCCUR SIMULTANEOUSLY // THE SOURGAS CONTENT CAN INCREASE ABOVE THE

36 02 GIVEN VALUES E.G. BY MISOPERATION OF THE DMDS DOSING. COMPRESSOR SHALL BE DESIGNED FOR SOUR GAS SERVICE ACC.

37 02 TO NACE INDEPENDENT FROM GAS ANALYSIS BECAUSE HIGHER H2S CONTENT CAN BE OCCURE DURING UPSET CONDITIONS.

38 05 SEAL GAS DESIGN (MORE DETAILS ARE SHOWN IN "SEAL GAS CONCEPT FOR 11-KC-301"; &AA-00-P-PA 1210)

39 02 UNHYDROGENATED C2- AND PLANT NITROGEN ARE USED AS SEAL GAS DURING NORMAL OPERATION. ETHYLENE PRODUCT AND

40 02 PLANT NITROGEN ARE AVAILABLE AS BACK-UP SEAL GAS AND ETHANE (FROM THE C2 REFRIGERATION CYCLE FILLED WITH

41 02 ETHANE) IS USED WITH PLANT NITROGEN DURING START-UP

42 02 DELVERY CONDITIONS OF SEAL GAS AT B.L. OF THE CRACK GAS COMPRESSOR ARE:

43 02 C2- ETHYLENE ETHANE PLANT N2 (UN-INTERUPTED N2 SUPPLY FOR SECOND SEALGAS)

44 02 TEMPERATURE MIN (°C) 50.0 33.0 33.0

45 02 TEMPERATURE NORM (°C) 68.0 45.0 / 90 45.0 40.0 (AMBIENT)

46 02 TEMPERATURE MAX (°C) 98.0 50.0 / 100 50.0

47 04 PRESSURE MIN (BARA) 31.0 31.0 34.0 5.0

48 02 PRESSURE NORM (BARA) 36.6 37.0 37.0 6.0

49 02 PRESSURE MAX (BARA) 38.5 39.0 39.0 7.0

50 02 NOTES:

51 02 NORMAL OPERATION - ETHYLENE SEAL GAS INLET TEMP.: 90°C // WORST CASE: NORM. 45°C (COMING FROM ETHYLENE STORAGE TANK)

52 05 AS PER ELLIOTT DETAIL CHECK, NO SEALGAS HEATER IS REQUIRED (BASED O SEALGAS PRESSURE REDUCTION AT EACH CASING)

53 03

54 02 BEFORE STARTING THE 11-KC-301, THE ETHYLENE COMPRESSOR 11-KC-401 IS IN OPERATION AND THEREFORE THE PRIMARY

55 02 SEALGAS (ETHYLENE OR ETHANE) IS AVAILABLE.

56

57 02 POLYMERISATION INHIBITOR INJECTION

58 02 DOSING OF POLYMERISATION INHIBITOR INTO THE SUCTION LINE UP STREAM STAGE I, II, III AND VI OF THE COMPRESSOR IS

59 02 PROVIDED

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 4 of 33

1 OPERATING CONDITIONS

2 03 z OPERATING POINT CASE 1-100 (WITH CONSTANT WATER INJECTION)

3 z PROCESS STAGE 1 2 3 4 5

4 02 z PROCESS STR. NO. 31-019 31-028 31-029 31-039 31-031

5 CASING LP MP HP

6 z GAS ANALYSIS DATA SEE PAGE # 7

7 02 z WEIGHT FLOW KG/H 461 085 471 835 456 431 428 017 401 852

8 03 WATER INJECTION KG/H appr. 2270 appr. 1360 appr. 1320 appr. 3350 appr. 2800 )

9 03 TOTAL WEIGHT FLOW KG/H 463 355 473 195 457 751 431 367 404 652

10 INLET CONDITIONS

11 02 z PRESSURE SPECIFIED BAR A 1.20 2.20 4.40 9.03 18.27 1)

12 03 ACTUAL BAR A 1.20 2.37 4.68 9.17 18.52

13 03 z MAX. ALLOW. PRESS. TOLER. % +0/-0

14 02 z TEMPERATURE °C 38.0 33.1 35.8 36.9 36.6

15 RELATIVE HUMIDITY %

16 02 z MOLECULAR WEIGHT G/MOL 25.92 25.70 25.23 24.21 23.15

17 03 CP/CV (K1) OR (KAVG) 1.217 1.227 1.237 1.258 1.301

18 03 COMPRESSIBILITY (Z1) OR (ZAVG) 0.994 0.988 0.979 0.965 0.937

19 03 INLET VOLUME (WET) OR (DRY) M³/H 381 128 195 156 97 818 47 959 23 301

20 DISCHARGE CONDITIONS

21 z PRESSURE SPECIFIED BAR A 2.40 4.60 9.30 19.10 38.47 1)

22 03 ACTUAL BAR A 2.57 4.88 9.44 19.35 38.47

23 02 z MAX. ALLOW. PRESS. TOLER. % + 10 / - 5 + 10 / -5 +5/-5 +5/-5 +5/-0

24 03 TEMPERATURE:ACTUAL/MAX.ALLOW. °C 82 / 90 76 / 90 80 / 90 81 / 90 85 / 90 2) 4)

25 03 CP/CV (K2) OR (KAVG) 1.200 1.210 1.222 1.251 1.300

26 03 COMPRESSIBILITY(Z2) OR (ZAVG) 0.992 0.985 0.974 0.954 0.926

27 02 z MAX PRESS. DROP BTW. STAGES BAR 0.20 0.20 0.27 0.83 1)

28

29

30 03 TOTAL POWER/TOLERANCE KW / % EXPECTED: 57591 3)

31 03 SPEED RPM 3666

32 04 ESTIM. SURGE @ RPM ABOVE M³/H 286792 144290 69045 35784 18123

33 03 POLYTROPIC HEAD KJ/KG 80.81 75.82 74.86 82.04 81.86

34 POLYTROPIC HEAD @ SURGE KJ/KG

35 03 POLYTROPIC EFFICIENCY % 87.8 88.8 86.1 86.3 82.2 4)

36 z CERTIFIED POINT (GUARANTEE) NO

37 PERFORMANCE CURVE NO.

38 z SETTLING OUT PRESSURE BAR G SEE PAGE 2

39 z RV-VALVE SETTING PRESSURE BAR G SEE PAGE 2

40 03 REMARKS: ) A CONSTANT BFW-INJECTION FLOW FOR ALL CASES TO BE USED

41 1) INTERMEDIATE PRESSURE MAY VARY WITHIN ABOVE TOLERANCE; SPECIFIED INTERSTAGE PRESSURE DROPS SHALL BE MET

42 2) DISCHARGE TEMPERATURE OF NEITHER STAGE SHOULD EXCEED +90°C (WITH WATER INJECTION) and +95 °C DRY

43 04 3) MECH. LOSSES INCL. ARE: 323 kW (for BEARINGS&SEALS)

44 4) FLANGE TO FLANGE

45 02 BOILER FEED WATER INJECTION

46 02 PROVISIONS FOR THE INJECTION OF BOILER FEED WATER VIA THE COMPRESSOR CASING MUST BE PROVIDED.

47 02 FOR PRELIMARY DESIGN PURPOSE THE BOILER FEED WATER IS AVAILABLE AT THE FOLLOWING CONDITIONS:

48 02 - TEMPERATURE 42.0 °C

49 02 - PRESSURE 50.5 BARA

50 04

51 02

52 04

53 04

54 02 NOZZLE CHANGE SHALL BE POSSIBLE DURING COMPRESSOR OPERATION

55 04

56 04

57 04 WATER-INJECTION PROCESS SKETCH Æ REFER TO SKETCH ON PAGE 5

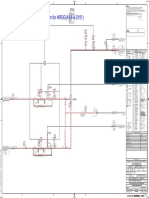

58 03

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 5 of 33

1 OPERATING CONDITIONS

2 z OPERATING POINT CASE 1-105 (WITHOUT WATER INJECTION)

3 z PROCESS STAGE 1 2 3 4 5

4 02 z PROCESS STR. NO. 31-019 31-028 31-029 31-039 31-031

5 CASING LP MP HP

6 z GAS ANALYSIS DATA SEE PAGE # 7

7 02 z WEIGHT FLOW KG/H 484 139 495 427 479 252 449 418 421 945

8 z WATER INJECTION KG/H NO NO NO NO NO

9 TOTAL WEIGHT FLOW KG/H

10 INLET CONDITIONS

11 02 z PRESSURE SPECIFIED BAR A 1.20 2.20 4.40 9.03 18.27 1)

12 04 ACTUAL BAR A 1.20 2.36 4.65 9.15 18.44

13 03 z MAX. ALLOW. PRESS. TOLER. % +0/-0

14 02 z TEMPERATURE °C 38.0 33.1 35.8 36.9 36.6

15 RELATIVE HUMIDITY %

16 02 z MOLECULAR WEIGHT G/MOL 25.92 25.70 25.23 24.21 23.15

17 04 CP/CV (K1) OR (KAVG) 1.217 1.227 1.236 1.258 1.301

18 04 COMPRESSIBILITY (Z1) OR (ZAVG) 0.994 0.988 0.980 0.965 0.937

19 04 INLET VOLUME (WET) OR (DRY) M³/H 400 184 205 467 103 276 50 455 24 534

20 DISCHARGE CONDITIONS

21 z PRESSURE SPECIFIED BAR A 2.40 4.60 9.30 19.10 38.47 1)

22 04 ACTUAL BAR A 2.56 4.85 9.42 19.27 38.47

23 02 z MAX. ALLOW. PRESS. TOLER. % + 10 / - 5 + 10 / -5 +5/-5 +5/-5 +5/-0

24 04 TEMPERATURE:ACTUAL/MAX.ALLOW. °C 87 / 95 79 / 95 83 / 95 88 / 95 92 / 95 2) 4)

25 04 CP/CV (K2) OR (KAVG) 1.197 1.208 1.219 1.243 1.288

26 04 COMPRESSIBILITY(Z2) OR (ZAVG) 0.992 0.986 0.975 0.959 0.933

27 02 z MAX PRESS. DROP BTW. STAGES BAR 0.20 0.20 0.27 0.83 1)

28

29 04 POWER REQ'D PER CASING KW 12625 23728 24231

30 04 TOTAL POWER/TOLERANCE KW / % EXPECTED: 60584 5) 3)

31 03 SPEED RPM 3719

32 04 ESTIM. SURGE @ RPM ABOVE M³/H 296085 148586 71673 36564 18436

33 04 POLYTROPIC HEAD KJ/KG 81.11 75.80 75.57 82.61 83.21

34 POLYTROPIC HEAD @ SURGE KJ/KG

35 04 POLYTROPIC EFFICIENCY % 87.3 88.3 86.0 86.2 82.3 4)

36 z CERTIFIED POINT (GUARANTEE) NO

37 PERFORMANCE CURVE NO.

38 z SETTLING OUT PRESSURE BAR G SEE PAGE 2

39 z RV-VALVE SETTING PRESSURE BAR G SEE PAGE 2

40 REMARKS:

41 1) INTERMEDIATE PRESSURE MAY VARY WITHIN ABOVE TOLERANCE; SPECIFIED INTERSTAGE PRESSURE DROPS SHALL BE MET

42 2) DISCHARGE TEMPERATURE OF NEITHER STAGE SHOULD EXCEED +90°C (WITH WATER INJECTION) and +95 °C DRY

43 04 3) MECH. LOSSES INCL. ARE: 331 kW (for BEARINGS & SEALS).

44 03 4) FLANGE TO FLANGE

45 04 5) BASIS FOR TURBINE RATING

46

47 PROCESS SKETCH CRACKED GAS COMPRESSOR

48

49

50

51

52

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 6 of 33

1 OPERATING CONDITIONS

2 03 z OPERATING POINT CASE 1-105 (WITH CONSTANT WATER INJECTION)

3 z PROCESS STAGE 1 2 3 4 5

4 02 z PROCESS STR. NO. 31-019 31-028 31-029 31-039 31-031

5 CASING LP MP HP

6 z GAS ANALYSIS DATA SEE PAGE # 7

7 02 z WEIGHT FLOW KG/H 484 139 495 427 479 252 449 418 421 945

8 03 WATER INJECTION KG/H appr. 2270 appr. 1360 appr. 1320 appr. 3350 appr. 2800 6)

9 03 TOTAL WEIGHT FLOW KG/H 486 409 496 787 480 572 452 768 424 745

10 INLET CONDITIONS

11 02 z PRESSURE SPECIFIED BAR A 1.20 2.20 4.40 9.03 18.27 1)

12 03 ACTUAL BAR A 1.20 2.36 4.64 9.11 18.39

13 03 z MAX. ALLOW. PRESS. TOLER. % +0/-0

14 02 z TEMPERATURE °C 38.0 33.1 35.8 36.9 36.6

15 RELATIVE HUMIDITY %

16 02 z MOLECULAR WEIGHT G/MOL 25.92 25.70 25.23 24.21 23.15

17 03 CP/CV (K1) OR (KAVG) 1.217 1.227 1.236 1.258 1.301

18 03 COMPRESSIBILITY (Z1) OR (ZAVG) 0.994 0.989 0.980 0.965 0.937

19 03 INLET VOLUME (WET) OR (DRY) M³/H 400 184 205 572 103 526 50 695 24 618

20 DISCHARGE CONDITIONS

21 z PRESSURE SPECIFIED BAR A 2.40 4.60 9.30 19.10 38.47 1)

22 03 ACTUAL BAR A 2.56 4.84 9.38 19.22 38.47

23 02 z MAX. ALLOW. PRESS. TOLER. % + 10 / - 5 + 10 / -5 +5/-5 +5/-5 +5/-0

24 03 TEMPERATURE:ACTUAL/MAX.ALLOW. °C 82 / 90 76 / 90 80 / 90 81 / 90 86 / 90 2) 4)

25 03 CP/CV (K2) OR (KAVG) 1.200 1.210 1.221 1.250 1.299

26 03 COMPRESSIBILITY(Z2) OR (ZAVG) 0.992 0.985 0.975 0.955 0.927

27 02 z MAX PRESS. DROP BTW. STAGES BAR 0.20 0.20 0.27 0.83 1)

28

29

30 03 TOTAL POWER/TOLERANCE KW / % EXPECTED : 60323 3)

31 03 SPEED RPM 3712

32 04 ESTIM. SURGE @ RPM ABOVE M³/H 294347 147883 71368 36536 18589

33 03 POLYTROPIC HEAD KJ/KG 80.52 75.36 75.09 82.03 82.78

34 POLYTROPIC HEAD @ SURGE KJ/KG

35 03 POLYTROPIC EFFICIENCY % 87.2 88.3 86.2 86.2 82.2 4)

36 z CERTIFIED POINT (GUARANTEE) NO

37 PERFORMANCE CURVE NO.

38 z SETTLING OUT PRESSURE BAR G SEE PAGE 2

39 z RV-VALVE SETTING PRESSURE BAR G SEE PAGE 2

40 REMARKS:

41 1) INTERMEDIATE PRESSURE MAY VARY WITHIN ABOVE TOLERANCE; SPECIFIED INTERSTAGE PRESSURE DROPS SHALL BE MET

42 2) DISCHARGE TEMPERATURE OF NEITHER STAGE SHOULD EXCEED +90°C (WITH WATER INJECTION) and +95 °C DRY

43 04 3) MECH. LOSSES INCL. ARE: 330 kW (for BEARINGS & SEALS)

44 4) FLANGE TO FLANGE

45 04 5) -----

46 03 6) A CONSTANT BFW-INJECTION FLOW FOR ALL CASES TO BE USED

47

48 02 BOILER FEED WATER (BFW-) INJECTION (SEE PAGE 4)

49

50

51 04

52

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 7 of 33

1 OPERATING CONDITIONS

2 03 GAS ANALYSIS MOL / MOL MW CASE 1

3 1ST STAGE 2ND STAGE 3RD STAGE 4TH STAGE 5TH STAGE

4 PROCESS STREAM NO. 31-019 31-028 31-029 31-039 31-031

5 HYDROGEN H2 2.02 0.2115 0.2075 0.2106 0.2162 0.2226

6 CARBON MONOXIDE CO 28.01 0.0003 0.0003 0.0003 0.0003 0.0003

7 CARBON DIOXIDE CO2 44.01 0.0001 0.0000 0.0001 0.0001 0.0000

8 HYDROGEN SULFIDE H2S 34.08 0.0000 0.0000 0.0000 0.0000 0.0000

9 METHANE CH4 16.04 0.1676 0.1995 0.2026 0.2075 0.2142

10 ACETYLENE C2H2 26.04 0.0043 0.0041 0.0042 0.0043 0.0044

11 ETHYLENE C2H4 28.05 0.2747 0.2786 0.2835 0.2906 0.2974

12 ETHANE C2H6 30.07 0.1083 0.1074 0.1094 0.1121 0.1144

13 MAPD 40.07 0.0042 0.0041 0.0042 0.0043 0.0042

14 PROPENE C3H6 42.08 0.0659 0.0643 0.0660 0.0685 0.0680

15 PROPANE C3H8 44.10 0.0103 0.0100 0.0103 0.0107 0.0106

16 VINYL ACETYLENE C4H4 52.08 0.0003 0.0003 0.0004 0.0004 0.0003

17 1-3 BUTADIENE C4H6 54.09 0.0158 0.0157 0.0165 0.0168 0.0158

18 1 BUTENE C4H8 56.11 0.0162 0.0161 0.0169 0.0173 0.0162

19 i-BUTANE i-C4H10 58.12 0.0015 0.0015 0.0015 0.0016 0.0015

20 n-BUTANE n-C4H10 58.12 0.0019 0.0019 0.0020 0.0020 0.0019

21 BENZENE C6H6 78.11 0.0207 0.0293 0.0260 0.0144 0.0064

22 TOLUENE C7H8 92.14 0.0127 0.0083 0.0030 0.0007 0.0001

23 XYLENES C8H10 106.20 0.0030 0.0006 0.0001 0.0000 0.0000

24 E-BENZENE / STYRENE C8H8 105.16 0.0031 0.0005 0.0001 0.0000 0.0000

25 C5 69.00 0.0158 0.0175 0.0197 0.0186 0.0145

26 C6 84.60 0.0056 0.0077 0.0085 0.0062 0.0035

27 C7 99.20 0.0011 0.0012 0.0007 0.0003 0.0001

28 C8+ 116.60 0.0015 0.0006 0.0001 0.0000 0.0000

29 C9 / C10 AR 126.43 0.0010 0.0001 0.0000 0.0000 0.0000

30 H2O 18.02 0.0529 0.0229 0.0135 0.0071 0.0036

31

32

33

34

35

36 REMARKS: GENERAL:

37 1) THE COMPRESSOR SHALL BE DESIGNED TO POSITIVELY ASSSURE THAT NO CRACKED GAS CAN SLIP FROM

38 THE FOURTH STAGE TO THE FIFTH STAGE

39 2) FOR BFW- & WASHOIL INJECTION REFER TO COMMENTS ON PREVIOUS PAGES

40 3) INDICATED FLOW RATES AND GAS COMPOSITIONS DO NOT INCLUDE ANY INJECTION FLOW

41 4) NOZZLE CHANGE SHALL BE POSSIBLE DURING COMPRESSOR OPERATION

42 5) FOR ALL OPERATING POINTS VENDOR SHALL PROVIDE WITH BID AT LEAST:

43 - CURVES to SHOW: VOLUME FLOW m3/h vs HEAD kj/kg

44 04 VOLUME FLOW m3/h vs PRESSURE

45 VOLUME FLOW m3/h vs POLYTR. EFFICIENCY

46 VOLUME FLOW m3/h vs SHAFT POWER kW

47 - CURVES TO COVER SPECIFIED SPEED RANGE AT 5% STEPS.

48 6) PERFORMANCE DATA ALSO TO BE SUPPLIED IN DIGITAL / TABULAR FORM (EXCEL 6.0 OR HIGHER).

49

50

51

52

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 8 of 33

1 OPERATING CONDITIONS

2 03 z OPERATING POINT CASE 14 – BYPASS with LOW MOLWEIGHT (W/O WATER INJECTION) )

3 z PROCESS STAGE 1 2 3 4 5

4 02 z PROCESS STR. NO. 31-019 31-028 31-029 31-039 31-031

5 CASING LP MP HP

6 z GAS ANALYSIS DATA SEE PAGE # 9

7 03 z WEIGHT FLOW (PER PROCESS) KG/H 196 313 206 269 200 199 197 144 196 412

8 03 z RECYCLE FLOW (AS PER CURVES) KG/H 121 000 121 000 121 000 155500 155500 5)

9 03 TOTAL WEIGHT FLOW (L7 + L8) KG/H 317313 327269 321199 362644 351612

10 INLET CONDITIONS

11 02 z PRESSURE SPECIFIED BAR A 1.20 2.20 4.40 9.03 18.27 1)

12 04 ACTUAL BAR A 1.20 2.38 4.69 9.14 18.32

13 03 z MAX. ALLOW. PRESS. TOLER. % +0/-0

14 03 z TEMPERATURE °C 35.4 37.1 37.9 38.6 36.7

15 RELATIVE HUMIDITY %

16 03 z MOLECULAR WEIGHT G/MOL 21.15 21.15 21.06 20.90 20.86

17 04 CP/CV (K1) OR (KAVG) 1.243 1.247 1.254 1.268 1.301

18 03 COMPRESSIBILITY (Z1) OR (ZAVG) 0.996 0.993 0.987 0.976 0.952

19 04 INLET VOLUME (WET) OR (DRY) M³/H 319 502 166 550 83 746 46 711 23 308

20 DISCHARGE CONDITIONS

21 z PRESSURE SPECIFIED BAR A 2.40 4.60 9.30 19.10 38.47 1)

22 04 ACTUAL BAR A 2.58 4.89 9.41 19.15 38.47

23 02 z MAX. ALLOW. PRESS. TOLER. % + 10 / - 5 + 10 / -5 +5/-5 +5/-5 +5/-0

24 04 TEMPERATURE:ACTUAL/MAX.ALLOW. °C 90.5 / 95 88.3 / 95 90.1 / 95 93.5 / 95 94.9 / 95 2)

25 04 CP/CV (K2) OR (KAVG) 1.219 1.225 1.232 1.248 1.283

26 03 COMPRESSIBILITY(Z2) OR (ZAVG) 0.996 0.992 0.986 0.974 0.952

27 02 z MAX PRESS. DROP BTW. STAGES BAR 0.20 0.20 0.27 0.83 1)

28

29

30 03 TOTAL POWER/TOLERANCE KW / % EXPECTED: 53171 3)

31 04 SPEED RPM 3918 (= 100%)

32 04 ESTIM. SURGE @ RPM ABOVE M³/H 288177 146978 72158 37475 19022

33 04 POLYTROPIC HEAD KJ/KG 100.73 94.23 91.50 97.33 95.33

34 POLYTROPIC HEAD @ SURGE KJ/KG

35 04 POLYTROPIC EFFICIENCY % 86.2 87.7 83.7 85.9 81.9 4)

36 z CERTIFIED POINT (GUARANTEE) NO

37 PERFORMANCE CURVE NO.

38 z SETTLING OUT PRESSURE BAR G SEE PAGE 2

39 z RV-VALVE BAR G SEE PAGE 2

40 03 REMARKS:

41 1) INTERMEDIATE PRESSURE MAY VARY WITHIN ABOVE TOLERANCE; SPECIFIED INTERSTAGE PRESSURE DROPS SHALL BE MET

42 2) DISCHARGE TEMPERATURE OF NEITHER STAGE SHOULD EXCEED +90°C (WITH WATER INJECTION) and +95 °C DRY

43 04 3) MECH. LOSSES INCL. ARE: 366 kW (for BEARINGS & SEALS)

44 4) FLANGE TO FLANGE

45 03 5) MINIMUM REQUIRED BYPASS FLOWS AS PER BY VENDOR DESIGN

46

47

48 02 KICKBACK OPERATION )

49 02 THE MOLECULAR WEIGTH OF THE CRACK GAS AT THE SUCTION OF THE 1ST STAGE CAN VARY BETWEEN 20.5 KG/KMOL AND

50 02 29.0 KG/KMOL FOR COMPRESSOR OPERATION WHERE THE KICKBACK LINE(S) ARE OPEN

51 02 CASE 14 AND CASE 15 SHOW KICKBACK OPERATION.

52 03

53 03

54

55

56

57

58

59 .

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 9 of 33

1 OPERATING CONDITIONS

2 03 GAS ANALYSIS MOL / MOL MW CASE 14

3 1ST STAGE 2ND STAGE 3RD STAGE 4TH STAGE 5TH STAGE

4 PROCESS STREAM NO. 31-019 31-028 31-029 31-039 31-031

5 HYDROGEN H2 2.02 0.2739 0.2662 0.2703 0.2736 0.2751

6 CARBON MONOXIDE CO 28.01 0.0002 0.0002 0.0002 0.0002 0.0003

7 CARBON DIOXIDE CO2 44.01 0.0000 0.0000 0.0000 0.0000 0.0000

8 HYDROGEN SULFIDE H2S 34.08 0.0000 0.0000 0.0000 0.0000 0.0000

9 METHANE CH4 16.04 0.1357 0.1492 0.1515 0.1532 0.1540

10 ACETYLENE C2H2 26.04 0.0040 0.0039 0.0040 0.0040 0.0040

11 ETHYLENE C2H4 28.05 0.3046 0.3087 0.3134 0.3163 0.3175

12 ETHANE C2H6 30.07 0.1698 0.1675 0.1701 0.1716 0.1721

13 MAPD 0.0017 0.0016 0.0017 0.0017 0.0017

14 PROPENE C3H6 44.09 0.0337 0.0327 0.0332 0.0334 0.0334

15 PROPANE C3H8 52.08 0.0162 0.0157 0.0159 0.0160 0.0160

16 VINYL ACETYLENE C4H4 56.10 0.0002 0.0002 0.0002 0.0002 0.0002

17 1-3 BUTADIENE C4H6 58.12 0.0069 0.0067 0.0068 0.0067 0.0067

18 1 BUTENE C4H8 78.11 0.0046 0.0045 0.0045 0.0045 0.0045

19 i-BUTANE i-C4H10 0.0013 0.0013 0.0013 0.0013 0.0013

20 n-BUTANE n-C4H10 0.0023 0.0022 0.0023 0.0022 0.0022

21 BENZENE C6H6 0.0028 0.0028 0.0028 0.0025 0.0024

22 TOLUENE C7H8 0.0006 0.0006 0.0006 0.0005 0.0005

23 XYLENES C8H10 0.0002 0.0002 0.0002 0.0001 0.0001

24 E-BENZENE / STYRENE C8H8 0.0002 0.0002 0.0002 0.0001 0.0001

25 C5 0.0039 0.0037 0.0038 0.0036 0.0036

26 C6 0.0004 0.0004 0.0004 0.0004 0.0004

27 C7 0.0001 0.0001 0.0001 0.0001 0.0000

28 C8+ 0.0001 0.0001 0.0001 0.0001 0.0001

29 C9 / C10 AR 0.0029 0.0024 0.0012 0.0004 0.0002

30 H2O 0.0334 0.0285 0.0150 0.0074 0.0036

31

32

33

34

35

36 REMARKS: GENERAL

37 1) THE COMPRESSOR SHALL BE DESIGNED TO POSITIVELY ASSSURE THAT NO CRACKED GAS CAN SLIP FROM

38 THE FOURTH STAGE TO THE FIFTH STAGE

39 2) FOR BFW- & WASHOIL INJECTION REFER TO COMMENTS ON PREVIOUS PAGES

40 3) INDICATED FLOW RATES AND GAS COMPOSITIONS DO NOT INCLUDE ANY INJECTION FLOW

41 03 4) SEE NOTE 4) ON PAGE 7

42 04 5) SEE NOTE 5) ON PAGE 7

43 6) PERFORMANCE DATA ALSO TO BE SUPPLIED IN DIGITAL / TABULAR FORM (EXCEL 6.0 OR HIGHER).

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 10 of 33

1 OPERATING CONDITIONS

2 03 z OPERATING POINT CASE 15 – BYPASS with HIGH MOLWEIGHT (W/O WATER INJECTION)

3 z PROCESS STAGE 1 2 3 4 5

4 02 z PROCESS STR. NO. 31-019 31-028 31-029 31-039 31-031

5 CASING LP MP HP

6 z GAS ANALYSIS DATA SEE PAGE # 11

7 03 z WEIGHT FLOW (PER PROCESS) KG/H 301 160 314 913 300 626 271 640 255 920

8 04 z RECYCLE FLOW (AS PER CURVES) KG/H 60 000 60 000 60 000 77 000 77 000 5)

9 04 TOTAL WEIGHT FLOW (L7 + L8) KG/H 361 160 374 913 360 626 348 640 332 920

10 INLET CONDITIONS

11 02 z PRESSURE SPECIFIED BAR A 1.20 2.20 4.40 9.03 18.27 1)

12 04 ACTUAL BAR A 1.20 2.36 4.79 9.55 18.96

13 02 z MAX. ALLOW. PRESS. TOLER. % +0/-0

14 03 z TEMPERATURE °C 35.2 32.7 35.8 37.9 36.4

15 RELATIVE HUMIDITY %

16 03 z MOLECULAR WEIGHT G/MOL 26.14 26.94 26.39 24.54 23.68

17 04 CP/CV (K1) OR (KAVG) 1.220 1.224 1.235 1.260 1.307

18 04 COMPRESSIBILITY (Z1) OR (ZAVG) 0.994 0.987 0.977 0.963 0.931

19 04 INLET VOLUME (WET) OR (DRY) M³/H 293 549 148 312 72 220 37 079 18 425

20 DISCHARGE CONDITIONS

21 z PRESSURE SPECIFIED BAR A 2.40 4.60 9.30 19.10 38.47 1)

22 04 ACTUAL BAR A 2.56 4.99 9.82 19.79 38.47

23 02 z MAX. ALLOW. PRESS. TOLER. %+ 10 / - 5 + 10 / - 5 + 5 / -5 +5/-5 +5/-0

24 03 TEMPERATURE:ACTUAL/MAX.ALLOW. °C 85 / 95 80 / 95 85 / 95 89 / 95 89 / 95 2)

25 04 CP/CV (K2) OR (KAVG) 1.199 1.204 1.217 1.245 1.295

26 04 COMPRESSIBILITY(Z2) OR (ZAVG) 0.992 0.984 0.972 0.957 0.927

27 02 z MAX PRESS. DROP BTW. STAGES BAR 0.20 0.20 0.27 0.83 1)

28

29

30 04 TOTAL POWER/TOLERANCE KW / % EXPECTED: 45823 3)

31 03 SPEED RPM 3492

32 04 ESTIM. SURGE @ RPM ABOVE M³/H 260774 134829 63941 33099 16706

33 04 POLYTROPIC HEAD KJ/KG 79.70 75.25 73.55 79.93 77.62

34 POLYTROPIC HEAD @ SURGE KJ/KG

35 04 POLYTROPIC EFFICIENCY % 86.7 87.4 82.8 84.7 80.9 4)

36 z CERTIFIED POINT (GUARANTEE) NO

37 PERFORMANCE CURVE NO.

38 z SETTLING OUT PRESSURE BAR G SEE PAGE 2

39 z RV-VALVE SETTING PRESSURE BAR G SEE PAGE 2

40 REMARKS:

41 1) INTERMEDIATE PRESSURE MAY VARY WITHIN ABOVE TOLERANCE; SPECIFIED INTERSTAGE PRESSURE DROPS SHALL BE MET

42 2) DISCHARGE TEMPERATURE OF NEITHER STAGE SHOULD EXCEED +90°C (WITH WATER INJECTION) and +95 °C DRY

43 04 3) MECH. LOSSES INCL. ARE: 295 kW (for BEARINGS & SEALS)

44 4) FLANGE TO FLANGE

45 03 5) MINIMUM REQUIRED BYPASS FLOWS AS PER BY VENDOR DESIGN

46

47

48 02 KICKBACK OPERATION )

49 02 THE MOLECULAR WEIGTH OF THE CRACK GAS AT THE SUCTION OF THE 1ST STAGE CAN VARY BETWEEN 20.5 KG/KMOL AND

50 02 29.0 KG/KMOL FOR COMPRESSOR OPERATION WHERE THE KICKBACK LINE(S) ARE OPEN

51 03 CASE 14 AND CASE 15 SHOW KICKBACK OPERATION.

52 03

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 11 of 33

1 OPERATING CONDITIONS

2 03 GAS ANALYSIS MOL / MOL MW CASE 15

3 1ST STAGE 2ND STAGE 3RD STAGE 4TH STAGE 5TH STAGE

4 PROCESS STREAM NO. 31-019 31-028 31-029 31-039 31-031

5 HYDROGEN H2 2.02 0.1591 0.1599 0.1625 0.1713 0.1749

6 CARBON MONOXIDE CO 28.01 0.0004 0.0004 0.0004 0.0004 0.0004

7 CARBON DIOXIDE CO2 44.01 0.0000 0.0000 0.0000 0.0000 0.0000

8 HYDROGEN SULFIDE H2S 34.08 0.0000 0.0000 0.0000 0.0000 0.0000

9 METHANE CH4 16.04 0.2609 0.2601 0.2645 0.2782 0.2864

10 ACETYLENE C2H2 26.04 0.0032 0.0032 0.0032 0.0034 0.0034

11 ETHYLENE C2H4 28.05 0.2932 0.2928 0.2984 0.3105 0.3175

12 ETHANE C2H6 30.07 0.0564 0.0564 0.0575 0.0596 0.0607

13 MAPD 0.0047 0.0047 0.0049 0.0048 0.0047

14 PROPENE C3H6 0.0754 0.0757 0.0779 0.0788 0.0779

15 PROPANE C3H8 0.0026 0.0026 0.0027 0.0028 0.0027

16 VINYL ACETYLENE C4H4 0.0003 0.0003 0.0003 0.0003 0.0003

17 1-3 BUTADIENE C4H6 0.0189 0.0195 0.0205 0.0192 0.0181

18 1 BUTENE C4H8 0.0212 0.0218 0.0229 0.0215 0.0203

19 i-BUTANE i-C4H10 0.0007 0.0007 0.0007 0.0007 0.0006

20 n-BUTANE n-C4H10 0.0001 0.0001 0.0001 0.0001 0.0001

21 BENZENE C6H6 0.0185 0.0306 0.0247 0.0103 0.0051

22 TOLUENE C7H8 0.0083 0.0069 0.0023 0.0004 0.0001

23 XYLENES C8H10 0.0019 0.0005 0.0001 0.0000 0.0000

24 E-BENZENE / STYRENE C8H8 0.0019 0.0004 0.0000 0.0000 0.0000

25 C5 0.0235 0.0277 0.0305 0.0239 0.0194

26 C6 0.0073 0.0114 0.0116 0.0064 0.0038

27 C7 0.0009 0.0012 0.0007 0.0002 0.0001

28 C8+ 0.0010 0.0005 0.0001 0.0000 0.0000

29 C9 / C10 AR 0.0008 0.0001 0.0000 0.0000 0.0000

30 H2O 0.0387 0.0224 0.0135 0.0073 0.0036

31

32

33

34

35 TOTAL

36 REMARKS:

37 1) THE COMPRESSOR SHALL BE DESIGNED TO POSITIVELY ASSSURE THAT NO CRACKED GAS CAN SLIP FROM THE FOURTH

38 STAGE TO THE FIFTH STAGE

39 2) FOR BFW- & WASH OIL INJECTION REFER TO COMMENTS ON PREVIOUS PAGES

40 3) INDICATED FLOW RATES AND GAS COMPOSITIONS DO NOT INCLUDE ANY INJECTION FLOW

41 03 4) SEE NOTE 4) ON PAGE 7

42 04 5) SEE NOTE 5) ON PAGE 7

43 6) PERFORMANCE DATA ALSO TO BE SUPPLIED IN DIGITAL / TABULAR FORM (EXCEL 6.0 OR HIGHER).

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 12 of 33

1 OPERATING CONDITIONS

2 z OPERATING POINT CASE AIR DRYING

3 z PROCESS STAGE 1 2 3 4 5

4 z PROCESS STR. NO.

5 CASING LP MP HP

6 z GAS ANALYSIS HIGH GRADE INDIAN INDUSTRIAL AIR (@ SEA SIDE)

7 04 z WEIGHT FLOW KG/H 298 254 287 485 284 293 188 749 187 977

8 04 RECYCLE FLOW KG/H 0 0 0 0 0

9 04 TOTAL WEIGHT FLOW KG/H 298 254 287 485 284 293 188 749 187 977

10 INLET CONDITIONS

11 02 z PRESSURE SPECIFIED BAR A 0.96 1)

12 04 ACTUAL BAR A 0.96 1.61 2.76 4.48 7.96

13 { MAX. ALLOW. PRESS. TOLER. %

14 z TEMPERATURE (RECOOLING) °C 47.0 38.0 38.0 38.0 38.0

15 03 RELATIVE HUMIDITY % 90

16 03 z MOLECULAR WEIGHT G/MOL 27.93 28.52 28.71 28.81 28.88

17 03 CP/CV (K1) OR (KAVG) 1.400 1.400 1.400 1.400 1.400

18 03 COMPRESSIBILITY (Z1) OR (ZAVG) 1.000 1.000 1.000 1.000 1.000

19 04 INLET VOLUME (WET) OR (DRY) M³/H 296050 162056 93503 37869 21728

20 DISCHARGE CONDITIONS

21 02 z PRESSURE SPECIFIED BAR A APPR.:15.0 1)

22 03 ACTUAL BAR A 1.81 2.96 4.75 8.79 15.0

23 { MAX. ALLOW. PRESS. TOLER. %

24 03 TEMPERATURE:ACTUAL °C 121 106 102 117 115 2)

25 03 CP/CV (K2) OR (KAVG) 1.400 1.400 1.400 1.400 1.400

26 03 COMPRESSIBILITY(Z2) OR (ZAVG) 1.000 1.000 1.000 1.000 1.000

27 02 z MAX PRESS. DROP BTW. STAGES BAR 0.20 0.20 0.27 0.83 1)

28

29

30 04 TOTAL POWER/TOLERANCE KW / % EXPECTED: 25665

31 04 SPEED RPM 3298

32 04 ESTIM. SURGE @ RPM ABOVE M³/H 233359 122820 59357 29798 15525

33 04 POLYTROPIC HEAD KJ/KG 67.12 60.98 53.80 68.06 63.51

34 POLYTROPIC HEAD @ SURGE KJ/KG

35 04 POLYTROPIC EFFICIENCY % 87.0 88.2 83.7 85.2 81.8 4)

36 z CERTIFIED POINT (GUARANTEE) NO

37 PERFORMANCE CURVE NO.

38 z SETTLING OUT PRESSURE BAR G SEE PAGE 2

39 z RV-VALVE SETTING PRESSURE BAR G SEE PAGE 2

40 REMARKS:

41 02 1) SPECIFIED INTERSTAGE PRESSURE DROPS AS PER CASE 1-100 SHALL BE CONSIDERED

42 03 2) MAX. DISCHARGE TEMPERATURE AS PER VENDOR DESIGN

43 04 3) MECH. LOSSES INCL. ARE: 266 kW (for BEARINGS & SEALS)

44 4) FLANGE TO FLANGE

45

46 AS PER NEXT PAGE, SITE DATA FOR AIR DRYING OPERATION ARE AS FOLLOWS:

47 - AMBIENT TEMP:. 47 °C:

48 - RELATIVE HUMIDITY 90 %

49 - AIR PRESSURE MIN.: 1008 MBAR

50

51 02 NOTE:

52 02 NO DESIGN CASE FOR MACHINE UNIT

53

54 05 DGS - CONDITIONS FOR AIR DRYING OPERATION : (REFER ALSO TO "SEAL GAS CONCEPT FOR 11-KC-301"; &AA-00-P-PA 1210)

55 04 N2-SEAL GAS (LP-N2) IS AVAILABLE DURING AIR DRYING OPERATION, THIS LP-N2 GAS WILL BE USED FOR PURGING THE DGS

56 04 AFTER START OF THE 11-KC-301 UNIT, COMPRESSED AIR (AFTER 5TH STAGE) WILL AUTOMATIC SUPPLY THE PRIMARY SEAL

57 04 GAS PART AND LP-N2 WILL BE UNCHANGED USED FOR SECONDARY- AND/ BUFFER GAS PART OF DGS.

58 04 AIR DRYING OPERATION : COMPRESSOR ALWAYS TO BE STARTED FROM A DEPRESSURIZED STATE (ALL STAGES)

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 13 of 33

1 OPERATING CONDITIONS

2 02 z OPERATING POINT CASE N2 OPERATION (PLANT N2-CASE)

3 z PROCESS STAGE 1 2 3 4 5

4 03 WATER INJECTION KG/H 4630 3297 2701 3502 2702 5)

5 CASING LP MP HP

6 z GAS ANALYSIS

7 03 z WEIGHT FLOW KG/H 80 000 80 000 80 000 80 000 80 000 5)

8 04 RECYCLE FLOW KG/H 300 000 300 000 300 000 170 000 170 000 (W/O WATER-

9 04 TOTAL WEIGHT FLOW KG/H 380 000 380 000 380 000 250 000 250 000 INJECTION)

10 INLET CONDITIONS

11 02 z PRESSURE SPECIFIED BAR A 1.20 1)

12 04 ACTUAL BAR A 1.20 2.10 3.64 5.91 10.68

13 { MAX. ALLOW. PRESS. TOLER. %

14 z TEMPERATURE (RECOOLING) °C 47.0 38.0 38.0 38.0 38.0

15 RELATIVE HUMIDITY %

16 z MOLECULAR WEIGHT G/MOL 28.0 28.0 28.0 28.0 28.0

17 03 CP/CV (K1) OR (KAVG) 1.401 1.402 1.404 1.407 1.413

18 03 COMPRESSIBILITY (Z1) OR (ZAVG) 1.000 0.999 0.999 0.998 0.997

19 04 INLET VOLUME (WET) OR (DRY) M³/H 300 853 167 055 96 835 39 030 22 125

20 DISCHARGE CONDITIONS

21 02 z PRESSURE SPECIFIED BAR A APPR.:20.0 1)

22 04 ACTUAL BAR A 2.30 3.84 6.18 11.51 20.00 1)

23 { MAX. ALLOW. PRESS. TOLER. %

24 04 TEMPERATURE (W/O / WITH WATERINJECT.) °C 123 / 108 106 / 96 101 / 91 116 / 90 114 / 94 2)

25 03 CP/CV (K2) OR (KAVG) 1.399 1.401 1.403 1.407 1.413

26 03 COMPRESSIBILITY(Z2) OR (ZAVG) 1.000 1.000 1.000 1.000 1.000

27 02 z MAX PRESS. DROP BTW. STAGES BAR 0.20 0.20 0.28 0.83 1)

28

29

30 04 TOTALPOWER/TOLERANCE KW / % 34076 // WITH BFW-INJECTION: 33538

31 04 SPEED RPM 3335 // WITH BFW-INJECTION: 3314

32 04 ESTIM. SURGE @ RPM ABOVE M³/H 236841 124342 60020 30146 15681

33 04 POLYTROPIC HEAD KJ/KG 68.9 61.59 53.52 69.06 64.71

34 POLYTROPIC HEAD @ SURGE KJ/KG

35 04 POLYTROPIC EFFICIENCY % 87.3 88.2 83.1 85.5 81.9 4)

36 z CERTIFIED POINT (GUARANTEE) NO

37 PERFORMANCE CURVE NO.

38 z SETTLING OUT PRESSURE BAR G SEE PAGE 2

39 z RV-VALVE SETTING PRESSURE BAR G SEE PAGE 2

40 REMARKS:

41 02 1) SPECIFIED INTERSTAGE PRESSURE DROPS AS PER CASE 1-100 SHALL BE CONSIDERED

42 04 2) MAX. DISCH. TEMP. AS PER VENDOR DESIGN (W/O / W) BFW-INJECTION (CALCULATED FOR INJECTION FLOWS AS PER CASE 1)

43 03 3) ---

44 4) FLANGE TO FLANGE

45

46 02 5) NET FRESH NITROGEN FLOW THROUGH THE COMPRESSOR WILL BE CIRCA 80 T/H (VENDOR TO SPECIFY THE KICKBACK

47 02 FLOWS IF REQUIRED)

48 03 BOILER FEED WATER INJECTION CONSIDERED FOR NITROGEN OPERATION TO REDUCE DISCHARGE TEMP. // WATERFLOW TO

49 03 BE ADJUSTED AT SIDE

50 02 NO DESIGN CASE FOR MACHINE UNIT

51

52

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 14 of 33

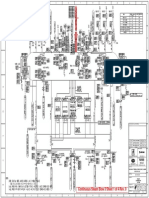

1 PROCESS CONTROL

2 METHOD { SUCTION THROTTLING FROM BARA TO BARA

3 { VARIABLE INLET GUIDE VANES

4 z SPEED VARIATION FROM 80% TO 105%

5 05 BASED ON DYN. z HOTGAS BYPASS FROM ( STAGE) 5TH DISCH. TO 5TH SUCTION 5)

SIMULATION

6 z COOLED BYPASS FROM ( STAGE) 3RD DISCH. TO 1ST SUCTION 5)

7 FROM ( STAGE) 5TH DISCH. TO 4TH SUCTION 5)

8 FROM ( STAGE) TO

9

10 04 SIGNAL SOURCE SUCTION PRESSURE 1ST STAGE VIA 11-PIC-31301

11 SIGNAL TYPE z ELECTRONIC { PNEUMATIC { OTHER

12 RANGE z 4 – 20 MA { 0.2 - 1.0 BARG

13 ANTI SURGE BYPASS z AUTOMATIC { MANUAL { NONE

14 BY z VENDOR 1) { PURCHASER

15

16 LOCATION

17 { INDOOR { HEATED z UNHEATED z OUTDOOR

18 z UNDER ROOF z PARTIAL SIDES { GRADE z MEZZANINE

19 z ELECTR. AREA / MOTOR CLASS.: ZONE 2, GRP. IIC, T3 (PER IEC)

20 { WINTERIZATION REQUIRED z TROPICALIZATION REQUIRED

21

22 SITE DATA 2) 3) 4)

23 z ELEVATION M: 7.1 M (ABOVE SEA LEVEL) z BAROMETER HPA: MAX. 1011 MIN. 1008

24 z RANGE OF AMBIENT TEMPERATURES DRY BULB 42 °C MEAN MAX.: 40 / MEAN MIN.: 13

25 z SITE RATED: 47 NORMAL: AVG 40 MAXIMUM: 47 MINIMUM: 5.6

26 UNUSUAL COND.: { DUST { FUMES z MARINE ATMOSPH.

27 z OTHER:: HUMID AND SALT LADDEN ATMOSPHERE, RELATIVE HUMIDITY: 90%

28

29 APPLICABLE SPECIFICATIONS

30 z API 617, ISSUE NO. 7 { API 613, ISSUE NO. 5 z API 614, ISSUE NO. 4

31 z API 670, ISSUE NO. 4 z API 671, ISSUE NO. 3

32 z LIST OF ATTACHMENTS { MANUFACTURER STANDARD z OTHER

33

34 PAINTING ACCORDING TO

35 { MANUFACTURER STANDARD { LIST OF ATTACHMENT z OTHER: SEE "LOA"

36

37 SHIPMENT

38 { DOMESTIC z EXPORT z EXPORT BOXING REQUIRED

39 z OUTDOOR STORAGE MORE THAN 6 MONTHS

40

41 REMARKS:

42 1) ANTI-SURGE VALVES AND ANTI-SURGE CONTROL SYSTEM

43 03 2) EARTHQUAKE ZONE III (PER INDIAN STANDARD IS 1893 – 2005)

44 3) MINIMUM AMBIENT DESIGN TEMPERATURE 0° C

45 4) EQUIPMENT AND INSTRUMENTATION NOT INSTALLED UNDER A ROOF, OR SHELTER, OR PROVIDED WITH A SUNSHADE,

46 SHALL BE DESIGNED FOR AN AMBIENT TEMPERATURE OF 60 °C

47 05 5) FOR DETAIL INFORMATION OF ALL BYPASS CONFIGURATIONS –BASED ON THE DYNAMIC SIMULATION STUDY- PLS. REFER TO

48 05 THE ELLIOTT PROCESS PID: 0012KC-P-FP-0801

49

50

51

52

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 15 of 33

1 UTILITIES

2 z COOLING WATER (FOR OIL COOLER AND GLANDSTEAM CONDENSER)

3 MIN NORMAL MAX MECH.DESIGN

4 02 SUPPLY PRESSURE BAR G 3.5 4.5 8.4

5 SUPPLY TEMPERATURE °C 25 33 35 65

6 RETURN PRESSURE BAR G 2.5 8.4

7 02 RETURN TEMPERATURE °C 42 65

2

8 02 FOULING FACTOR M K/W 0.00034

9 WATER SOURCE z COOLING TOWER { FRESH WATER

10 03 { OTHER z CHLORIDE MG/L 51

11 CORROSION DUE TO

12 MATERIAL

13

14 02 z INSTRUMENT AIR (FREE OF OIL)

15 MIN NORMAL MAX MECH.DESIGN

16 04 PRESSURE BAR G 4.0 5.5 8.8

17 TEMPERATURE °C AMBIENT AMBIENT AMBIENT 65

18 DEW POINT @ ATM. °C -40

19

20 02 z INERT GAS (NITROGEN) (FREE OF OIL)

21 05 (LP-N2) MIN NORMAL MAX MECH.DESIGN

22 04 PRESSURE BAR G 4.0 5.0 6.0 10.3

23 TEMPERATURE °C AMBIENT AMBIENT 65

24 02 DEW POINT @ ATM. °C -100

25

26 z STEAM @ HEADER => FOR CONDITIONS AT TURBINE FLANGES REFER TO TURBINE DATA SHEETS

27 MIN NORMAL MAX MECH.DESIGN

28 02 VHP PRESSURE BAR G 102 118.0

29 TEMPERATURE °C 500 0 / 530

30 HP PRESSURE BAR G 35.0 40.0

31 02 TEMPERATURE °C 370 0 / 475

32 04 MP PRESSURE BAR G 12.0 13.0 14.0 18.0

33 03 TEMPERATURE °C 260 280 300 0 / 380

34 03 LP PRESSURE BAR G 3 3.0 4.0 7.5

35 03 TEMPERATURE °C 185 210 230 0 / 300

36 04 COND. PRESSURE BAR G 0.18 BAR A F.V / 1.0

37

38 z ELECTRICITY

39 VOLTAGE HERTZ PHASES

40 DRIVERS BELOW 0.18 KW 230 (+/- 6%) 50 (+/- 3%) 1

41 DRIVERS BETWEEN 0.18 AND 160 KW 415 (+/- 6%) 50 (+/- 3%) 3

42 DRIVERS ABOVE 160 KW 6 600 (+/- 6%) 50 (+/- 3%) 3

43 HEATING > 2KW 230 (+/- 6%) 50 (+/- 3%) 1

44 CONTROL MAINS & INSTRUMENTATION

45 SOLENOIDS; PLC; TRANSMITTERS

46 03 TOTAL UTILITY CONSUMPTION FOR MORE DETAILS REFER TO UTILITY LIST: 0012KC6401-11-P-CU

47 04 COOLING WATER (CW), OIL OOLER M³/H ~ 150 (FOR EACH)

48 04 CW, OIL OOLER FOR OIL PUMP M³/H ~ 0.5

49 04 POWER MAIN OIL PUMP (STEAM) KG/H ~ 15650 SEAL GAS HEATER (KW) N.A.

50 04 POWER AUX. OIL PUMP KW 160 JACKING OIL PUMP (KW) N.A.

51 04 POWER EMERGENCY OIL PUMP KW 18.5 LOCAL CONTROL PANEL (VA) SEE 11-KT-301

52 04 HEATERS, OIL TANK KW 36

53 04 INSTRUMENT AIR,CONTR VALVE NM³/H ~ 12

54 04 INERT GAS N2, OILTANK NM³/H 40

55 REMARKS:

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 16 of 33

1 CONSTRUCTION FEATURES LP COMPRESSOR CASING

2 SPEEDS

3 MIN. 80% 100% MAX.CONT.: 105% TRIP SPEED

4 04 RANGE 1) RPM 3134 3918 4114 4525

5

6 LATERAL CRITICAL SPEEDS 1ST 2ND 3RD 4TH

7 UNDAMPED (CALC.) RPM

8 05 DAMPED (CALC. / TEST) RPM 1800–1900 / 1885 6600 / ---

9 03 MODE BENDING BENDING

10

11 TORSIONAL CRITICAL SPEEDS 1ST 2ND 3RD 4TH

12 04 RPM 461 923 1092 12299

13 z VIBRATION

14 03 z ALLOWABLE TEST LEVEL (PEAK TO PEAK) µM 25.4

15 (API 617. CHAPTER 1 PARA.2.6.8.8)

16 03 ROTATION, VIEWED FROM TURBINE TO COMPR. { CW z CCW

17

18 03 CASING (WELDED)

19 03 CASING MODEL 88MD2-2 CASING SPLIT HORIZONTAL

20 03 MATERIAL 4) ASTM A516 Gr.60 CASING SEALING METAL TO METAL

21 03 THICKNESS MM ~65 CORROS. ALLOW. MM 3.2

22 03 MAX. CASING CAPACITY M³/H ~ 339500

23 03 MAX. OPER.PRESS.. BAR G 8.0 MAX. OPER. TEMP. °C 170

24 03 MAWP BAR G 8.0 MIN. OPER. TEMP. °C 0

25 03 TEST PRESS. HYDRO BAR G 12.0 MIN/MAX ALLOW. TEMP. °C 0 / +170

26 TEST PRESS. HELIUM BAR G

27 RADIOGRAPHIC QUALITY { NO z YES FOR: FOR BUTT WELDS

28

29 04 DIAPHRAGMS MATERIAL JIS SS400 (ASTM A36)

30 04 DISCH. VOLUTE MATERIAL ASTM A536 GR.60-40-18

31

32 SHAFT

33 04 MATERIAL AISI 4340 Mod. DIAM. AT COUPLING:

34 04 MAX. YIELD STRENGTH N/MM² 827.8 DRIVE END MM APPR.: 190.5

35 04 SHAFT HARDNESS BNH 248 – 302 NON DRIVE END MM APPR.: 165.1

36 SHAFT END z TAPERED { CYLINDRICAL

37 03 BALANCE PISTON N/A

38 MATERIAL ------ AREA MM² ------

39 FIXATION METHOD ------

40

41 SHAFT SLEEVES

42 04 AT INTERSTAGE - MATERIAL AISI 410 (SS) AT SHAFT END - MATERIAL SS

43

44 LABYRINTHS 2) 3)

45 03 SHAFT END TYPE ABRADABLE ROTATING/STATIONARY ROTATING

46 03 MATERIAL STEEL / FLUOROSINT ABRADABLE SEALS z YES { NO

47

48 03 IMPELLER EYE TYPE ABRADABLE ROTATING/STATIONARY ROTATING

49 03 MATERIAL STEEL / FLUOROSINT ABRADABLE SEALS z YES { NO

50

51 03 IMP. BACK TYPE ABRADABLE ROTATING/STATIONARY ROTATING

52 03 MATERIAL STEEL / FLUOROSINT ABRADABLE SEALS z YES { NO

53

54 03 BALANCE PISTON N/A ROTATING/STATIONARY N/A

55 MATERIAL ABRADABLE SEALS { YES { NO

56 REMARKS:

57 03 1) DELETED

58 03 2) ABRADABLE SEALS: PTFE-MATERIAL (= FLUOROSINT)

59 3) USE OF ALUMINIUM NOT PERMITTED // 4) @ BARREL SECTION

60 04 5) ASTMA34 or Eq.

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 17 of 33

1 CONSTRUCTION FEATURES (CONTINUED) LP COMPRESSOR CASING

2 04 IMPELLERS (WITH VANED RETURN CHANNEL)

3

D3

D2

D0

D1

4 COMPRESSOR STAGE NO. 1ST STAGE (DOUBLE FLOW)

5 04 BEARING SPAN MM ~ 5099

6 IMPELLER NO. 1 2 2 1

7 03 OPEN/CLOSED CLOSED CLOSED CLOSED CLOSED

8 03 2-D / 3-D 3D 3D 3D 3D

9 03 IMP. FABRICATION WELDED CLOSED CLOSED CLOSED

10 03 IMP. GEOMETRY D0 MM 540 540 540 540

11 D1 MM

12 04 D2 MM 1459 1452 1452 1459

13 03 B MM 99.1 81.9 81.9 99.1

14 04 β IN/OUT °/ ° 32.4 / 52.9 31.2 / 49.6 31.2 / 49.6 32.4 / 52.9

15 03 NO. OF BLADES 13 15 15 13

16 04 MACH NO. @ IMP. EYE 1) 0.49 0.45 0.45 0.49

17 04 DIFF.GEOMETRY D3 MM 2068 2241 2241 2068

18 03 DIFFUSER VANED / UNVANED U U U U

19 04 POLYTR. HEAD KJ/KG 40.41 41.29 41.29 40.41 @ DESIGN

20 03 FLOW COEFF. ϕ = V / ((π/4)D2²U2) 2) 0.113 0.083 0.083 0.113 @ DESIGN

-4 -4 -4 -4

21 03 PRESS. COEFF. ψ = 2Y / U2² 2) 10.0x10 11.0x10 11.0x10 10.0x10 @ DESIGN

22 04 POLYTR. EFFICIENCY % 88.6 87.7 87.7 88.6 @ DESIGN

23 03 MATERIALS: DISC 17-4PH 17-4PH 3)

24 03 COVER 17-4PH 17-4PH 3)

25 03 VANES 17-4PH 17-4PH 3)

26 03 TIP SPEED @ 100% SPEED M/S 300 300 300 300

27 04 MAX. YIELD STRENGTH N/MM² 896.3 827.4 827.4 896.3 3)

28 03 BRINELL HARDN.: MAX./ MIN. BNH 311 / 258 311 / 258 311 / 258 311 / 258

29 COUPLINGS & GUARDS

30 z COUPLING BETWEEN z MP & LP CASING { LP & HP CASING

31 z COUPLING FURNISHED BY VENDOR

32 03 z TYPE DRY FLEXIBLE TYPE

33 z LUBRICATION NON LUBE

34 04 MANUFACTURER EAGLE

35 04 MODEL 100E416

36 04 RATING/RPM / S.F. KW/100RPM 1510 KW/100 RPM / S.F. 1.52

37 04 MAX. OUTER DIAMETER MM 433.1

38 04 DISTANCE TO GUARD MM ~ 50

39 04 SPACER/ WT/ LENGTH/ DBSE 83.5 KG / 1180.7 / 1200

40 04 COUPLING TAPER 1/16

41 04 COUPLING MATERIAL SNCM 439

42 04 HUB WEIGHT KG 68.4 / 68.4

43 04 TOTAL WEIGHT KG 220.3

44 z GUARD FURNISHED BY: { COMPR. VENDOR z COMPR. VENDOR { COMPR. VENDOR

45 z TYPE: z NON SPARKING z FULLY CLOSED z OIL TIGHT

46 04 z GUARD VENT(S) / DRAIN 5) NUMBER 2 SIZE MIN 2" MATERIAL ALUM. (NON SPARKING)

47 z VENDOR MOUNT COUPLING HALF z VENDOR SHIP COUPLING HALF TO DRIVER MFR

48 03 REMARKS: 1) @ 100% SPEED (CASE 14)

49 2) V: ACTUAL INLET VOLUME (M³/S), D2: IMPELLER DIAMETER, U2: TIP SPEED (M/S) Y: STAGE HEAD (KJ/KG)

50 02 3) MATERIALS SUITABLE FOR SOUR GAS SERVICE ACCORDING TO NACE-STANDARD

51 03 4) DELETED

52 03 5) TEMPERATURE INSIDE THE GUARD SHALL NOT EXCEED + 90 °C // PERSONNEL PROTECTION (WIRE FENCE) TO BE USED

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 18 of 33

1 CONSTRUCTION FEATURES (CONTINUED) LP COMPRESSOR CASING

2 BEARING HOUSING CONSTRUCTION

3 03 TYPE (SEPARATE/INTEGRAL) SEPARATE SPLIT HORIZONTAL

4 04 MATERIAL JIS SS400 z PROVISION FOR N2 PURGING (1/4 NPT)

5 04

6 BEARING AND BEARING HOUSINGS

7 LOCATION RADIAL INLET DISCHARGE

8 z TYPE 1) TILTING PAD TILTING PAD

9 03 MANUFACTURER ELLIOTT ELLIOTT

10 04 DIAMETER / LENGTH MM 254 / 203.2 254 / 203.2

11 04 LOADING ACTUAL / ALLOW. N/MM² 1.18 / 4.14 1.17 / 4.14

12 04 MATERIAL BASE / BABBITT 2) CS / TIN CS / TIN

13 03 LOAD B'TWN / ON PAD B'TWN B'TWN

14 03 PIVOT: CTR / OFF SET % CTR CTR

15 NO. OF PADS 5 5

16 03 z LUBRICATION FLOODED / DIRECTED FLOODED

17

18 THRUST BEARING LOCATED AT:

19 z LOCATION THRUST ACTIVE INACTIVE

20 TYPE 1) TILTING PAD TILTING PAD

21 04 MANUFACTURER KINGSBURY KINGSBURY

22 03 AREA MM² 67548 67548

23 03 LOADING ACTUAL / ALLOW. N/MM² - / 6.0 - / 6.0

24 03 MATERIAL BASE / BABBITT 2) CS / TIN CS / TIN

25 PIVOT: CTR / OFF SET % CTR CTR

26 03 NO. OF PADS 6 6

27 03 LUBRICATION FLOODED / DIRECTED FLOODED

28 z THRUST COLLAR INTEGR./REPL. REPLACEABLE

29 03 THRUST COLLAR MATERIAL JIS SNCM 439 (AISI 4340 OR EQ.)

30

31 BEARING TEMPERATURE DEVICES

32 { THERMOCOUPLES { SINGLE { DOUBLE ELEMENTS

33 z RESISTANCE TEMP. DETECTORS { SINGLE z DOUBLE ELEMENTS

34 z RESISTANCE MATERIAL PT OHMS 100

35 LOCATION: RADIAL BEARING

36 NO. OF SENSORS EACH BRG. TWO

37 LOCATION: THRUST BEARING

38 NO. OF SENSORS ACT. / INACT. TWO / TWO

39 z MONITOR SUPPL. BY VENDOR

40 z LOCATION CCR { ENCLOSURE

41 z MANUFACTURER BN MODEL

42 05 SCALE RANGE 3)

43 05 ALARM SET °C 3) SHUTDOWN SET °C 3)

44

45 REMARKS:

46 1) TO BE SUITABLE FOR REVERSE ROTATION

47 03 2) THE USE OF COPPER & COPPER ALLOYS IS ACCEPTABLE FOR BEARING PADS-METAL

48 05 3) ALARM AND SHUTDOWN VALUES ARE SHOWN IN THE ELLIOTT INSTRUMENT LIST: 0012KC6401-11-J-LA-3100.001

49

50

51

52

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 19 of 33

1 CONSTRUCTION FEATURES (CONTINUED) LP COMPRESSOR CASING

2 z SHAFT END SEALS 1) )

3 SEAL TYPE { LABYRINTH

4 { MECHANICAL SEAL { SINGLE { DOUBLE

5 z DRY GAS SEAL { SINGLE z TANDEM { DOUBLE

6 z INTERMEDIATE LABYRINTHS { LABYRINTHS @ BEARING SIDE

7 z CARBON RINGS & SEPARATION GAS AS SEPARATION SEAL

8 { OTHER:

9 04 MANUFACTURER JOHN CRANE MODEL 28ATBD

10 04 NOTE: SEALS ARE BALANCED

11 BUFFER GAS- / SEAL GAS SYSTEM (DATA PER SHAFT SEAL)

12 03 z DRY GAS SEAL (TANDEM GAS SEAL)

13

to safe

6 4 3 1

location Process

Bearing 5 2 side

side

14 z 1 TYPE PRIMARY SEALGAS C2 - 4) z 1 SOURCE OPER./START UP ETHYLENE 4)

15 04 1 PRIMARY SEALGAS FLOW KG/H

228 1 PRIMARY SEALGAS PRESS. BARG 35.6 4)

16 04 2 LEAK GAS FLOW (GUAR.) 2) KG/H 0.50 / 1.28 3 FLOW TO FLARE MIN / MAX KG/H / 24.9

17 02 z 4 TYPE SECONDARY SEALGAS NITROGEN z 3 MIN/MAX: FLARE BACK PRESS. BARG 0.2 / 2.5 5)

18 04 4 SECONDARY SEALGAS FLOW KG/H 24.4 4 SECONDARY SEALGAS PRESS BARG 0.4

19 04 z 5 LEAKGAS FLOW (GUAR.) 2) KG/H 0.35 / 0.71 5 SEPARATION GAS PRESS. BARG 0.45

20 z 6 TYPE SEPARATION GAS NITROGEN z SLOW ROLL REQUIRED YES

21 04 6 SEPARATION GAS FLOW KG/H 8.5 / 17.03 LIFT OFF SPEED RPM 230

22 03 MATERIAL STATIONARY RING CARBON MATERIAL ROTATING RING SILICON CARBIDE

23 { DRY GAS SEAL (DOUBLE GAS SEAL)

24

Bearing 4 3 2

1 Process

side side

25 { 1 TYPE BUFFER GAS { 1 SOURCE OPER./START UP

26 1 BUFFER GAS FLOW NM³/H 1 BUFFER GAS PRESS. BARG

27 { 2 TYPE SEAL GAS SUPPLY 2 SEAL GAS PRESSURE BARG

28 { 2 SEAL GAS FLOW (GUAR:) 2) NM³/H 4 SEPARATION GAS PRESS. BARG

29 3 FLOW TO SAFE AREA NM³/H

30 4 TYPE SEPARATION GAS { SLOW ROLL REQUIRED

31 4 SEPARATION GAS FLOW 2) NM³/H LIFT OFF SPEED RPM

32 MATERIAL STATIONARY RING MATERIAL ROTATING RING

33 04 REMARKS: ) WITHIN THE TRAIN, THE SAME MATERIAL COMPONENTS AND O-RING-MATERIAL WILL BE USED

34 1) TO BE SUITABLE FOR REVERSE ROTATION / BI-DIRECTIONAL TYPE

35 04 2) NORM FLOW / MAX. FLOW (GUARANTEED ) - INDICATION

36 03 3) ----

37 02 4) FOR SEAL GAS CONDITIONS REFER TO PAGE 3, AT START-UP ETHYLENE OR ETHANE IS USED AS EXTERNAL GAS

38

39 03 PRIMARY SEAL GAS IS REQUIRED FOR TURNING OF ROTOR (AFTER SHUT DOWN OF THE COMPR.-UNIT) AS PER VENDOR DESIGN

40 03

41 04 INITIAL PLANT-START UP CASE FOR 11-KC-301: AN EMERGENCY BACKUP WITH N2-SUPPLY VIA N2 LORRY FOR THE PRIMARY

42 04 SEAL IS NECESSARY (ONLY IN CASE OF A FAILURE OF 11-KC-401 COMPRESSOR)- TEMPORARY FACILITY ONLY-

43 04 - NORMAL CASE: THE ETHYLENE/ETHANE GAS –SUPPLIED BY 11-KC-401-COMPR. WILL BE USED FOR THE PRIMARY SEALS

44 04 - FOR FURTHER DETAILS / REQUIRED DEPRESSURIZATION AFTER STOP OF 11-KC-301 – REFER TO THE SEAL GAS CONCEPT

45 04 (DOCUMENT NUMBER: &AA-00-P-PA 1210)

46

47 04 SEALS FOR AIR DRYING CASE: NO OTHER / SPECIAL SEALS REQUIRED

48 02 5) FLARE HEADER – MECHAN. DESIGN PRESSURE: 3,5 BARG

49

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 20 of 33

1 CONSTRUCTION FEATURES (CONTINUED) LP COMPRESSOR CASING

2 VIBRATION DETECTORS 1)

3 z TYPE: NON CONTACT MODEL

4 z MANUFACTURER BN

5 z NO. @ EA SHAFT BEARING TWO TOTAL NO. FOUR

6 z OSCILLATOR-DETECTOR BN SUPPLIED BY VENDOR

7 03 z MANUFACTURER BN MODEL 3500

8 MONITOR: z SUPPLIED BY VENDOR

9 z LOCATION CCR { ENCLOSURE

10 z MANUFACTURER BN MODEL

11 05 SCALE RANGE 2) TIME DELAY SEC.

12 05 ALARM SET µM 2) SHUTDOWN SET µM 2)

13

14 KEY PHASOR

15 z TYPE: NON CONTACT MODEL

16 z MANUFACTURER BN

17 z NO. @ EA SHAFT BEARING ONE PER SHAFT TOTAL NO. ONE

18 z OSCILLATOR-DETECTOR BN SUPPLIED BY VENDOR

19

20

21 AXIAL POSITION DETECTOR

22 z TYPE: NON CONTACT MODEL

23 z MANUFACTURER BN z NO. REQUIRED P. SHAFT TWO

24 z OSCILL.-DEMODULATOR BN SUPPLIED BY VENDOR

25 03 z MANUFACTURER BN MODEL 3500

26 MONITOR: SUPPLIED BY VENDOR

27 z LOCATION CCR { ENCLOSURE

28 z MANUFACTURER BN MODEL

29 05 SCALE RANGE 2) TIME DELAY SEC

30 05 ALARM SET MM 2) SHUTDOWN SET MM 2)

31

32 CASING VIBRATION TRANSDUCERS NOT APPLICABLE

33 { TYPE: MODEL

34 { MANUFACTURER { NO. REQUIRED

35 { LOCATION

36 { OSCILL.-DEMODULATOR SUPPLIED BY

37 { MANUFACTURER MODEL

38 MONITOR: SUPPLIED BY

39 { LOCATION { ENCLOSURE

40 { MANUFACTURER MODEL

41 SCALE RANGE

42 ALARM SET µM SHUTDOWN SET µM

43

44 REMARKS:

45 1) PREFERRED ARRANGEMENT 45° / 45° FROM HORIZONTAL

46

47 COMPRESSION FITTINGS AT CASING FOR BEARING TEMPERATURE PROBES AND NON CONTACT PROBES TO BE OILTIGHT

48

49 05 2) ALARM AND SHUTDOWN VALUES ARE SHOWN IN THE ELLIOTT INSTRUMENT LIST: 0012KC6401-11-J-LA-3100.001

50

51

52

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 21 of 33

1 CONSTRUCTION FEATURES MP COMPRESSOR CASING

2 SPEEDS

3 MIN. 80% 100% MAX.CONT.: 105% TRIP SPEED

4 04 RANGE 1) RPM 3134 3918 4114 4525

5

6 LATERAL CRITICAL SPEEDS 1ST 2ND 3RD 4TH

7 UNDAMPED (CALC.) RPM

8 05 DAMPED (CALC. / TEST) RPM 1900-2000 / 1952 5700 / ---

9 03 MODE BENDING BENDING

10

11 TORSIONAL CRITICAL SPEEDS 1ST 2ND 3RD 4TH

12 04 RPM 461 923 1092 12299

13 z VIBRATION

14 03 z ALLOWABLE TEST LEVEL (PEAK TO PEAK) µM 25,4

15 (API 617. CHAPTER 1 PARA.2.6.8.8)

16 03 ROTATION, VIEWED FROM TURBINE TO COMPR. { CW z CCW

17

18 03 CASING (WELDED)

19 03 CASING MODEL 88M4I CASING SPLIT HORIZONTAL

20 03 MATERIAL 4) ASTM A516 Gr.60 CASING SEALING METAL TO METAL

21 03 THICKNESS MM ~65 CORROS. ALLOW. MM 3.2

22 03 MAX. CASING CAPACITY M³/H ~ 339000

23 03 MAX. OPER.PRESS.. BAR G 14.0 MAX. OPER. TEMP. °C 170

24 03 MAWP BAR G 14.0 MIN. OPER. TEMP. °C 0

25 TEST PRESS. HYDRO BAR G 21.0 MIN/MAX ALLOW. TEMP. °C 0 / +170

26 TEST PRESS. HELIUM BAR G

27 RADIOGRAPHIC QUALITY { NO z YES FOR: FOR BUTT WELDS

28

29 04 DIAPHRAGMS MATERIAL JIS SS400 (ASTM A36) AND ASTM A536 GR. 60-40-18

30 04 DISCH. VOLUTES MATERIAL ASTM A536 GR.60-40-18

31

32 SHAFT

33 04 MATERIAL AISI 4340 Mod. DIAM. AT COUPLING:

34 03 MAX. YIELD STRENGTH 827.8 DRIVE END MM APPR.: 228.6

35 03 SHAFT HARDNESS 248 – 302 NON DRIVE END MM APPR.: 190.5

36 SHAFT END z TAPERED { CYLINDRICAL

37 BALANCE PISTON

38 03 MATERIAL AISI 4140 AREA MM²

39 03 FIXATION METHOD SHRINK FIT

40

41 SHAFT SLEEVES

42 04 AT INTERSTAGE - MATERIAL AISI 410 (SS) AT SHAFT END - MATERIAL SS

43

44 LABYRINTHS 2) 3)

45 03 SHAFT END TYPE ABRADABLE ROTATING/STATIONARY ROTATING

46 03 MATERIAL STEEL / FLUOROSINT ABRADABLE SEALS z YES { NO

47

48 03 IMPELLER EYE TYPE ABRADABLE ROTATING/STATIONARY ROTATING

49 03 MATERIAL STEEL / FLUOROSINT ABRADABLE SEALS z YES { NO

50

51 03 IMP. BACK TYPE ABRADABLE ROTATING/STATIONARY ROTATING

52 03 MATERIAL STEEL / FLUOROSINT ABRADABLE SEALS z YES { NO

53

54 03 BALANCE PISTON ABRADABLE ROTATING/STATIONARY ROTATING

55 03 MATERIAL STEEL / FLUOROSINT ABRADABLE SEALS z YES { NO

56 REMARKS:

57 03 1) DELETED

58 03 2) ABRADABLE SEALS: PTFE-MATERIAL (= FLUOROSINT)

59 03 3) USE OF ALUMINIUM NOT PERMITTED // 4) @ BARREL SECTION

60 04 5) ASTMA34 or Eq

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 22 of 33

1 CONSTRUCTION FEATURES (CONTINUED) MP COMPRESSOR CASING

2 04 IMPELLERS (INLINE CONCEPT WITH VANED RETURN CHANNEL)

3

D3

D2

D0

D1

4 COMPRESSOR STAGE NO. ND 2 STAGE 3RD STAGE

5 04 BEARING SPAN MM ~ 4952

6 IMPELLER NO. 1 2 3 4

7 OPEN/CLOSED CLOSED CLOSED

8 2-D / 3-D 3D 3D

9 IMP. FABRICATION WELDED WELDED

10 03 IMP. GEOMETRY D0 MM 522 522 522 522

11 D1 MM

12 04 D2 MM 1410 1410 1410 1368

13 03 B MM 107 94 84 74

14 04 β IN/OUT °/ ° 31.7 / 52.9 30.4 / 49.7 30.6 / 43.0 32.0 / 39.0

15 03 NO. OF BLADES 13 15 15 15

16 04 MACH NO. @ IMP. EYE 1) 0.49 0.45 0.43 0.39

17 04 DIFF.GEOMETRY D3 MM 2068 2201 2186 2228

18 03 DIFFUSER VANED / UNVANED U U U U

19 04 POLYTR. HEAD KJ/KG 37.30 39.44 39.89 36.46 @ C1-100

20 03 FLOW COEFF. ϕ = V / ((π/4)D2²U2) 2) 0.129 0.096 0.064 0.047 @ C1-100

-4 -4 -4 -4

21 03 PRESS. COEFF. ψ = 2Y / U2² 2) 10.0x10 11.0x10 11.0x10 10.0x10 @ C1-100

22 04 POLYTR. EFFICIENCY % 88.0 88.5 88.9 88.2 @ C1-100

23 03 MATERIALS: DISC 17-4PH 17-4PH 3)

24 03 COVER 17-4PH 17-4PH 3)

25 03 VANES 17-4PH 17-4PH 3)

26 03 TIP SPEED @ 100% SPEED M/S 289.9 289.9 289.9 289.9

27 04 MAX. YIELD STRENGTH N/MM² 896.3 827.4 827.4 827.4 3)

28 03 BRINELL HARDN. MAX./MIN. BNH 311 / 258 311 / 258 311 / 258 311 / 258

29 COUPLINGS & GUARDS

30 z COUPLING BETWEEN z MP CASING & TURBINE { MP CASING & LP CASING

31 z COUPLING FURNISHED BY VENDOR

32 03 z TYPE DRY FLEXIBLE TYPE

33 z LUBRICATION NON LUBE

34 04 MANUFACTURER EAGLE

35 04 MODEL 100F322

36 04 RATING/RPM / S. F. KW/ 100 RPM 2510 KW/100 RPM / S.F. 1.53

37 04 MAX. OUTER DIAMETER MM 568.3

38 DISTANCE TO GUARD MM ~ 50

39 04 SPACER/ WT/ LENGTH/ DBSE 109 KG / 1133.6 / 1200

40 04 COUPLING TAPER 1/16

41 04 COUPLING MATERIAL SNCM 439

42 04 HUB WEIGHT KG 37.7 / 128.5

43 04 TOTAL WEIGHT KG 275.2

44 z GUARD FURNISHED BY: { COMPR. VENDOR z COMPR. VENDOR { COMPR. VENDOR

45 z TYPE: z NON SPARKING z FULLY CLOSED z OIL TIGHT

46 04 z GUARD VENT(S) / DRAIN 5) NUMBER 2 SIZE MIN.: 2" MATERIAL ALUM. (NON SPARKING)

47 z VENDOR MOUNT COUPLING HALF z VENDOR SHIP COUPLING HALF TO DRIVER MFR

48 03 REMARKS: 1) @ 100% SPEED (CASE 14)

49 2) V: ACTUAL INLET VOLUME (M³/S), D2: IMPELLER DIAMETER, U2: TIP SPEED (M/S) Y: STAGE HEAD (KJ/KG)

50 02 3) MATERIALS SUITABLE FOR SOUR GAS SERVICE ACCORDING TO NACE-STANDARD

51 03 4) DELETED

52 03 5) TEMPERATURE INSIDE THE GUARD SHALL NOT EXCEED + 90 °C // PERSONNEL PROTECTION (WIRE FENCE) TO BE USED

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 23 of 33

1 CONSTRUCTION FEATURES (CONTINUED) MP COMPRESSOR CASING

2 BEARING HOUSING CONSTRUCTION

3 03 TYPE (SEPARATE/INTEGRAL) SEPARATE SPLIT HORIZONTAL

4 04 MATERIAL JIS SS400 z PROVISION FOR N2 PURGING (1/4" NPT)

5 04

6 BEARING AND BEARING HOUSINGS

7 LOCATION RADIAL INLET DISCHARGE

8 z TYPE 1) TILTING PAD TILTING PAD

9 03 MANUFACTURER ELLIOTT ELLIOTT

10 03 DIAMETER / LENGTH MM 254 / 203.2 254 / 203.2

11 04 LOADING ACTUAL / ALLOW. N/MM² 1.06 / 4.14 1.12 / 4.14

12 04 MATERIAL BASE / BABBITT 2) CS / TIN CS / TIN

13 03 LOAD B'TWN / ON PAD B'TWN B'TWN

14 03 PIVOT: CTR / OFF SET % CTR CTR

15 NO. OF PADS 5 5

16 03 z LUBRICATION FLOODED / DIRECTED FLOODED

17

18 THRUST BEARING LOCATED AT:

19 z LOCATION THRUST ACTIVE INACTIVE

20 TYPE 1) TILTING PAD TILTING PAD

21 04 MANUFACTURER KINGSBURY KINGSBURY

22 03 AREA MM² 86710 86710

23 03 LOADING ACTUAL / ALLOW. N/MM² 0.78 / 6.28 - / 6.28

24 03 MATERIAL BASE / BABBITT 2) CS / TIN CS / TIN

25 PIVOT: CTR / OFF SET % CTR CTR

26 03 NO. OF PADS 6 6

27 03 LUBRICATION FLOODED / DIRECTED FLOODED

28 z THRUST COLLAR INTEGR./REPL. REPLACEABLE

29 03 THRUST COLLAR MATERIAL JIS SNCM 439 (AISI 4340 OR EQ.)

30

31 BEARING TEMPERATURE DEVICES

32 { THERMOCOUPLES { SINGLE { DOUBLE ELEMENTS

33 z RESISTANCE TEMP. DETECTORS { SINGLE z DOUBLE ELEMENTS

34 z RESISTANCE MATERIAL PT OHMS 100

35 LOCATION: RADIAL BEARING

36 NO. OF SENSORS EACH BRG. TWO

37 LOCATION: THRUST BEARING

38 NO. OF SENSORS ACT. / INACT. TWO / TWO

39 z MONITOR SUPPL. BY VENDOR

40 z LOCATION CCR { ENCLOSURE

41 z MANUFACTURER BN MODEL

42 05 SCALE RANGE 3)

43 05 ALARM SET °C 3) SHUTDOWN SET °C 3)

44

45 REMARKS:

46 1) TO BE SUITABLE FOR REVERSE ROTATION

47 03 2) THE USE OF COPPER & COPPER ALLOYS IS ACCEPTABLE FOR BEARING PADS-METAL

48 05 3) ALARM AND SHUTDOWN VALUES ARE SHOWN IN THE ELLIOTT INSTRUMENT LIST: 0012KC6401-11-J-LA-3100.001

49

50

51

52

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 24 of 33

1 CONSTRUCTION FEATURES (CONTINUED) MP COMPRESSOR CASING

2 z SHAFT END SEALS 1) )

3 SEAL TYPE { LABYRINTH

4 { MECHANICAL SEAL { SINGLE { DOUBLE

5 z DRY GAS SEAL { SINGLE z TANDEM { DOUBLE

6 z INTERMEDIATE LABYRINTHS { LABYRINTHS @ BEARING SIDE

7 z CARBON RINGS & SEPARATION GAS AS SEPARATION SEAL

8 { OTHER:

9 04 MANUFACTURER JOHN CRANE MODEL 28ATBD

10 04 NOTE: SEALS ARE BALANCED

11 BUFFER GAS- / SEAL GAS SYSTEM (DATA PER SHAFT SEAL)

12 03 z DRY GAS SEAL (TANDEM GAS SEAL)

13

to safe

6 4 3 1

location Process

Bearing 5 2 side

side

14 z 1 TYPE PRIMARY SEALGAS C2 - 4) z 1 SOURCE OPER./START UP ETHYLENE 4)

15 04 1 PRIMARY SEALGAS FLOW KG/H

313 1 PRIMARY SEALGAS PRESS. BARG 35.6 4)

16 04 2 LEAK GAS FLOW (GUAR.) 2) KG/H 0.5 / 1.28 3 FLOW TO FLARE MIN / MAX KG/H / 24.9

17 02 z 4 TYPE SECONDARY SEALGAS NITROGEN 3 MIN/MAX: FLARE BACK PRESS. BARG BARG

18 04 4 SECONDARY SEALGAS FLOW KG/H 24.4 4 SECONDARY SEALGAS PRESS BARG 0.4

19 04 z 5 LEAKGAS FLOW (GUAR.) 2) KG/H 0.35 / 0.71 5 SEPARATION GAS PRESS. BARG 0.45

20 z 6 TYPE SEPARATION GAS NITROGEN z SLOW ROLL REQUIRED YES

21 04 6 SEPARATION GAS FLOW KG/H 8.51 / 17.03 LIFT OFF SPEED RPM 230

22 04 MATERIAL STATIONARY RING CARBON MATERIAL ROTATING RING SILICON CARBIDE

23 { DRY GAS SEAL (DOUBLE GAS SEAL)

24

Bearing 4 3 2

1 Process

side side

25 { 1 TYPE BUFFER GAS { 1 SOURCE OPER./START UP

26 1 BUFFER GAS FLOW NM³/H 1 BUFFER GAS PRESS. BARG

27 { 2 TYPE SEAL GAS SUPPLY 2 SEAL GAS PRESSURE BARG

28 { 2 SEAL GAS FLOW (GUAR:) 2) NM³/H 4 SEPARATION GAS PRESS. BARG

29 3 FLOW TO SAFE AREA NM³/H

30 4 TYPE SEPARATION GAS { SLOW ROLL REQUIRED

31 4 SEPARATION GAS FLOW 2) NM³/H LIFT OFF SPEED RPM

32 MATERIAL STATIONARY RING MATERIAL ROTATING RING

33 04 REMARKS: ) WITHIN THE TRAIN, THE SAME MATERIAL COMPONENTS AND O-RING-MATERIAL WILL BE USED

34 1) TO BE SUITABLE FOR REVERSE ROTATION / BI-DIRECTIONAL TYPE

35 03 2) NORM FLOW / MAX. FLOW (GUARANTEED) - INDICATION

36 03 3) ---

37 02 4) FOR SEAL GAS CONDITIONS REFER TO PAGE 3, AT START-UP ETHYLENE OR ETHANE IS USED AS EXTERNAL GAS

38

39 03 PRIMARY SEAL GAS IS REQUIRED FOR TURNING OF ROTOR (AFTER SHUT DOWN OF THE COMPR.-UNIT) AS PER VENDOR DESIGN

40 03

41

42 04 INITIAL PLANT-START UP CASE - EMERGENCY BACKUP: SEE NOTE ON PAGE 19

43

44

45

46 04 SEALS FOR AIR DRYING CASE: NO OTHER / SPECIAL SEALS REQUIRED

47

48 02 5) FLARE HEADER – MECHAN. DESIGN PRESSURE: REFER TO PAGE 19

49

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 25 of 33

1 CONSTRUCTION FEATURES (CONTINUED) MP COMPRESSOR CASING

2 VIBRATION DETECTORS 1)

3 z TYPE: NON CONTACT MODEL

4 z MANUFACTURER BN

5 z NO. @ EA SHAFT BEARING TWO TOTAL NO. FOUR

6 z OSCILLATOR-DETECTOR BN SUPPLIED BY VENDOR

7 03 z MANUFACTURER BN MODEL 3500

8 MONITOR: z SUPPLIED BY VENDOR

9 z LOCATION CCR { ENCLOSURE

10 z MANUFACTURER BN MODEL

11 05 SCALE RANGE 2) TIME DELAY SEC.

12 05 ALARM SET µM 2) SHUTDOWN SET µM 2)

13

14 KEY PHASOR

15 z TYPE: NON CONTACT MODEL

16 z MANUFACTURER BN

17 z NO. @ EA SHAFT BEARING ONE PER SHAFT TOTAL NO. ONE

18 z OSCILLATOR-DETECTOR BN SUPPLIED BY VENDOR

19

20

21 AXIAL POSITION DETECTOR

22 z TYPE: NON CONTACT MODEL

23 z MANUFACTURER BN z NO. REQUIRED P. SHAFT TWO

24 z OSCILL.-DEMODULATOR BN SUPPLIED BY VENDOR

25 03 z MANUFACTURER BN MODEL 3500

26 MONITOR: SUPPLIED BY VENDOR

27 z LOCATION CCR { ENCLOSURE

28 z MANUFACTURER BN MODEL

29 05 SCALE RANGE 2) TIME DELAY SEC

30 05 ALARM SET MM 2) SHUTDOWN SET MM 2)

31

32 CASING VIBRATION TRANSDUCERS NOT APPLICABLE

33 { TYPE: MODEL

34 { MANUFACTURER { NO. REQUIRED

35 { LOCATION

36 { OSCILL.-DEMODULATOR SUPPLIED BY

37 { MANUFACTURER MODEL

38 MONITOR: SUPPLIED BY

39 { LOCATION { ENCLOSURE

40 { MANUFACTURER MODEL

41 SCALE RANGE

42 ALARM SET µM SHUTDOWN SET µM

43

44 REMARKS:

45 1) PREFERRED ARRANGEMENT 45° / 45° FROM HORIZONTAL

46

47 COMPRESSION FITTINGS AT CASING FOR BEARING TEMPERATURE PROBES AND NON CONTACT PROBES TO BE OILTIGHT

48

49 05 2) ALARM AND SHUTDOWN VALUES ARE SHOWN IN THE ELLIOTT INSTRUMENT LIST: 0012KC6401-11-J-LA-3100.001

50

51

52

53

54

55

56

57

58

59

60

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 26 of 33

1 CONSTRUCTION FEATURES HP COMPRESSOR CASING

2 SPEEDS

3 MIN. 80% 100% MAX.CONT.: 105% TRIP SPEED

4 04 RANGE 1) RPM 3134 3918 4114 4525

5

6 LATERAL CRITICAL SPEEDS 1ST 2ND 3RD 4TH

7 UNDAMPED (CALC.) RPM

8 05 DAMPED (CALC. / TEST) RPM 1800-1900 / 1905 6300 / ---

9 03 MODE BENDING BENDING

10

11 TORSIONAL CRITICAL SPEEDS 1ST 2ND 3RD 4TH

12 RPM 461 923 1092 12299

13 z VIBRATION

14 03 z ALLOWABLE TEST LEVEL (PEAK TO PEAK) µM 25.4

15 (API 617. CHAPTER 1 PARA.2.6.8.8)

16 03 ROTATION, VIEWED FROM TURBINE TO COMPR. { CW z CCW

17

18 03 CASING (WELDED)

19 03 CASING MODEL 60M4/4I CASING SPLIT HORIZONTAL

20 03 MATERIAL 4) ASTM A516 Gr.60 CASING SEALING METAL TO METAL

21 04 THICKNESS MM ~70 CORROS. ALLOW. MM 3.2

22 03 MAX. CASING CAPACITY M³/H ~ 71300

23 03 MAX. OPER.PRESS.. BAR G 41.5 MAX. OPER. TEMP. °C 170

24 03 MAWP BAR G 41.5 MIN. OPER. TEMP. °C 0

25 04 TEST PRESS. HYDRO BAR G 62.3 MIN/MAX ALLOW. TEMP. °C 0 / +170

26 TEST PRESS. HELIUM BAR G

27 RADIOGRAPHIC QUALITY { NO z YES FOR: FOR BUTT WELDS

28

29 04 DIAPHRAGMS MATERIAL JIS SS400 (ASTM A36 ) AND ASTM A536 GR.60-40-18

30 04 DISCH. VOLUTE MATERIAL ASTM A536 GR.60-40-18

31

32 SHAFT

33 04 MATERIAL AISI 4340 Mod. DIAM. AT COUPLING:

34 03 MAX. YIELD STRENGTH 827.8 DRIVE END MM APPR.: 165.1

35 03 SHAFT HARDNESS 248 – 302 NON DRIVE END MM N/A

36 SHAFT END z TAPERED { CYLINDRICAL

37 03 CENTER SEAL SLEEVE (BACK TO BACK ARRANGEMENT OF THE IMPELLERS)

38 03 MATERIAL AISI 410SS AREA MM²

39 03 FIXATION METHOD SHRINK FIT

40

41 SHAFT SLEEVES

42 04 AT INTERSTAGE - MATERIAL AISI 410 (SS) AT SHAFT END - MATERIAL SS

43

44 LABYRINTHS 2) 3)

45 03 SHAFT END TYPE ABRADABLE ROTATING/STATIONARY ROTATING

46 03 MATERIAL STEEL / FLUOROSINT ABRADABLE SEALS z YES { NO

47

48 03 IMPELLER EYE TYPE ABRADABLE ROTATING/STATIONARY ROTATING

49 03 MATERIAL STEEL / FLUOROSINT ABRADABLE SEALS z YES { NO

50

51 03 IMP. BACK TYPE ABRADABLE ROTATING/STATIONARY ROTATING

52 03 MATERIAL STEEL / FLUOROSINT ABRADABLE SEALS z YES { NO

53

54 03 CENTER SEAL ABRADABLE ROTATING/STATIONARY ROTATING

55 04 MATERIAL STEEL / NI-CR ABRADABLE SEALS z YES { NO

56 REMARKS:

57 1) DELETED

58 03 2) ABRADABLE SEALS: PTFE-MATERIAL (= FLUOROSINT)

59 03 3) USE OF ALUMINIUM NOT PERMITTED // 4) @ BARREL SECTION

60 04 5) ----

03.11.03 Copying is only allowed after approval by LINDE AG

Code DAHEJ

Job No. 3110 A9NK

Data Sheet Item No. 11-KC-301

CENTRIFUGAL COMPRESSOR Doc. No. &AA-11-M-DE 3101.001

CRACKED GAS COMPRESSION Issue / Date 05 / 31.03.11

Page 27 of 33

1 CONSTRUCTION FEATURES (CONTINUED) HP COMPRESSOR CASING

2 04 IMPELLERS (BACK TO BACK ARRANGEMENT)

3

D3

D2

D0

D1

4 COMPRESSOR STAGE NO. 4TH STAGE 5TH STAGE

5 04 BEARING SPAN MM 4425

6 IMPELLER NO. 1 2 3 4 8 7 6 5

7 OPEN/CLOSED CLOSED CLOSED

8 03 2-D / 3-D 3D 3D

9 03 IMP. FABRICATION WELDED WELDED

10 04 IMP. GEOMETRY D0 MM 355 355 355 355 458 458 458 458

11 D1 MM

12 04 D2 MM 1032 1032 1032 1032 982 1013 1013 1013

13 03 B MM 57 50 45 51 22 23 27 31

14 04 β IN/OUT °/ ° 30.1/ 49.7 30.1/ 49.7 31.2/ 49.7 30.4/ 43.0 32.8/ 61 32.9/ 60 33.1/ 60 33.1/ 60

15 03 NO. OF BLADES 15 15 15 15 15 15 15 15

16 04 MACH NO. @ IMP. EYE 0.33 0.31 0.30 0.28 0.29 0.31 0.30 0.33 1)

17 04 DIFF.GEOMETRY D3 MM 1360 1360 1360 1407 1557 1522 1522 1522

18 03 DIFFUSER VANED / UNVANED U U U U U U U U

19 04 POLYTR. HEAD KJ/KG 20.30 20.73 21.13 20.95 19.72 20.81 21.04 21.20 2)

20 04 FLOW COEFF. ϕ = V / ((π/4)D2²U2) 0.081 0.069 0.059 0.051 0.026 0.030 0.035 0.041 2)

21 03 PRESS. COEFF. ψ = 2Y / U2² 10.0x10-4 10.0x10-4 11.0x10-4 10.0x10-4 11.0x10-4 11.0x10-4 11.0x10-4 11.0x10-4 2)

22 04 POLYTR. EFFICIENCY % 87.3 86.9 86.5 86.8 81.5 82.2 82.9 84.0

23 03 MATERIALS: DISC 3) AISI 410 SS 3)

24 03 COVER 3) AISI 410 SS 3)

25 03 VANES 3) AISI 410 SS 3)

26 04 TIP SPEED @ 100% SPEED M/S 212.0 212.0 212.0 212.0 201.4 207.7 207.7 207.7

27 03 MAX. YIELD STRENGTH N/MM² 620.5 620.5 620.5 620.5 620.5 620.5 620.5 620.5 3)

28 03 BRINELL HARDN. MAX./MIN. BNH 235 / 212 235 / 212 235 / 212 235 / 212 235 / 212 235 / 212 235 / 212 235 / 212

29 COUPLINGS & GUARDS

30 z COUPLING BETWEEN z HP-CASING & LP-CASING

31 z COUPLING FURNISHED BY VENDOR

32 03 z TYPE DRY FLEXIBLE TYPE

33 z LUBRICATION NON LUBE

34 04 MANUFACTURER EAGLE

35 04 MODEL 100E316

36 04 RATING/RPM/S. F. KW/ 100 RPM 1030 KW/100 RPM / S.F. 1.57

37 04 MAX. OUTER DIAMETER MM 433.1

38 DISTANCE TO GUARD MM ~ 50

39 SPACER/ WT/ LENGTH/ DBSE 55.8 KG / 762.6 / 782.2

40 04 COUPLING TAPER 1/16

41 04 COUPLING MATERIAL SNCM 439

42 04 HUB WEIGHT KG 48.4 / 48.5

43 04 TOTAL WEIGHT KG 152.7

44 z GUARD FURNISHED BY: { COMPR. VENDOR z COMPR. VENDOR { COMPR. VENDOR

45 z TYPE: z NON SPARKING z FULLY CLOSED z OIL TIGHT

46 04 z GUARD VENT(S) / DRAIN 5) NUMBER 2 SIZE MIN.: 2" MATERIAL ALUM. (NON SPARKING)

47 z VENDOR MOUNT COUPLING HALF z VENDOR SHIP COUPLING HALF TO DRIVER MFR

48 REMARKS: 1) @ 100% SPEED

49 2) V: ACTUAL INLET VOLUME (M³/S), D2: IMPELLER DIAMETER, U2: TIP SPEED (M/S) Y: STAGE HEAD (KJ/KG)

50 02 3) MATERIALS SUITABLE FOR SOUR GAS SERVICE ACCORDING TO NACE-STANDARD

51 03 4) DELETED