Professional Documents

Culture Documents

Magnavis WCP 2 White Contrast Paint Aerosol

Magnavis WCP 2 White Contrast Paint Aerosol

Uploaded by

InspectorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magnavis WCP 2 White Contrast Paint Aerosol

Magnavis WCP 2 White Contrast Paint Aerosol

Uploaded by

InspectorCopyright:

Available Formats

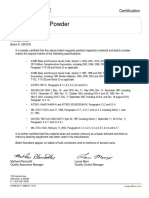

Inspection Certificate

Abnahmeprüfungszeugnis DIN EN 10204.3.1

Certificat De reception

Certificado di collaudo

Keuringsrapport

Magnavis WCP-2 White

Batch Number 220404 Product Name

Contrast Paint Aerosol

Date of Manufacture 06/04/2022 13/04/2022 B.B.E. 04/2025

Specification: Test Results:-

WCP-2 is a rapid drying White Contrast Paint designed to aid contrast during magnetic particle inspection in white light using colour contrast (black

or red) magnetic particles.

We hereby certify that the above material supplied against your order:

A. Meets the requirements of EN ISO 9934-2 & EN ISO 9934-1, Paragraph 7 & 10 as applicable.

B. ASME Boiler and Pressure Vessel Code, 2019 Edition, Section V, Non-destructive Examination.

C. Was manufactured, in accordance with our standard procedures within the requirements of BS EN ISO 9001 - 2015 for Quality systems.

We further certify that the material does not contain mercury as a basic element and no mercury bearing equipment was used in its manufacture.

Sulphur and Halogen levels according to ASME B&PV Code Section V and EN ISO 9934-2.

When tested at the time of manufacture the following results were obtained:

Test Section Limit Result

7.1 in EN

Performance Equal to standard Passed

ISO 9934-2

7.2 in EN

Colour Equal to standard Passed

ISO 9934-2

--- EOR ---

Notes:

1. Our batch number appears on the label of bulk containers. Aerosols have batch numbers printed on bottom of the container. Bulk materials have

a minimum shelf life of 5 years from date of manufacture. Aerosols have a minimum shelf life of 3 years from date of manufacture.

2. Most specifications require test results stated in percent, but some require parts per million (ppm). To convert "percent" figures to "parts per

million" move the decimal four places to the right.

3. MIL-STD-271, MIL-STD-2132 and ASME Sec V, all require that materials be subject to a procedure to evaporate off volatile solvents before

analysis for Sulfur and Halogens. According to these specifications, only those residues higher than 0.005 g/100ml shall be analysed for Sulfur and

Halogens. Lower residues shall be reported.

4. The above certification gives the results obtained at the time of manufacture. Age and use may alter the properties of any material.

Magnaflux (A Division of ITW Ltd),

Faraday Road, South Dorcan Industrial Estate,

Swindon, Wiltshire, SN3 5HE, UK

Tel: +44 (0)1793 524566

Fax: +44 (0)1793 490459

Email: sales.eu@magnaflux.com

FORMAT: MX 101.137 MC-09 Rev 13 www.magnaflux.eu

You might also like

- Market Anaysis MarigoldDocument32 pagesMarket Anaysis MarigoldAh Hui23% (13)

- Ingersoll Rand AC260D Operators Manual PDFDocument103 pagesIngersoll Rand AC260D Operators Manual PDFGustavo Quintero100% (1)

- 090629173312preview - SS EN 12620-2008+amd1Document6 pages090629173312preview - SS EN 12620-2008+amd1Majid Al-Gburi100% (1)

- Magnavis WCP 2 White Contrast Paint AerosolDocument1 pageMagnavis WCP 2 White Contrast Paint AerosolMohamed themees mNo ratings yet

- WCP 2Document1 pageWCP 2Rahmat HidayatNo ratings yet

- WCP 2Document1 pageWCP 2petrolift SalNo ratings yet

- Spotcheck SKD S2 Developer AerosolDocument2 pagesSpotcheck SKD S2 Developer AerosolInspectorNo ratings yet

- SKD S2Document2 pagesSKD S2eka prasetyaNo ratings yet

- 220401 - Spotcheck-SKL-SP2-Red-Penetrant-Aerosol (2) - распознанDocument2 pages220401 - Spotcheck-SKL-SP2-Red-Penetrant-Aerosol (2) - распознанbaurzhannNo ratings yet

- Magnavis 7HF Oil Based Black MPI Ink AerosolDocument2 pagesMagnavis 7HF Oil Based Black MPI Ink AerosolMohamed themees mNo ratings yet

- CERTIFICADO PLASSON PORTABRIDA 90 MMDocument1 pageCERTIFICADO PLASSON PORTABRIDA 90 MMangel rojasNo ratings yet

- Marker For Terminal Blocks - UCT-TM 5 - 0828734Document4 pagesMarker For Terminal Blocks - UCT-TM 5 - 0828734ibrahim abd elhadyNo ratings yet

- Magnavis 7HF Oil Based Black MPI Ink AerosolDocument2 pagesMagnavis 7HF Oil Based Black MPI Ink AerosolInspectorNo ratings yet

- FR Class - k98 2022 Version 2 EngDocument5 pagesFR Class - k98 2022 Version 2 Engklimovets.omtsNo ratings yet

- SGS Ce-Bk22Document15 pagesSGS Ce-Bk22gqg9sw6kbgNo ratings yet

- Jarvis 1096 - EN 13501. B s2 d0Document5 pagesJarvis 1096 - EN 13501. B s2 d0Calin SimionNo ratings yet

- Safety 60950 Move2500Document224 pagesSafety 60950 Move2500vishalvsinghonlineNo ratings yet

- Panelview 5310 Terminals Specifications: Technical DataDocument10 pagesPanelview 5310 Terminals Specifications: Technical DataMarcosNo ratings yet

- CN 27635 - Test Standard Beschichtete Oberflächen An Kunststoffteilen - Einsazt Im FahrzeuginnenraumDocument8 pagesCN 27635 - Test Standard Beschichtete Oberflächen An Kunststoffteilen - Einsazt Im FahrzeuginnenraumOliver SteinrötterNo ratings yet

- EMC TEST - REPORT - FalcomDocument25 pagesEMC TEST - REPORT - FalcomVictor PerezNo ratings yet

- Pub BDC Codeti2014 Div3 GB x2xDocument4 pagesPub BDC Codeti2014 Div3 GB x2xaladinsaneNo ratings yet

- P21526 01 19 IntDocument3 pagesP21526 01 19 IntinterhamNo ratings yet

- TL 262 EnglischDocument4 pagesTL 262 Englischjsantos_865904No ratings yet

- SKL SP2Document2 pagesSKL SP2Mangalraj MadasamyNo ratings yet

- bf502n CGBDocument4 pagesbf502n CGBmehdi.ss910No ratings yet

- Norsok P - R: RE Qualification EportDocument18 pagesNorsok P - R: RE Qualification EportJackz UlNo ratings yet

- MODEL NO.: G070Y2 SUFFIX: T02 (Rev.C3) : Product SpecificationDocument28 pagesMODEL NO.: G070Y2 SUFFIX: T02 (Rev.C3) : Product Specificationjose luisNo ratings yet

- ETA 13-0004 PERINSUL S Final 13-6-2013Document14 pagesETA 13-0004 PERINSUL S Final 13-6-2013Attila SiklodiNo ratings yet

- Ir 21:215 Operation & Mainrenance ManualDocument76 pagesIr 21:215 Operation & Mainrenance Manualmaher_eng2010No ratings yet

- Radiated EmissionDocument73 pagesRadiated EmissionnewtonbuiNo ratings yet

- Ravenol MTF-3 Sae 75WDocument3 pagesRavenol MTF-3 Sae 75WMariusNONo ratings yet

- Test Report No. 7191250395-EEC21-WBH: Dated 07 Jan 2021Document5 pagesTest Report No. 7191250395-EEC21-WBH: Dated 07 Jan 2021edwin morrisonNo ratings yet

- NEMKO03ATEX218XDocument10 pagesNEMKO03ATEX218XLuís Felipe SchrirNo ratings yet

- Gear and Spline InspectionDocument12 pagesGear and Spline InspectionAtulNo ratings yet

- Ecosafe Fire Test EN 13501-1Document6 pagesEcosafe Fire Test EN 13501-1Diego Maria CatellaniNo ratings yet

- S Iec 60335-2-98 PDFDocument176 pagesS Iec 60335-2-98 PDFtechnicalconsultationstc03No ratings yet

- Aikin 1068 - EN 13501 B s2 d0Document5 pagesAikin 1068 - EN 13501 B s2 d0فاعل الخيرNo ratings yet

- Atex Os E1ufDocument3 pagesAtex Os E1ufPrabu BaskaranNo ratings yet

- 7HFDocument2 pages7HFrtsdsdgNo ratings yet

- Iridex Group Plastic S.R.L.: B-Dul Eroilor 6 - 8, Cod 077190, Voluntari, Ilfov E-Mail: WebsiteDocument6 pagesIridex Group Plastic S.R.L.: B-Dul Eroilor 6 - 8, Cod 077190, Voluntari, Ilfov E-Mail: WebsiteRoxana IoanaNo ratings yet

- SRPC 2nd Week 2014Document1 pageSRPC 2nd Week 2014manil_5No ratings yet

- 13.PHI-Repport IEC 62368-1 - 2020Document164 pages13.PHI-Repport IEC 62368-1 - 2020Alex Ramadhan SabananyoNo ratings yet

- Kema02atex1006 Ultrasonic Level Trans.Document2 pagesKema02atex1006 Ultrasonic Level Trans.josip miskovicNo ratings yet

- Epd Kiwa Ee 000382 en Reno MattressDocument12 pagesEpd Kiwa Ee 000382 en Reno MattressSuntharathevan RamasamyNo ratings yet

- Approved - Guidance: GNB-CPDDocument23 pagesApproved - Guidance: GNB-CPDHelloKids Poppins100% (1)

- Sksp2redpenDocument2 pagesSksp2redpenJamal Mohamed RahamathullahNo ratings yet

- Service Bulletin: AB Volvo PentaDocument3 pagesService Bulletin: AB Volvo Pentaanees ahmedNo ratings yet

- Ingersoll Rand AC105D Operators ManualDocument97 pagesIngersoll Rand AC105D Operators ManualRenārs Bērtiņš100% (2)

- Aggregates Tullamore Certification 1Document9 pagesAggregates Tullamore Certification 1jesusNo ratings yet

- Formal Service Report: General InformationDocument7 pagesFormal Service Report: General Informationjamel SibugNo ratings yet

- Test Report - Flammability - EN 9239-1 - SGS (Page 4)Document12 pagesTest Report - Flammability - EN 9239-1 - SGS (Page 4)sarinurkhsnhNo ratings yet

- NO18537, System 17 C5 Very High, 2217059 PDFDocument8 pagesNO18537, System 17 C5 Very High, 2217059 PDFHector MacavilcaNo ratings yet

- TL 218 EnglischDocument14 pagesTL 218 Englischjsantos_865904No ratings yet

- NDT Procedure (Ut, RT & Penetrant Test) : Pressure VesselDocument47 pagesNDT Procedure (Ut, RT & Penetrant Test) : Pressure VesselSooraj VsNo ratings yet

- Questionnaire - en 1090-1 - Fill in All Parts: C I F FDocument3 pagesQuestionnaire - en 1090-1 - Fill in All Parts: C I F FHong Phong LeNo ratings yet

- Y-Q5 CRXM180118054A1-03 RED FinalDocument1 pageY-Q5 CRXM180118054A1-03 RED Finalalbu mihailNo ratings yet

- 33 3 101 - UsDocument3 pages33 3 101 - UsYè WințNo ratings yet

- RAVENOL Oldtimer 50-Er SAE 20W-50 API SCDocument3 pagesRAVENOL Oldtimer 50-Er SAE 20W-50 API SCddNo ratings yet

- EN Nemko 03 ATEX 263 UDocument4 pagesEN Nemko 03 ATEX 263 Ulim wyNo ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Portable HardnessDocument15 pagesPortable HardnessInspectorNo ratings yet

- Octl EcatalogDocument32 pagesOctl EcatalogInspectorNo ratings yet

- Pie Field Indicator Product Data Sheet EnglishDocument1 pagePie Field Indicator Product Data Sheet EnglishInspectorNo ratings yet

- Magnetic Particle Centrifuge Tubes Product Data Sheet EnglishDocument2 pagesMagnetic Particle Centrifuge Tubes Product Data Sheet EnglishInspectorNo ratings yet

- Spotcheck SKD S2 Developer AerosolDocument2 pagesSpotcheck SKD S2 Developer AerosolInspectorNo ratings yet

- Posi Tector UTGDocument5 pagesPosi Tector UTGInspectorNo ratings yet

- API Specification 7-1 1st Edition Errata 1 20200724Document1 pageAPI Specification 7-1 1st Edition Errata 1 20200724InspectorNo ratings yet

- Ios Mini Catalog WebDocument12 pagesIos Mini Catalog WebInspectorNo ratings yet

- API 5B Card Large Ver 2 With Photos 2sided July 1 2019 DateDocument2 pagesAPI 5B Card Large Ver 2 With Photos 2sided July 1 2019 DateInspectorNo ratings yet

- JA550 Fearnley Procter NS-2 Accreditation ProgrammeDocument2 pagesJA550 Fearnley Procter NS-2 Accreditation ProgrammeInspectorNo ratings yet

- Magnaflux Shelf-Life-Statement EnglishDocument1 pageMagnaflux Shelf-Life-Statement EnglishInspectorNo ratings yet

- Installation GuideDocument4 pagesInstallation GuideInspectorNo ratings yet

- API 7-1 1st-Edition Addendum-4 February 2019Document4 pagesAPI 7-1 1st-Edition Addendum-4 February 2019InspectorNo ratings yet

- Octg - Verbindertypen - TPS Topseal Field Inspection Connection QP 17 02 18.08.21Document8 pagesOctg - Verbindertypen - TPS Topseal Field Inspection Connection QP 17 02 18.08.21InspectorNo ratings yet

- 14A Magnaglo Powder: CertificationDocument2 pages14A Magnaglo Powder: CertificationInspectorNo ratings yet

- 168 PBLDocument1 page168 PBLInspectorNo ratings yet

- Magnavis 7HF Oil Based Black MPI Ink AerosolDocument2 pagesMagnavis 7HF Oil Based Black MPI Ink AerosolInspectorNo ratings yet

- 14A Safety-Data-Sheet EnglishDocument5 pages14A Safety-Data-Sheet EnglishInspectorNo ratings yet

- Api Compass Fact SheetDocument1 pageApi Compass Fact SheetInspectorNo ratings yet

- Tourniquet Conversion Drew JSOM Fall 2015 Edition-2Document5 pagesTourniquet Conversion Drew JSOM Fall 2015 Edition-2Oleg ShubinNo ratings yet

- Jurnal Ketahanan Nasional: Kodam XVII/CenerawasihDocument26 pagesJurnal Ketahanan Nasional: Kodam XVII/CenerawasihnathasaNo ratings yet

- All About URCDocument3 pagesAll About URCHYacinth MuYcoNo ratings yet

- The Foundations of ChemistryDocument38 pagesThe Foundations of ChemistryJesusBlasVitangcolNo ratings yet

- Arya Kristian LandeDocument5 pagesArya Kristian LandeGina TariganNo ratings yet

- Term Paper On Organic FarmingDocument8 pagesTerm Paper On Organic Farmingc5rm5y5p100% (1)

- Combined Over-Voltage & Under-Voltage Protection System Submitted byDocument9 pagesCombined Over-Voltage & Under-Voltage Protection System Submitted byAdarsh ChavdaNo ratings yet

- At Home Training Guide: Workout BuilderDocument22 pagesAt Home Training Guide: Workout BuilderAnonymous NO0urGNo ratings yet

- Dance TherapyDocument1 pageDance TherapyRoxanne Dooma0% (1)

- Park Rapids MeetDocument18 pagesPark Rapids MeetinforumdocsNo ratings yet

- Kitchen Checklist: Where We EatDocument1 pageKitchen Checklist: Where We EatNicoleta AlexandraNo ratings yet

- The Goa GuideDocument48 pagesThe Goa GuideNehaNo ratings yet

- Short Procedure Engineering Chemistry SASTRA UniversityDocument13 pagesShort Procedure Engineering Chemistry SASTRA UniversitystarNo ratings yet

- Cod and PodDocument5 pagesCod and PodYasser AshourNo ratings yet

- Geriatric Nursing: Trends and IssuesDocument11 pagesGeriatric Nursing: Trends and IssuesNikkaDablioNo ratings yet

- Giraffe Shuttle OM - M1187805 Rev 006Document70 pagesGiraffe Shuttle OM - M1187805 Rev 006Erwin TeknisiNo ratings yet

- 4 Mass Transfer Coefficients PDFDocument17 pages4 Mass Transfer Coefficients PDFYee LingNo ratings yet

- Future of Clinical Engineering - J.tobey Clark - 2003Document10 pagesFuture of Clinical Engineering - J.tobey Clark - 2003ManojNo ratings yet

- Print For ChrysoberylDocument2 pagesPrint For ChrysoberylToh Yang75% (4)

- Assingment - Subject: Eduction For Sustainable Development. - Course Code: EDUC3146. - Topic: Challenges SD & Sustainable SolutionsDocument18 pagesAssingment - Subject: Eduction For Sustainable Development. - Course Code: EDUC3146. - Topic: Challenges SD & Sustainable SolutionsIqra MunirNo ratings yet

- EML2322L-Abrasive Water Jet ProcessesDocument16 pagesEML2322L-Abrasive Water Jet ProcessesTurgut GülmezNo ratings yet

- Abu Dhabi Recommended Plant PDFDocument30 pagesAbu Dhabi Recommended Plant PDFelmerbarrerasNo ratings yet

- Guidelines For Hard MaterialDocument30 pagesGuidelines For Hard MaterialMuhamad MuzakkirNo ratings yet

- Energy Efficiency PPT NotesDocument2 pagesEnergy Efficiency PPT Notesapi-235634024No ratings yet

- Revised - AL Form - Document - MITC PDFDocument10 pagesRevised - AL Form - Document - MITC PDFVijayNo ratings yet

- DR Carey Reams - The Story of RBTIDocument40 pagesDR Carey Reams - The Story of RBTINepthus Metal100% (3)

- Camunacavi CatalogoDocument76 pagesCamunacavi CatalogoAHMED YOUSEFNo ratings yet

- Lijadora de Palma DW412 DewaltDocument35 pagesLijadora de Palma DW412 DewaltMARIA FERNo ratings yet

- What Should PDFDocument20 pagesWhat Should PDFCarlos Charlotte SalvadorNo ratings yet