Professional Documents

Culture Documents

Spotcheck SKD S2 Developer Aerosol

Spotcheck SKD S2 Developer Aerosol

Uploaded by

InspectorCopyright:

Available Formats

You might also like

- MBN 10494-6 2016-03Document22 pagesMBN 10494-6 2016-03cmorabitoNo ratings yet

- Chapter 1 Fundamentals of Pharmaceutical CalculationsDocument48 pagesChapter 1 Fundamentals of Pharmaceutical Calculationsgizachew assefaNo ratings yet

- High Performance Diesel Engine Oil: For Engines With Aftertreatment SystemsDocument6 pagesHigh Performance Diesel Engine Oil: For Engines With Aftertreatment SystemsNadia SalemNo ratings yet

- DD Cen TS 12390-9-2006Document28 pagesDD Cen TS 12390-9-2006DoicielNo ratings yet

- 220401 - Spotcheck-SKL-SP2-Red-Penetrant-Aerosol (2) - распознанDocument2 pages220401 - Spotcheck-SKL-SP2-Red-Penetrant-Aerosol (2) - распознанbaurzhannNo ratings yet

- SKD S2Document2 pagesSKD S2eka prasetyaNo ratings yet

- Magnavis WCP 2 White Contrast Paint AerosolDocument1 pageMagnavis WCP 2 White Contrast Paint AerosolMohamed themees mNo ratings yet

- Magnavis WCP 2 White Contrast Paint AerosolDocument1 pageMagnavis WCP 2 White Contrast Paint AerosolInspectorNo ratings yet

- SKL SP2Document2 pagesSKL SP2Mangalraj MadasamyNo ratings yet

- Inspection Certificate: Manufacture DateDocument2 pagesInspection Certificate: Manufacture Datemaheshmalaichamy007No ratings yet

- FORD WSS-M2P190-A1 Paint SpecificationDocument8 pagesFORD WSS-M2P190-A1 Paint SpecificationJuanPeriquitanNo ratings yet

- Sksp2redpenDocument2 pagesSksp2redpenJamal Mohamed RahamathullahNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- LGHP2Document1 pageLGHP2Ventas K LocalesNo ratings yet

- API Compliance Enviroline 376F-60Document4 pagesAPI Compliance Enviroline 376F-60Ahmed IbrahimNo ratings yet

- DSM-0289.1 AM NiCrMo SuperalloyDocument3 pagesDSM-0289.1 AM NiCrMo SuperalloyApichitNo ratings yet

- TDS 15360 Jotacote Universal N10 Euk GBDocument7 pagesTDS 15360 Jotacote Universal N10 Euk GByuri.barbotangolaNo ratings yet

- Formula 4T 20W50 HD Jaso Ma2 - enDocument1 pageFormula 4T 20W50 HD Jaso Ma2 - enĆerimovićDooNo ratings yet

- Bo 88 20 X 65 RJSDocument2 pagesBo 88 20 X 65 RJSDonny SetiawanNo ratings yet

- Certificado de Revelador PDFDocument3 pagesCertificado de Revelador PDFCarlos Eduardo Alvarez SantiagoNo ratings yet

- Cross Power 4T Sae 10W - 50 Jaso Ma2 - enDocument1 pageCross Power 4T Sae 10W - 50 Jaso Ma2 - enAlbertoNo ratings yet

- TDS 31002 Primax Protect Euk GBDocument3 pagesTDS 31002 Primax Protect Euk GBfawazNo ratings yet

- TDS 515 Jotamastic 87 Euk GBDocument6 pagesTDS 515 Jotamastic 87 Euk GBBarathan RajandranNo ratings yet

- Spotcheck Developer SKD-S2: CertificationDocument3 pagesSpotcheck Developer SKD-S2: Certificationnasser saldaña quinteroNo ratings yet

- Top Speed 4T Sae 10W40 Jaso Ma2 - enDocument1 pageTop Speed 4T Sae 10W40 Jaso Ma2 - enĆerimovićDooNo ratings yet

- Formula 4T 10W40 Jaso Ma2 - enDocument1 pageFormula 4T 10W40 Jaso Ma2 - enĆerimovićDooNo ratings yet

- Marker For Terminal Blocks - UCT-TM 5 - 0828734Document4 pagesMarker For Terminal Blocks - UCT-TM 5 - 0828734ibrahim abd elhadyNo ratings yet

- Cert Ultramat23 GB Metrol Sira Mcerts Mc040033 08Document9 pagesCert Ultramat23 GB Metrol Sira Mcerts Mc040033 08Nicolae VisanNo ratings yet

- OPC BAZ W13-2022 IQ - LafargeDocument1 pageOPC BAZ W13-2022 IQ - LafargeDilshadNo ratings yet

- Mcerts Forbes Marshal Insitu ProbeDocument8 pagesMcerts Forbes Marshal Insitu ProbeKunal KumarNo ratings yet

- Ex409 MmeDocument3 pagesEx409 MmeHERY HAKAT CHANELNo ratings yet

- Aral Degol BG 220: Gear Oil Type CLPDocument1 pageAral Degol BG 220: Gear Oil Type CLPdungdhtsNo ratings yet

- WCP 2Document1 pageWCP 2Rahmat HidayatNo ratings yet

- Katon - FKM Fk1 O-Ring DatasheetDocument8 pagesKaton - FKM Fk1 O-Ring DatasheetDipesh PhapeNo ratings yet

- Agip OSO: Characteristics (Typical Figures)Document2 pagesAgip OSO: Characteristics (Typical Figures)Luis Carlos Lagos SalinasNo ratings yet

- QCG Pe 2020-02Document13 pagesQCG Pe 2020-02Roosevelt A. SantosNo ratings yet

- Q8 El Greco 220 - enDocument1 pageQ8 El Greco 220 - enDeepak YadavNo ratings yet

- Vacumax-22 TDS 261700101 ENDocument2 pagesVacumax-22 TDS 261700101 ENJuan Diego GiraldoNo ratings yet

- Certificado Revelador Skd-S 2Document3 pagesCertificado Revelador Skd-S 2Enrique AntonioNo ratings yet

- GRP Specification BY CKDocument44 pagesGRP Specification BY CKchandana kumar100% (2)

- MAGNUM™ 3416 SC: ABS ResinDocument3 pagesMAGNUM™ 3416 SC: ABS ResinEduardo MazariegosNo ratings yet

- ZXMN6A07FDocument8 pagesZXMN6A07FbuntovNo ratings yet

- Socony Oven Conveyer LubricantDocument2 pagesSocony Oven Conveyer LubricantNoche de EstrellasNo ratings yet

- Brayco Micronic™ SV/B: DescriptionDocument5 pagesBrayco Micronic™ SV/B: DescriptionAlfonsus W.M.No ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- Wonder Cement OPC 53Document2 pagesWonder Cement OPC 53sudhaNo ratings yet

- 80 FKM B1OR81FK-en - 1Document2 pages80 FKM B1OR81FK-en - 1Joabe MartinsNo ratings yet

- HPF Fan - AnshanDocument28 pagesHPF Fan - AnshanDangolNo ratings yet

- Balmatech Go-26 Tds 2022-09 GBDocument2 pagesBalmatech Go-26 Tds 2022-09 GBAnalista De CalidadNo ratings yet

- Primary Fan - AnshanDocument26 pagesPrimary Fan - AnshanDangolNo ratings yet

- 3048421Document2 pages3048421Philippe VelhaNo ratings yet

- Bolt M10X25 410Document1 pageBolt M10X25 410avinash bahadurNo ratings yet

- Cross Power 2T - enDocument1 pageCross Power 2T - enKarankawakahlaNo ratings yet

- 03OHH SengYewDocument3 pages03OHH SengYewAbhie AlbukhariNo ratings yet

- Renolin PA 320 GBDocument3 pagesRenolin PA 320 GBdnoaisapsNo ratings yet

- NO18537, System 17 C5 Very High, 2217059 PDFDocument8 pagesNO18537, System 17 C5 Very High, 2217059 PDFHector MacavilcaNo ratings yet

- GP 11127Document5 pagesGP 11127SHivaprasad APITNo ratings yet

- Red Penetrant - MR62 - 2209040Document1 pageRed Penetrant - MR62 - 2209040Karthi KeyanNo ratings yet

- DSM-400.1 88WC12Co SintCrushDocument3 pagesDSM-400.1 88WC12Co SintCrushGunawan DarmaNo ratings yet

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentFrom EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentNo ratings yet

- Magnavis WCP 2 White Contrast Paint AerosolDocument1 pageMagnavis WCP 2 White Contrast Paint AerosolInspectorNo ratings yet

- Octl EcatalogDocument32 pagesOctl EcatalogInspectorNo ratings yet

- Pie Field Indicator Product Data Sheet EnglishDocument1 pagePie Field Indicator Product Data Sheet EnglishInspectorNo ratings yet

- Posi Tector UTGDocument5 pagesPosi Tector UTGInspectorNo ratings yet

- Portable HardnessDocument15 pagesPortable HardnessInspectorNo ratings yet

- Ios Mini Catalog WebDocument12 pagesIos Mini Catalog WebInspectorNo ratings yet

- Magnetic Particle Centrifuge Tubes Product Data Sheet EnglishDocument2 pagesMagnetic Particle Centrifuge Tubes Product Data Sheet EnglishInspectorNo ratings yet

- JA550 Fearnley Procter NS-2 Accreditation ProgrammeDocument2 pagesJA550 Fearnley Procter NS-2 Accreditation ProgrammeInspectorNo ratings yet

- Installation GuideDocument4 pagesInstallation GuideInspectorNo ratings yet

- Magnaflux Shelf-Life-Statement EnglishDocument1 pageMagnaflux Shelf-Life-Statement EnglishInspectorNo ratings yet

- API 7-1 1st-Edition Addendum-4 February 2019Document4 pagesAPI 7-1 1st-Edition Addendum-4 February 2019InspectorNo ratings yet

- Magnavis 7HF Oil Based Black MPI Ink AerosolDocument2 pagesMagnavis 7HF Oil Based Black MPI Ink AerosolInspectorNo ratings yet

- Api Compass Fact SheetDocument1 pageApi Compass Fact SheetInspectorNo ratings yet

- API Specification 7-1 1st Edition Errata 1 20200724Document1 pageAPI Specification 7-1 1st Edition Errata 1 20200724InspectorNo ratings yet

- 14A Safety-Data-Sheet EnglishDocument5 pages14A Safety-Data-Sheet EnglishInspectorNo ratings yet

- API 5B Card Large Ver 2 With Photos 2sided July 1 2019 DateDocument2 pagesAPI 5B Card Large Ver 2 With Photos 2sided July 1 2019 DateInspectorNo ratings yet

- 14A Magnaglo Powder: CertificationDocument2 pages14A Magnaglo Powder: CertificationInspectorNo ratings yet

- 168 PBLDocument1 page168 PBLInspectorNo ratings yet

- Octg - Verbindertypen - TPS Topseal Field Inspection Connection QP 17 02 18.08.21Document8 pagesOctg - Verbindertypen - TPS Topseal Field Inspection Connection QP 17 02 18.08.21InspectorNo ratings yet

- Module 2. Binary Phase Diagram: Reading: Chapter 1.5 Porter and EasterlingDocument75 pagesModule 2. Binary Phase Diagram: Reading: Chapter 1.5 Porter and EasterlingAdivadewanggaNo ratings yet

- Fungal LipasesDocument20 pagesFungal LipasesKhaled Abu-AlruzNo ratings yet

- Shale-Oil Resource Systems - AAPG WikiDocument35 pagesShale-Oil Resource Systems - AAPG WikiAmrNo ratings yet

- Dental FilmDocument53 pagesDental Filmهبلتنى الكورةNo ratings yet

- Incident RatesDocument7 pagesIncident RatesSamantha Meril PandithaNo ratings yet

- PerfumesDocument35 pagesPerfumesNehaNo ratings yet

- Solubility Enhancement Techniques: An Overview: World Journal of Pharmaceutical Research May 2022Document16 pagesSolubility Enhancement Techniques: An Overview: World Journal of Pharmaceutical Research May 202222031010064 Febby Nur Izza VaniaNo ratings yet

- Activated Sludge Combined With Powdered Activated Carbon (PACT Process) For The Petroleum Industry Wastewater Treatment: A ReviewDocument10 pagesActivated Sludge Combined With Powdered Activated Carbon (PACT Process) For The Petroleum Industry Wastewater Treatment: A ReviewAmmr MahmoodNo ratings yet

- Basic Principles of Radiopharmacy Questions and AnswersDocument4 pagesBasic Principles of Radiopharmacy Questions and AnswersMelavNo ratings yet

- Uji Aktivitas Antidiare Ekstrak Etanol Biji Teratai Putih (Nymphaea Pubescens Willd) TERHADAP MENCIT Dengan Metode Transit IntestinalDocument8 pagesUji Aktivitas Antidiare Ekstrak Etanol Biji Teratai Putih (Nymphaea Pubescens Willd) TERHADAP MENCIT Dengan Metode Transit IntestinalSestri SNo ratings yet

- Drug Release KineticsDocument51 pagesDrug Release KineticsSagar kishor savale80% (5)

- TDS MasterSeal-540 PDFDocument2 pagesTDS MasterSeal-540 PDFTaposh PaulNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- Biology IADocument20 pagesBiology IAVenice LoNo ratings yet

- PRE DVS Technical Codes On Plastics Joining TechnologiesDocument11 pagesPRE DVS Technical Codes On Plastics Joining TechnologiesAmr Mohamed Soliman100% (1)

- Iso Dis 18218-1 Iuc-28-1 Apeo Direct-MethodDocument11 pagesIso Dis 18218-1 Iuc-28-1 Apeo Direct-MethodNguyen Trung HuyNo ratings yet

- National Red Oxide Primer PDFDocument3 pagesNational Red Oxide Primer PDFCyril J Padiyath100% (1)

- ICE Quiz 3AC Fall 17 Stoic PDFDocument1 pageICE Quiz 3AC Fall 17 Stoic PDFAbdullahJavedNo ratings yet

- 6AG12266DA325XB0 Datasheet enDocument2 pages6AG12266DA325XB0 Datasheet ensandeshNo ratings yet

- 118 Elements Name List With SymbolDocument5 pages118 Elements Name List With SymbolSathya BharathiNo ratings yet

- Acrylic Sunscreen Sealer: Technical Data SheetDocument1 pageAcrylic Sunscreen Sealer: Technical Data SheetShaijan JosephNo ratings yet

- Air POLLUTION CONTROLDocument71 pagesAir POLLUTION CONTROLsishu21No ratings yet

- Lecture 5.2 Inorganic MaterialsDocument22 pagesLecture 5.2 Inorganic Materialsdawit gashuNo ratings yet

- Brochure CEPIC enDocument12 pagesBrochure CEPIC enRathawit SingpanjanateeNo ratings yet

- Concentrationnf M M N ALOTDocument37 pagesConcentrationnf M M N ALOTMarcelo BaldonNo ratings yet

- Profiles of Drug Substances Excipients and Related Methodology Volume 30 2003 PDFDocument322 pagesProfiles of Drug Substances Excipients and Related Methodology Volume 30 2003 PDFchemtabNo ratings yet

- Measurement of SilicaDocument4 pagesMeasurement of SilicaKumaraswamyNo ratings yet

- Hesse Oil Product RangeDocument16 pagesHesse Oil Product RangeBhaskar BhatiaNo ratings yet

Spotcheck SKD S2 Developer Aerosol

Spotcheck SKD S2 Developer Aerosol

Uploaded by

InspectorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spotcheck SKD S2 Developer Aerosol

Spotcheck SKD S2 Developer Aerosol

Uploaded by

InspectorCopyright:

Available Formats

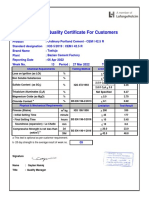

Inspection Certificate

Abnahmeprüfungszeugnis DIN EN 10204.3.1

Certificat De reception

Certificado di collaudo

Keuringsrapport

Spotcheck SKD-S2

Batch Number 220701 Product Name

Developer Aerosol

Date of Manufacture 06/07/2022 11/07/2022 B.B.E. 07/2025

Specification: Specification

We hereby certify that when tested at the time of manufacture, the above material:

1. Meets the requirements of and has been tested for sulfur and halogens according to:

a) ASME Boiler and Pressure Vessel Code, 2019 Edition, Section V, Non-destructive Examination.

b) Anion analysis by ASTM D129 decomposition followed by Ion Chromatography method Annex A4.

c) ASTM E-165/E-165M-18, Paragraph 7.1.

d) MIL-STD-2132E, March 29, 2016, Paragraph 6.1.3.

2. Meets the requirements of EN ISO 3452-1, EN ISO 3452-2, SAFRAN Pr 5000 / In 5000D, AMS 2644H and ASTM E 1417/E 1417M-21 Paragraph 5.1

& 6.5.1.

3. We further certify that the material does not contain mercury as a basic element and no mercury bearing equipment was used in its manufacture.

Test Section Limit Result

Specification Passed

Specification: EN ISO 3452-2

When tested at the time of manufacture the following results were obtained. The information is derived from our quality checks. It does not relive

the purchaser from examining the proodct upon delivery and gives no assurance of the product for any particular purpose.

Test Section Limit Result

Appearance 6.1 Equal to standard Passed

Sensitivity for ISO 3452-2 (SMT 58) 6.2 Equal to standard Passed

No Corrosion on Magnesium

Corrosive Properties 6.11 Passed

Alloy

Solid Content (SMT 28) 6.13 9.0 - 15.0 % 13.91 %

Developer Performance 6.15 Equal to standard Passed

Re-Dispersion 6.16 Readily Dispersed Passed

Density of Carrier Fluid 6.17 0.746 - 0.825 g/cm3 0.824 g/cm3

Flashpoint (SMT 14)

Aerosol -40ºC

Specification: AMS 2644H Developer Results

When sampled according to paragraph 4.3.2 section 4.2.2.3 of AMS 2644H the following results were obtained:

Test Section Limit Result

Developer Fluorescence 3.3.10.2 Conforms Passed

Developer Removability 3.3.10.4 Conforms Passed

Redispersibility (Forms c,d &e only) 3.3.10.5 Conforms Passed

Specification: Ion Testing Results

Test results obtained were as follows:

Test Section Limit Result

Sulphur Content 28 ppm

Halogen Content 147 ppm

--- EOR ---

Inspection Certificate

Abnahmeprüfungszeugnis DIN EN 10204.3.1

Certificat De reception

Certificado di collaudo

Keuringsrapport

Notes:

1. Our batch number appears on the label of bulk containers. Aerosols have batch numbers printed on bottom of the container. Bulk materials have

a minimum shelf life of 5 years from date of manufacture. Aerosols have a minimum shelf life of 3 years from date of manufacture.

2. Most specifications require test results stated in percent, but some require parts per million (ppm). To convert "percent" figures to "parts per

million" move the decimal four places to the right.

3. MIL-STD-271, MIL-STD-2132 and ASME Sec V, all require that materials be subject to a procedure to evaporate off volatile solvents before

analysis for Sulfur and Halogens. According to these specifications, only those residues higher than 0.005 g/100ml shall be analysed for Sulfur and

Halogens. Lower residues shall be reported.

4. The above certification gives the results obtained at the time of manufacture. Age and use may alter the properties of any material.

Magnaflux (A Division of ITW Ltd),

Faraday Road, South Dorcan Industrial Estate,

Swindon, Wiltshire, SN3 5HE, UK

Tel: +44 (0)1793 524566

Fax: +44 (0)1793 490459

Email: sales.eu@magnaflux.com

FORMAT: MX 101.137 MC-09 Rev 22 www.magnaflux.eu

You might also like

- MBN 10494-6 2016-03Document22 pagesMBN 10494-6 2016-03cmorabitoNo ratings yet

- Chapter 1 Fundamentals of Pharmaceutical CalculationsDocument48 pagesChapter 1 Fundamentals of Pharmaceutical Calculationsgizachew assefaNo ratings yet

- High Performance Diesel Engine Oil: For Engines With Aftertreatment SystemsDocument6 pagesHigh Performance Diesel Engine Oil: For Engines With Aftertreatment SystemsNadia SalemNo ratings yet

- DD Cen TS 12390-9-2006Document28 pagesDD Cen TS 12390-9-2006DoicielNo ratings yet

- 220401 - Spotcheck-SKL-SP2-Red-Penetrant-Aerosol (2) - распознанDocument2 pages220401 - Spotcheck-SKL-SP2-Red-Penetrant-Aerosol (2) - распознанbaurzhannNo ratings yet

- SKD S2Document2 pagesSKD S2eka prasetyaNo ratings yet

- Magnavis WCP 2 White Contrast Paint AerosolDocument1 pageMagnavis WCP 2 White Contrast Paint AerosolMohamed themees mNo ratings yet

- Magnavis WCP 2 White Contrast Paint AerosolDocument1 pageMagnavis WCP 2 White Contrast Paint AerosolInspectorNo ratings yet

- SKL SP2Document2 pagesSKL SP2Mangalraj MadasamyNo ratings yet

- Inspection Certificate: Manufacture DateDocument2 pagesInspection Certificate: Manufacture Datemaheshmalaichamy007No ratings yet

- FORD WSS-M2P190-A1 Paint SpecificationDocument8 pagesFORD WSS-M2P190-A1 Paint SpecificationJuanPeriquitanNo ratings yet

- Sksp2redpenDocument2 pagesSksp2redpenJamal Mohamed RahamathullahNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- LGHP2Document1 pageLGHP2Ventas K LocalesNo ratings yet

- API Compliance Enviroline 376F-60Document4 pagesAPI Compliance Enviroline 376F-60Ahmed IbrahimNo ratings yet

- DSM-0289.1 AM NiCrMo SuperalloyDocument3 pagesDSM-0289.1 AM NiCrMo SuperalloyApichitNo ratings yet

- TDS 15360 Jotacote Universal N10 Euk GBDocument7 pagesTDS 15360 Jotacote Universal N10 Euk GByuri.barbotangolaNo ratings yet

- Formula 4T 20W50 HD Jaso Ma2 - enDocument1 pageFormula 4T 20W50 HD Jaso Ma2 - enĆerimovićDooNo ratings yet

- Bo 88 20 X 65 RJSDocument2 pagesBo 88 20 X 65 RJSDonny SetiawanNo ratings yet

- Certificado de Revelador PDFDocument3 pagesCertificado de Revelador PDFCarlos Eduardo Alvarez SantiagoNo ratings yet

- Cross Power 4T Sae 10W - 50 Jaso Ma2 - enDocument1 pageCross Power 4T Sae 10W - 50 Jaso Ma2 - enAlbertoNo ratings yet

- TDS 31002 Primax Protect Euk GBDocument3 pagesTDS 31002 Primax Protect Euk GBfawazNo ratings yet

- TDS 515 Jotamastic 87 Euk GBDocument6 pagesTDS 515 Jotamastic 87 Euk GBBarathan RajandranNo ratings yet

- Spotcheck Developer SKD-S2: CertificationDocument3 pagesSpotcheck Developer SKD-S2: Certificationnasser saldaña quinteroNo ratings yet

- Top Speed 4T Sae 10W40 Jaso Ma2 - enDocument1 pageTop Speed 4T Sae 10W40 Jaso Ma2 - enĆerimovićDooNo ratings yet

- Formula 4T 10W40 Jaso Ma2 - enDocument1 pageFormula 4T 10W40 Jaso Ma2 - enĆerimovićDooNo ratings yet

- Marker For Terminal Blocks - UCT-TM 5 - 0828734Document4 pagesMarker For Terminal Blocks - UCT-TM 5 - 0828734ibrahim abd elhadyNo ratings yet

- Cert Ultramat23 GB Metrol Sira Mcerts Mc040033 08Document9 pagesCert Ultramat23 GB Metrol Sira Mcerts Mc040033 08Nicolae VisanNo ratings yet

- OPC BAZ W13-2022 IQ - LafargeDocument1 pageOPC BAZ W13-2022 IQ - LafargeDilshadNo ratings yet

- Mcerts Forbes Marshal Insitu ProbeDocument8 pagesMcerts Forbes Marshal Insitu ProbeKunal KumarNo ratings yet

- Ex409 MmeDocument3 pagesEx409 MmeHERY HAKAT CHANELNo ratings yet

- Aral Degol BG 220: Gear Oil Type CLPDocument1 pageAral Degol BG 220: Gear Oil Type CLPdungdhtsNo ratings yet

- WCP 2Document1 pageWCP 2Rahmat HidayatNo ratings yet

- Katon - FKM Fk1 O-Ring DatasheetDocument8 pagesKaton - FKM Fk1 O-Ring DatasheetDipesh PhapeNo ratings yet

- Agip OSO: Characteristics (Typical Figures)Document2 pagesAgip OSO: Characteristics (Typical Figures)Luis Carlos Lagos SalinasNo ratings yet

- QCG Pe 2020-02Document13 pagesQCG Pe 2020-02Roosevelt A. SantosNo ratings yet

- Q8 El Greco 220 - enDocument1 pageQ8 El Greco 220 - enDeepak YadavNo ratings yet

- Vacumax-22 TDS 261700101 ENDocument2 pagesVacumax-22 TDS 261700101 ENJuan Diego GiraldoNo ratings yet

- Certificado Revelador Skd-S 2Document3 pagesCertificado Revelador Skd-S 2Enrique AntonioNo ratings yet

- GRP Specification BY CKDocument44 pagesGRP Specification BY CKchandana kumar100% (2)

- MAGNUM™ 3416 SC: ABS ResinDocument3 pagesMAGNUM™ 3416 SC: ABS ResinEduardo MazariegosNo ratings yet

- ZXMN6A07FDocument8 pagesZXMN6A07FbuntovNo ratings yet

- Socony Oven Conveyer LubricantDocument2 pagesSocony Oven Conveyer LubricantNoche de EstrellasNo ratings yet

- Brayco Micronic™ SV/B: DescriptionDocument5 pagesBrayco Micronic™ SV/B: DescriptionAlfonsus W.M.No ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- Wonder Cement OPC 53Document2 pagesWonder Cement OPC 53sudhaNo ratings yet

- 80 FKM B1OR81FK-en - 1Document2 pages80 FKM B1OR81FK-en - 1Joabe MartinsNo ratings yet

- HPF Fan - AnshanDocument28 pagesHPF Fan - AnshanDangolNo ratings yet

- Balmatech Go-26 Tds 2022-09 GBDocument2 pagesBalmatech Go-26 Tds 2022-09 GBAnalista De CalidadNo ratings yet

- Primary Fan - AnshanDocument26 pagesPrimary Fan - AnshanDangolNo ratings yet

- 3048421Document2 pages3048421Philippe VelhaNo ratings yet

- Bolt M10X25 410Document1 pageBolt M10X25 410avinash bahadurNo ratings yet

- Cross Power 2T - enDocument1 pageCross Power 2T - enKarankawakahlaNo ratings yet

- 03OHH SengYewDocument3 pages03OHH SengYewAbhie AlbukhariNo ratings yet

- Renolin PA 320 GBDocument3 pagesRenolin PA 320 GBdnoaisapsNo ratings yet

- NO18537, System 17 C5 Very High, 2217059 PDFDocument8 pagesNO18537, System 17 C5 Very High, 2217059 PDFHector MacavilcaNo ratings yet

- GP 11127Document5 pagesGP 11127SHivaprasad APITNo ratings yet

- Red Penetrant - MR62 - 2209040Document1 pageRed Penetrant - MR62 - 2209040Karthi KeyanNo ratings yet

- DSM-400.1 88WC12Co SintCrushDocument3 pagesDSM-400.1 88WC12Co SintCrushGunawan DarmaNo ratings yet

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentFrom EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentNo ratings yet

- Magnavis WCP 2 White Contrast Paint AerosolDocument1 pageMagnavis WCP 2 White Contrast Paint AerosolInspectorNo ratings yet

- Octl EcatalogDocument32 pagesOctl EcatalogInspectorNo ratings yet

- Pie Field Indicator Product Data Sheet EnglishDocument1 pagePie Field Indicator Product Data Sheet EnglishInspectorNo ratings yet

- Posi Tector UTGDocument5 pagesPosi Tector UTGInspectorNo ratings yet

- Portable HardnessDocument15 pagesPortable HardnessInspectorNo ratings yet

- Ios Mini Catalog WebDocument12 pagesIos Mini Catalog WebInspectorNo ratings yet

- Magnetic Particle Centrifuge Tubes Product Data Sheet EnglishDocument2 pagesMagnetic Particle Centrifuge Tubes Product Data Sheet EnglishInspectorNo ratings yet

- JA550 Fearnley Procter NS-2 Accreditation ProgrammeDocument2 pagesJA550 Fearnley Procter NS-2 Accreditation ProgrammeInspectorNo ratings yet

- Installation GuideDocument4 pagesInstallation GuideInspectorNo ratings yet

- Magnaflux Shelf-Life-Statement EnglishDocument1 pageMagnaflux Shelf-Life-Statement EnglishInspectorNo ratings yet

- API 7-1 1st-Edition Addendum-4 February 2019Document4 pagesAPI 7-1 1st-Edition Addendum-4 February 2019InspectorNo ratings yet

- Magnavis 7HF Oil Based Black MPI Ink AerosolDocument2 pagesMagnavis 7HF Oil Based Black MPI Ink AerosolInspectorNo ratings yet

- Api Compass Fact SheetDocument1 pageApi Compass Fact SheetInspectorNo ratings yet

- API Specification 7-1 1st Edition Errata 1 20200724Document1 pageAPI Specification 7-1 1st Edition Errata 1 20200724InspectorNo ratings yet

- 14A Safety-Data-Sheet EnglishDocument5 pages14A Safety-Data-Sheet EnglishInspectorNo ratings yet

- API 5B Card Large Ver 2 With Photos 2sided July 1 2019 DateDocument2 pagesAPI 5B Card Large Ver 2 With Photos 2sided July 1 2019 DateInspectorNo ratings yet

- 14A Magnaglo Powder: CertificationDocument2 pages14A Magnaglo Powder: CertificationInspectorNo ratings yet

- 168 PBLDocument1 page168 PBLInspectorNo ratings yet

- Octg - Verbindertypen - TPS Topseal Field Inspection Connection QP 17 02 18.08.21Document8 pagesOctg - Verbindertypen - TPS Topseal Field Inspection Connection QP 17 02 18.08.21InspectorNo ratings yet

- Module 2. Binary Phase Diagram: Reading: Chapter 1.5 Porter and EasterlingDocument75 pagesModule 2. Binary Phase Diagram: Reading: Chapter 1.5 Porter and EasterlingAdivadewanggaNo ratings yet

- Fungal LipasesDocument20 pagesFungal LipasesKhaled Abu-AlruzNo ratings yet

- Shale-Oil Resource Systems - AAPG WikiDocument35 pagesShale-Oil Resource Systems - AAPG WikiAmrNo ratings yet

- Dental FilmDocument53 pagesDental Filmهبلتنى الكورةNo ratings yet

- Incident RatesDocument7 pagesIncident RatesSamantha Meril PandithaNo ratings yet

- PerfumesDocument35 pagesPerfumesNehaNo ratings yet

- Solubility Enhancement Techniques: An Overview: World Journal of Pharmaceutical Research May 2022Document16 pagesSolubility Enhancement Techniques: An Overview: World Journal of Pharmaceutical Research May 202222031010064 Febby Nur Izza VaniaNo ratings yet

- Activated Sludge Combined With Powdered Activated Carbon (PACT Process) For The Petroleum Industry Wastewater Treatment: A ReviewDocument10 pagesActivated Sludge Combined With Powdered Activated Carbon (PACT Process) For The Petroleum Industry Wastewater Treatment: A ReviewAmmr MahmoodNo ratings yet

- Basic Principles of Radiopharmacy Questions and AnswersDocument4 pagesBasic Principles of Radiopharmacy Questions and AnswersMelavNo ratings yet

- Uji Aktivitas Antidiare Ekstrak Etanol Biji Teratai Putih (Nymphaea Pubescens Willd) TERHADAP MENCIT Dengan Metode Transit IntestinalDocument8 pagesUji Aktivitas Antidiare Ekstrak Etanol Biji Teratai Putih (Nymphaea Pubescens Willd) TERHADAP MENCIT Dengan Metode Transit IntestinalSestri SNo ratings yet

- Drug Release KineticsDocument51 pagesDrug Release KineticsSagar kishor savale80% (5)

- TDS MasterSeal-540 PDFDocument2 pagesTDS MasterSeal-540 PDFTaposh PaulNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- Biology IADocument20 pagesBiology IAVenice LoNo ratings yet

- PRE DVS Technical Codes On Plastics Joining TechnologiesDocument11 pagesPRE DVS Technical Codes On Plastics Joining TechnologiesAmr Mohamed Soliman100% (1)

- Iso Dis 18218-1 Iuc-28-1 Apeo Direct-MethodDocument11 pagesIso Dis 18218-1 Iuc-28-1 Apeo Direct-MethodNguyen Trung HuyNo ratings yet

- National Red Oxide Primer PDFDocument3 pagesNational Red Oxide Primer PDFCyril J Padiyath100% (1)

- ICE Quiz 3AC Fall 17 Stoic PDFDocument1 pageICE Quiz 3AC Fall 17 Stoic PDFAbdullahJavedNo ratings yet

- 6AG12266DA325XB0 Datasheet enDocument2 pages6AG12266DA325XB0 Datasheet ensandeshNo ratings yet

- 118 Elements Name List With SymbolDocument5 pages118 Elements Name List With SymbolSathya BharathiNo ratings yet

- Acrylic Sunscreen Sealer: Technical Data SheetDocument1 pageAcrylic Sunscreen Sealer: Technical Data SheetShaijan JosephNo ratings yet

- Air POLLUTION CONTROLDocument71 pagesAir POLLUTION CONTROLsishu21No ratings yet

- Lecture 5.2 Inorganic MaterialsDocument22 pagesLecture 5.2 Inorganic Materialsdawit gashuNo ratings yet

- Brochure CEPIC enDocument12 pagesBrochure CEPIC enRathawit SingpanjanateeNo ratings yet

- Concentrationnf M M N ALOTDocument37 pagesConcentrationnf M M N ALOTMarcelo BaldonNo ratings yet

- Profiles of Drug Substances Excipients and Related Methodology Volume 30 2003 PDFDocument322 pagesProfiles of Drug Substances Excipients and Related Methodology Volume 30 2003 PDFchemtabNo ratings yet

- Measurement of SilicaDocument4 pagesMeasurement of SilicaKumaraswamyNo ratings yet

- Hesse Oil Product RangeDocument16 pagesHesse Oil Product RangeBhaskar BhatiaNo ratings yet