Professional Documents

Culture Documents

ACFrOgC0EVPbmcxczw5NSKfoQiO8EaGyKUowbr iP4nF2YTyDHYiM0zJhagdIXt23OhU53TFk8 - zQyxMNsU cz4ewrJ4Aa4JbYKguSky4HppDX38J2 9TkILlXsaO - G

ACFrOgC0EVPbmcxczw5NSKfoQiO8EaGyKUowbr iP4nF2YTyDHYiM0zJhagdIXt23OhU53TFk8 - zQyxMNsU cz4ewrJ4Aa4JbYKguSky4HppDX38J2 9TkILlXsaO - G

Uploaded by

ganeshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACFrOgC0EVPbmcxczw5NSKfoQiO8EaGyKUowbr iP4nF2YTyDHYiM0zJhagdIXt23OhU53TFk8 - zQyxMNsU cz4ewrJ4Aa4JbYKguSky4HppDX38J2 9TkILlXsaO - G

ACFrOgC0EVPbmcxczw5NSKfoQiO8EaGyKUowbr iP4nF2YTyDHYiM0zJhagdIXt23OhU53TFk8 - zQyxMNsU cz4ewrJ4Aa4JbYKguSky4HppDX38J2 9TkILlXsaO - G

Uploaded by

ganeshCopyright:

Available Formats

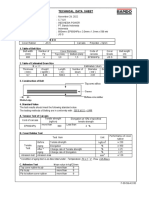

GUARANTEED TECHNICAL PARTICULARS OF # SI-GTP-HT-AMST-SUS,

Rev- 02

SUSPENSION CLAMP ASSEMBLY FOR ACCC

AMSTERDAM CONDCUTOR Page 1 of 1 Date:-30/09/2022

PRODUCT LINE : Transmission - HTLS Pre:-JPR Ckd & App :- VIJ

Sl. No. Description Unit Value guaranteed by the Bidder

SICAME INDIA CONNECTORS PVT LTD.,

1. Name & address S.No 473/1 (Part) ,Sirukundram,

Chengalpet District, Chennai - 603108.

2. Drawing enclosed Yes/No Yes

3. Slipping strength of suspension assembly kN > 8% of Conductor UTS

Particulars of standard/AGS Standard /

4. AGS preformed armor rod set for

suspension assembly

a) No. of rods per set No. 12

b) Diameter of each rod mm Ø6.35

c) Tolerance in

i) Diameter of each rod % ±1

ii) Length of each rod ±mm ±5

iii) Difference of length between the

±mm ±5

longest and shortest rod in a set

d) Material Al Alloy

Particulars of Elastomer (For AGS

5.

Clamp only)

b) Type of elastomer Silicone

c) Shore hardness of elastomer 65 - 80 Shore A

d) Temperature range for which elastomer

Deg. C 200ºC on the conductor

is designed

e) Moulded on insert Yes/No Yes

Maximum permissible continuous

6.

operating temperature of

i) Clamp body Deg. C 180° C

ii) Standard/AGS preformed rods Deg. C 180° C

Maximum permissible temperature for

7. short term operation Deg. C 200° C

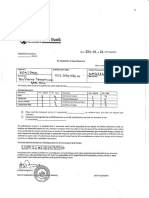

GUARANTEED TECHNICAL PARTICULARS OF # SI-GTP-HT- AMST -DEC,

Rev- 02

TENSION HARDWARE FITTINGS FOR ACCC

AMSTERDAM CONDCUTOR Page 1 of 1 Date:-30/09/2022

PRODUCT LINE : Transmission - HTLS Pre:-JPR Ckd & App :- VIJ

Sl. No. Description Unit Value guaranteed by the Bidder

SICAME INDIA CONNECTORS PVT LTD.,

1. Name & address S.No 473/1 (Part) ,Sirukundram,

Chengalpet District, Chennai - 603108.

2. Drawing enclosed Yes/No Yes

Purity of aluminum used for aluminum

3. % Al Alloy 6060

sleeve

Aluminum Steel Alloy

Outside diameter of sleeve before

4. mm Ø52.5 Not Applicable

compression

Inside diameter of sleeve before

5. mm Ø34 Not Applicable

compression

6. Length of sleeve before compression mm 620 Not Applicable

7. Dimensions of sleeve after compression

52 +3/-2

(a) Corner to Corner mm Not Applicable

(Radius to Radius)

(b) Surface to Surface mm 46 Not Applicable

Approx. 10% increase in length of

8. Length of sleeve after compression

compression zone after compression

Electrical resistance of dead end assembly

9. as a percentage of equivalent length of % <75%

Conductor

10. Slip strength of dead end assembly kN 95% of Conductor UTS

Maximum permissible continuous

11. operating temperature of dead end Deg. C 180° C

assembly

Maximum permissible temperature for

12. short term operation Deg. C 200° C

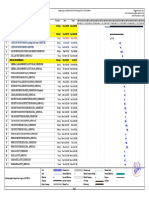

GUARANTEED TECHNICAL PARTICULARS OF # SI-GTP-HT- AMST --MSJ,

Rev- 02

MID SPAN COMPRESSION JOINT FOR ACCC

AMSTERDAM CONDCUTOR Page 1 of 1 Date:-30/09/2022

PRODUCT LINE : Transmission - HTLS Pre:-JPR Ckd & App :- VIJ

Sl. No. Description Unit Value guaranteed by the Bidder

SICAME INDIA CONNECTORS PVT LTD.,

1. Name & address S.No 473/1 (Part) ,Sirukundram,

Chengalpet District, Chennai - 603108.

2. Drawing enclosed Yes/ No Yes

3. Suitable for conductor size mm Ø23.55

Purity of aluminum used for aluminum

4. % Al Alloy 6060

sleeve

Aluminum Steel Alloy

Outside diameter of sleeve before

5. mm Ø52.5 Not Applicable

compression

Inside diameter of sleeve before

6. mm Ø34 Not Applicable

compression

7. Length of sleeve before compression mm 1220 Not Applicable

8. Dimensions of sleeve after compression

52 +3/-2

(a) Corner to Corner mm Not Applicable

(Radius to Radius)

(b) Surface to Surface mm 46 Not Applicable

Approx. 10% increase in length of

9. Length of sleeve after compression

compression zone after compression

10. Slip strength kN 95% of Conductor UTS

Resistance of compressed unit expressed,

11. as percentage of the resistivity of % <75%

equivalent length of bare conductor.

Maximum permissible continuous

12. operating temperature of mid span Deg. C 180° C

compression joint

Maximum permissible temperature for

13. short term operation Deg. C 200° C

GUARANTEED TECHNICAL PARTICULARS OF # SI-GTP-HT- AMST -RPS,

Rev- 02

REPAIR SLEEVE FOR ACCC

AMSTERDAM CONDCUTOR Page 1 of 1 Date:-30/09/2022

PRODUCT LINE : Transmission - HTLS Pre:-JPR Ckd & App :- VIJ

Sl. No. Description Unit Value guaranteed by the Bidder

SICAME INDIA CONNECTORS PVT LTD.,

1. Name & address S.No 473/1 (Part) ,Sirukundram,

Chengalpet District, Chennai - 603108.

2. Drawing enclosed Yes/ No Yes

3. Suitable for conductor size mm Ø23.55

4. Purity of aluminum / A1 Alloy type % Al Alloy 1050 A / 1060

5. Dimension of sleeves before compression

i) Inside diameter of sleeve mm Ø25.5

ii) Outside dimensions of sleeve mm Ø48

iii) Length of sleeve mm 290

6. Dimension of sleeve after compression

i) Corner to Corner mm 49 +3/-2 (Radius to Radius)

ii) Surface to Surface mm 43

Approx. 10% increase in length of

iii) Length of sleeve mm

compression zone after compression

Maximum permissible continuous

7. Deg. C 180° C

operating temperature of Repair Sleeve

Maximum permissible temperature for

8. short term operation Deg. C 200° C

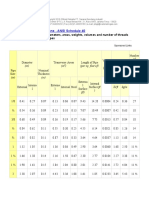

GUARANTEED TECHNICAL PARTICULARS OF # SI-GTP-HT- AMST -VD,

Rev- 02

VIBRATION DAMPER FOR ACCC

AMSTERDAM CONDCUTOR Page 1 of 1 Date:-30/09/2022

PRODUCT LINE : Transmission - HTLS Pre:-JPR Ckd & App :- VIJ

Sl. No. Description Unit Value guaranteed by the Bidder

SICAME INDIA CONNECTORS PVTLTD.,

1. Name & address S.No 473/1 (Part) ,Sirukundram,

Chengalpet District, Chennai - 603108.

2. Drawing enclosed

(a) Design Drawing Yes/ No Yes

(b) Placement Chart Yes/ No No (to be calculated with line data)

3. Suitable for conductor size mm Ø23.55

4. Material of damper masses Galvanized Steel

5. Material of clamp Al Alloy

Material of the stranded messenger

6. Galvanized Steel

cable

Minimum ultimate tensile strength of

7. Kg/mm2 >135

stranded messenger cable

Slip strength of stranded messenger

8. kN >5

cable (mass pull off)

Right Left

9. Resonance frequencies

(a) First frequency Hz 10 ±2 18 ±3

(b) Second frequency Hz 25 ±5 37 ±7

10. Designed clamping torque Kg-m 6

11. Slipping strength of damper clamp kN >2.5

Maximum permissible continuous

12. operating temperature of Vibration Deg. C 180° C

Damper

Maximum permissible temperature

13. for short term operation Deg. C 200° C

You might also like

- Lift Wall DesignDocument4 pagesLift Wall DesignBajracharya A-sub25% (4)

- Strength of Materials: Axial StressesDocument3 pagesStrength of Materials: Axial Stressesmonique dianeNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- GTP FormatDocument9 pagesGTP FormatGokul KarthikeyanNo ratings yet

- Aluminum Conductors Carbon Fiber Core Reinforced-LAPWINGDocument6 pagesAluminum Conductors Carbon Fiber Core Reinforced-LAPWINGgabriel yair sanchez henandezNo ratings yet

- GTP Format For OdsspDocument12 pagesGTP Format For OdsspJainco Transmission LimitedNo ratings yet

- GTP TogoDocument6 pagesGTP TogoRamphani NunnaNo ratings yet

- 400kv Quad Tls - GTPDocument8 pages400kv Quad Tls - GTPChatterjee TanmoyNo ratings yet

- ZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Document5 pagesZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Benjamin SalinasNo ratings yet

- AL-SE3510 Servo Type CNC Turret Punching Machine ALLES Offersheet 20210722Document9 pagesAL-SE3510 Servo Type CNC Turret Punching Machine ALLES Offersheet 20210722mehrdadgeminiNo ratings yet

- Guaranteed Technical Particulars Guaranteed: ACCC Casablanca ACCC CasablancaDocument5 pagesGuaranteed Technical Particulars Guaranteed: ACCC Casablanca ACCC CasablancabinodeNo ratings yet

- MESP 130400-01 Technical Specification For Catenary Wire Hard-Drawn Copper 37/2.5 181mmDocument7 pagesMESP 130400-01 Technical Specification For Catenary Wire Hard-Drawn Copper 37/2.5 181mm4493464No ratings yet

- Aac 500, Aac 1267, Acsr 60Document5 pagesAac 500, Aac 1267, Acsr 60Rahmat IzaiziNo ratings yet

- Technical Specification (Medium Voltage) Aaa Covered Conductor & AccesoriesDocument36 pagesTechnical Specification (Medium Voltage) Aaa Covered Conductor & AccesoriesCabcon India100% (1)

- ZTT ACS Strand 7x3.21-1Document4 pagesZTT ACS Strand 7x3.21-1tees220510No ratings yet

- 1 ACSR380/50mm2 (NA)Document3 pages1 ACSR380/50mm2 (NA)bassamwael6689No ratings yet

- 02 ACSR ZEBRA ConductorDocument37 pages02 ACSR ZEBRA Conductorsanjeevchhabra100% (2)

- Cover Sheet With Doc. No, Revision No. Project Name, Client / Consultant Name Is To Be AddedDocument6 pagesCover Sheet With Doc. No, Revision No. Project Name, Client / Consultant Name Is To Be AddedsubudhiprasannaNo ratings yet

- GTP - Acsr DogDocument2 pagesGTP - Acsr DogBhagawati Prasad SharmaNo ratings yet

- Specs ZTT TACSR AW 410 PDFDocument5 pagesSpecs ZTT TACSR AW 410 PDFVictor DoyoganNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- 783 y AdaptorDocument1 page783 y AdaptorDavide GuerreiroNo ratings yet

- TDS 132 For Approval of 2CX1.5Sq MM ABC, MICA R0 With NormsDocument4 pagesTDS 132 For Approval of 2CX1.5Sq MM ABC, MICA R0 With Normssanjay dalviNo ratings yet

- Px784rex MetricDocument1 pagePx784rex MetricRomi SecoNo ratings yet

- IJCRT2305283Document6 pagesIJCRT2305283rrpatil1221No ratings yet

- GFRP RebarsDocument16 pagesGFRP Rebarsrajbir1001No ratings yet

- DS-01 - LR BendsDocument1 pageDS-01 - LR BendsMecon LtdNo ratings yet

- 18-Acoples Elastomericos LovejoyDocument70 pages18-Acoples Elastomericos LovejoyERIKSON EGUSQUIZANo ratings yet

- 2020001-DS-070-005-D HDG - Conductor OPGW - Es.enDocument2 pages2020001-DS-070-005-D HDG - Conductor OPGW - Es.enfixer_007722No ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetNiko SwandanaNo ratings yet

- 1 - CBT Welding NDT 26 02 2020 - Ans and ExplanetionDocument27 pages1 - CBT Welding NDT 26 02 2020 - Ans and ExplanetionAMALENDU PAULNo ratings yet

- DS-02 - LR BendsDocument1 pageDS-02 - LR BendsMecon LtdNo ratings yet

- Technical Specification For Aluminum Conductors Carbon Fiber Core ReinforcedDocument6 pagesTechnical Specification For Aluminum Conductors Carbon Fiber Core ReinforcedSteve HuamanNo ratings yet

- Trench Gate Field-Stop, 650 V, 10 A, Low-Loss M Series IGBT Die in D7 PackingDocument10 pagesTrench Gate Field-Stop, 650 V, 10 A, Low-Loss M Series IGBT Die in D7 Packingkrimo biomédicalNo ratings yet

- TPG Xiii.2.4 - Opgw 60 MMDocument5 pagesTPG Xiii.2.4 - Opgw 60 MMALVINNo ratings yet

- Ferrite in Stainless Steel Weld MetalDocument1 pageFerrite in Stainless Steel Weld MetalElizabeth SpenceNo ratings yet

- HIRAI LTCC Design GuidelineDocument19 pagesHIRAI LTCC Design GuidelineAkanksha BhutaniNo ratings yet

- 3C-ABC-Technical Spec 948Document9 pages3C-ABC-Technical Spec 948Kanwalnain madaanNo ratings yet

- CMP A2Document1 pageCMP A2mohd darusNo ratings yet

- Curved Jaw TypeDocument18 pagesCurved Jaw Typeadjime3No ratings yet

- Att.1-Technical Specification For ACSRDocument7 pagesAtt.1-Technical Specification For ACSRabdallahsabry.mNo ratings yet

- DTTN DT2 PC MET EL 0011 A Method Statement For Hydraulic CrimpingDocument8 pagesDTTN DT2 PC MET EL 0011 A Method Statement For Hydraulic CrimpingTariq Ali SialNo ratings yet

- Datasheet: 33kV Cold-Shrink Inline Joint With Cold-Shrink Re-Jacketing, Including ConnectorsDocument2 pagesDatasheet: 33kV Cold-Shrink Inline Joint With Cold-Shrink Re-Jacketing, Including ConnectorsMohammed MustafaNo ratings yet

- Apar Industries Limited: Marketing & Registered OfficeDocument1 pageApar Industries Limited: Marketing & Registered OfficeQM F ZeusNo ratings yet

- Crompton Motor Datasheet 0.75EN4 - 06dec23182720Document7 pagesCrompton Motor Datasheet 0.75EN4 - 06dec23182720Suhas KambleNo ratings yet

- SQUDFY212200052 - TPDDL & DTL - 33,66 & 220kV DC - Technical Offer DetailsDocument9 pagesSQUDFY212200052 - TPDDL & DTL - 33,66 & 220kV DC - Technical Offer DetailsSUJAL SHAH - SKIPPER LIMITEDNo ratings yet

- CMP 737 797 ExplosiveDocument2 pagesCMP 737 797 ExplosivemsuiaNo ratings yet

- Rdso SPN TC 97 2012Document13 pagesRdso SPN TC 97 2012Rahul MauryaNo ratings yet

- DDDDDDDocument43 pagesDDDDDDDhanush NairNo ratings yet

- Tds Wikon Ip. C 7&8Document1 pageTds Wikon Ip. C 7&8deni prastikoNo ratings yet

- EU Data Sheet Chainflex CF890Document8 pagesEU Data Sheet Chainflex CF890gaconlonton410No ratings yet

- IGS-M-TP-014-2-C (2) Sep. 2008: 3 Ply Co-Extruded Plastic Tape For Field Joint and Rehabilitation of Steel PipelineDocument13 pagesIGS-M-TP-014-2-C (2) Sep. 2008: 3 Ply Co-Extruded Plastic Tape For Field Joint and Rehabilitation of Steel PipelineTa GiNo ratings yet

- Ees 6.8-1 Hard Chrome PlatingDocument5 pagesEes 6.8-1 Hard Chrome PlatingRobyn NashNo ratings yet

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- ASTM C90700 - CuSn11 - Tin Bronze AlloysDocument1 pageASTM C90700 - CuSn11 - Tin Bronze Alloysİrem Şebnem SorucuNo ratings yet

- BareDocument1 pageBarennNo ratings yet

- CMP Products Cable Gland CatalogueDocument1 pageCMP Products Cable Gland CatalogueVictor HutahaeanNo ratings yet

- Customer Specification Rport 12 FCDocument12 pagesCustomer Specification Rport 12 FCSridharan VenkatNo ratings yet

- Getco - r1 Al59 Zebra & MooseDocument27 pagesGetco - r1 Al59 Zebra & Mooseakib javed100% (1)

- Technical Specification AL-59 Conductor 893Document18 pagesTechnical Specification AL-59 Conductor 893pramjitNo ratings yet

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesFrom EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesRating: 1 out of 5 stars1/5 (1)

- C S ParipatraDocument1 pageC S ParipatraganeshNo ratings yet

- The 400 KV Dhalkebar-Muzaffarpur 140 KM Transmission Line: Eight Years of Indo-Nepal Labor and Still No FruitDocument6 pagesThe 400 KV Dhalkebar-Muzaffarpur 140 KM Transmission Line: Eight Years of Indo-Nepal Labor and Still No FruitganeshNo ratings yet

- Yealy Progress 79 - 80Document5 pagesYealy Progress 79 - 80ganeshNo ratings yet

- Shutdown Sambandh MaaDocument1 pageShutdown Sambandh MaaganeshNo ratings yet

- ProgressDocument2 pagesProgressganeshNo ratings yet

- Moose SpecificationDocument1 pageMoose SpecificationganeshNo ratings yet

- Survey Report of Duhabi - Kusaha 132 KV LineDocument4 pagesSurvey Report of Duhabi - Kusaha 132 KV LineganeshNo ratings yet

- Schedule For Hetauda - PathalaiyaDocument4 pagesSchedule For Hetauda - PathalaiyaganeshNo ratings yet

- ATR 155-7.75-FAmDocument11 pagesATR 155-7.75-FAmganeshNo ratings yet

- View-Doc 213126917 Q AHR0cHM6Ly93d3cuc2NyaWJkLmNvbS9kb2N1bWVudC8yMTMxMjY5MTcvQWNzci1QYW50aGVyLUNvbmR1Y3Rvci1TaXppbmcteGxzLTA &F UERGDocument1 pageView-Doc 213126917 Q AHR0cHM6Ly93d3cuc2NyaWJkLmNvbS9kb2N1bWVudC8yMTMxMjY5MTcvQWNzci1QYW50aGVyLUNvbmR1Y3Rvci1TaXppbmcteGxzLTA &F UERGganeshNo ratings yet

- LC Document - HGDocument37 pagesLC Document - HGganeshNo ratings yet

- Screenshot 2023-03-30 152257Document1 pageScreenshot 2023-03-30 152257ganeshNo ratings yet

- Is 2486 1 1993Document18 pagesIs 2486 1 1993ganeshNo ratings yet

- Oht Cond Rating SpreadsheetDocument89 pagesOht Cond Rating SpreadsheetganeshNo ratings yet

- Disc IsulatorDocument11 pagesDisc IsulatorganeshNo ratings yet

- Stationary ItemsDocument96 pagesStationary ItemsganeshNo ratings yet

- Survey Report - Chovar SSDocument1 pageSurvey Report - Chovar SSganeshNo ratings yet

- 16 - Quotation For Bore Pile at Phutung SubstationDocument1 page16 - Quotation For Bore Pile at Phutung SubstationganeshNo ratings yet

- TRAX - Test Report Ta DeltaDocument3 pagesTRAX - Test Report Ta DeltaganeshNo ratings yet

- Vol I - Keraun PDFDocument219 pagesVol I - Keraun PDFganeshNo ratings yet

- Chovar SS - R01Document7 pagesChovar SS - R01ganeshNo ratings yet

- Nepal Electricity Authority (A Government of Nepal Undertaking)Document2 pagesNepal Electricity Authority (A Government of Nepal Undertaking)ganeshNo ratings yet

- SS SoR CombinedDocument56 pagesSS SoR Combinedganesh100% (1)

- Pile Minutes of Meeting Between NEA and Pinggao Group CoDocument1 pagePile Minutes of Meeting Between NEA and Pinggao Group CoganeshNo ratings yet

- Nepal: Electricity Grid Modernization Project Environmental Audit Checklist For Existing SubstationsDocument15 pagesNepal: Electricity Grid Modernization Project Environmental Audit Checklist For Existing SubstationsganeshNo ratings yet

- A Function Defines A Particular Output For A Particular InputDocument11 pagesA Function Defines A Particular Output For A Particular InputganeshNo ratings yet

- Rev - 01 Invitation For Bids IFB - DCCDocument2 pagesRev - 01 Invitation For Bids IFB - DCCganeshNo ratings yet

- PCX - ReportDocument22 pagesPCX - ReportganeshNo ratings yet

- Notice For Registration of Pre-Bid Meeting - DCC - 9th Sept 2020Document1 pageNotice For Registration of Pre-Bid Meeting - DCC - 9th Sept 2020ganeshNo ratings yet

- Sanchay Kosh Rate Multple Month 3236 2 36 232992 3818 2 5 38180 Total 271172 LoanDocument2 pagesSanchay Kosh Rate Multple Month 3236 2 36 232992 3818 2 5 38180 Total 271172 LoanganeshNo ratings yet

- Deublin 155 000 001Document3 pagesDeublin 155 000 001mmkattaNo ratings yet

- Is 4573 1982Document45 pagesIs 4573 1982pankaj100% (1)

- Ch06 Shallow FoundationsDocument26 pagesCh06 Shallow FoundationsVaibhav Sharma100% (1)

- New Home Inclusion - Laksh Luxury Inclusion - v1Document11 pagesNew Home Inclusion - Laksh Luxury Inclusion - v1humtum007No ratings yet

- Rivulis ProFlat English US 20190512 WebDocument2 pagesRivulis ProFlat English US 20190512 WebMehdi BassouNo ratings yet

- NIET No. 16 of 2018-2019 WBSIDC LTDDocument52 pagesNIET No. 16 of 2018-2019 WBSIDC LTDgoutammandNo ratings yet

- SG - Product CatalogueDocument12 pagesSG - Product CatalogueManish JhaNo ratings yet

- Steel Pipes Dimensions - ANSI Schedule 40Document4 pagesSteel Pipes Dimensions - ANSI Schedule 40ciblixNo ratings yet

- Kwiksplice™ Aluminum Cable Tray SystemDocument40 pagesKwiksplice™ Aluminum Cable Tray SystemHubert Maraza JaliriNo ratings yet

- 010 Vendor's Letter For Price ReasonabilityDocument2 pages010 Vendor's Letter For Price ReasonabilityAmeen SyedNo ratings yet

- Hand Out-Boiler CompleteDocument40 pagesHand Out-Boiler Completemuhammad umarNo ratings yet

- Reinforcement Rusting Prevention PDFDocument6 pagesReinforcement Rusting Prevention PDFJitu SinghNo ratings yet

- AISC DG31 Example 003Document14 pagesAISC DG31 Example 003alejandro mantillaNo ratings yet

- Product Index Bridges Other SDocument28 pagesProduct Index Bridges Other SbradrimmNo ratings yet

- B - Namrata Karuna - Mit Chandya U21172 - Kalyan Mudris U21064Document8 pagesB - Namrata Karuna - Mit Chandya U21172 - Kalyan Mudris U21064Mit ChandyaNo ratings yet

- SKB Tube Dan OutriggerDocument8 pagesSKB Tube Dan OutriggerMiftahul AulizaNo ratings yet

- Trench Excavation, Backfilling & RR 03.09.2018Document19 pagesTrench Excavation, Backfilling & RR 03.09.2018Civil EngineerNo ratings yet

- Brochure PDFDocument10 pagesBrochure PDFpunitha_pNo ratings yet

- Alt II (Apron)Document25 pagesAlt II (Apron)HanafiahHamzahNo ratings yet

- Castle Builder Vol 4 TowersDocument21 pagesCastle Builder Vol 4 TowersClay Liford100% (1)

- Halfen Hit - Insulated Balcony Connection - CatalogDocument12 pagesHalfen Hit - Insulated Balcony Connection - CatalogPaul ConstantinescuNo ratings yet

- Vaswani Reserve Progress ReportDocument17 pagesVaswani Reserve Progress ReportvaswanigroupNo ratings yet

- Juk LH-1152Document32 pagesJuk LH-1152RHoskaNo ratings yet

- Piping EngineeringDocument5 pagesPiping EngineeringArun Zac100% (2)

- Shell Omala S4 WE 220Document3 pagesShell Omala S4 WE 220Muhammad SaputraNo ratings yet

- Finish Carpentry Module 1Document6 pagesFinish Carpentry Module 1GianJyrellAlbertoCorletNo ratings yet

- NC NF NefDocument4 pagesNC NF Nefgeav25653855No ratings yet

- Dr. Fixit Pidicrete CF 101: Water Reducing & Retarding Admixture For ConcreteDocument1 pageDr. Fixit Pidicrete CF 101: Water Reducing & Retarding Admixture For Concretenickdash09No ratings yet