Professional Documents

Culture Documents

HD 318 HD Inertsys Gas Supression System

HD 318 HD Inertsys Gas Supression System

Uploaded by

Juhar MohammedCopyright:

Available Formats

You might also like

- MS2015-Building Installation ElectricalDocument44 pagesMS2015-Building Installation ElectricalScalperNo ratings yet

- AEGIS 2.0 and AEGIS-XLT Conventional Suppression Control UnitsDocument2 pagesAEGIS 2.0 and AEGIS-XLT Conventional Suppression Control UnitsAlwin WanNo ratings yet

- MP-627 Y 628 HerzogDocument4 pagesMP-627 Y 628 HerzogNavi Morales0% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Substation Grounding Grid Design Using Alternative Transients Program-ATP and ASPIXDocument23 pagesSubstation Grounding Grid Design Using Alternative Transients Program-ATP and ASPIXJose Dariel ArcilaNo ratings yet

- Suppression SystemsDocument5 pagesSuppression Systemsf.BNo ratings yet

- Akronex INERT InteractiveDocument12 pagesAkronex INERT InteractiveYunus güneşNo ratings yet

- System Overview - Complete System - Cooltek - 060320Document29 pagesSystem Overview - Complete System - Cooltek - 060320Entity ArchitectsNo ratings yet

- NAFFCOInert BrochureDocument8 pagesNAFFCOInert Brochurerennes desamparadoNo ratings yet

- Industrial Flame Monitoring IFM Brochure 67 7148Document11 pagesIndustrial Flame Monitoring IFM Brochure 67 7148swapnil28.08 kNo ratings yet

- CONTEXT PLUS - HFC227ea Systems - SALES BROCHURE - 01-17Document4 pagesCONTEXT PLUS - HFC227ea Systems - SALES BROCHURE - 01-17Ronny HasanNo ratings yet

- Ta Ignition-101 PDFDocument7 pagesTa Ignition-101 PDFमेनसन लाखेमरूNo ratings yet

- Gaseous Automatic Supression SystemsDocument21 pagesGaseous Automatic Supression SystemseimrehNo ratings yet

- DBR - Fire Fighting - HPMC ParalaDocument16 pagesDBR - Fire Fighting - HPMC ParalaKiran LokhandeNo ratings yet

- Brochure Siex-Inert 01 200bar Eng WebDocument12 pagesBrochure Siex-Inert 01 200bar Eng WebAhmed El Sayed SalamaNo ratings yet

- Inergen 150 Bar System SpecificationDocument2 pagesInergen 150 Bar System SpecificationDragan CvetkovićNo ratings yet

- Inergen System AnsulDocument2 pagesInergen System AnsulJayFouresNo ratings yet

- Automatic Fire Detection and Suppression SystemDocument2 pagesAutomatic Fire Detection and Suppression SystemProdip SarkarNo ratings yet

- HVAC and PressurizationDocument12 pagesHVAC and PressurizationtareqNo ratings yet

- MX Argotec With Carbon Dioxide PDFDocument7 pagesMX Argotec With Carbon Dioxide PDFNarendra Reddy BhumaNo ratings yet

- Thermox-Brochure LR107 PDFDocument16 pagesThermox-Brochure LR107 PDFedwinmenaNo ratings yet

- Ig 100Document16 pagesIg 100Rhoderic Radomes JrNo ratings yet

- Argonite: A World of ProtectionDocument6 pagesArgonite: A World of Protectionrodrigo.shaolimNo ratings yet

- 04 AP Sensing DTS - Fiber Optic Linear Heat DetectionDocument8 pages04 AP Sensing DTS - Fiber Optic Linear Heat DetectionDoan Anh TuanNo ratings yet

- LPCO2Document15 pagesLPCO2don timoNo ratings yet

- RNXDDocument30 pagesRNXDashbal alfanNo ratings yet

- Wartsila Moss Generator System For Cas CarriersDocument4 pagesWartsila Moss Generator System For Cas CarriersShubham MishraNo ratings yet

- Brochure Siex-Inert 541 300bar Eng WebDocument12 pagesBrochure Siex-Inert 541 300bar Eng WebLuisNo ratings yet

- Brochure Hc-227 Eng 2015Document12 pagesBrochure Hc-227 Eng 2015Jaime Alberto VillarrealNo ratings yet

- 24112015XAG3KELRAnnexureRiskAssesment PDFDocument16 pages24112015XAG3KELRAnnexureRiskAssesment PDFenduNo ratings yet

- UC169986 PTY 0313 Insight Gaseous Fire Suppression System - tcm2538-373444Document3 pagesUC169986 PTY 0313 Insight Gaseous Fire Suppression System - tcm2538-373444Maxmore KarumamupiyoNo ratings yet

- Special Hazard Fire Suppression Systems: A Guide For All Business EnvironmentsDocument21 pagesSpecial Hazard Fire Suppression Systems: A Guide For All Business EnvironmentsMEGAN ASBROCK0% (1)

- MANUAL - DISEÑO - IG541 - NOVEMBER - 2010 - Ing - SEGUN ISODocument60 pagesMANUAL - DISEÑO - IG541 - NOVEMBER - 2010 - Ing - SEGUN ISOMuhammad Hassan100% (1)

- Argonite Fixed Fire Extinguishing SystemDocument4 pagesArgonite Fixed Fire Extinguishing SystemJoel Shelton LasradoNo ratings yet

- AutoFireX Pre Engineered Systems For LATAMDocument19 pagesAutoFireX Pre Engineered Systems For LATAMPaola LopezNo ratings yet

- Detector de Humo-Alk-V - 02-2014 PDFDocument2 pagesDetector de Humo-Alk-V - 02-2014 PDFArthur Alexis Buitron DurandNo ratings yet

- FGD ADS Power Flame Gas Oil Mist Detection TurbinesDocument4 pagesFGD ADS Power Flame Gas Oil Mist Detection Turbinesaugur886No ratings yet

- 81381C Plastic Machinery Eng PDFDocument76 pages81381C Plastic Machinery Eng PDFEvandro Amaral RodriguesNo ratings yet

- VHS200 BrochureDocument4 pagesVHS200 BrochureAhmed HakamNo ratings yet

- Đầu Báo Khói Kết Hợp Nhiệt Địa Chỉ Acc-V - 09-2015Document2 pagesĐầu Báo Khói Kết Hợp Nhiệt Địa Chỉ Acc-V - 09-2015Nguyễn Kỳ TúNo ratings yet

- 6) CYCLOPSZPurgeIndicatorBrochureDocument6 pages6) CYCLOPSZPurgeIndicatorBrochureAnish KarthikeyanNo ratings yet

- Coal Conveyor Protection-Ih153es Ir Ember DetectorDocument72 pagesCoal Conveyor Protection-Ih153es Ir Ember DetectorShanmuganathan ShanNo ratings yet

- Fire SuppressionDocument19 pagesFire SuppressionSalley BukhariNo ratings yet

- L01040704 - 10052022 - Rev.22.1 - en - 1p - Multi Zone TechnologyDocument1 pageL01040704 - 10052022 - Rev.22.1 - en - 1p - Multi Zone TechnologyAshokkumar SamikannuNo ratings yet

- FiresafeDocument8 pagesFiresafeDANE80No ratings yet

- Inergen 200-Bar Fire Suppression System: Data/SpecificationsDocument2 pagesInergen 200-Bar Fire Suppression System: Data/SpecificationsEmmanuel ToretaNo ratings yet

- Det-Tronics - 95-8666-8.1 (Model HD)Document19 pagesDet-Tronics - 95-8666-8.1 (Model HD)jimmiilongNo ratings yet

- Fire Supression SystemDocument4 pagesFire Supression SystemPriya UdamaleNo ratings yet

- m600 DatasheetDocument4 pagesm600 DatasheetCost RootsNo ratings yet

- AFDSS Freeze FireDocument2 pagesAFDSS Freeze FireemilianoNo ratings yet

- Delivering Excellence in Combustion and Process HeatingDocument11 pagesDelivering Excellence in Combustion and Process HeatingsajjadyasinNo ratings yet

- Ft-Tcpa-Ing-14-02-2022 Ficha Tecnica Tanques de Supresion AlmacenadaDocument6 pagesFt-Tcpa-Ing-14-02-2022 Ficha Tecnica Tanques de Supresion AlmacenadaSugeily CalvoNo ratings yet

- ABB Gas AnalyserDocument4 pagesABB Gas AnalyserAbhay SalavkarNo ratings yet

- Ficha Tecnica Inergen F-9312Document2 pagesFicha Tecnica Inergen F-9312Yairton Vargas MuñozNo ratings yet

- Hydran 201ti (Mark IV) Essential DGA Monitoring For TransformersDocument2 pagesHydran 201ti (Mark IV) Essential DGA Monitoring For Transformerslxd.hepNo ratings yet

- Kidde Nitrogen Fire Protection Systems K-79-001 Print AADocument6 pagesKidde Nitrogen Fire Protection Systems K-79-001 Print AADaddy YantulaNo ratings yet

- Context Plus EP203 August 17Document4 pagesContext Plus EP203 August 17nalakaNo ratings yet

- Low Pressure: Fire SystemsDocument8 pagesLow Pressure: Fire SystemsKrishna N H100% (1)

- D.1 General Katalog BfiDocument28 pagesD.1 General Katalog Bfihardy ferrysianNo ratings yet

- Inert Siex 100 200bar Brochure 2015 03Document12 pagesInert Siex 100 200bar Brochure 2015 03JayFouresNo ratings yet

- Ft-Tcpa-Ing-14-02-2022 Ficha Tecnica Tanques de Supresion Almacenada PDFDocument6 pagesFt-Tcpa-Ing-14-02-2022 Ficha Tecnica Tanques de Supresion Almacenada PDFSugeily CalvoNo ratings yet

- Yi 437Document55 pagesYi 437Juhar MohammedNo ratings yet

- Minimax Oxeo Extinguishing Systems With Nitrogen and ArgonDocument12 pagesMinimax Oxeo Extinguishing Systems With Nitrogen and ArgonJuhar MohammedNo ratings yet

- Argon Fire Systems The Simple Solution: ExtinguishingDocument10 pagesArgon Fire Systems The Simple Solution: ExtinguishingJuhar MohammedNo ratings yet

- Nitrogen Gas Extinguisher System As A Countermeasure Against A Sodium Fire at MonjuDocument9 pagesNitrogen Gas Extinguisher System As A Countermeasure Against A Sodium Fire at MonjuJuhar MohammedNo ratings yet

- N 2023 Unit Test-5 - (19-Sep-21)Document26 pagesN 2023 Unit Test-5 - (19-Sep-21)ThilshathNo ratings yet

- TMP 30212C TMP 30105C. TMPM 10103 TMP 07103Document11 pagesTMP 30212C TMP 30105C. TMPM 10103 TMP 07103Mohammed Al gobariNo ratings yet

- WasteToEnergy EOI TMC 20210521Document19 pagesWasteToEnergy EOI TMC 20210521YADNYAYEE PAWARNo ratings yet

- Procedure de Test BOPDocument12 pagesProcedure de Test BOPkhireddineboulifaNo ratings yet

- P1 Chemical PropertiesDocument7 pagesP1 Chemical PropertiesAdrianMirzaNo ratings yet

- Flow Accelerated Corrosion (FAC) of Deaerator TankDocument1 pageFlow Accelerated Corrosion (FAC) of Deaerator TankAliNo ratings yet

- Bangalore Solid Waste SectorDocument28 pagesBangalore Solid Waste SectorjustakashNo ratings yet

- Prometheus BoundDocument36 pagesPrometheus BoundGiovanni TapangNo ratings yet

- Anatomy of An Oil Analysis ReportDocument8 pagesAnatomy of An Oil Analysis ReportRuben_3115No ratings yet

- A Numerical Study of Some Aspects of The Spherical Charge Cratering TheoryDocument15 pagesA Numerical Study of Some Aspects of The Spherical Charge Cratering TheoryÁALNo ratings yet

- MC34063AMDocument16 pagesMC34063AMSajjad4434No ratings yet

- Fluid Mechanics & Machinery: Topic: Water Hammer in PipesDocument12 pagesFluid Mechanics & Machinery: Topic: Water Hammer in PipesLoga MadishNo ratings yet

- Lab 3Document7 pagesLab 3jisteeleNo ratings yet

- FDK - BBCV2.MH13421 - Lithium Batteries - ComponentDocument7 pagesFDK - BBCV2.MH13421 - Lithium Batteries - ComponentMedSparkNo ratings yet

- Rural Development Unit-5Document14 pagesRural Development Unit-5rmauryaji47No ratings yet

- Rube Goldberg MachineDocument12 pagesRube Goldberg Machineapi-2966931090% (1)

- In ES 001 General Instrument Design - Rev.0Document56 pagesIn ES 001 General Instrument Design - Rev.0chedaniel100% (1)

- Testo-Direct: Testo 330 Flue Gas AnalyzerDocument79 pagesTesto-Direct: Testo 330 Flue Gas AnalyzerDedyNo ratings yet

- 19-0165P-DR-GA-400 Reva - Container #4Document1 page19-0165P-DR-GA-400 Reva - Container #4Jaime Arturo Trujillo RemolinaNo ratings yet

- Titan 250 Perfomance DataDocument2 pagesTitan 250 Perfomance DatasrikarmallampatiNo ratings yet

- Aditya KumarDocument4 pagesAditya KumarAnil B YadavNo ratings yet

- SM Volvo Ew180c Wheeled ExcavatorDocument22 pagesSM Volvo Ew180c Wheeled ExcavatorAl AminNo ratings yet

- Audi 2.0 Tfsi Cdma: Ancillary Drive Belt: Removal/installationDocument3 pagesAudi 2.0 Tfsi Cdma: Ancillary Drive Belt: Removal/installationalejandroNo ratings yet

- Electr MalDocument102 pagesElectr MalPopica ClaudiuNo ratings yet

- RRF 5Document21 pagesRRF 5Porkkodi SugumaranNo ratings yet

- Lookah Seahorse Coil VDocument1 pageLookah Seahorse Coil VChaudhary AbubakarNo ratings yet

- Dabba ResumeDocument5 pagesDabba ResumeAnkur SaxenaNo ratings yet

HD 318 HD Inertsys Gas Supression System

HD 318 HD Inertsys Gas Supression System

Uploaded by

Juhar MohammedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HD 318 HD Inertsys Gas Supression System

HD 318 HD Inertsys Gas Supression System

Uploaded by

Juhar MohammedCopyright:

Available Formats

HD-INERTSYS GAS SUPPRESSION SYSTEM

HD FIRE PROTECT

PVT. LTD.

TECHNICAL DATA

SUPPRESSION IG55, IG541, IG100, IG01

AGENT

CYLINDER SIZES 80 and 140L

OPERATING 200/300 Bar

PRESSURE

DISCHARGE VALVE Brass

RELEASE DEVICE Manual

Pneumatic

Electro-Magnetic

DISCHARGE Brass

NOZZLES

APPROVAL VdS Approved

ORDERING Size of Cylinder,

INFORMATION Number of Cylinders &

Nozzles, Pressure Rating,

Requirement of Accessories

such as Directional Valve, etc.

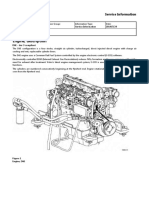

DESCRIPTION Each nozzle is drilled with a specific fixed opening

designed to deliver an uniform amount of extinguishing

The HD-INERTSYS System is a fire suppression agent into the protected area. The cylinders are

system, that is particularly useful for suppressing fires connected to the pipework or the manifold by means

in hazards where an electrically non-conductive medium of flexible discharge hoses and discharge constant

is required; where clean-up of other extinguishing flow and pressure discharge regulators. Various types

agents is a problem; or where the hazard is normally of actuators are available for the release of the inert

occupied and requires a non-toxic extinguishing agent gas into the protected area in case of fire.

and where an extinguishing capability with low weight

is required. The HD-INERTSYS System can be actuated by

detection and control equipment for automatic system

The following examples are typical hazards protected operation along with providing local and remote manual

by an HD-INERTSYS System: operation as needed. Accessories are used to provide

• Computer rooms alarms, ventilation control, door closures, or other

auxiliary shutdown functions.

• Telecommunication switch gear

The HD-INERTSYS System combines an environmentally

• Storages safe extinguishing agent and specially developed

• Vaults components for a fast-extinguishing agent discharge.

The resulting rapid-fire suppression reduces property

• Process equipment damage to the lowest possible level.

• Machinery spaces The HD-INERTSYS System is designed for total

flooding in accordance with the VdS Guidelines for fire

• Historic buildings and museums

extinguishing systems, VdS 2380en Fire Extinguishing

• All normally occupied or non-occupied electronic Systems using non-liquefied Inert Gases, 2014-06

areas where equipment is either very sensitive or (04).

irreplaceable.

The complexity of the HD-INERTSYS System does not

The HD-INERTSYS System uses inert gas as allow for any simple method of manual calculation.

extinguishing agent. The inert gas is stored in steel Therefore, the flow calculations and design criteria

cylinders located in a safe and accessible location. described in this manual have been incorporated into

The inert gas is distributed and discharged into the a VdS calculation software. The calculations are based

area affected by fire through a network of pipes and on conserving mass, energy and momentum in the

nozzles. pipework.

APRIL, 2021 PAGE 1 OF 4 HD 318

HD FIRE PROTECT

PVT. LTD.

The routine calculates the flow in quasi-steady state The system can be actuated electrically from a

steps from the initiation of the discharge to the final control panel or manually actuated from the cylinder

gas distribution. The system designer must become bank, and the discharged gas pressure is reduced to

thoroughly familiar with this manual to learn the proper less than 60 bar after the manifold. The system is

procedures for applying the input parameters to the normally designed as such that 95% of the gas will be

HD-INERTSYS System flow calculation software. There discharged into the protected area within 60 seconds.

are several limitations to these input parameters

The system has one Master Cylinder and other Slave

which must be observed if accurate results are to be

Cylinders for Actuation and Inert Gas Discharge.

obtained.

The HD-INERTSYS System is designed for the use

with these inert gases:

• IG55 (Argon and Nitrogen)

• IG541 (Nitrogen IG100, Argon IG01 and

Carbon dioxide)

• IG100 (Nitrogen)

• IG01 (Argon)

As inert gases are derived from gases present in the

earth’s atmosphere, they exhibit no ozone depletion

potential and they do not contribute to global warming. INSTALLATION INSTRUCTIONS

When an inert gas is discharged into an enclosure, it Inert fire suppression system should only be

introduces the proper mixture of gas that will allow installed by a trained and specialized fire suppression

persons to breathe in a reduced oxygen atmosphere. installation personnel only. The person should be

The advantages of inert gases are: conversant with HD Fire’s Design, Installation,

Operation and Maintenance Manual for HD-INERTSYS

• Safe for people at concentration levels required SYSTEM.

to suppress fire

Any area to be protected by an Inert gas fire

• Zero ozone depletion potential suppression system must be accurately measured

• Colorless and odorless to ensure the correct amount of agent is used to

sufficiently suppress a fire/potential fire within the

• No residue to clean up after discharge specific risk area.

• No decomposition products

This is especially important for inert gas suppression

• Electrically non-conductive systems such as IG55 and IG541 systems due to the

oxygen reducing properties used to extinguish a fire.

The extinguishing effect of the HD-INERTSYS System

is based on distributing the inert gas into the For inspection and testing requirements one can refer

protected area by total flooding. All gases used in the to relevant NFPA standard like NFPA 2001Standard

HD-INERTSYS System are chemically inert. on Clean Agent Fire Extinguishing Systems.

For installations in India, please follow relevant BIS

WORKING PRINCIPLE guidelines.

The basic working principle behind an inert gas fire 1. 15506:2004 Gaseous fire extinguishing systems

system is to reduce the amount of oxygen present in IG 55

the area where the fire breaks out. This is important

because fires need oxygen to spread. The oxygen 2. 15501:2004 Gaseous fire extinguishing systems

concentration is minimized by the application of IG 541

inert gas until it reaches a level of 12-13% where 3. 15525:2004 Gaseous fire extinguishing systems

combustion is no longer supported. Each system IG 100

is designed to decrease oxygen to a specific level.

When discharged, inert gas is quickly and uniformly 4. 15497:2004 Gaseous fire extinguishing systems

distributed within the enclosure, achieving design IG 01

concentration in 60 seconds.

Similarly, for inspection and testing please follow

While the oxygen level is lowered, it does not eliminate 1S 15496:2004 that lays down recommendations

oxygen from the space altogether. There is still enough for inspection and maintenance of gaseous fire

present to support proper breathing as anyone in the extinguishing systems including IG 55, IG541, IG100,

immediate area moves along the escape route and IG01.

exits the room.

APRIL, 2021 PAGE 2 OF 4 HD 318

HD FIRE PROTECT

PVT. LTD.

IMPORTANT POINTS FOR PRECAUTIONS • Always secure a standing cylinder to prevent

AND CARE falling.

• Refer to HD Fire Protect Manual of HD-INERTSYS • Do not grab the protective cap to move or lift the

System for all points of precautions, care in cylinder.

handling and installations. • Factory charged cylinders shall be inspected for

• Read the section 2.3.2 Hazard due to reduced correct pressure shown in the gauge. If their

oxygen level for further information on effects of pressure is found to be lower then the cylinder

reduced oxygen on personnel. needs to be re-filled or replaced. Refilling of

HD-INERTSYS cylinders must only be performed

• Refer to HD individual component datasheets for HD Fire Protect Pvt. Ltd. certified filling stations.

more information on each component.

• After every 6 monthly visual inspection, tags

• Each HD-INERTSYS cylinder is factory-equipped must be attached to the system indicating date

with an outlet safety plug installed on the cylinder of inspection, name of the inspector, type of agent

outlet and securely chained to the cylinder to in the cylinder, status of the system.

prevent loss. The outlet safety plug must be

always installed on the cylinder, except when the • At least once a year, all hoses should be examined

cylinder is connected to the pipework or when the to ensure there is no visible damage that could

cylinder is filled or refilled. compromise their ability to function. If the visual

inspection indicates any damage, the hose must

• Cylinders must be transported properly secured. either be immediately replaced or tested.

Cylinders must not be rolled, dragged or slid,

nor allowed to be slid from tailgates of vehicles. • You are required to notify the authority having

Cylinders next to the driver’s cabin must be jurisdiction (AHJ) if your system is activated

parallel with vehicle axles or standing up. or found through inspection and testing to be

impaired in any way. You are also required to notify

• Cylinders must not be dropped or permitted to the AHJ as soon as you have restored the system

strike against other surfaces or each other. to working order.

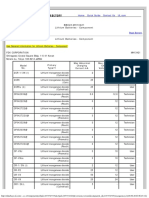

TYPICAL SYSTEM SCHEMATIC

COMPONENT DETAILS (300 BAR)

Ref. Approval

Component Item Code Type

No No.

1 Actuator B04425131 G302023

2 Container Valve B04802007 G302023

3 Connector B06920225 DN16 G314020

4 Check Vave B04600008 G315005

5 Manifold -- -- --

6 Pressure Gauge 029720083 PGS 21.020 G309005

7 Bleed Valve 029730040 N/A

8 Nozzle B04611400 G315010

9 Safety Valve (Option) -- -- --

10 Pressure Regulator B08400003 G311002

11 Pilot Line B06920212 G314018

12 Pneumatic Release Device B04420066 G302023

APRIL, 2021 PAGE 3 OF 4 HD 318

HD FIRE PROTECT

PVT. LTD.

LIMITED WARRANTY

HD FIRE PROTECT PVT. LTD. hereby referred to as HD FIRE warrants to the original purchaser of the fire protection products manufactured by HD FIRE and to any other person

to whom such equipment is transferred, that such products will be free from defect in material and workmanship under normal use and care, for two (2) years from the date of

shipment by HD FIRE. Products or Components supplied or used by HD FIRE, but manufactured by others, are warranted only to the extent of the manufacturer’s warranty.

No warranty is given for product or components which have been subject to misuse, improper installation, corrosion, unauthorized repair, alteration or un-maintained.

HD FIRE shall not be responsible for system design errors or improper installation or inaccurate or incomplete information supplied by buyer or buyer’s representatives.

HD FIRE will repair or replace defective material free of charge, which is returned to our factory, transportation charge prepaid, provided after our inspection the material is

found to have been defective at the time of initial shipment from our works. HD FIRE shall not be liable for any incidental or consequential loss, damage or expense arising directly

or indirectly from the use of the product including damages for injury to person, damages to property and penalties resulting from any products and components manufactured

by HD FIRE. HD FIRE shall not be liable for any damages or labour charges or expense in making repair or adjustment to the product. HD FIRE shall not be liable for any

damages or charges sustained in the adaptation or use of its engineering data & services. In no event shall HD Fire’s product liability exceed an amount equal to the sale price.

The foregoing warranty is exclusive and in lieu of all other warranties and representation whether expressed, implied, oral or written, including but not limited

to, any implied warranties or merchantability or fitness for a particular purpose. All such other warranties and representations are hereby cancelled.

NOTICE :

The equipment presented in this bulletin is to be installed in accordance with the latest publication standards of NFPA or other similar organisations and also with the

provision of government codes or ordinances wherever applicable.

The information provided by us is to the best of our knowledge and belief, and consist of general guidelines only. Site handling and installation control is not in our scope.

Hence we give no guarantee for result and take no liability for damages, loss or penalties whatsoever, resulting from our suggestion, information, recommendation or

damages due to our product.

Product development is a continuous programme of HD FIRE PROTECT PVT. LTD. and hence the right to modify any specification without prior notice is reserved with

the company.

D-6/2, ROAD NO. 34, WAGLE INDUSTRIAL ESTATE, THANE 400 604, INDIA.

HD FIRE PROTECT PVT. LTD. • TEL: + (91) 22 2158 2600 • FAX: +(91) 22 2158 2602

Protecting What Matters Most to You • EMAIL: info@hdfire.com • WEB: www.hdfire.com

APRIL, 2021 PAGE 4 OF 4 HD 318

You might also like

- MS2015-Building Installation ElectricalDocument44 pagesMS2015-Building Installation ElectricalScalperNo ratings yet

- AEGIS 2.0 and AEGIS-XLT Conventional Suppression Control UnitsDocument2 pagesAEGIS 2.0 and AEGIS-XLT Conventional Suppression Control UnitsAlwin WanNo ratings yet

- MP-627 Y 628 HerzogDocument4 pagesMP-627 Y 628 HerzogNavi Morales0% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Substation Grounding Grid Design Using Alternative Transients Program-ATP and ASPIXDocument23 pagesSubstation Grounding Grid Design Using Alternative Transients Program-ATP and ASPIXJose Dariel ArcilaNo ratings yet

- Suppression SystemsDocument5 pagesSuppression Systemsf.BNo ratings yet

- Akronex INERT InteractiveDocument12 pagesAkronex INERT InteractiveYunus güneşNo ratings yet

- System Overview - Complete System - Cooltek - 060320Document29 pagesSystem Overview - Complete System - Cooltek - 060320Entity ArchitectsNo ratings yet

- NAFFCOInert BrochureDocument8 pagesNAFFCOInert Brochurerennes desamparadoNo ratings yet

- Industrial Flame Monitoring IFM Brochure 67 7148Document11 pagesIndustrial Flame Monitoring IFM Brochure 67 7148swapnil28.08 kNo ratings yet

- CONTEXT PLUS - HFC227ea Systems - SALES BROCHURE - 01-17Document4 pagesCONTEXT PLUS - HFC227ea Systems - SALES BROCHURE - 01-17Ronny HasanNo ratings yet

- Ta Ignition-101 PDFDocument7 pagesTa Ignition-101 PDFमेनसन लाखेमरूNo ratings yet

- Gaseous Automatic Supression SystemsDocument21 pagesGaseous Automatic Supression SystemseimrehNo ratings yet

- DBR - Fire Fighting - HPMC ParalaDocument16 pagesDBR - Fire Fighting - HPMC ParalaKiran LokhandeNo ratings yet

- Brochure Siex-Inert 01 200bar Eng WebDocument12 pagesBrochure Siex-Inert 01 200bar Eng WebAhmed El Sayed SalamaNo ratings yet

- Inergen 150 Bar System SpecificationDocument2 pagesInergen 150 Bar System SpecificationDragan CvetkovićNo ratings yet

- Inergen System AnsulDocument2 pagesInergen System AnsulJayFouresNo ratings yet

- Automatic Fire Detection and Suppression SystemDocument2 pagesAutomatic Fire Detection and Suppression SystemProdip SarkarNo ratings yet

- HVAC and PressurizationDocument12 pagesHVAC and PressurizationtareqNo ratings yet

- MX Argotec With Carbon Dioxide PDFDocument7 pagesMX Argotec With Carbon Dioxide PDFNarendra Reddy BhumaNo ratings yet

- Thermox-Brochure LR107 PDFDocument16 pagesThermox-Brochure LR107 PDFedwinmenaNo ratings yet

- Ig 100Document16 pagesIg 100Rhoderic Radomes JrNo ratings yet

- Argonite: A World of ProtectionDocument6 pagesArgonite: A World of Protectionrodrigo.shaolimNo ratings yet

- 04 AP Sensing DTS - Fiber Optic Linear Heat DetectionDocument8 pages04 AP Sensing DTS - Fiber Optic Linear Heat DetectionDoan Anh TuanNo ratings yet

- LPCO2Document15 pagesLPCO2don timoNo ratings yet

- RNXDDocument30 pagesRNXDashbal alfanNo ratings yet

- Wartsila Moss Generator System For Cas CarriersDocument4 pagesWartsila Moss Generator System For Cas CarriersShubham MishraNo ratings yet

- Brochure Siex-Inert 541 300bar Eng WebDocument12 pagesBrochure Siex-Inert 541 300bar Eng WebLuisNo ratings yet

- Brochure Hc-227 Eng 2015Document12 pagesBrochure Hc-227 Eng 2015Jaime Alberto VillarrealNo ratings yet

- 24112015XAG3KELRAnnexureRiskAssesment PDFDocument16 pages24112015XAG3KELRAnnexureRiskAssesment PDFenduNo ratings yet

- UC169986 PTY 0313 Insight Gaseous Fire Suppression System - tcm2538-373444Document3 pagesUC169986 PTY 0313 Insight Gaseous Fire Suppression System - tcm2538-373444Maxmore KarumamupiyoNo ratings yet

- Special Hazard Fire Suppression Systems: A Guide For All Business EnvironmentsDocument21 pagesSpecial Hazard Fire Suppression Systems: A Guide For All Business EnvironmentsMEGAN ASBROCK0% (1)

- MANUAL - DISEÑO - IG541 - NOVEMBER - 2010 - Ing - SEGUN ISODocument60 pagesMANUAL - DISEÑO - IG541 - NOVEMBER - 2010 - Ing - SEGUN ISOMuhammad Hassan100% (1)

- Argonite Fixed Fire Extinguishing SystemDocument4 pagesArgonite Fixed Fire Extinguishing SystemJoel Shelton LasradoNo ratings yet

- AutoFireX Pre Engineered Systems For LATAMDocument19 pagesAutoFireX Pre Engineered Systems For LATAMPaola LopezNo ratings yet

- Detector de Humo-Alk-V - 02-2014 PDFDocument2 pagesDetector de Humo-Alk-V - 02-2014 PDFArthur Alexis Buitron DurandNo ratings yet

- FGD ADS Power Flame Gas Oil Mist Detection TurbinesDocument4 pagesFGD ADS Power Flame Gas Oil Mist Detection Turbinesaugur886No ratings yet

- 81381C Plastic Machinery Eng PDFDocument76 pages81381C Plastic Machinery Eng PDFEvandro Amaral RodriguesNo ratings yet

- VHS200 BrochureDocument4 pagesVHS200 BrochureAhmed HakamNo ratings yet

- Đầu Báo Khói Kết Hợp Nhiệt Địa Chỉ Acc-V - 09-2015Document2 pagesĐầu Báo Khói Kết Hợp Nhiệt Địa Chỉ Acc-V - 09-2015Nguyễn Kỳ TúNo ratings yet

- 6) CYCLOPSZPurgeIndicatorBrochureDocument6 pages6) CYCLOPSZPurgeIndicatorBrochureAnish KarthikeyanNo ratings yet

- Coal Conveyor Protection-Ih153es Ir Ember DetectorDocument72 pagesCoal Conveyor Protection-Ih153es Ir Ember DetectorShanmuganathan ShanNo ratings yet

- Fire SuppressionDocument19 pagesFire SuppressionSalley BukhariNo ratings yet

- L01040704 - 10052022 - Rev.22.1 - en - 1p - Multi Zone TechnologyDocument1 pageL01040704 - 10052022 - Rev.22.1 - en - 1p - Multi Zone TechnologyAshokkumar SamikannuNo ratings yet

- FiresafeDocument8 pagesFiresafeDANE80No ratings yet

- Inergen 200-Bar Fire Suppression System: Data/SpecificationsDocument2 pagesInergen 200-Bar Fire Suppression System: Data/SpecificationsEmmanuel ToretaNo ratings yet

- Det-Tronics - 95-8666-8.1 (Model HD)Document19 pagesDet-Tronics - 95-8666-8.1 (Model HD)jimmiilongNo ratings yet

- Fire Supression SystemDocument4 pagesFire Supression SystemPriya UdamaleNo ratings yet

- m600 DatasheetDocument4 pagesm600 DatasheetCost RootsNo ratings yet

- AFDSS Freeze FireDocument2 pagesAFDSS Freeze FireemilianoNo ratings yet

- Delivering Excellence in Combustion and Process HeatingDocument11 pagesDelivering Excellence in Combustion and Process HeatingsajjadyasinNo ratings yet

- Ft-Tcpa-Ing-14-02-2022 Ficha Tecnica Tanques de Supresion AlmacenadaDocument6 pagesFt-Tcpa-Ing-14-02-2022 Ficha Tecnica Tanques de Supresion AlmacenadaSugeily CalvoNo ratings yet

- ABB Gas AnalyserDocument4 pagesABB Gas AnalyserAbhay SalavkarNo ratings yet

- Ficha Tecnica Inergen F-9312Document2 pagesFicha Tecnica Inergen F-9312Yairton Vargas MuñozNo ratings yet

- Hydran 201ti (Mark IV) Essential DGA Monitoring For TransformersDocument2 pagesHydran 201ti (Mark IV) Essential DGA Monitoring For Transformerslxd.hepNo ratings yet

- Kidde Nitrogen Fire Protection Systems K-79-001 Print AADocument6 pagesKidde Nitrogen Fire Protection Systems K-79-001 Print AADaddy YantulaNo ratings yet

- Context Plus EP203 August 17Document4 pagesContext Plus EP203 August 17nalakaNo ratings yet

- Low Pressure: Fire SystemsDocument8 pagesLow Pressure: Fire SystemsKrishna N H100% (1)

- D.1 General Katalog BfiDocument28 pagesD.1 General Katalog Bfihardy ferrysianNo ratings yet

- Inert Siex 100 200bar Brochure 2015 03Document12 pagesInert Siex 100 200bar Brochure 2015 03JayFouresNo ratings yet

- Ft-Tcpa-Ing-14-02-2022 Ficha Tecnica Tanques de Supresion Almacenada PDFDocument6 pagesFt-Tcpa-Ing-14-02-2022 Ficha Tecnica Tanques de Supresion Almacenada PDFSugeily CalvoNo ratings yet

- Yi 437Document55 pagesYi 437Juhar MohammedNo ratings yet

- Minimax Oxeo Extinguishing Systems With Nitrogen and ArgonDocument12 pagesMinimax Oxeo Extinguishing Systems With Nitrogen and ArgonJuhar MohammedNo ratings yet

- Argon Fire Systems The Simple Solution: ExtinguishingDocument10 pagesArgon Fire Systems The Simple Solution: ExtinguishingJuhar MohammedNo ratings yet

- Nitrogen Gas Extinguisher System As A Countermeasure Against A Sodium Fire at MonjuDocument9 pagesNitrogen Gas Extinguisher System As A Countermeasure Against A Sodium Fire at MonjuJuhar MohammedNo ratings yet

- N 2023 Unit Test-5 - (19-Sep-21)Document26 pagesN 2023 Unit Test-5 - (19-Sep-21)ThilshathNo ratings yet

- TMP 30212C TMP 30105C. TMPM 10103 TMP 07103Document11 pagesTMP 30212C TMP 30105C. TMPM 10103 TMP 07103Mohammed Al gobariNo ratings yet

- WasteToEnergy EOI TMC 20210521Document19 pagesWasteToEnergy EOI TMC 20210521YADNYAYEE PAWARNo ratings yet

- Procedure de Test BOPDocument12 pagesProcedure de Test BOPkhireddineboulifaNo ratings yet

- P1 Chemical PropertiesDocument7 pagesP1 Chemical PropertiesAdrianMirzaNo ratings yet

- Flow Accelerated Corrosion (FAC) of Deaerator TankDocument1 pageFlow Accelerated Corrosion (FAC) of Deaerator TankAliNo ratings yet

- Bangalore Solid Waste SectorDocument28 pagesBangalore Solid Waste SectorjustakashNo ratings yet

- Prometheus BoundDocument36 pagesPrometheus BoundGiovanni TapangNo ratings yet

- Anatomy of An Oil Analysis ReportDocument8 pagesAnatomy of An Oil Analysis ReportRuben_3115No ratings yet

- A Numerical Study of Some Aspects of The Spherical Charge Cratering TheoryDocument15 pagesA Numerical Study of Some Aspects of The Spherical Charge Cratering TheoryÁALNo ratings yet

- MC34063AMDocument16 pagesMC34063AMSajjad4434No ratings yet

- Fluid Mechanics & Machinery: Topic: Water Hammer in PipesDocument12 pagesFluid Mechanics & Machinery: Topic: Water Hammer in PipesLoga MadishNo ratings yet

- Lab 3Document7 pagesLab 3jisteeleNo ratings yet

- FDK - BBCV2.MH13421 - Lithium Batteries - ComponentDocument7 pagesFDK - BBCV2.MH13421 - Lithium Batteries - ComponentMedSparkNo ratings yet

- Rural Development Unit-5Document14 pagesRural Development Unit-5rmauryaji47No ratings yet

- Rube Goldberg MachineDocument12 pagesRube Goldberg Machineapi-2966931090% (1)

- In ES 001 General Instrument Design - Rev.0Document56 pagesIn ES 001 General Instrument Design - Rev.0chedaniel100% (1)

- Testo-Direct: Testo 330 Flue Gas AnalyzerDocument79 pagesTesto-Direct: Testo 330 Flue Gas AnalyzerDedyNo ratings yet

- 19-0165P-DR-GA-400 Reva - Container #4Document1 page19-0165P-DR-GA-400 Reva - Container #4Jaime Arturo Trujillo RemolinaNo ratings yet

- Titan 250 Perfomance DataDocument2 pagesTitan 250 Perfomance DatasrikarmallampatiNo ratings yet

- Aditya KumarDocument4 pagesAditya KumarAnil B YadavNo ratings yet

- SM Volvo Ew180c Wheeled ExcavatorDocument22 pagesSM Volvo Ew180c Wheeled ExcavatorAl AminNo ratings yet

- Audi 2.0 Tfsi Cdma: Ancillary Drive Belt: Removal/installationDocument3 pagesAudi 2.0 Tfsi Cdma: Ancillary Drive Belt: Removal/installationalejandroNo ratings yet

- Electr MalDocument102 pagesElectr MalPopica ClaudiuNo ratings yet

- RRF 5Document21 pagesRRF 5Porkkodi SugumaranNo ratings yet

- Lookah Seahorse Coil VDocument1 pageLookah Seahorse Coil VChaudhary AbubakarNo ratings yet

- Dabba ResumeDocument5 pagesDabba ResumeAnkur SaxenaNo ratings yet